-

Posts

13,377 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

I agree with Robin about dates and number of reef bands. The animation is terrific, Magnus!

-

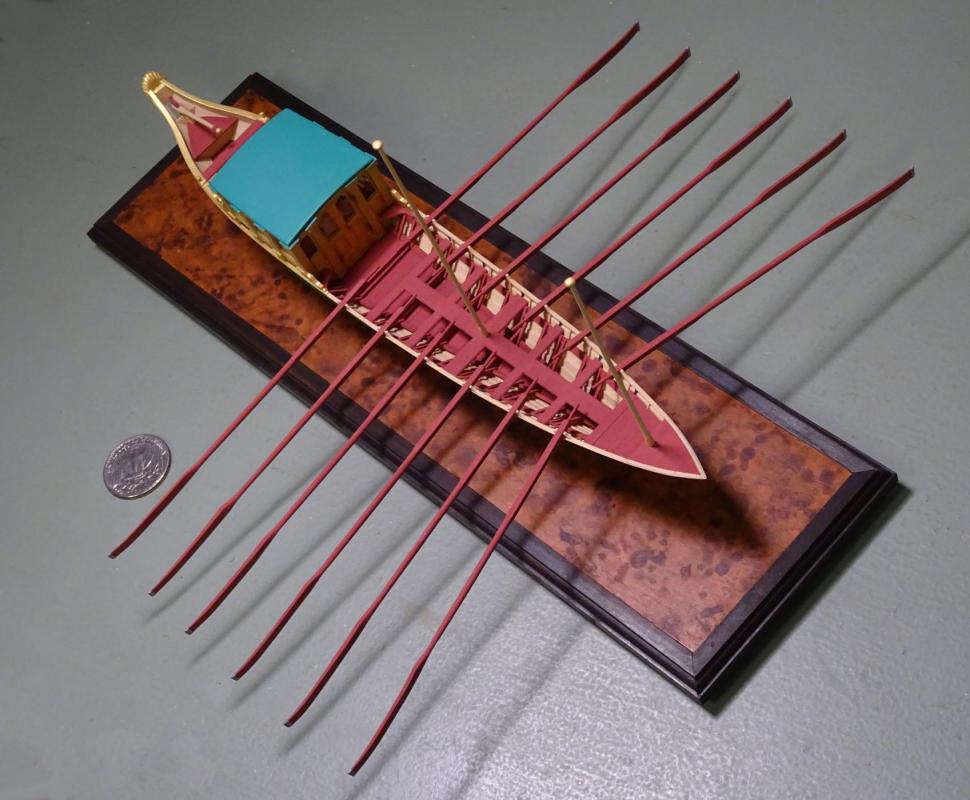

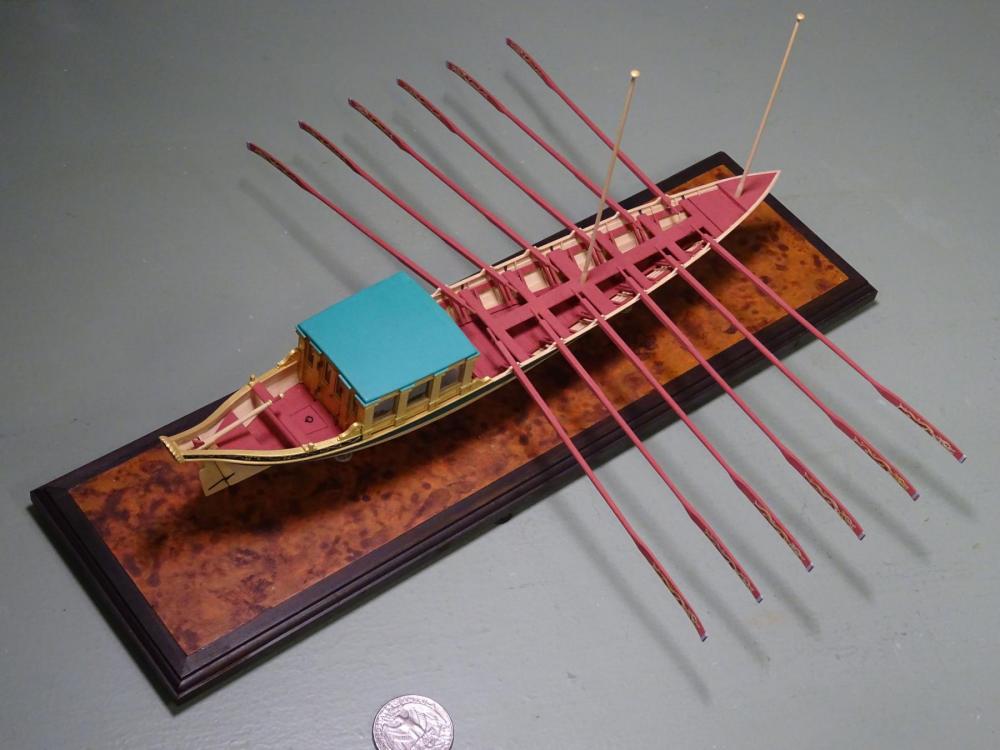

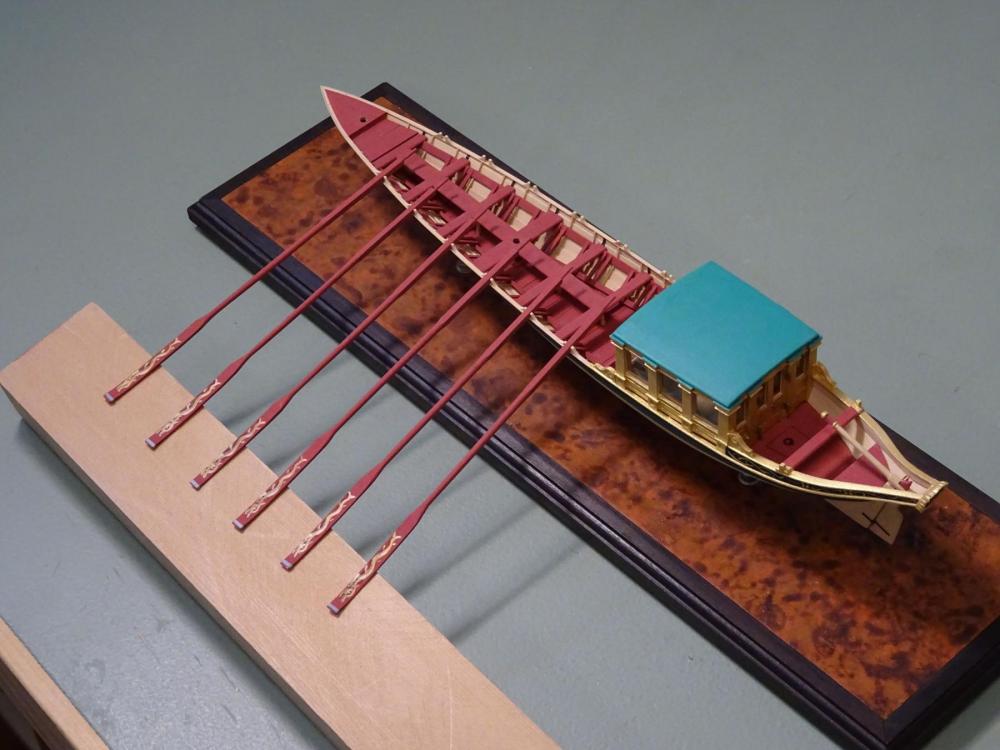

Well, the sweeps are now fixed in position, after a rare weekend off work. Hopefully I made the right call on displaying them in this way. I still have the two ensigns to complete and fly on their staffs before calling it quits. I hope you enjoy the pictures.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Yes, half the dolphins will be inverted. Live with it! I'm a bad model-maker.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Self-criticism is good - but only if it spurs one to better efforts, not if it brings one to a stand-still. It's also good to have a goal to strive for, as well as moveable goal-posts!

-

Difficult decision. But you've a ship to complete first, so there's lots of time to make up your mind! Seriously, I find many decisions become clear if I stow the problem in my sub-conscious for a while.

-

Well, decision time for the sweeps! While 'feathered' is an attractive and perhaps obvious choice, I think I'll place the oars with blades vertical. Why? The dolphins draw the eye away from the boat too much and, by placing the blades vertically, one can see the transition from body to blade on the other side clearly. The viewer will only 'discover' the dolphins as his or her point of view changes. I really appreciate the time and trouble those of you took to give me input on this issue. It certainly helped clarifying my own thinking. Pictures later!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Papegojan 1627 by mati - FINISHED - 1/48

druxey replied to mati's topic in - Build logs for subjects built 1501 - 1750

Lovely neat metalwork, Mati! -

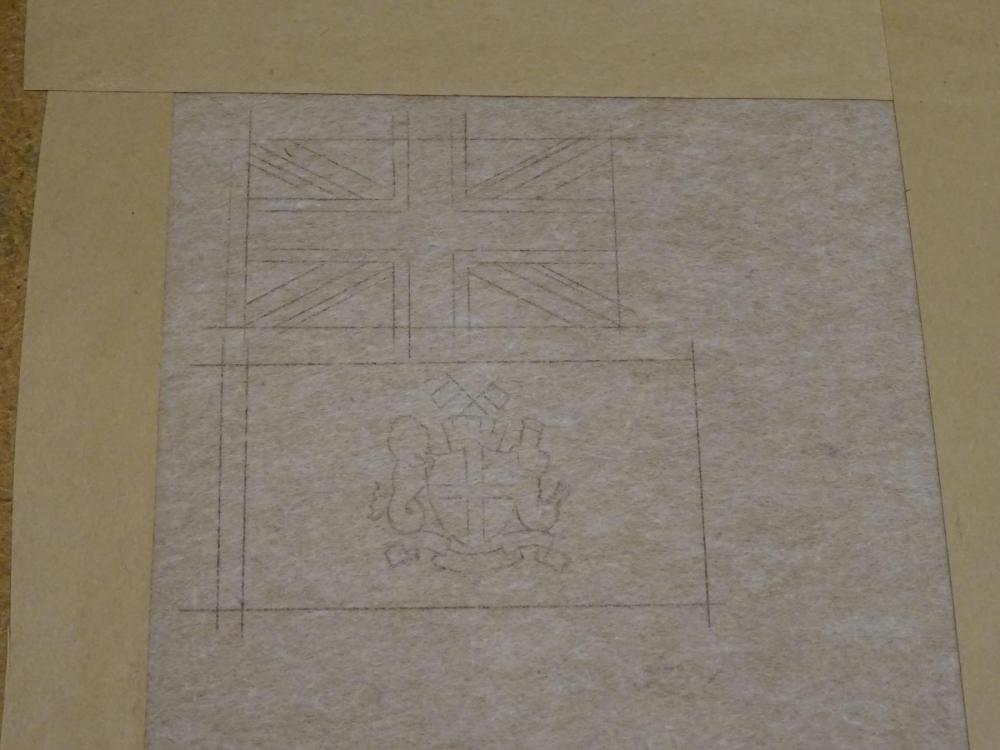

Thanks for participating in the straw poll! I'm still dithering, but tending toward vertical orientation. Meanwhile, work on the ensigns continues. The first sides are painted. As these will be hanging naturally in folds, the coat of arms is more impressionistic than realistic. The 'white' is actually more a cream color.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Well, any advantage to showing the sweeps in a more operational orientation? Opinions welcomed. The standards have been started. Some SilkSpan has been stretched (like watercolour paper) and the designs laid down using graphite paper. One is the Union Jack, the other is the Greenwich Hospital coat of arms.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

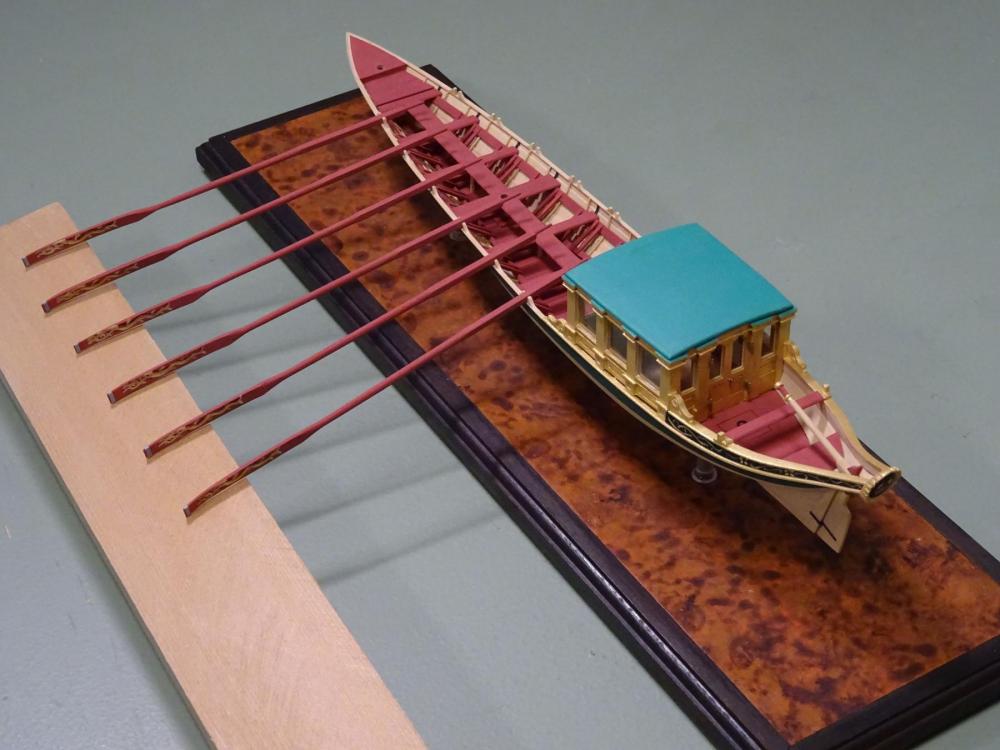

Thanks, Michael. In actual use, I agree that the blades would be more vertical, but I was using the City of London barge model as my example. Perhaps I need to try orienting them that way.... Oh, the indecision! Joel: not quite yet launch time: there are still two standards to make, hoist and fly.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Have the users no shame? I hope that you get an apology at very least, Robin. That's a fine image, even in monochrome, by the way.

-

Well, a dozen dolphins done! I've secured the model permanently on the base and pedestals and set up a trial placement for the sweeps on one side. Comments, anyone?

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Enjoy your new toy - I mean, tool! Nice progress on your frames as well, Frank.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

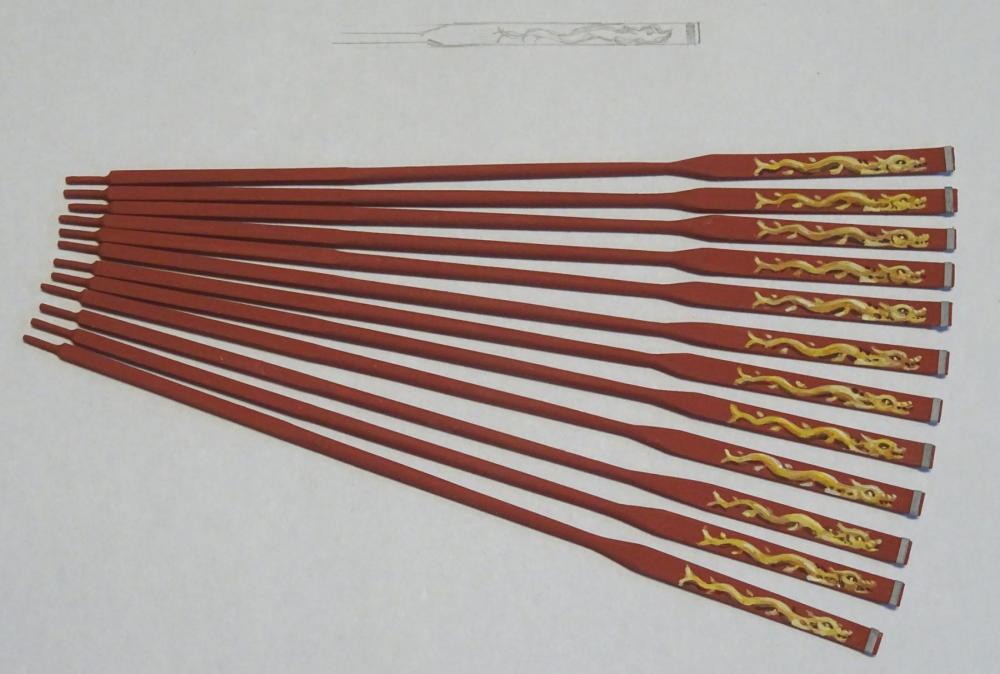

Thanks for the pictures and comments, everyone. How do I curve the blades? They are carved that way. I thought of steam bending, but they would never be entirely consistent. The dolphin paint job is done with high-grade watercolour sable brushes in 0 and 1 sizes, using acrylic paints.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

The first of twelve dolphins has been painted. It is based on an actual example in the RMG collection. By the way, the oar blade is ⅛" wide. Eleven more to go! (Click on the image to see the complete sweep)

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Pandora by marsalv - FINISHED - 1:52

druxey replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Terrific progress, Marsalv. -

Just catching up on your progress. Lovely work and detail!

- 184 replies

-

- ruby & arthur reed

- lifeboat

-

(and 1 more)

Tagged with:

-

Free floating at an appropriate level, E&T. As the sweeps will overhang the base by some distance, there will be sub-base as well. Thanks for the other comments above. I've decided to paint dolphins on the blades. Why not? The oars are now crimson and look a little unfinished yet. More later.

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.