-

Posts

4,118 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

It isn’t the turning knob adjusting the table, but the black collar on each of those turning easily to set the zero mark while not moving the adjustment of the table. Yes I know about that gibs adjustment (forgot they’re called gibs). The table moves smoothly. And if you told me about gibs before yesterday odds are I don’t remember🙃. Anyway, I’ll Google it or contact Proxxon. It’s not a big deal.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’m thinking not as I don’t know what gibs are🤣

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

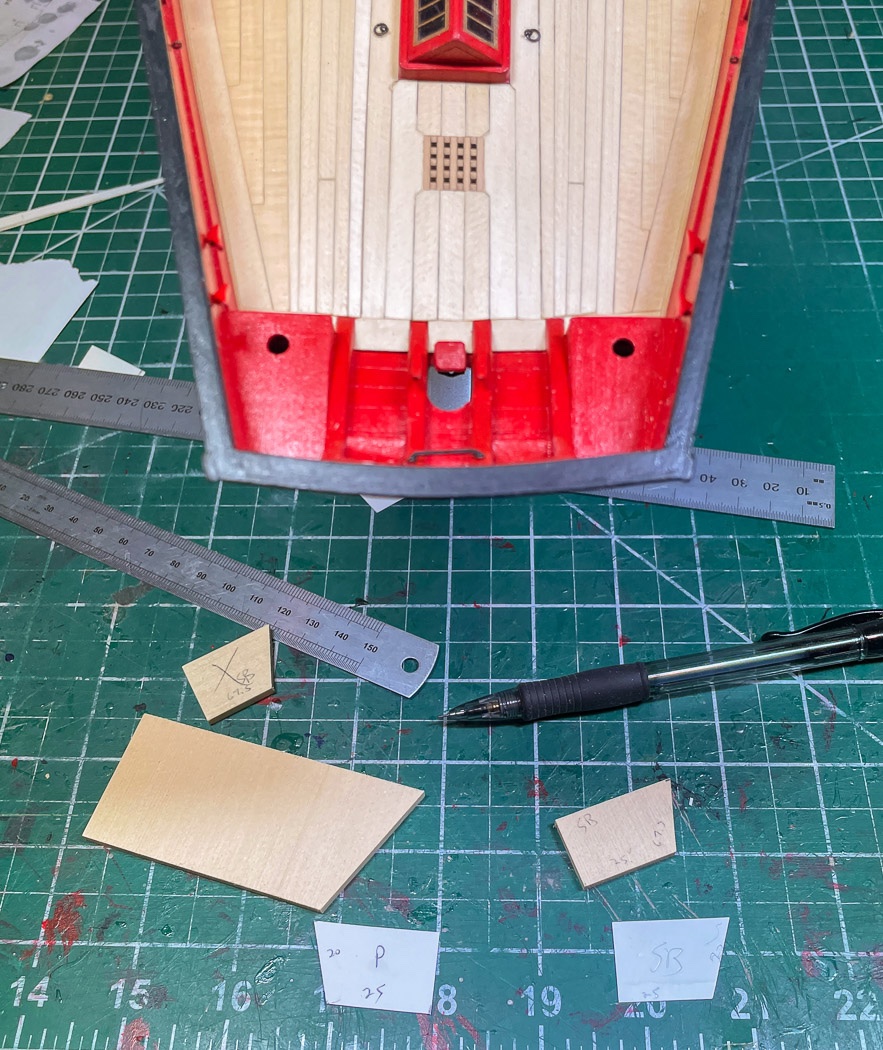

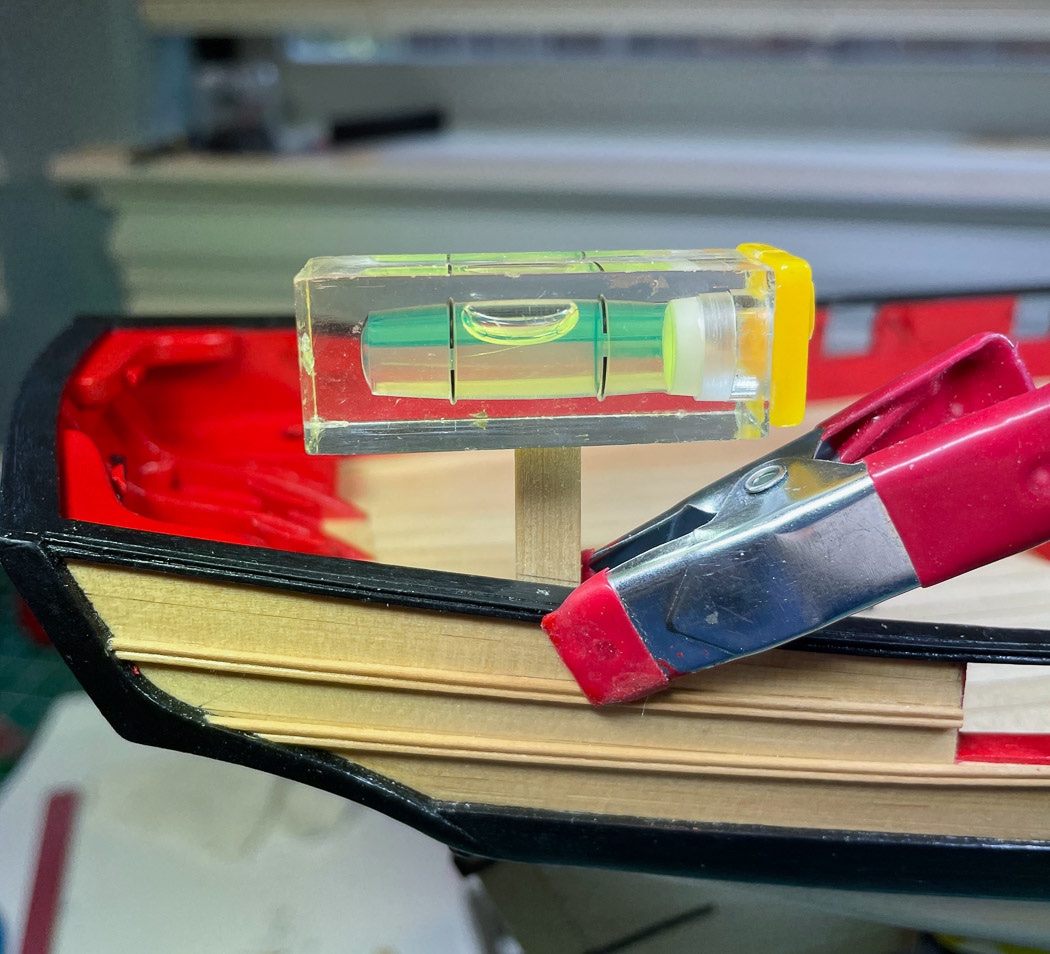

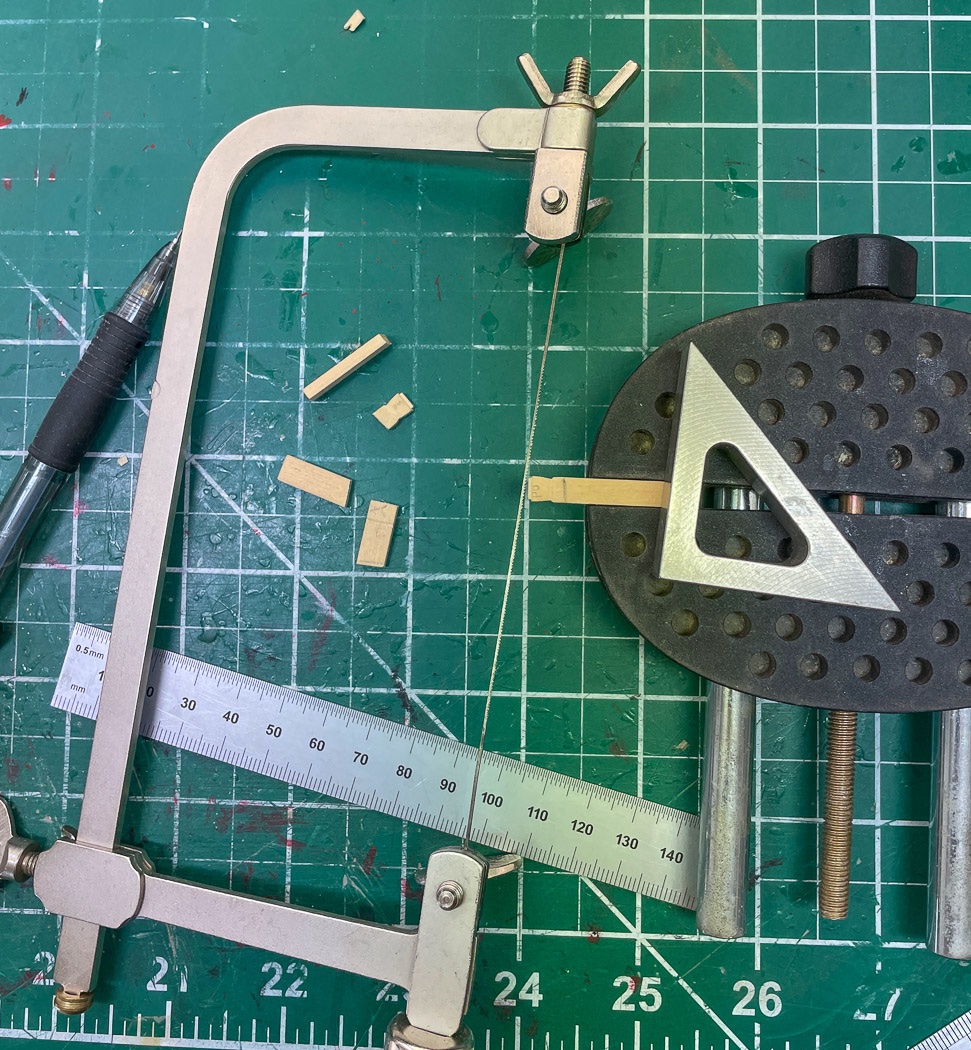

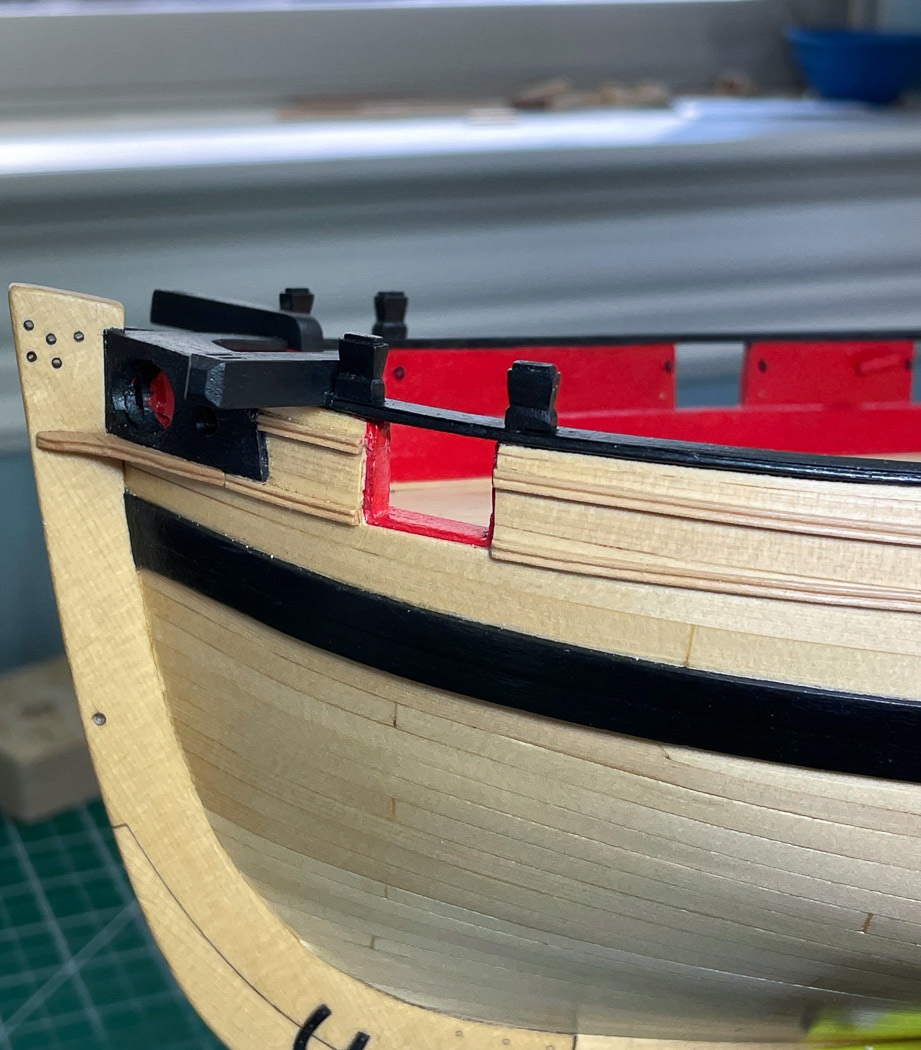

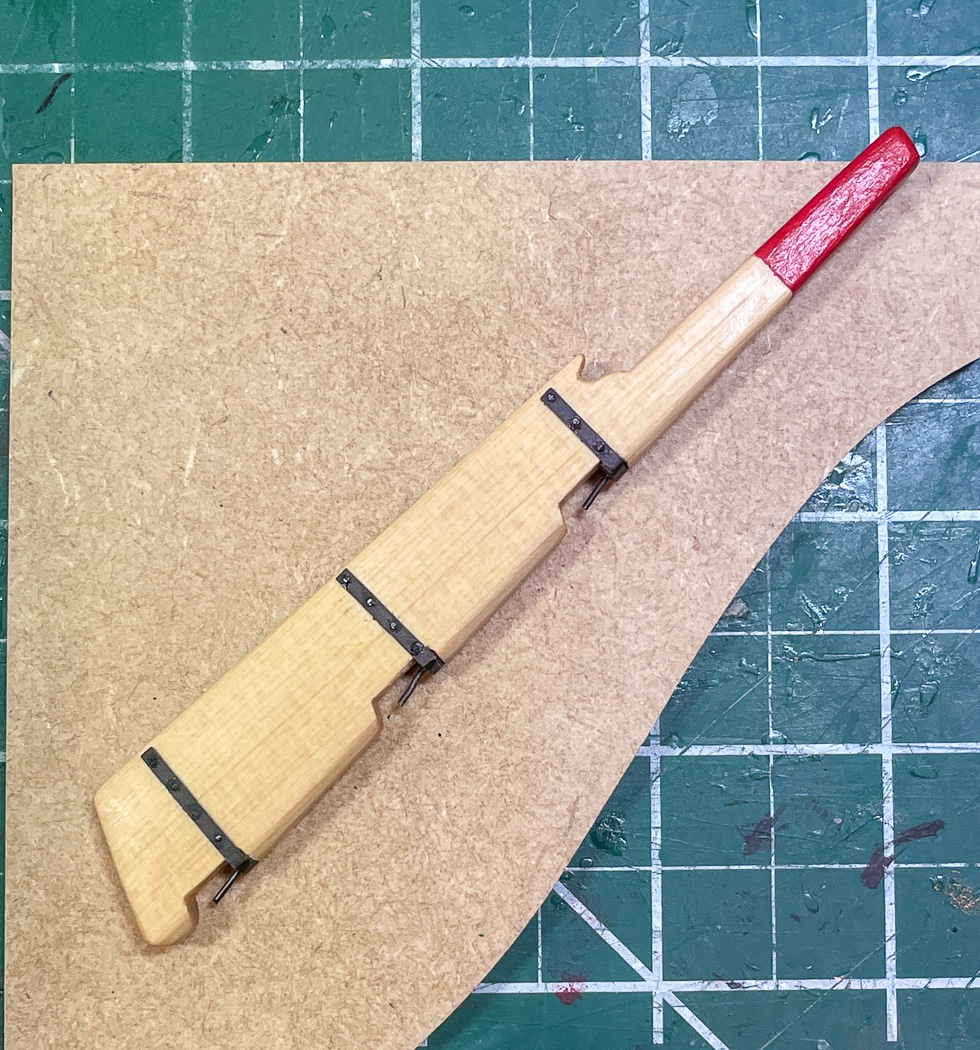

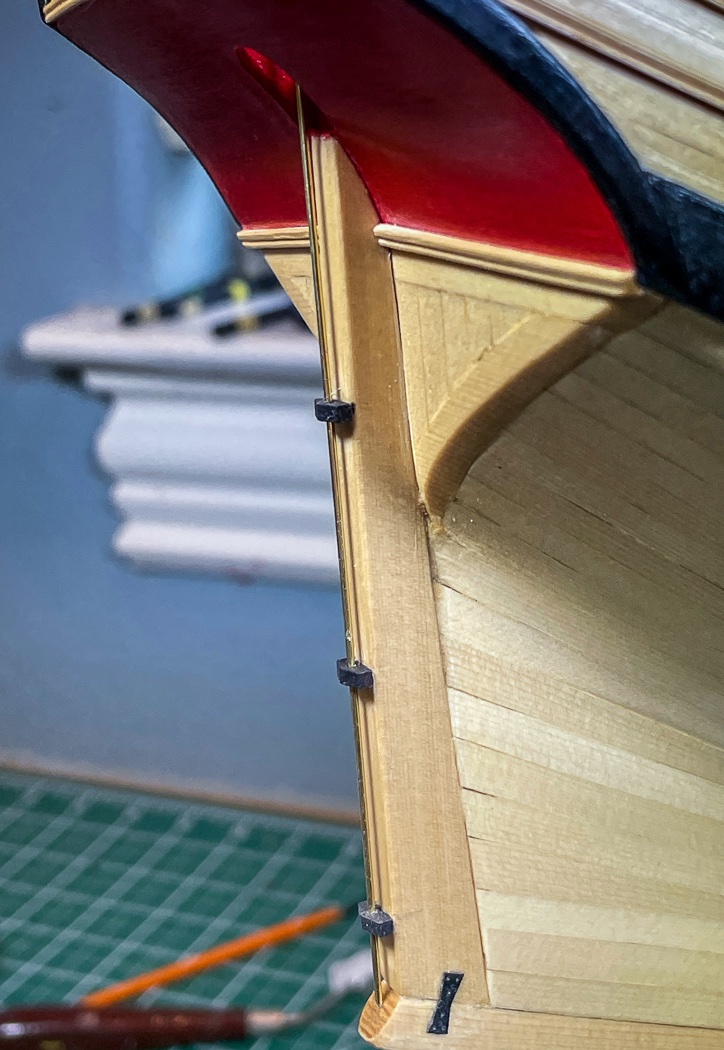

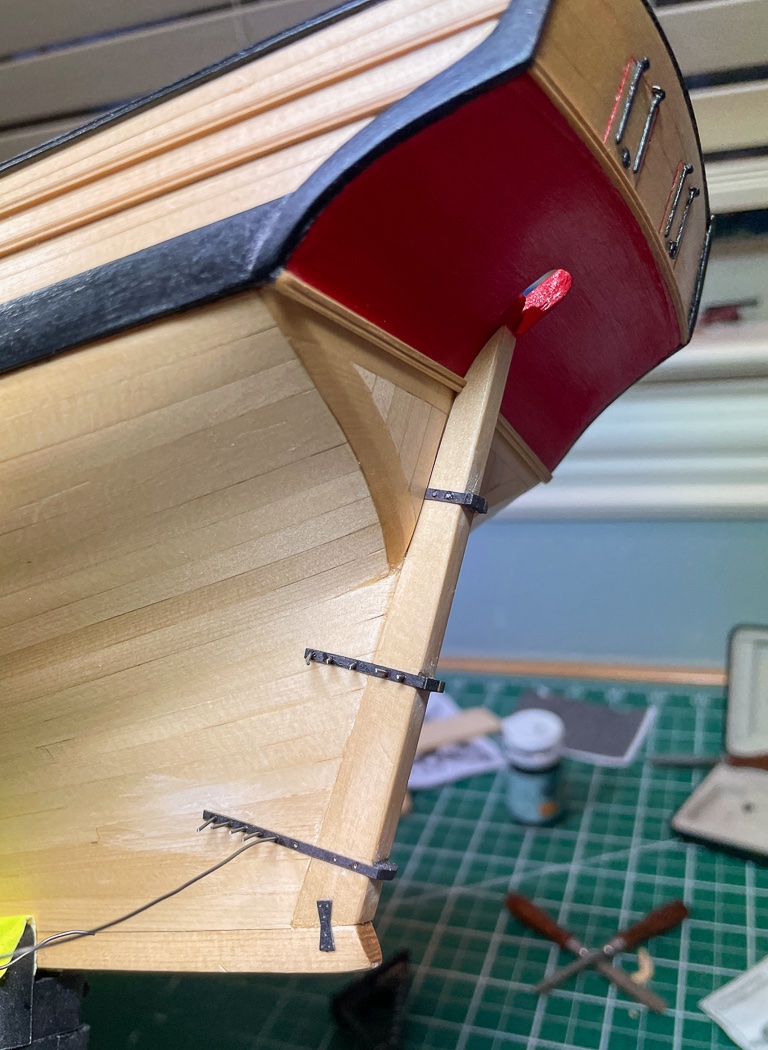

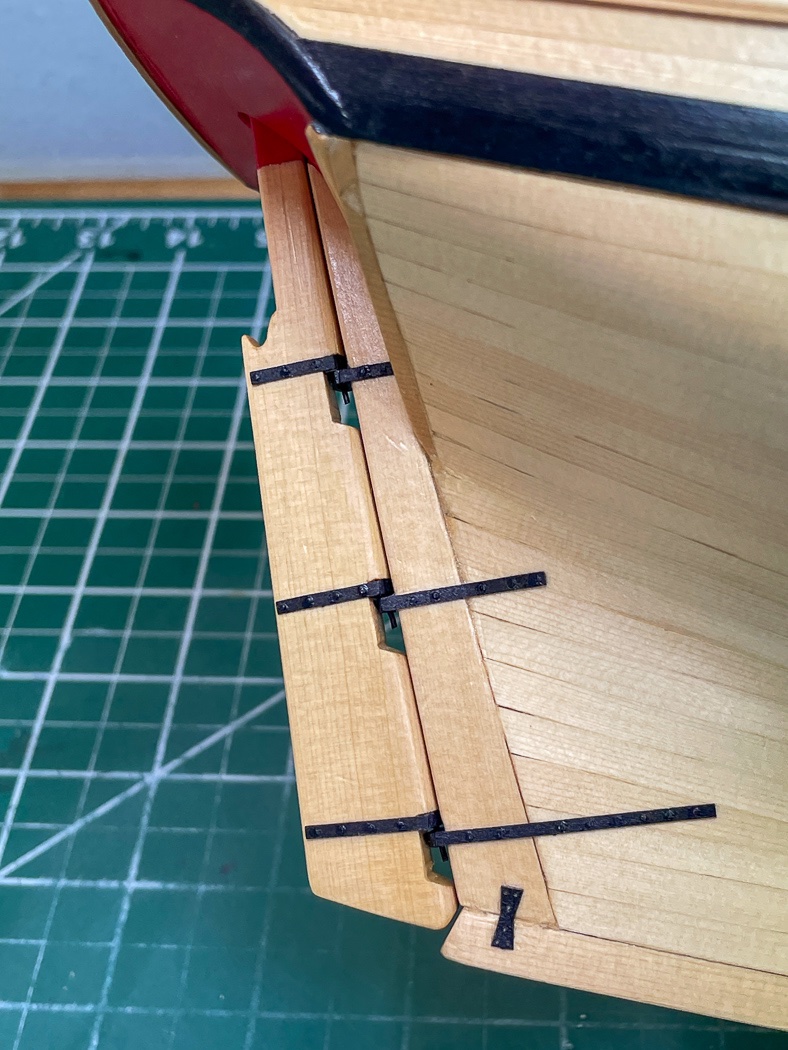

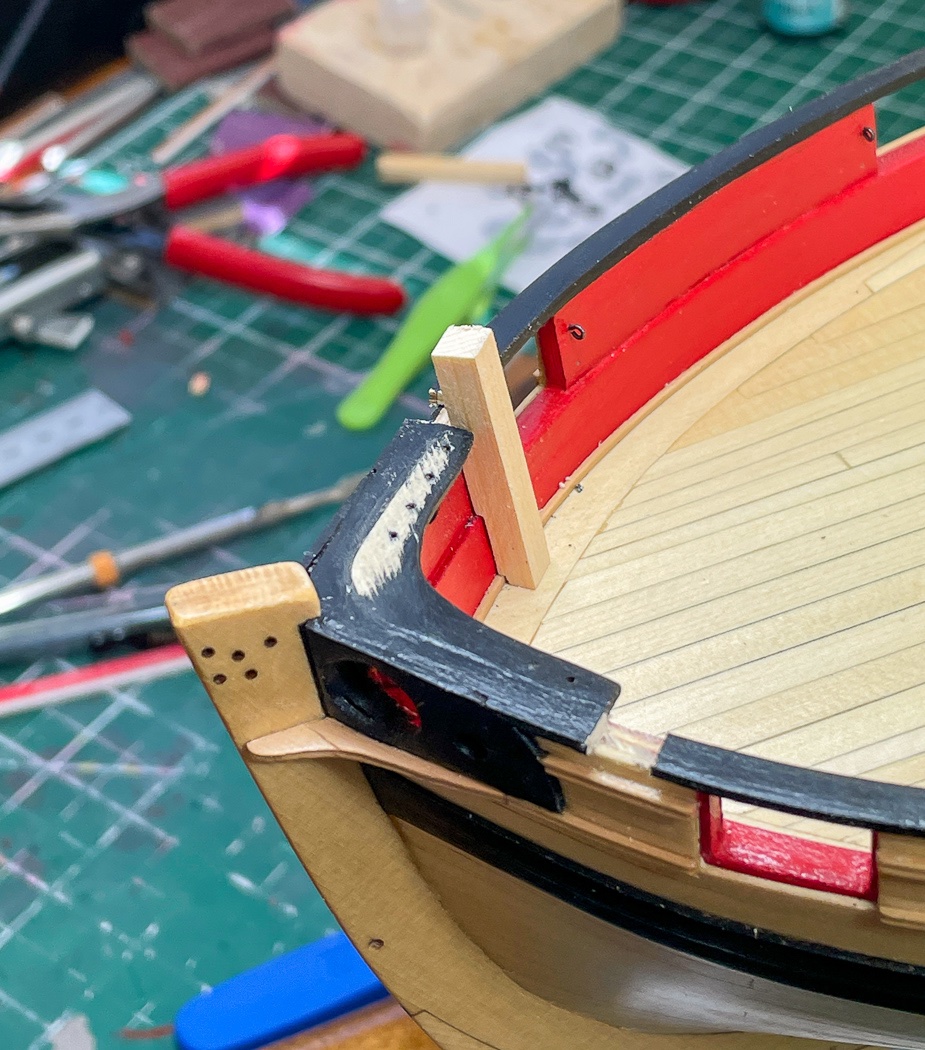

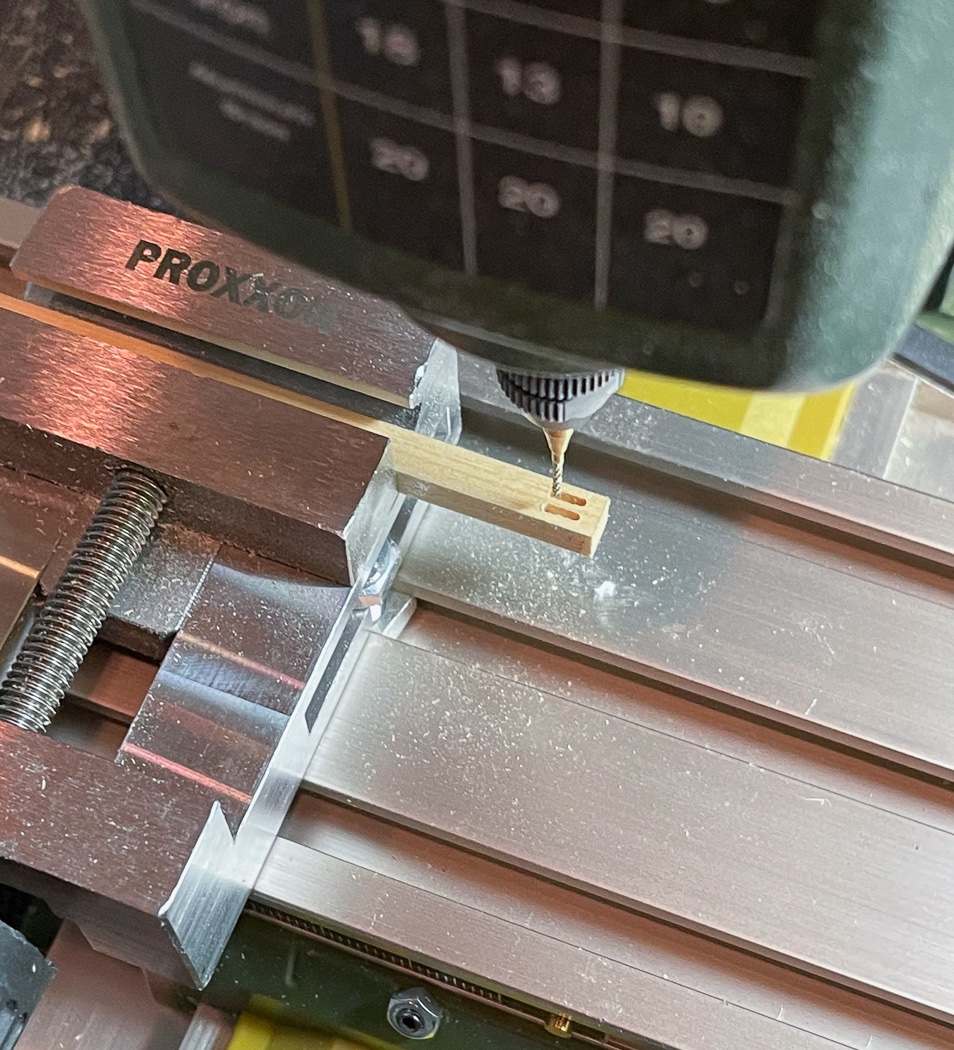

Small things take time and iteration to get right. That’s the lesson I have to remember at this stage of the build. The Tiller V.2 I decided to re-make the tiller. As I did the last time I started with a square length of boxwood, a couple of inches longer than the tiller, and turned it on the lathe after following the 7-10-7 rule to remove the edges with my mini-planer. I wanted a different tiller handle and did most of that on the lathe with needle files and sanding sticks. Out came the bending station. Just as it is for planking, the heat of the iron made for a relatively easy bend, though it did require a couple of iterations to more slowly work the shape than with a standard plank. By using a metal clamp in the center I was able to tilt the iron onto it so the iron didn’t physically touch the round tiller - I used steam, it worked well and took very little time to get right. I got a better result the second time around, more of a bow instead of a bend, beefier, and a better handle so I’m glad I took the time. I checked it’s height with mini-me on the deck, it looks right to me now. And then off it came and along with the rudder up on the shelf it went until I install them later. I have a lot of stuff on the shelf now, install day is going to be fun whenever that is. The Knees These were not simple and serve as a reminder this is mostly a scratch build, I doubt even if they were laser cut it would have helped much. I started by duplicating the drawing from the plans with the scroll saw - it wasn’t even close and I tossed it aside. Back to card stock to determine the angles, always the angles. The first step is getting the stern and sides and to decide on the length for both. I settled on 25mm on the stern and 20mm on the bulwark for no other reason than it looked right and it was more or less in line with the plans. I used my Byrnes saw to cut the blanks from 4mm sheet. There were a few iterations as I discovered the various angles and notching I had to account for, it wasn’t initially obvious to my untrained eye. I quickly determined the yellow cedar was a bit soft for all the shaping, sanding and beveling required (my problem not the wood’s) so I turned to my precious and limited store of boxwood. Before cutting them to their ‘knee’ shape I worked to get the proper fit snug into the corners and just below the cap rail. More angles, the transom curve and the flat cap rail required beveling both top and bottom, and then there are the stern frames, the knees are a tight fit between the rail above and the frames below. It wasn’t pretty - I notched the bottom of the knees and had to remove a bit of the frames, seaworthiness is assured by the tight fit, or so I decided. I scraped some paint off the transom just to ensure good surfaces for the glue. I chose TiteBond for this, I needed a few minutes to get them seated with the proper angle along the bulwarks and I didn’t want to test the strength of just PVA. These knees are there to stay. The boxwood sands nicely into shape, I gently rounded the outer edges before I glued them in. I was momentarily tempted to leave them natural - it would make no sense but they look nice. I added the smaller cleats as shown on the plan. I’ve used three different sizes on the model so far, all from Chuck’s store. As before there is some sanding to remove the char and to shape them a bit. Like the other cleats these are pinned on using the stem of an eyelet. Having gotten past my natural look impulse, I painted it all my usual Red. The knees were another of those things I had to stare at and think about to decide the process and order of things. It was a good move to get the fitting right before cutting them into their final ‘knee’ shaped, it gave me something to hold onto as I tweaked and tweaked and tweaked again to get the required tight fit, top, bottom. left and right. It took a good deal of time, several days, to get through the iterations for something seemingly so simple and maybe not that noticeable in context of the larger ship. I will say though it was rewarding when they were done. Something I can look at, know what went into it, and think to myself - I made those. I showed my wife, who took a look, looked at me, and said “those are nice…..” and walked out. Timber heads I’ve come up with my own way for making pillars and by result, timber heads. I know there are better ways in using the mill for the total job, Derek has been kind enough to share one of those. My method is a hybrid. For the timber heads I’ve cut the “cap” by cutting in .8mm from the top and .4mm deep on all four sides then dropping down 4mm and cutting a .3mm deep all using a 1mm cutter bit. I usedmy freshly sharpened chisels to slice from the top down to the cut to shape the timber head, which of course isn’t square. At this point I’m just more comfortable, and considerably faster, cutting it partially by hand with the chisels. I really like the mill, I’m learning more how to use it - but it’s a process to set an accurate zero on two, sometimes all three axis and repeating that for each side after I flip it and again for each of the 5 additional timber heads (actually 6 additional, I choose the best six after cutting seven) so that all are completely identical. While it’s true I can make .4 and .8mm cuts, that only happens with an accurate, repeatable zero starting point. The Proxxon mill is great, but I wish the zero turning dials were a little bit smoother as I set those zeros, maybe they wear in over time. Anyway. In addition to the chisels, I finish them up with files and sanding sticks. You might notice the paper below in the photo, I spend a little time, and that iteration thing again, getting to the sizes and cuts I think look right. There is no clear design and the size is a bit flexible. I once again got to exercise my - if ‘it’s not right rip it off and do it again’ motto. After making all six timber heads I decided they were too wide and tall so I tossed them and started over. I guess I could have figured that out after making one - but I didn’t until I saw them sitting (not glued fortunately) on the cap rail. I drilled holes and pinned them all into place using those ubiquitous little nails from past models with the heads removed. The four on the bow were straightforward, once I got the size right, the two on the stern are a little tricky - they need to be perpendicular to the water line, while mounted on a cap rail that has a significant sloop at the stern. I leveled the boat in the Amati working stand then used another level (these little ones come in handy over and over) and some scrap wood to determine the angle, cut the scrap on that line as a template and transferred it to the timber head.. I had made all the timber heads intentionally long to give me grip when cutting and filing and plenty to work with to cut the angle. BTW, that’s light glare, not bad painting on the wales and fashion piece, along with a little dust which will all get cleaned up later. …close up photos reveal all … I have “The Cutter” I normally use to chop small pieces on exact angles, but in this case it would not get as flush a cut as I needed on the thicker wood. I got this jeweler’s saw to cut the stern frames way back when, it’s coming in handy again now. In addition to this cut on the stern timber head I used it to cut the knee part of the knees (much too small for the scroll saw, at least for me) after I had fitted the pieces as described above. It makes short work of cutting wood too thick for my #11 blade and is accurate in staying on the cut line. Here they are all glued on and painted with Admiralty Dull Black, its all good and on to the next thing. I’m betting this is more than you ever wanted to know about timber heads. Everything is more interesting to me when I made it from scratch I guess. Speaking of which, time to move to the next fun item, the boom crutches - and guess what - there are a lot of angles involved. Thanks for stopping by, the likes and especially the comments are always appreciated.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wow, so this is why you had to let the butler go, paying all that crew must weigh heavily on the estate. My captain works on half salary due to current economy.

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I think you should copper it😁🤣 Although it’s pretty boxwood it’s more how it looks as a ship accessory on display so in my opinion I’d paint it, at least below the waterline. I’m sure it will look great either way. Congrats on the ratlines. I have an actual boat at our Lakehouse. I’m pretty good at full scale clove hitches at that scale. It’s the tedium of one after another that gets to me, and the forced labor of Just..,Do...One...More...😩

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

The pins on the spars are fine and a good idea Tim, of course it isn’t historically accurate, but it’s a model. You don’t want them bouncing all over the place, Cut the pin shorter and/or hold it tight against the mast with a pin dab of C A.

- 436 replies

-

- vanguard models

- alert

-

(and 1 more)

Tagged with:

-

Yes the spike turned out to be very helpful, it’s not something I’d done before because the Nelson frame was pretty wobbly for the mast. Side supports, that leave room to adjust as you described, are likely a good idea. I used wood glue, Titebond (not white PVA), dripped down that frame slot on both sides. It is tricky with this model, a hold your breath moment aligning it. While you’re here think about how you’re going to display it. If on pedestals drill the holes now and supports there. The holes need to go past the keel into the, rather fragile, MDF frame.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

I’m sure you’re watching the reference lines with your reinforcements, remember those lines are the top of the wood you’ll place there for the gun ports, you need from below them too. It may not seem like it now but getting the bottom of the gun ports right is important later when you’re doing a 1/64th rabbit. I’m enjoying seeing another Cheerful come to life.

-

Real ships also had good seat to hold them, this model doesn’t. It’s a bit ambitious to try to center and hold it with rigging. More than I’d try. The odds are if you have a mishap it’s going to be a droopy or off center mast. I’d glue, again I described how I did it in the log. Just my opinion, up to you.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

It’s going to be interesting to see how you work this out and keep the hull integrity. I will enjoy watching you progress but don’t have any help to offer other than I can only see about 1 square inch thru the skylight. Should be fun, enjoy. Do keep in mind the stern frames are a delicate part of the frame in your planning.

-

Thank you for the likes and those taking the time to comment. It is all greatly appreciated, especially those whose work I have long admired and followed. The heads, or rather the afts are and will remain an interesting feature of Cheerful, wind direction or proximity to the helmsman notwithstanding. Thanks Derek. I know BE added such drainage holes, I decided mine would be less visible (as in invisible) there is only so far I'll go in honoring those who serve and poop. 😄 Thanks BE Your logic on the topic is one I followed, I need more clever terminology as you provided the best I could come up with was "Well, s**t might as well." Hardly does it justice I know. 😄 Not to mention I continue to consult your log as a frequent reference on the big steps, you may recognize many things I do, as they are ones I learned from you. Thank you, sometimes I think I get carried away with the details and bore the socks off people, I just can't help myself though. Thanks Rusty, high praise from a master builder - your current work on the Duchess and Winnie are amazing. And of course I borrow many good ideas from those logs. Thanks Chuck, coming from the master and designer that means a lot. You gave us a great model, I continue to enjoy the building of her. Thank you, I glad they are helpful and appreciated. Regardless of wind direction the image of the helmsman with seated individuals either side remains comic to me. 😄

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Such neat and crisp work, great job.

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Yes there is a guide. You have them the on the plans for Nelson, if you want to replace the kit rope just get equivalent size, or closest to it, from Syren. That’s what I did, I also replaced the blocks, a more important step. The Nelson blocks are junk. Note that other than ropes and blocks most stuff on Syren is 1:48 scale and Nelson is 1:64.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

The decks of Cheerful and Nelson are pretty much the same. The bigger effort is getting some of the Nelson stuff to scale, meaning scratch building. There really isn't anything to add to the deck, just stuff to make better.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

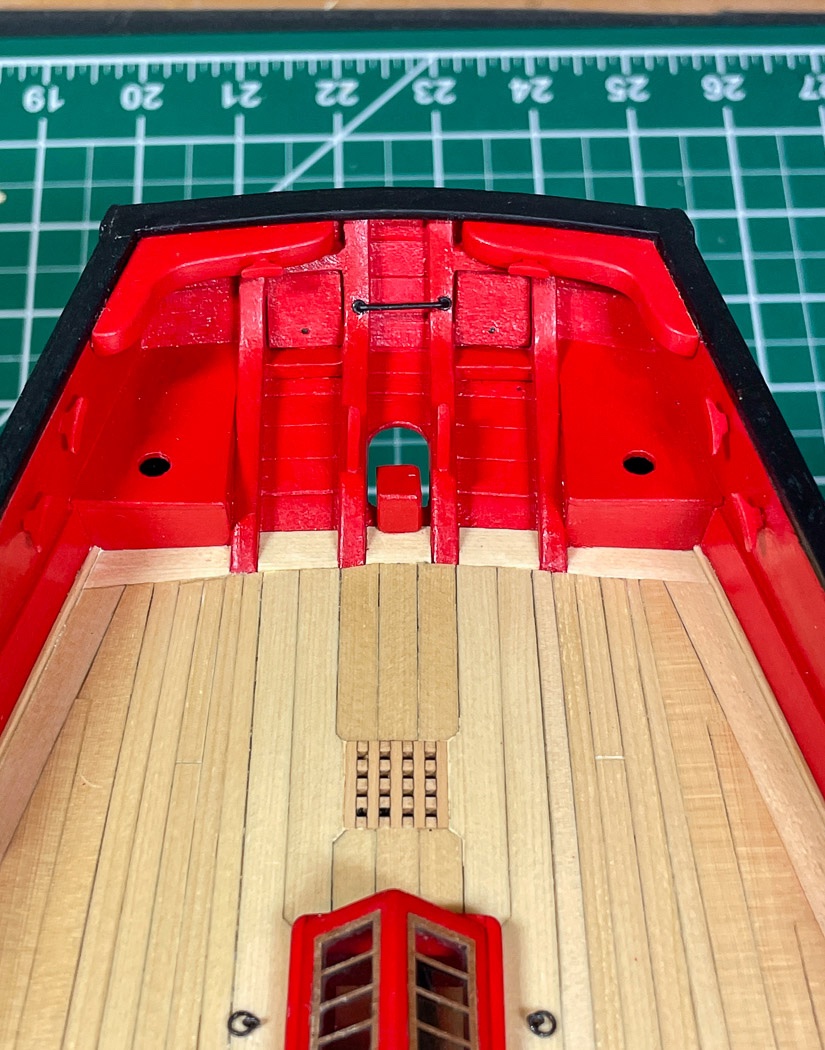

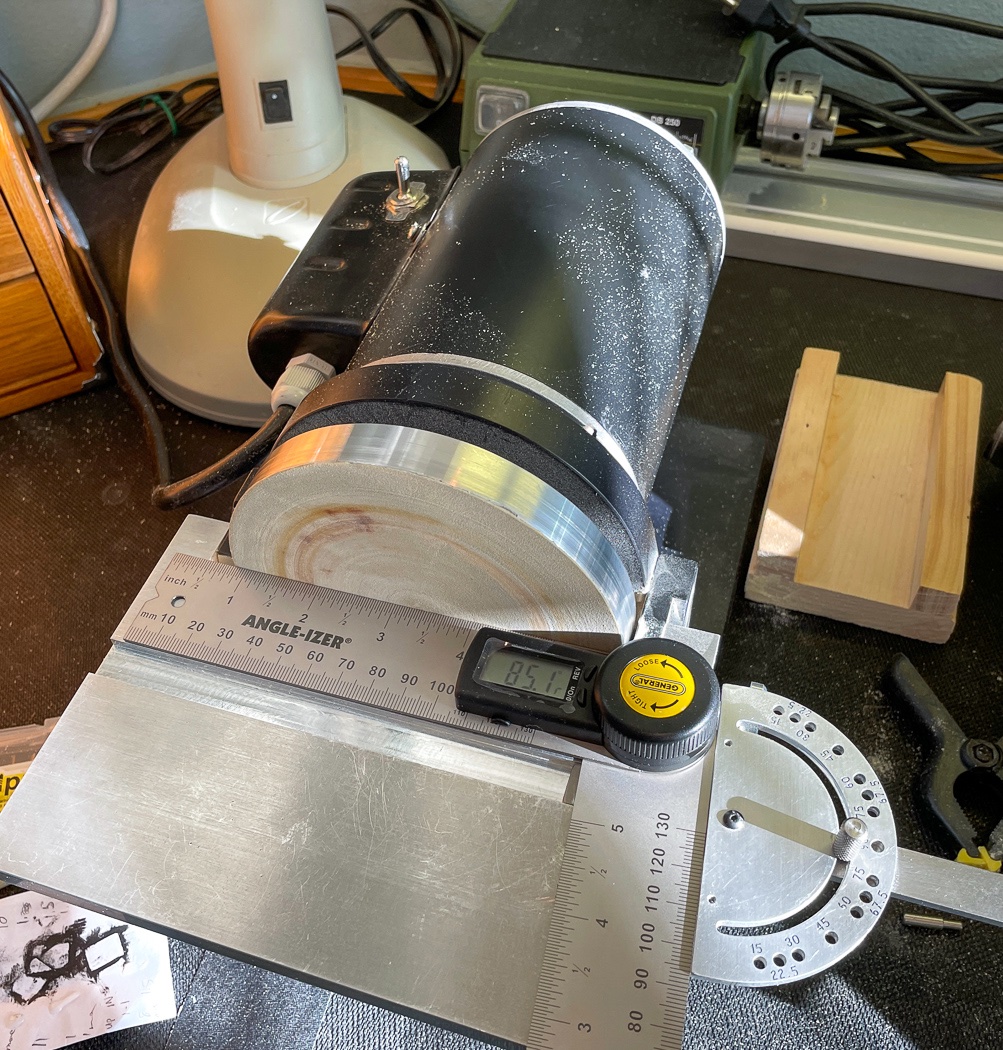

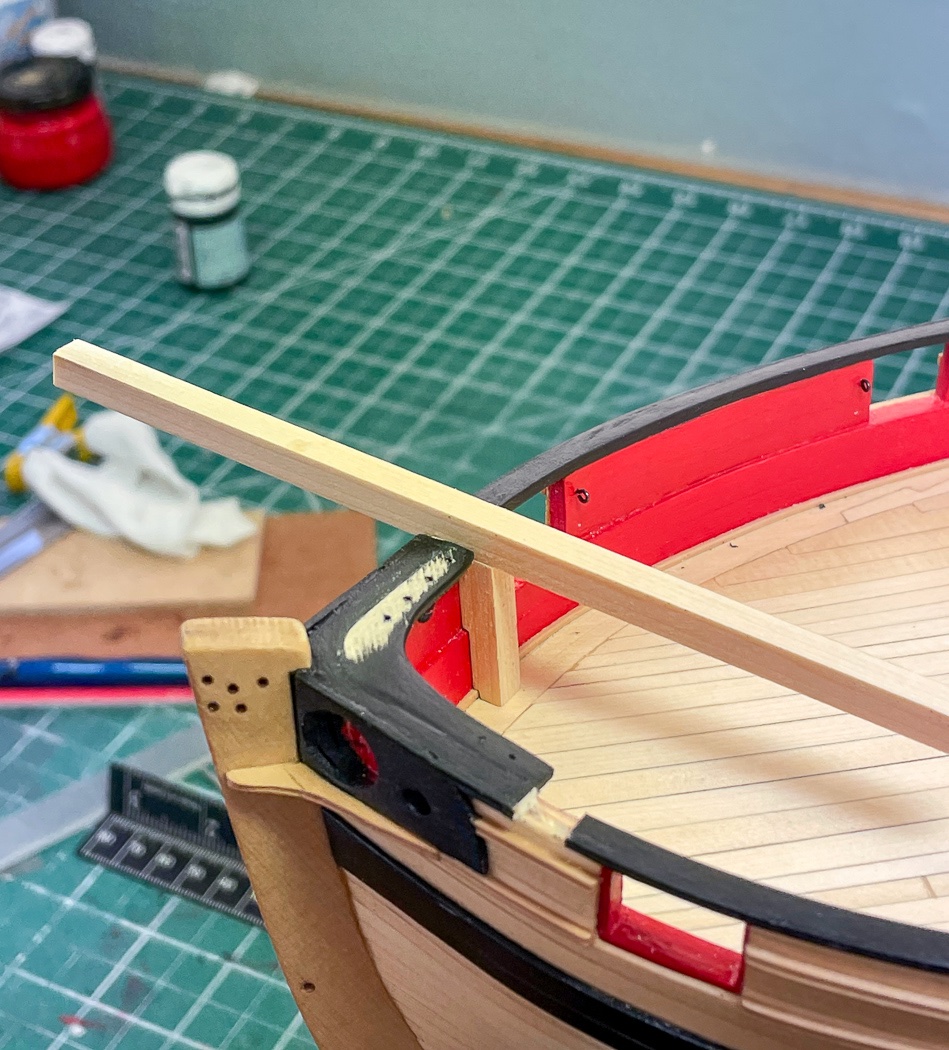

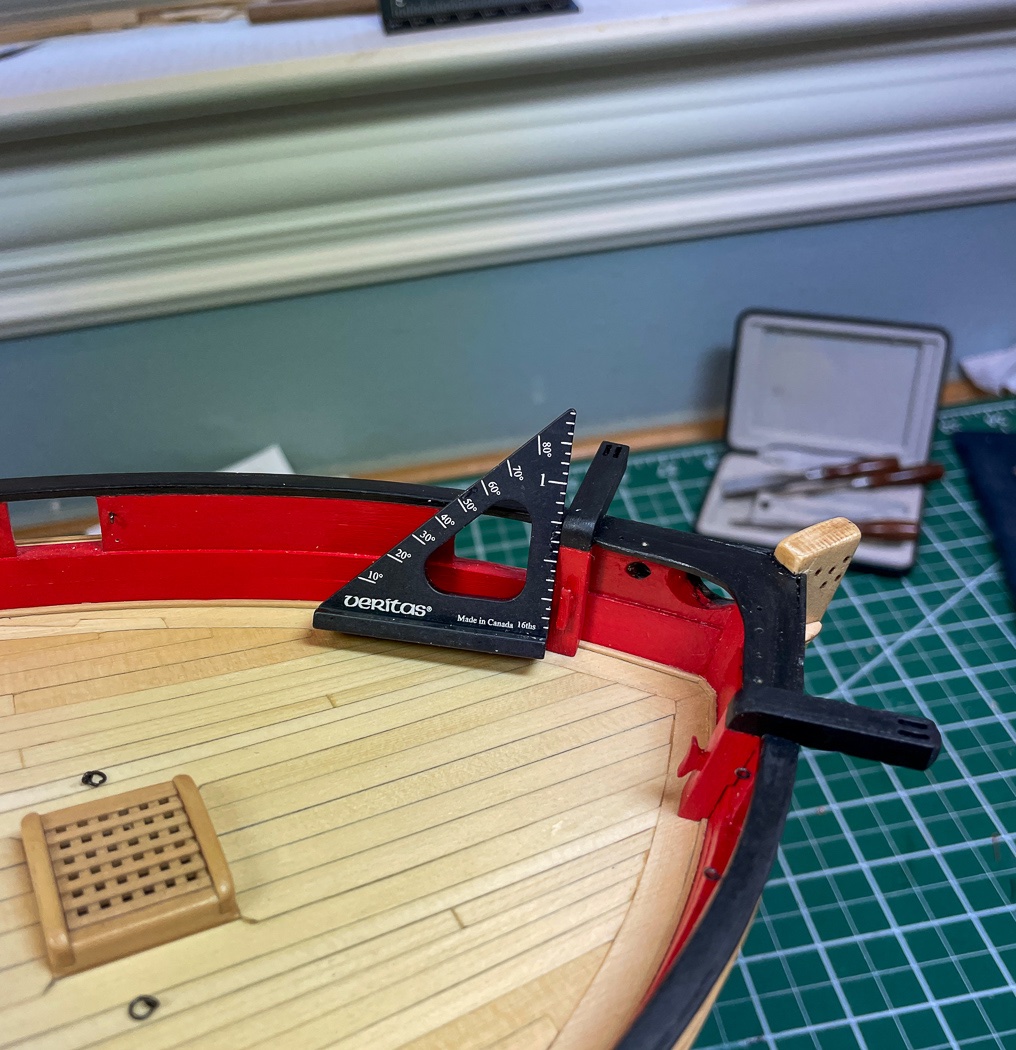

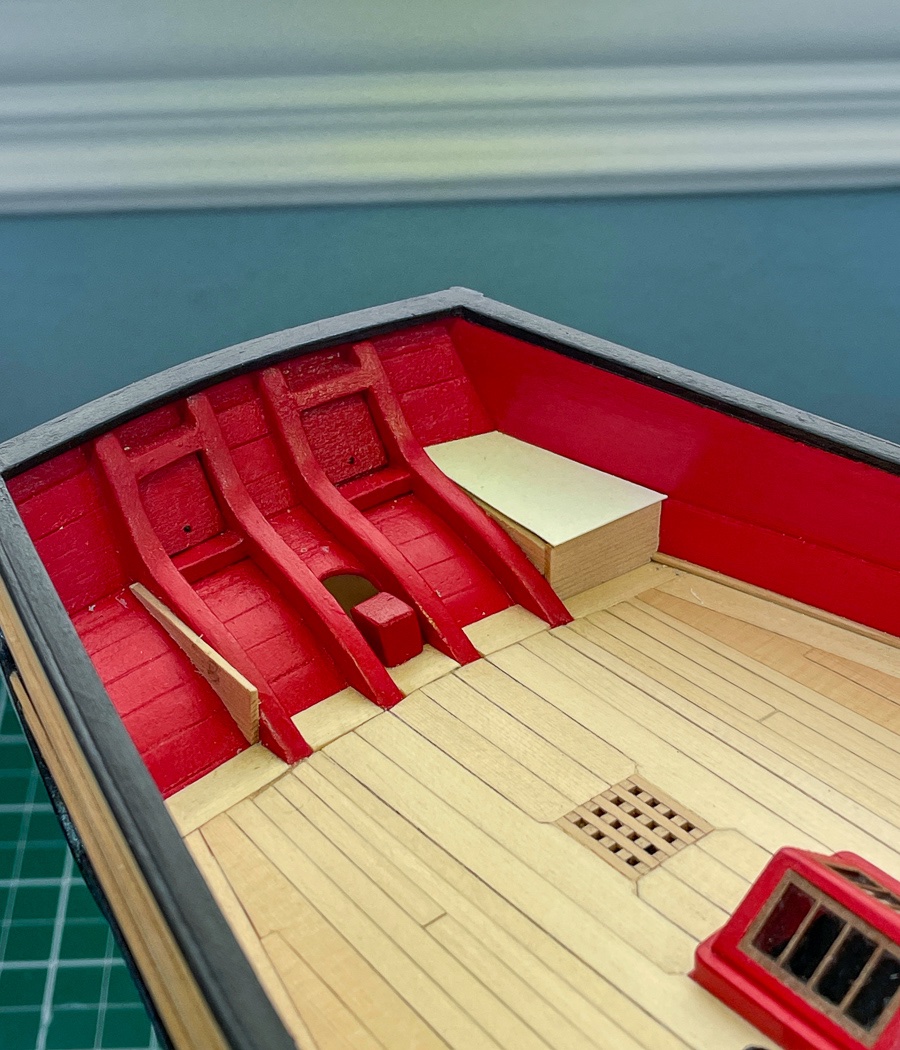

I’m continuing to do mini-projects in no particular order - following the ‘why don’t I do that next’ plan. So: Mounting the rudder When I first looked at the Pintles and Gudgeons mini-kit I wondered what do you do with those. Turns out it’s another brilliant design and a simple way for attaching the rudder. Simple in concept anyway. The first step was to paint the gudgeons Ironwood Black then dust them and the straps with weathering powder, because you know you can never do enough weather powdering. Attaching to the rudder itself was straight forward, I left the pintles long initially then trimmed it back after some test fitting. Then came the more challenging part, attaching the gudgeons to the hull in the right place to fit the rudder and in line. After some careful measuring and marking I used a piece of brass wire to make sure they were aligned. There isn’t any forgiveness here, everything has to be in the right place. I encountered a problem, I couldn’t get the glue to adhere to the hull, after several frustrating attempts I determined that glue sticking to wood with too many coats of WOP doesn’t work - I simply had let it get it too thick on the stern post. I roughed up the wood with some 220 grit, and after that no problem. I of course knew this, but sometimes in the thick of it you just want the wood to shut up and do what you tell it to do - the wood laughs. I also shouldn’t do these things at night, or maybe not at night after drinking scotch, or maybe just not after drinking scotch. Anyway. The straps and bolts are added. I liked how drilling holes as marked on the strap, inserting wire a little long to glue it in and then cutting it near flush made for nice bolts after touching with Ironwood Black (a little touch up there to do on the hull too, oops). And there you have it, my ship can now be steered should it find itself adrift in the ocean somewhere. I still think I’m going to remake the tiller, we’ll see, it’s just hanging there loose for the photo. So with that done the rudder is removed and put on the shelf to be permanently installed later, bye rudder. The Catheads Then, since it can be steered I figured I better be able to anchor it, so do the catheads next. That meant it was time to play with the mill again and pretend I know what I’m doing. Following the monograph I constructed the catheads in two parts. First the upright, which to fit tight against the bulwark had to be notched for the spirketting and again for the waterway. I cut both notches with the mill. While it takes the unskilled like me a bit of work and trial effort to get the measurements right, the mill cut nice and clean once I had it correct (actually it cut nice and clean when I had it wrong too). I bought a car engine feeler gauge, took it apart and used the thinest one to set a good zero for between the bit and the wood for the X,Y,Z axis. This proved pretty handy in getting a consistent starting point for the cuts. It was fortunate I read the monograph first (not that fortunate as I always do). Before starting on the catheads, the forward pin rail has to be made and installed. That has to be sized carefully so that the cathead doesn’t impede the flow of the anchor rope through the hawse hole or restrict the gun tackle for the forward chase port, there isn’t that much room between the two. I had to do a little fine tuning on the pin rail not related to the cathead as shown here. Next up is getting the correct angle on the upper piece of the cathead, hint, it’s not 90 degrees. There needs to be some upward angle to it, while also accounting for the bit of lean of the upright on the bulwarks. After some experimenting I determined 85 degrees was best (or 95 degrees depending on how you look at it). Since the Byrnes gauges don’t do notch anything less than 15 I set the angle on the sander for a smooth edge using a digital protractor. Then to get a good feel for it I set the top piece on for a look. I decided this made a great ship's crane and installed it just like shown here. Well, it did cross my mind for a second. When I know I’m going to need multiple equal sized pieces, plus several more for testing I cut a properly sized long length and cut everything from it, hence the long piece shown. Then its back to the mill to cut the sheaves into the top piece. This is so incredibly easier and better than doing it by hand with a blade as I’ve always had to do in the past. Just cut the slots a 1.5 mm deep and drill all the way through on both ends. I added flush-cut 24 gauge wire to either side later but it doesn’t go all the way through and is just for simulation. This little Veritas triangle, a new tool, has been coming in handy a lot for deck work, here to make sure the cathead is perpendicular to the deck. Some filing at the leading edge, paint, a couple of cleats, and I have catheads. No anchors yet so the ship is still drifting, but at least they have someplace to attach one, or maybe attach Fred, their fellow crewman who drank all the grog, and just let him hang there a while. BTW, they are straight, the photo is a warped perspective due to the angle. The Seats of Ease I struggled with the concept of this a bit. These seats are such a prominent feature of the deck. I have this vision of two crew members availing themselves of the seats, just a few feet from the helmsman. There is no cover on them (I almost added one) so I wonder, given the prevailing wind on a sailing ship is generally from either rear quarter, if the helmsman - often the captain on a ship this size - was constantly bombarded by the smell. So I almost turned them into lockers and let the crew poop over the rail. In the end I decided to stay true to Chuck’s design and accepted they’d be a topic for conversation once the ship was finished. So I began to build my two onboard outhouses with apologies to the helmsman…courtesy flush dude (which would be a bucket of water I suppose). It seems simple, just glue together three pieces of wood, the top, one side, and the front. The thing is, again, there are a lot of angles and curves involved - plus you are making two and the two have to be both identical, level and even in height with the spirketting since that forms the outboard side, and the width of the inboard stern frames. Here’s hoping I installed all of those equal on both sides so long ago. I started by cutting card templates (as Chuck suggests) - its kinda essential here to get the right fit. I’m sure there is a geometric name for the shape of the top, let’s just say it doesn’t remotely resemble a rectangle. I also cut a long strip 9mm wide from 1\32 sheet so that the front and sides for both seats came from the same piece of wood. This photo is from later in the instruction. I first did the sides since everything else is based on them. The challenge is cutting the curve of the counter on the bottom, having both end up the same height and level, be the same length coming forward, and the leading edge perpendicular to the deck…no problem…who doesn’t love geometry. And what do you know on the first try both sides are level…or maybe not on the first try… After cutting the fronts - with the outboard side beveled to fit snug to the bulwarks, it was on to the top. There is no substitute for card templates here. I marked the measurements, tested it and remarked until I had the varied lengths on the four sides required for it to fit, the angle of the hypotenuse or something like that. I used the cross cutting table on my Byrnes saw to get precise cuts on two of the sides, there is likely some way to do it with the saw, but I opted to cut the remaining two sides with my heavy steel rule and #11 blade. It’s possible I didn’t get all this right on the first try, card stock or not. With the pieces cut and only the sides glued in I test fitted everything, and found it’s all level and equal sized, how’d that happen. The last step before mounting and painting is the ease part of the seat, cutting the hole, which after all the work to get two fitted tops I didn’t want to screw up. So I went slow with a small pilot hole, then a bigger one, then a round needle file, then a larger file marked with a sharpie to finish at a 4mm hole, and finally an ultra fine sanding stick to smooth it out. I added two large cleats and 4 smaller ones then painted it by brush with thin coats of my favorite RED (again some iPhone camera distortion on the angles). The cleats come from Syren, available in multiple sizes. I had to remove the laser char (it would show through the red paint) and shape them a bit. I used the stem of a standard eyelet to pin them to the bulwark so they can take rope tension later. I also added the horse, created from 24 gauge wire. I used the eyelet portion, cutting off the stem flush to the circle, to accent the horse either side, painted it Ironwood Black and weathered it to finish off the stern - except the knees and boom crutches which are up next…maybe… Pin rails and cleats I finished up this phase by adding the bulwark pin rails along with the rest of the cleats noted on the plans. Turned out to be a pretty tight fit for the cleat nearest the ladder. I’m glad I checked that, I had to give it a little extra turn to allow the ladder and gun tackle to fit with room for the future lines shown on the rigging plan. It’s generally a good idea to take a look around at what might happen or be added later to make sure nothing gets in the way of something else. That was evident here and especially evident with the catheads. As I noted I’ve been turning pages in the monograph and doing what I felt like doing next - at this phase, at least so far nothing has to be sequential, though that will change soon. Thanks everyone for the likes and for stopping by. I better go check to make sure the crew didn’t actually drown Fred.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Bulging 2nd Planks

glbarlow replied to drjeckl's topic in Building, Framing, Planking and plating a ships hull and deck

Hard to say, haven’t encountered that. I put little dabs of CA, don’t need much, along the whole plank. I leave only a small space between each dab, no big gaps along the way. It’s also important to have the right bends in the plank both in and down using Chuck’s method. You’re right, no edge gluing is needed. So the only thing I can guess is your gaps between CA are too large or the bend isn’t right or a combination of both. Your first planking needs to be very smooth and faired. You can’t get a different hull with the second planking, it conforms to the first. -

First, sorry for the typos, me and my iPad are not friends when it comes to typing.... That is your best advice. It’s understandable to want to get to a result, but harder to remember your not on a schedule. If I had remembered that Cheerful would have both sides planked once instead of 2-3 times, my having ripped off work I wasn’t happy with. Which bring me to my other advice - don’t settle. If it’s just “ok for me” then rip it off and do it again. That’s the nice thing about wood, there is almost nothing you can’t fix. I often say if things had three sides my third side would look great because if the practice from the first two. And of course enjoy it, it’s a hobby not a chore.

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

Yep, that’s why I described using the lans to cut the hull shape out of a board for bending the pattern, not to pile n...

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.