-

Posts

3,812 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by glbarlow

-

-

-

-

You should consider not tree nailing the hull. It is very beautiful as it is. My opinion is the tree nailing gives the hull a case of the measles. I’m still quite happy with my decision to forgo tree nailing on mine.

- WalrusGuy, FriedClams and Thukydides

-

3

3

-

Merry Christmas Chris, so glad your business has taken off, we’re Al the better for it.

- scrubbyj427, Rik Thistle, Canute and 5 others

-

8

8

-

Nice modifications to the hatches BE, well done and a step up from the kit for sure. My recommendation for the hatches is black I didn’t think I’d like it until I saw it on other Winchelsea build logs, it looks quite sharp and a nice contrast to the surrounding red.

Merry Christmas to you and your family as well. I find it fun we say ‘Merry’ and the English say ‘Happy.’ 🧐😊

- mtaylor and Blue Ensign

-

2

2

-

6 hours ago, DelF said:

My Sphinx is still in her box

I’m sure, like your Speedy and Duchess, it will become the Vanguard reference build once you do. With Winchelsea underway it will be a long time before I get my Sphinx out of the cabinet. I’ll likely follow BE’s path of an admiralty build when I do but I might miss rigging something by then.

- hollowneck, DelF and mtaylor

-

2

2

-

1

1

-

On 12/20/2021 at 1:47 PM, FrankWouts said:

Looking very good Glenn!

Thanks Frank, your build is one I regularly check to learn from as I move forward.

14 hours ago, BobG said:build log is informative and a pleasure to read.

Thanks Bob, as you know from my past logs this is something I strive to achieve.

1 hour ago, Edwardkenway said:come to expect nothing less

Thank you, glad to be a part of this journey.

- FrankWouts, Saburo, AlleyCat and 1 other

-

4

4

-

Your craftsmanship with the boxwood coupled with the well done decorations make for a stunning look. The window technique is very creative thinking.

Merry Christmas Derek to you and your family. I’ve enjoy our cross-pond dialog this past year and look forward to more next year.

- chris watton, hollowneck, Ryland Craze and 2 others

-

4

4

-

1

1

-

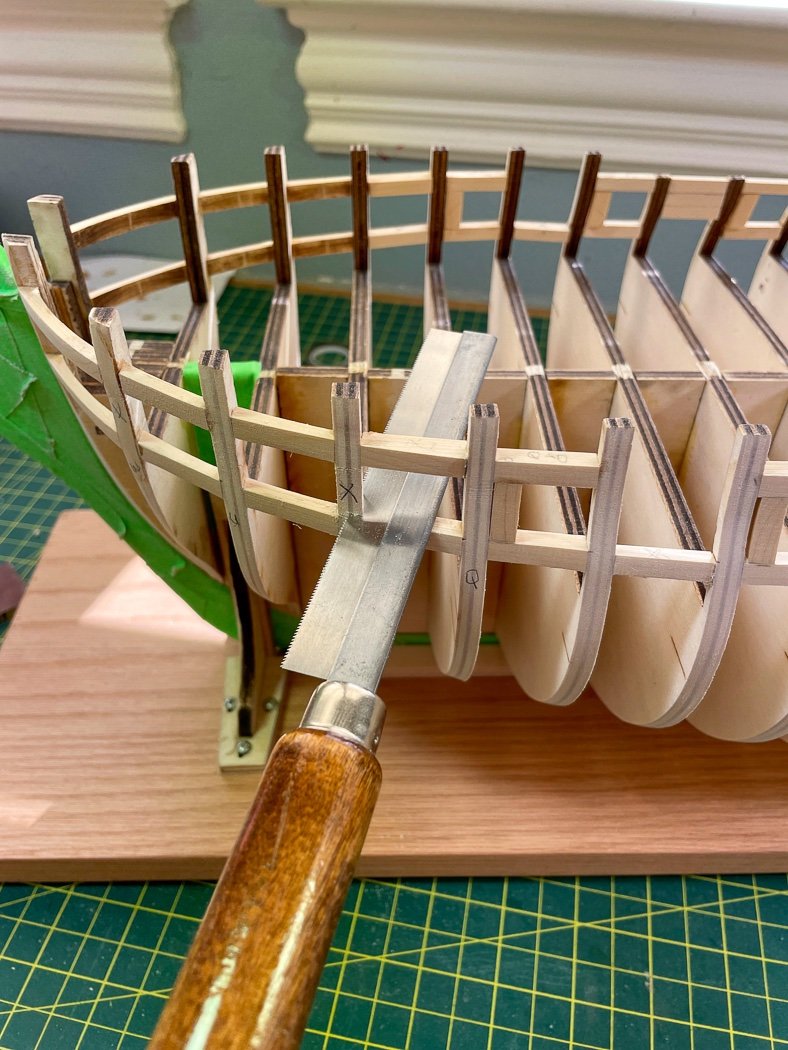

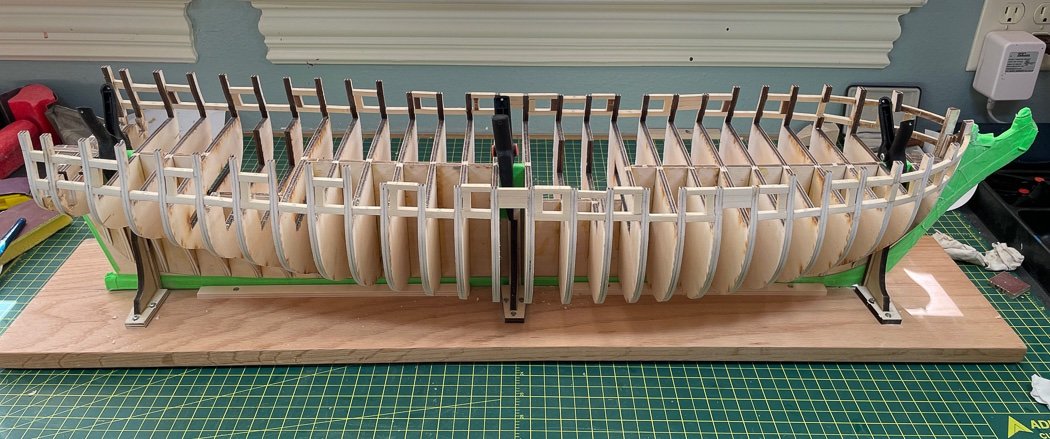

I thought I'd add a few closer photos of my framework before I move on to the stern. Maybe a little more interesting to look at than my previous post caught up more on the process than the result.

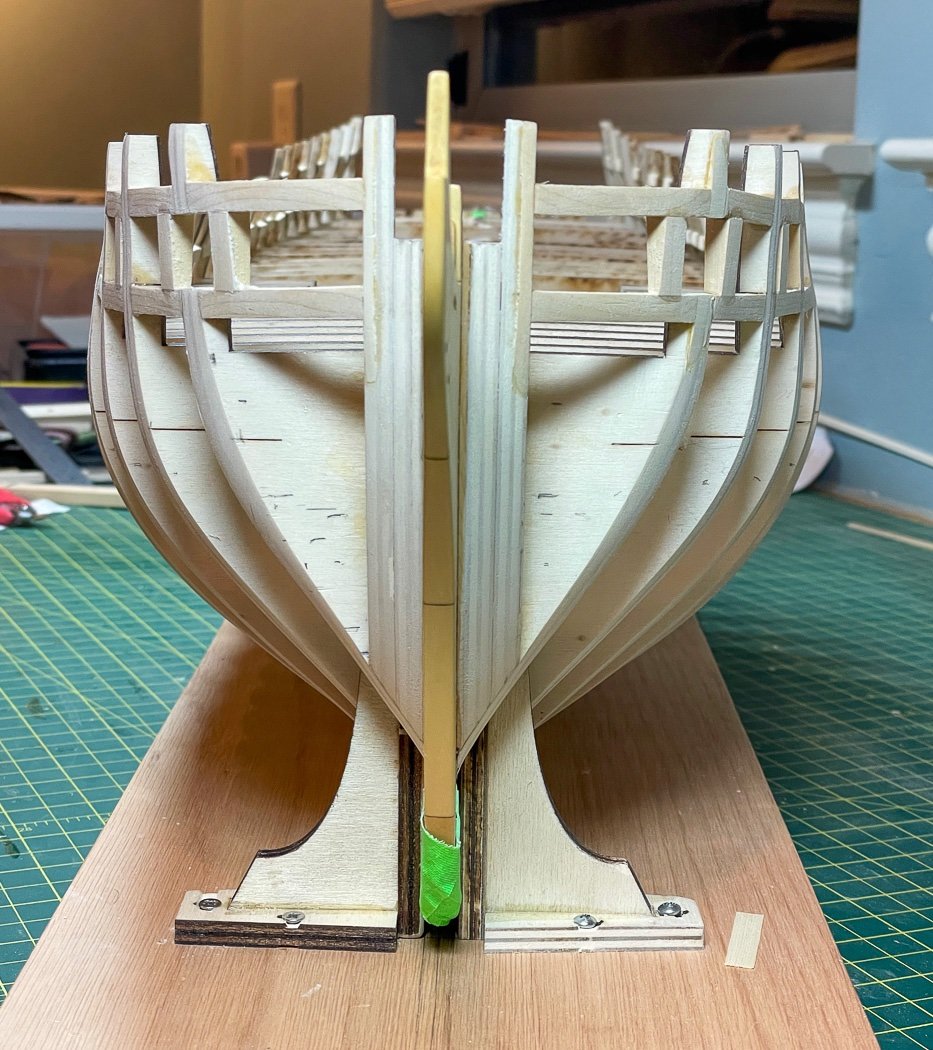

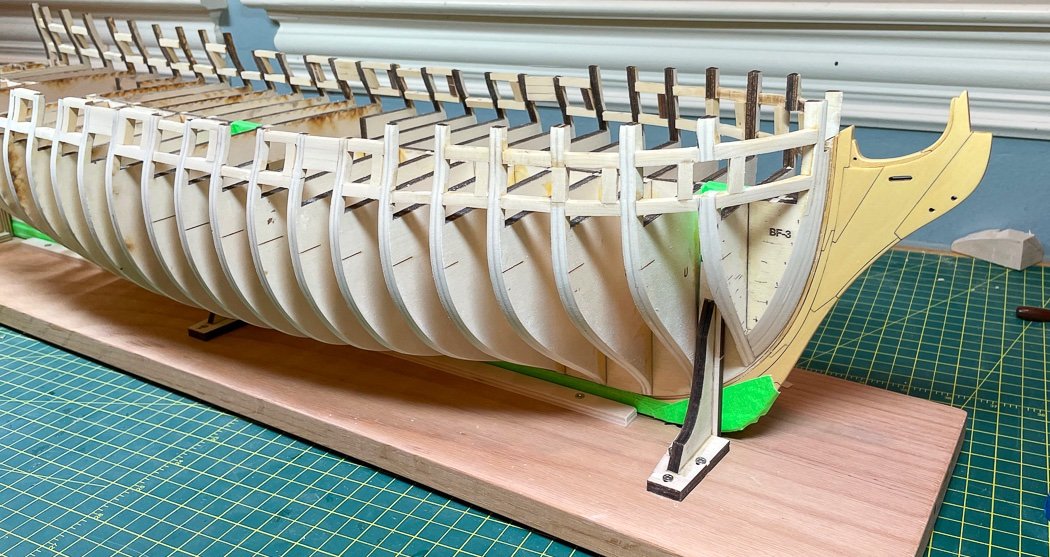

The ship is straight the photo isn't - the tick marks are a sign of my many measurements to ensure symmetry. No bulkhead from front to back has more than a .5mm difference from it's opposing side - the front three are through measured effort, the rest more ...'how'd that happen...'

Still have the top to fair. The off-centered ones between ports are there for support (two where a bulkhead was troublesome) and ensuring equal distance between bulkheads. Per Chuck's guidance every sill and support piece was measured close to the former, not at the outside, it's opposite on the other side is it's exact twin. The challenge, maybe not obvious in the photos with these are all the angles involved, as I noted above the angle finder and Byrnes sander were essential, for me anyway. A single plank run will be placed 1/32 from the bottom of all 14 ports, another along the top edge, front to back. I think I got it right, not a lot of tolerance, time will tell.

It does't quite look like a ship yet, but it's getting there. The lines are really nice, 1/48th is so cool to work with. I happened to notice the scale is very near the NMM plan I have framed on my work room wall - I was comparing measurements and was taken by my building a model so nearly equal in size to it's original draft.

More evidence of the tick marks, I showed in an earlier post how I record these on paper and fair for symmetry. I hope the eventual planks are appreciate of the beating the bulkheads took for them.

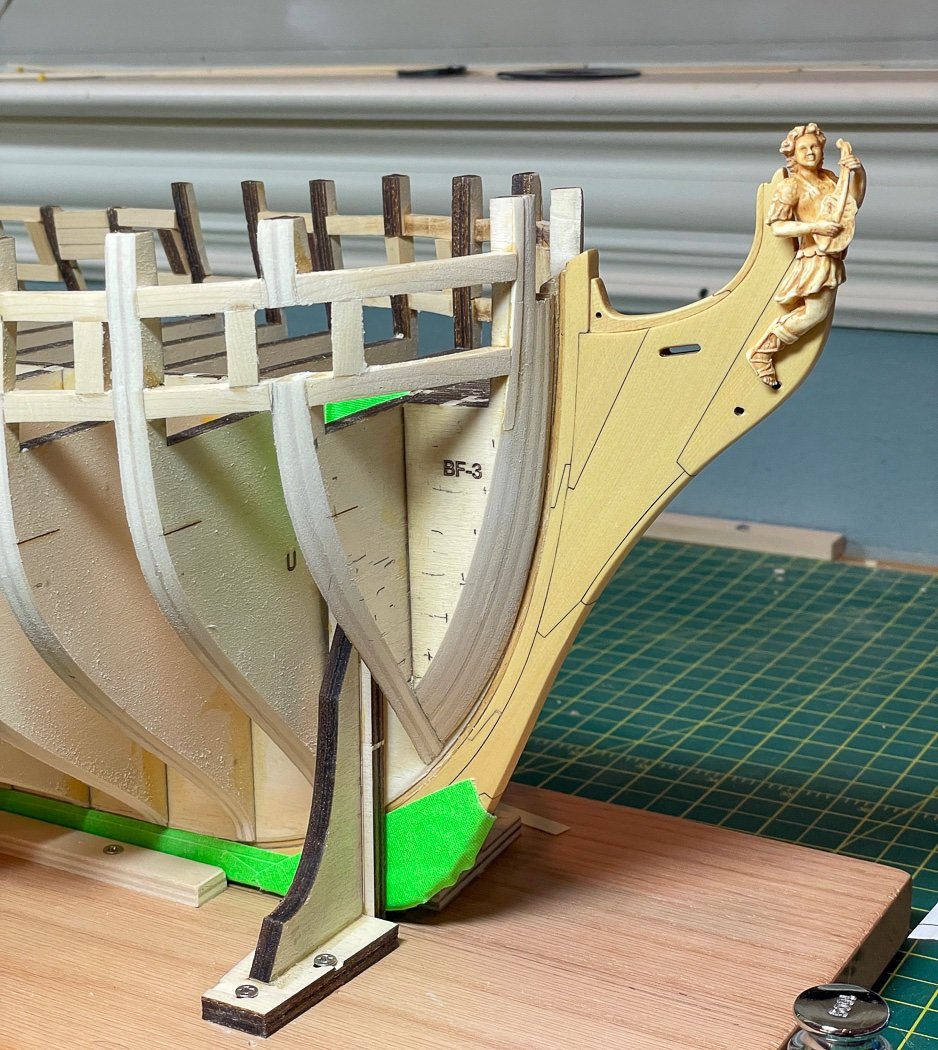

I messed up and not am happy with my staining of the figurehead, I'm going to acquire another from Chuck and practice a little more before staining the next one. Still it looks pretty cool setting there.

So now on to the stern, I've tried and continue to try to learn all I can not only from Chuck's monograph, but the many build logs long past this stage with dates more than two years old now. My journey is underway.

Thanks for stopping by. You have many choices in Winchelsea build logs, I appreciate your taking a look at mine.

-

I personally don’t think “speed” is a word I associate with good workmanship. The care and thoughtful forward thinking is more testament of what I see viewing BE’s work. This kit has a lot of new challenges based on its innovative design given what I’ve seen on various build logs.

BE, how did you come to have the black & white floor? I think it looks great but may over power the rest of the model based on what’s around it. I’m sure time will tell.

- tkay11, chris watton, mtaylor and 1 other

-

4

4

-

This is really helpful dialog, a great benefit of a group build and others willing to share their experience. 🍻

-

Great questions. I’m not that far behind you and benefiting from your nice work.

-

-

-

The Sills

It’s taken me a long while to finish the sills. There is a lot of work involved, as other I'm sure Winchelsea builders know. For half a moment I was wishing for a nice gunport pattern to bend on, but then I wouldn’t have had nearly as much fun.

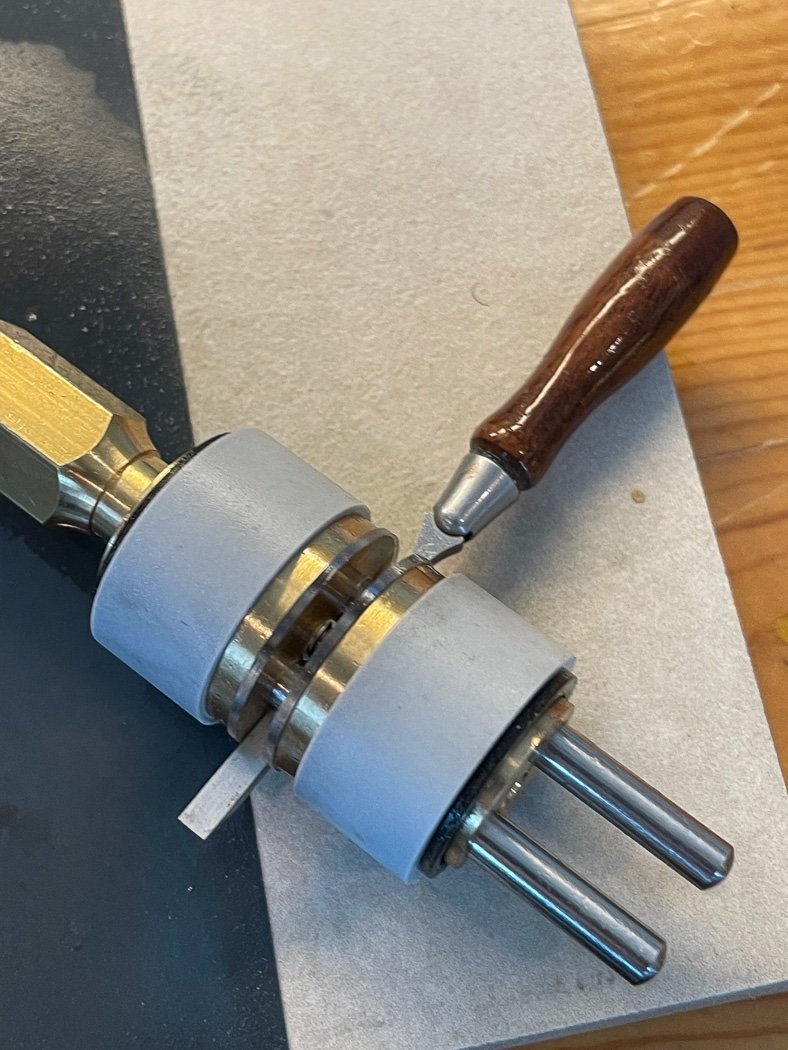

My Veritas Chisels played a big role in the process, so happy I acquired these. Even happier I learned how to properly sharpen them with the Kell Sharpener (thanks again @DelF for both). Someone asked how small of a chisel it would hold, here it is with my 1/8 chisel. With the cut angle set by the distance from the roller (½ inch for 30 degrees) and my sandpaper sharpening tile setup I get them nice and sharp. I tuned them up in preparation for this task.

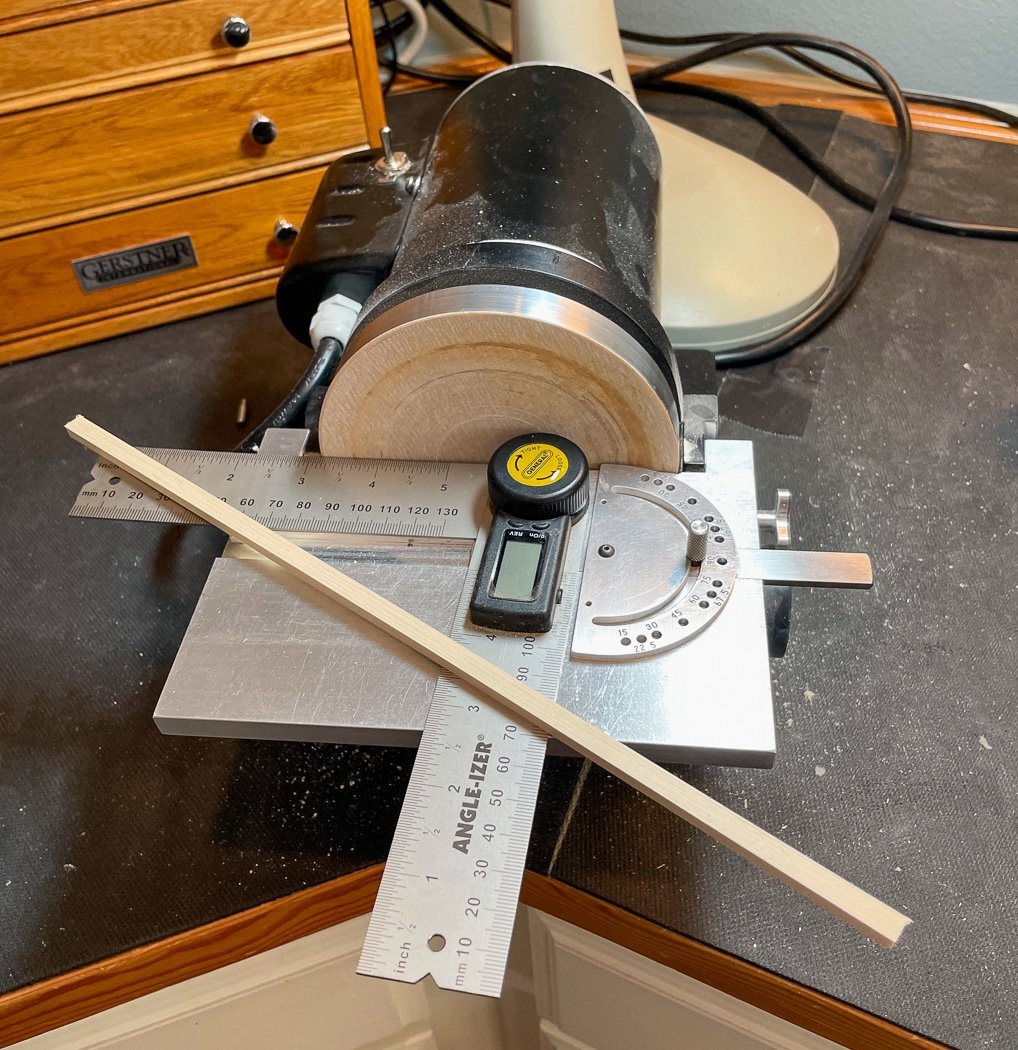

Invaluable in determining the many tricky angles involved is this inexpensive ,if a bit over-sized, angle finder. To precisely fit the sills the cross cut table on my Byrnes saw and the ability to both tilt the table and set the mitre guide of the Byrnes Sander proved equally invaluable.

As a side note I’ve had both Byrnes tools for over 10 years, I had the first problem ever, likely one I caused. I was unable to adjust the drum distance to and away from the table, it had locked in place. I called Jim Byrnes, he explained to me how to pull the sanding drum, file the spindle, and add the right grease. It took me less than an hour and I was back in business with the sander quieter than ever. The machining and precision of these tools is simply amazing along with the exceptional customer service that goes with them, they are worth every penny.

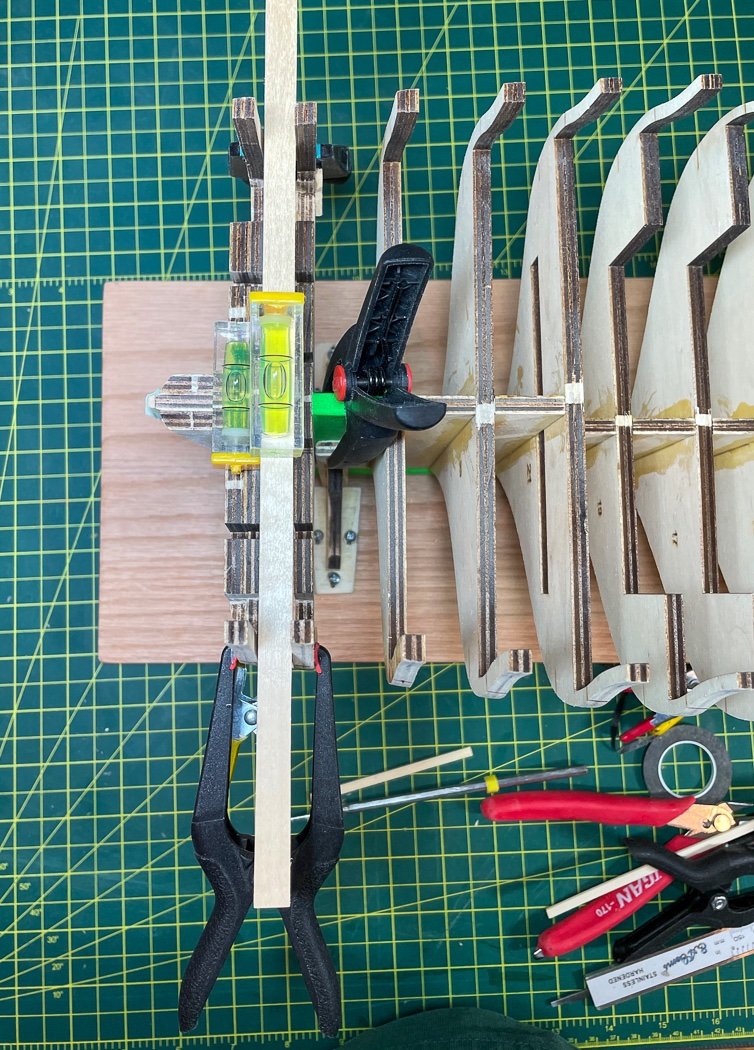

Rounding out the tools for this job are spacers I cut to fit the width and height of the ports, that plus a couple of bubble levels and off I went to build out 28 identical ports.

First were the sills and mantles both port and starboard, keeping both sides level and maintaining my line to conform with the sheer of the eventual deck. I stayed with the Titebond III, it really is stronger than the wood once cured. Per the monograph I included supports between bulkheads for extra strength, marked with a X so I didn’t obsess about their angles. Then on to the port sides and more angles to sort out. It’s a slow process process but one made more accurate and easier with these tools. I need all the help I can get.

Even with the right tools and a patient pace thank goodness for denatured alcohol. I’ve taken off various sills and sides only to reposition them for a millimeter or two difference. I could likely ignore and work past these small alignment errors, but while an omission now might never be noticed it might instead compound and multiply as the build progresses. I have to do what I can where I can to fix stuff, and I make enough mistakes to have stuff to fix.

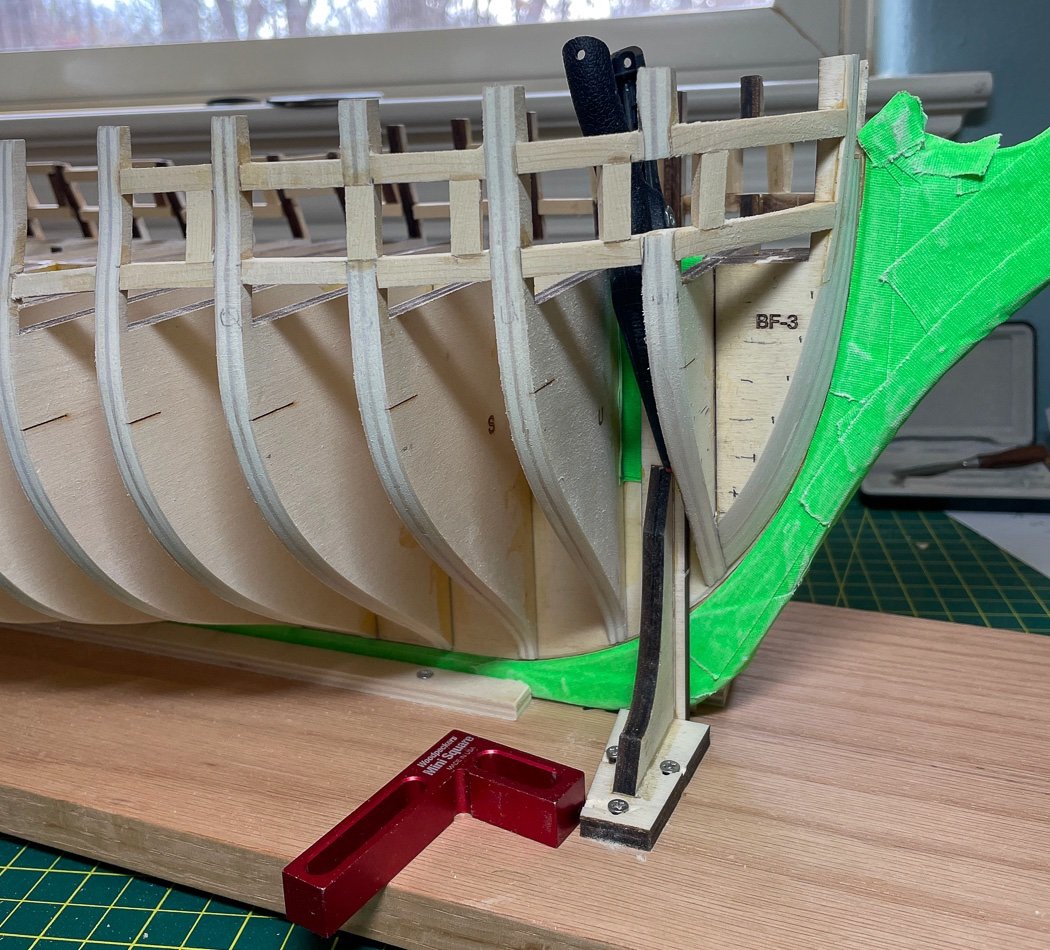

It all that wasn’t enough fun, then it was time to cut away two bulkhead uprights to make room for the forward two ports. It was a little bit frightening in concept, but by going slow and having the port sides ready to go in advance it turned out to be fairly easy (a little more fairing to do).

With almost three weeks spent on fairing and and cutting, aligning, and installing ports I’m finally ready to move on to the no less challenging task of installing the stern.

I won’t get much build time over the next two weeks with family around, so Merry Christmas to all.

-

I used the crafty sailor belaying pins as quoins, the do work well.

It’s a long way off for me but I’m thinking just breach ropes and on the ships wheel as the only rope on mine. But who knows…

I like the natural wheels, lots of char removal, so fun.

- Saburo and FrankWouts

-

2

2

-

You could start on the boom crutches, and the heads. Hope you aren’t gone long.

-

You can do a nice job painting the ones that came with the kit, mine didn’t need boring and the end result isn’t mediocre, it is consistent with the rest of the average starter kit this is.

The other option is buy new wood carriages and resin barrels and replace them entirely. They are 4 pounders, I’d bet Vanguard has them.

Pin vises in several sizes are essential tools. Power drills or rotary tools are hard to control at this scale, hand drilling yields the most accurate result. I would in any case drill these little things. I think they are bronze, not brass, any drilling may cause them to split.

-

On 12/12/2021 at 2:44 PM, niwotwill said:

spindle sander.

You have all the cool tools😆

-

-

Agree. No wait - Agree

- hollowneck, DelF and mtaylor

-

2

2

-

1

1

-

-

-

Epoxy HELP

in Wood discussion...Where to use it? Where to get it? What types are best? How to Finish it?

Posted

I can’t imagine recommending epoxy used in the way you have or why anyone on this site would recommend doing so for a wood model hub, it is an adhesive not a sealant at least for modeling purposes. If you ever sort out a means to sand it I wouldn’t think the finished result would be very appealing. You really should be able to remake the hull without sacrificing the rest of the kit provided there are decent plans. Modelers Sawmill can likely provide the wood you’d need, if you don’t have a scroll saw for the bulkheads you’d spend less time with hand tools cutting new bulkheads than you will with sanding your rock hard mistake. Sometimes you just have to accept the error and start over.