-

Posts

3,812 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by glbarlow

-

-

-

3 hours ago, Blue Ensign said:

Fettlin’ the rails

I think this is a country western song, or should be.

Your patience and time spent is well worth the result you've obtained and a blueprint for those that follow.

- Blue Ensign, chris watton, hollowneck and 2 others

-

3

3

-

1

1

-

1

1

-

We're all learning and striving to create a nice model of Winchelsea. I hope you do post soon, we all are helped by each other's work. The beautiful thing about this forum is there is no judgement - because we all know what it takes, or took, to get to any given point of the build. Jump on in with the rest of us, we're glad to have you.

- JpR62, scrubbyj427 and FrankWouts

-

3

3

-

It’s looking great! I don’t have the nerve to airbrush anything on board the ship for fear of paint drifting to places I don’t want it. So well done. I like the red.

- Saburo and FriedClams

-

2

2

-

Glad you found a place to bring her back to life

-

-

1 hour ago, Edwardkenway said:

you could do it blindfolded

Thank you, although I feel like some of my results that must have been what I did.

- Edwardkenway and FrankWouts

-

2

2

-

2 hours ago, Blue Ensign said:

love your planking.

Thanks BE, the yellow cedar is an easy plank to shape, I should know having done the same plank space over and over…😊

-

-

-

MSW included one of the photos from my last post on Facebook. Thank you MSW, it allows me to share with my friends so they can see what I do with my time.

i belong to a couple of Facebook wood ship model groups. They include many hapless lost souls (modeling wise I mean). I frequently recommend they join MSW to find help and answers to their questions, my small effort for a membership drive.

- BobG, CaptMorgan, ccoyle and 6 others

-

9

9

-

6 hours ago, DelF said:

Just catching up

GrantGeneGlenn.🤣😂. Thanks

Don! I too like the quarter shots, they really show the graceful lines of Winchelsea. I also thought you’d be impressed with my including the nautical term of tumblehome 😊(though I had to Google it)- BobG, FrankWouts, Rustyj and 1 other

-

4

4

-

5 hours ago, chris watton said:

So, it will always be this, for some, it is too much, but for others, it's not enough,

Well said. No reason for a V2, you’ve designed an innovative model that allow those of every experience level to build in the way their expertise provides. They can all enjoy the process and have a result to be justly proud.

-

12 hours ago, Dave_E said:

gives me a level of perfection to strive for.

Thanks, though It’s far from perfect, I continue to learn every day.

- FrankWouts and Saburo

-

2

2

-

15 hours ago, scrubbyj427 said:

That looks great! Nicely done Glenn!

Thanks, I’ve enjoyed your build as well.

15 hours ago, niwotwill said:got the thickness sander

Thank you. I am amazed by the difference it makes, and by the thickness variance of a plank cut by the same saw with the same settings.

16 hours ago, rafine said:Beautifully done Glenn.

Thanks Bob. Your excellent Winnie log is a regular reference for me.

14 hours ago, Rustyj said:some great planking

Thanks Rusty, my planking improved exponentially once I adopted Chuck’s method, and with all the practice Cheerful afforded me. I’m enjoying following your pear version of Winnie.

- FrankWouts, AlleyCat and Saburo

-

3

3

-

17 hours ago, Chuck said:

Nicely done!!!

Thanks Chuck, for the model and even more for your help and guidance.

- FrankWouts and AlleyCat

-

2

2

-

17 hours ago, BobG said:

Perfection, Grant, such a pleasure to follow your work!

Thanks Bob, but who’s Grant?😂

- FrankWouts and BobG

-

2

2

-

Great work Rusty, it’s always worth the effort to correct an error..

Guess your Winnie will be carrying cargo from here on…miscellaneous ship parts. 🤣

- Mldixon, hollowneck, Rustyj and 1 other

-

4

4

-

-

The way to do it is to cut them out with a #11 blade as you plank each row. It will be much harder now but you can still do if you’re careful and go slow. It’s a good idea to think these thinks out in advance. If you rush it you’re going to split the planking.

- Keith Black and Dave_E

-

2

2

-

Thank you for the kind comments and likes, much appreciated. I’m really enjoying this build.

- FrankWouts, AlleyCat and BobG

-

3

3

-

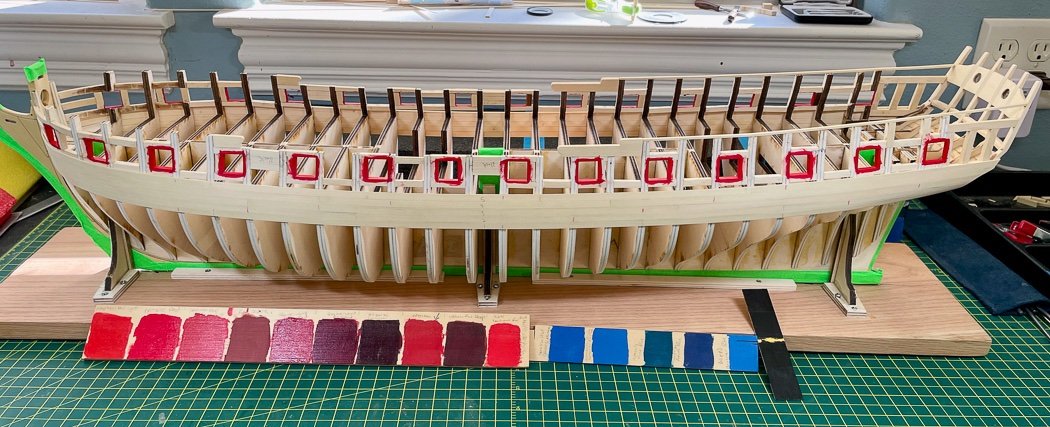

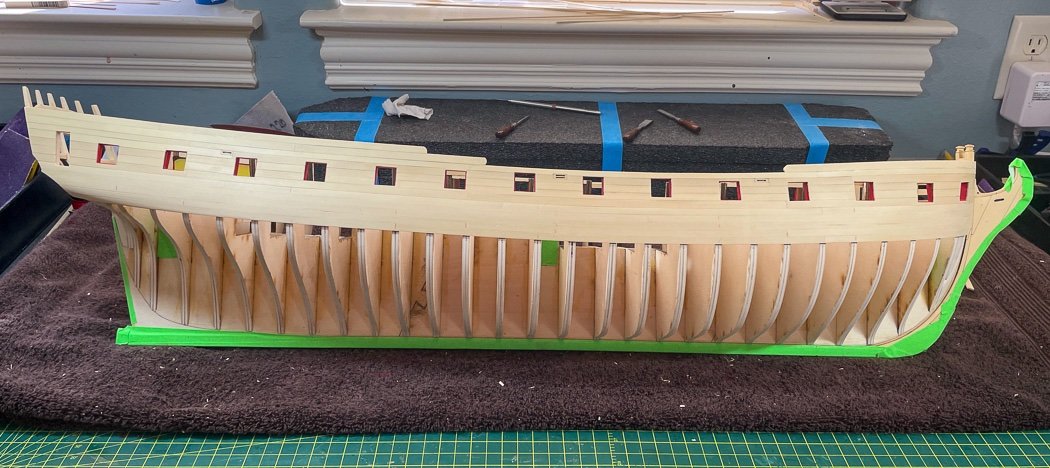

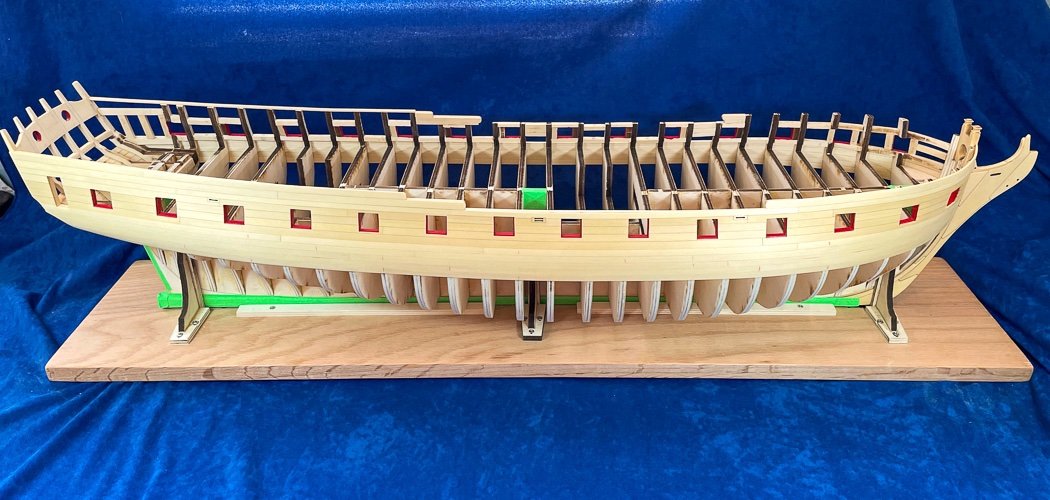

Planking above the wales

It’s been a minute since my last post, it took me this long to complete the planking above the wales on just one side.

The first step was deciding on what my primary color would be since the ports need to be painted before planking begins. My first thought was to go darker, perhaps more on the maroon scale, than I had done with my Cheerful. The more I looked at my paint board the easier the decision became. I liked Cheerful RED so Winchelsea would also be RED, maybe REDDER with Winsor & Newton Crimson as my choice.

While I was at it I also prepared a blue paint board to compliment the friezes, I’ll defer that choice until I get to that point. I also looked at a couple of black choices. Despite some nice other options I always come back to Admiralty Paints Ironworks Black - a paint that looks as good as matte black on wood as it does to imitate metal in my opinion. I may go with Grumbacher Mars Black, we’ll see when I get to painting the wales.

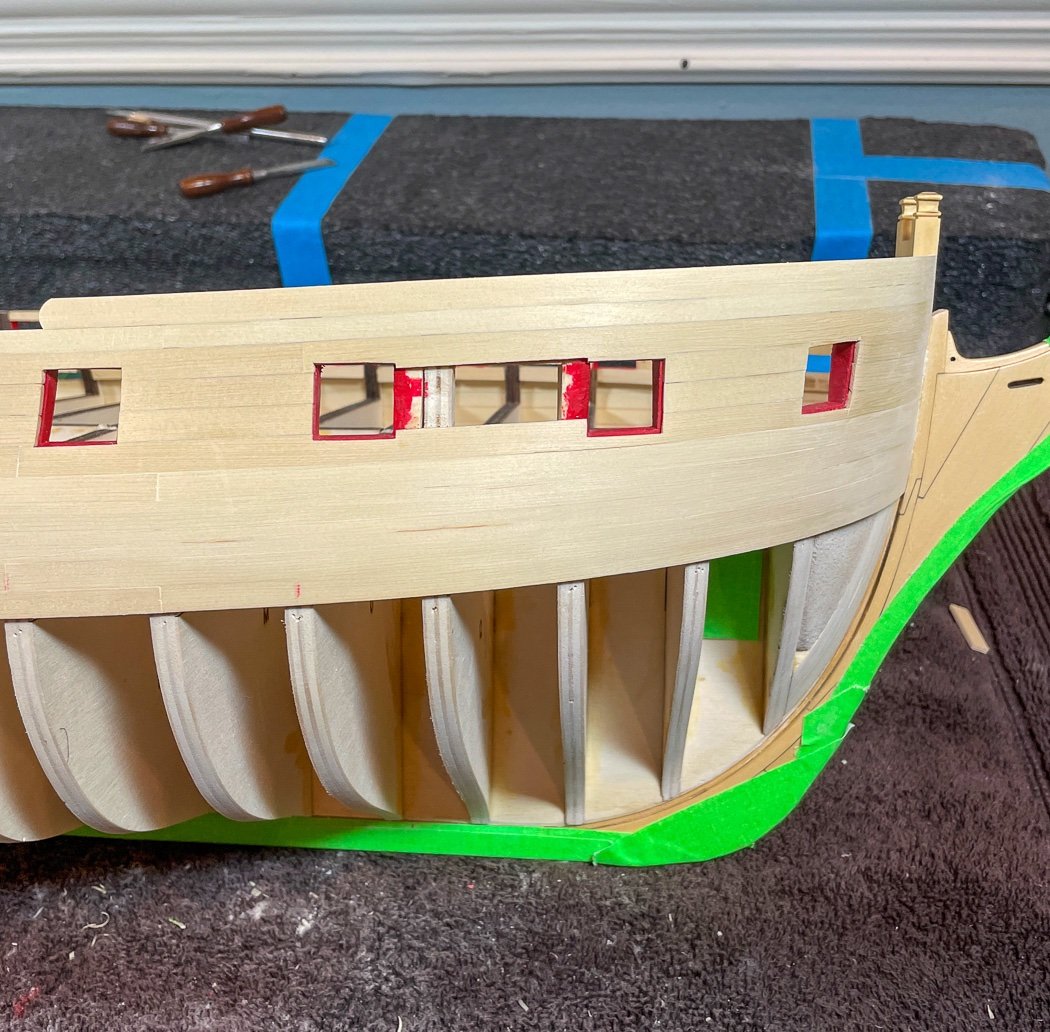

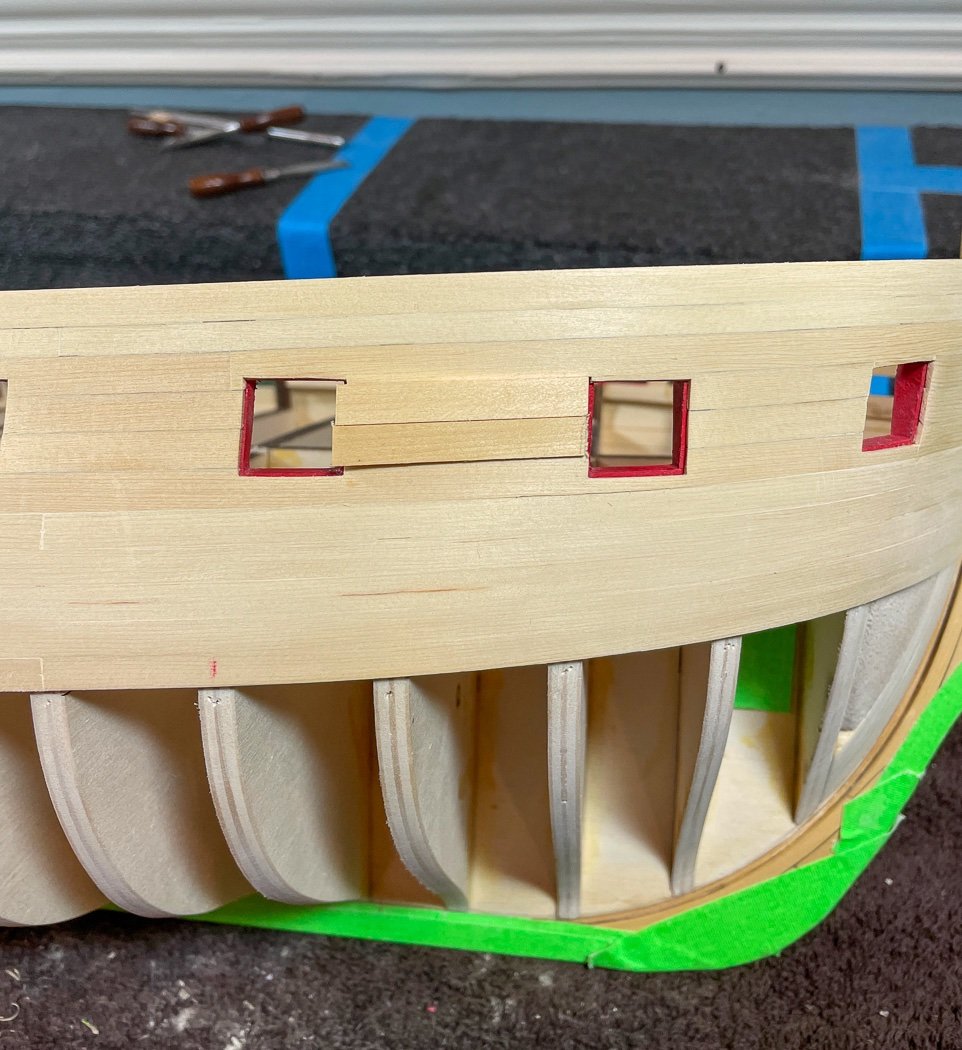

It would be challenging enough to cut planks around 28 ports, it is more fun, to do so while providing for a 1/32 rabbet around three sides of each port. It took me the better part of a day to cut the one shown in the photo that runs along the bottom of five ports midships. Each is a bit different as the ports follow the sheer of the eventual deck with the sides parallel to the waterline, in other words not square. The little port jigs came in handy to determine the 1/32 rabbet. The tops are equally challenging, and still with all that I still had more adjustments with sanding sticks to do later.

Once again I am amazed at what can be achieved with nothing more than the heat from a travel iron when it comes to shaping planks. Not easy see in the photo but this one plank follows a gentle S curve front to back and is curved to conform to the bow. Without soaking, clamping or nailing I can shape a plank to lay right onto the bulkheads with very little finger pressure. Like all my planks the inside bottom edge is softened for a tight seal to it's mate below. I do as little as needed, I don’t want to later sand right through the bottom edge. Every plank also has #2 pencil added to the top to imitate tar seams.

I recently added a Byrnes Thickness Sander to my shop, it has proven helpful. Even a nicely milled plank can vary in thickness enough to make for a bumpy planking. I ran all my planks though the thickness sander and it paid dividends. This is the un-sanded planking, I didn’t have to do a lot more to smooth it out.

-

After completing all the planking then sanding above the wales I didn’t like this one section, so I popped it out and replaced it. I plank happily with CA, I try to keep it in the middle of the plank and not too close to ports (the CA not the plank). So it didn’t take a lot to remove the planks without collateral damage. I planked a good part of one side of Cheerful three times, I’m not reluctant to remove a plank and do it again - though I’d like to determine that as I go and not after I’m done as happened here. (I rejected and replaced the lower piece for color match after the photo.)

One more step before adding WOP, touching up the ports. I’m normally pretty handy at free-handing this work but I wanted to make sure I had nice edges between the port and the plank. I choose not to paint the out to the edge of the planking. It would be difficult to do for one thing but more importantly the recessed painted port highlights the rabbet and is a better look in my opinion.

Excuse my impromptu photo studio, I just hung a bit of cloth over my workspace and used my iPhone. It offends the photographer in me but it’s fast and at least a little neater than my usual workshop photos.

After one last sanding with 400 grit I added a coat of wipe-on-poly to seal it up. This first coat is almost absorbed into the yellow cedar as fast as I put it on (and is still slightly wet in these photos). By the time I’m done the ship will have at least three coats, maybe more, of WOP. It is my opinion nothing brings out the rich gold tone of the Alaskan Yellow Cedar better than WOP, they are the perfect companions.

I tried to color match the planking rows above the wales and below where the friezes will eventually be, that made for and interesting ribbon of color it seems.

As a follow up from a prior post here is the bollard timbers tapered flush with the planking. I’ll shape them more when the other side is complete

Using the plans I’ve marked the butt shift pattern to follow for the second layer of the wales.

I love the sweeping lines and tumblehome of Winchelsea, so cool.

So after two weeks I have the starboard side done above the wale - off I go for another two weeks to complete the port side.

Thank you the follows, likes, and comments. I’m just one of many working on this magnificent, and very large, model, I appreciate your stopping by to see mine.

-

-

We’ll that’s a creative approach to those strips, very clever.

HMS Winchelsea 1764 by glbarlow - 1:48

in Member Build logs for the HMS Winchelsea

Posted

Thanks, it takes time and the willingness to tear it off if it’s not right, plus sore fingers from pressing the pieces together while the CA takes hold. 😩