-

Posts

1,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Bedford

-

-

-

If I understand what you're saying then I can see station placement in that drawing. Although the cross section seems very stubby.

The station lines are numbered 1 to 23 and immediately below that sketch is a horizontal line intersecting the vertical grid and numbered 1 to 23 right to left. The only things missing are stations 8, 9 &10 but I assume they are the same as 11.

All you have to do is sort out if the side view is drawn 1 to 1 or has been shortened to fit the page and by what proportion.

-

- Keith Black, Ian_Grant, Mark Pearse and 2 others

-

5

5

-

I've clearly been busy enjoying my new surrounds and haven't done a lot on the model, and to be honest the last few months have seen me not in the right mind set for this build but I thought it was time to have a bit of a go.

I've decided to build the ships boat and again, the kit needed improving because the floor boards would have been way too high so I changed the way it goes together and will be sanding the floors down further to reduce the floor board height. Also it is supposed to be double planked in 0.5mm planks, not easy to get a good fair flow over only 6 molds so I opted for a single layer with filling to fair it inside and out. Exterior is done, interior next. Oh and the top rail is to be made of 3x2mm stock, this would equate to a rail 141x94mm which is way too big for a 6.6mtr boat so I'll come up with an alternative.

- ccoyle, GrandpaPhil, Ian_Grant and 4 others

-

7

7

-

The model looks magnificent, well done on the rib fit out.

And now making 1700 trenails to replace the 1700 screws that replaced 1700 screws. there's nothing quite like the tedium of model making is there? It's like tying the ratlines on a tall ship. I find it good for calming the head.

- mtaylor, FriedClams, bruce d and 1 other

-

4

4

-

The lines of that boat are sheer beauty!

You're a braver, more determined man than I.

I know you'll succeed with this but I'll wish you luck anyway.

- mtaylor, Keith Black, FriedClams and 2 others

-

5

5

-

-

Keith, you're like me. You built the engine which will be hidden because you can and you know it's there.

So do we and it's brilliant.

- BANYAN, michael mott, Keith Black and 4 others

-

7

7

-

I found those diagrams interesting but as a rower I have some different ideas about it.

When rowing with others, ie a boat with 4 oarsmen, you come to learn how the physics have to work.

If the oars are already on the power stroke before entering the water you're wasting stroke power and putting undue stress on your body when they take up in the water. Ideally you need to learn to engage the water just as the power stroke starts so it's a much more pronounced plunge into the water than a gradual arc. This way the effort ramps up quickly as the stroke starts, more oar in water = more effort, but doesn't come on after you start the stroke if that makes sense.

The return stroke should be pretty flat, why waste effort raising the oar through an arc? The power stroke should also be fairly flat once the blade is fully immersed, diving deeper wastes power.

So I would suggest that the diagram of the movement of the oar handle is actually closer to the desired movement of the oar blade. Keep the directional arrows as they are but swap catch and finish, flatten the top of the stroke a bit and you've got a practical rowing stroke at the blade of the oar.

.jpg.85358ca601e190eca83276589eeaca2f.jpg)

-

22 hours ago, michael mott said:

Hi Steve can you use a couple of layers the material is quite forgiving really.

Michael

I probably can but for aesthetics I'd rather a single piece. It's the inner trim on a red cedar dash board, it surrounds the instrument panel.

- FriedClams, Jack12477 and mtaylor

-

3

3

-

Looking really good Michael.

I've been using some yellow cedar lately, as the inlay strips on the deck of a ski boat that was started in 1964 and never finished. I've got two bends to do in pieces 6mm x 12mm and the radius is about 30mm or less. That's been interesting. I'll try with more heat gun and see how it goes.

- michael mott, Keith Black, mtaylor and 1 other

-

4

4

-

Great to see you back at it Michael, I always love having one of yours to follow!

- Keith Black, FriedClams, druxey and 2 others

-

5

5

-

Beautiful work as we have come to expect!

-

In reality I'd say it's to keep the cockpit and deck area as clear as possible for load carrying

-

Keith, the fore and aft wheel is not uncommon in launches like that, I'd be inclined to keep to the original. If nothing else it's a bit of a talking point.

- mtaylor, Retired guy and Keith Black

-

3

3

-

You never cease to impress with your skill and determination

- FriedClams, druxey, Keith Black and 1 other

-

4

4

-

I'm going to have to buy a thesaurus to keep commenting on this build, superlative, superlative, etc, etc and so-forth.

- Retired guy, KeithAug, druxey and 4 others

-

7

7

-

Another master class, very interesting technique for creating the nav lights.

What did you use for the lenses?

-

Magnificent workmanship and detail

- mtaylor, Keith Black, Valeriy V and 3 others

-

6

6

-

Progress!

I've finally made some progress on the RC, the doors and windows to the kings cabin and since I want the doors open so you can see inside I had to redesign them.

One thing I will say to anyone wanting to build this model, for the sake of your sanity finish the exterior of this bulkhead BEFORE doing anything else on this model, don't lay the keel, don't fit the frames until this bulkhead has the facing planks, doors, windows and crest finished.

- GrandpaPhil, Cathead, Keith Black and 2 others

-

5

5

-

Eberhard, the coal bunker on S.T. Waratah has the same method of clamping down the canvas cover. I think you'd find there were wooden planks with bar handles set into rebates for ease of handling. Canvas over the top and wedges driven in between the clamping battens and their brackets.

You've recreated it very nicely.

- FriedClams, mtaylor, Keith Black and 2 others

-

5

5

-

A little update on my current situation, as a lot of you know I have finally found a new place to live and it is about 800 metres from the largest salt water lake in Aus.

My modelling progress has been slow but the "Miss Caroline" model suffered a little damage in transit with the turnbuckles for the stay and stb shroud letting go. This has now been repaired and she is as good as new. No pics because you've seen it.

The full size "Miss Caroline also suffered a little damage during transit in the form of a rope fender which is secured between the mast and stern sheets in transit somehow bailed on its duty allowing the mast and wire rope ends to damage the stern sheet planks. I have since sanded that out and re-oiled the affected timber, again no pics because it's not unlike what you've already seen.

Now onto the new stuff, I joined the Lake Macquarie Classic Boat Association and along with a weekly rowing session in an Oughtred designed "St Ayles Skiff" I am taking part in the restoration of an old wooden speed boat, lapstrake hull, copper nailed and roved and an old Ford V8 to go into her. I've been working on the laid deck consisting of Australian Cedar with Yellow Cedar inlay strips and it's something I've wanted to do for years so I'm really enjoying this little group. I'll make some progress on Royal Caroline in due course.

-

Beautiful work Keith, I never stop learning from your builds

- druxey, Keith Black, Retired guy and 3 others

-

6

6

-

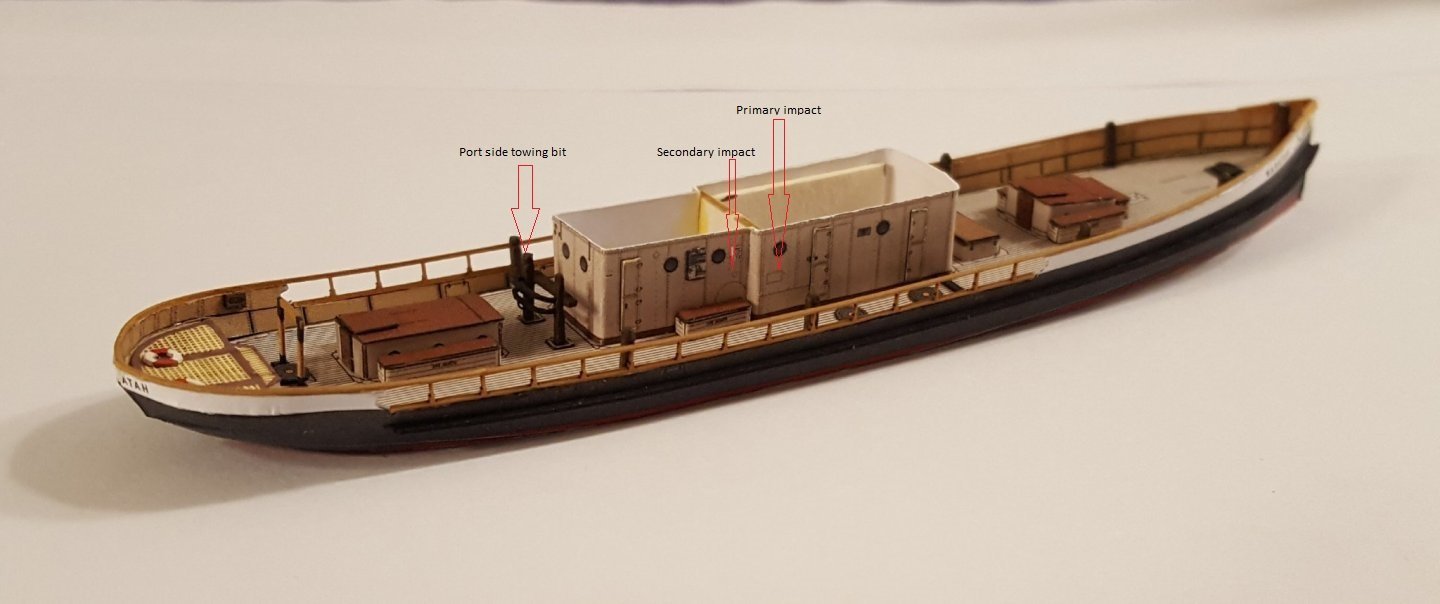

Chris, you should have got in touch with any questions, I didn't know you were building her and I crew her! I've said before that I'm impressed with the accuracy and detail and you've done a great job.

A few points of interest:-

- The towing bit (that's what we call it) has much greater rope wear on the port post than the stb. This is because the hooks were outlawed not long after she was built and they made tow lines off to the port post to counter prop walk.

- The "locker" aft of the forward accommodation is actually the coal bunker as are the circular covers either side of the superstructure.

- You seem to have the life jacket boxes in the correct places except their isn't one across the front of the forward accommodation. Rather there is a low frame to hold the fire buckets. The box there seems to be forcing the mast too close to vertical. The life jacket boxes go either side of the forward and aft accommodations and either side of the engine room.

- I'm impressed that the model even includes the wartime patches to the stb side of the superstructure, in both wars she was charged with clearing incoming ships (making sure they were friendly) and she had to fly the flag of the day when returning to harbour. One day ( in WW2 I believe ) they forgot said flag and on return to Newcastle harbour a shore battery opened fire. The shell penetrated the wall of the galley (big patch) then through to the upper engine room. No major damage as it didn't explode and I believe only minor injuries to one crew member.

Pardon the typo below, there's no such thing as a lox frame but there are low frames.

- Canute, Fernando E, yvesvidal and 2 others

-

5

5

Varyag 1901 by Valeriy V - FINISHED - scale 1:75 - Russian Cruiser

in - Build logs for subjects built 1901 - Present Day

Posted

Valeriy, that is nothing short of awesome!