-

Posts

7,010 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin

-

i started like that, then got a shed then converted the garage then got a dog dog is not allowed to get wet, according to the admiral, transiting between the house and my mancave so i have moved into the house/conservatory, which perhaps where i should have started from

-

HMS ROYAL KATHERINE 1664 by Doris - 1/55 - CARD

Kevin replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

wonderful, and so inspiring to everyone- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

hello my friend, glad to see you back at the bench, hope you and family are well, the pearl looks great

-

thank you i hope to see some real progress on her during Feb i am getting to the stage where i need to decide how i am going to secure the superstructure to the hull, at last i will be able to say, so much to do and all the time in the world to do it

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

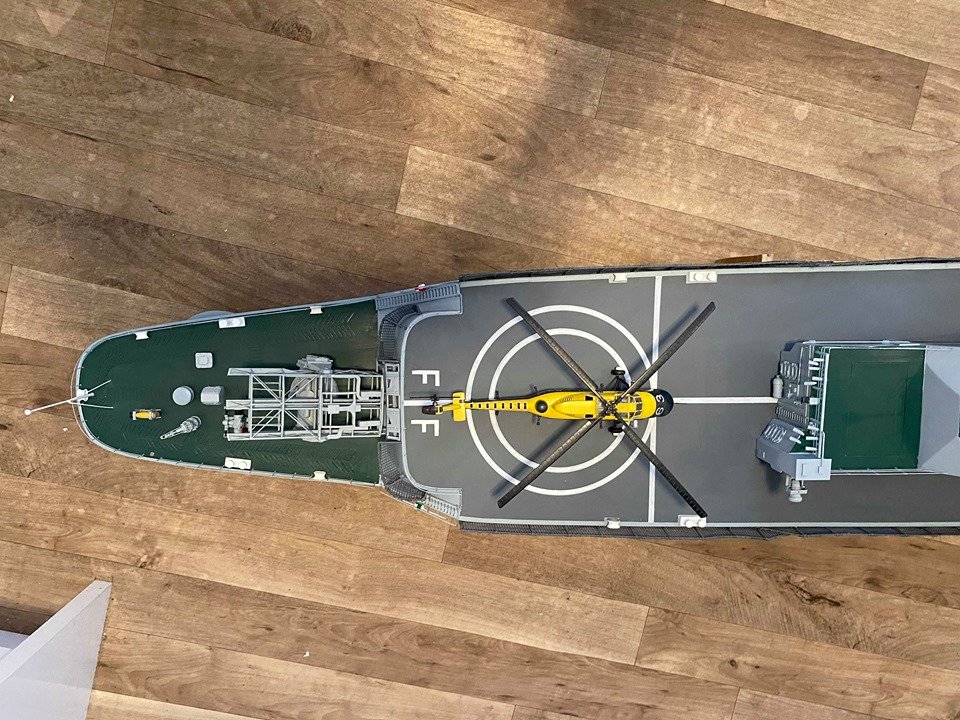

Good evening everyone progressing with the railings and netting also the stations on the bridge roof are nearly complete have stained half the netting with a Flory wash to see the difference as i tone the white primer down

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

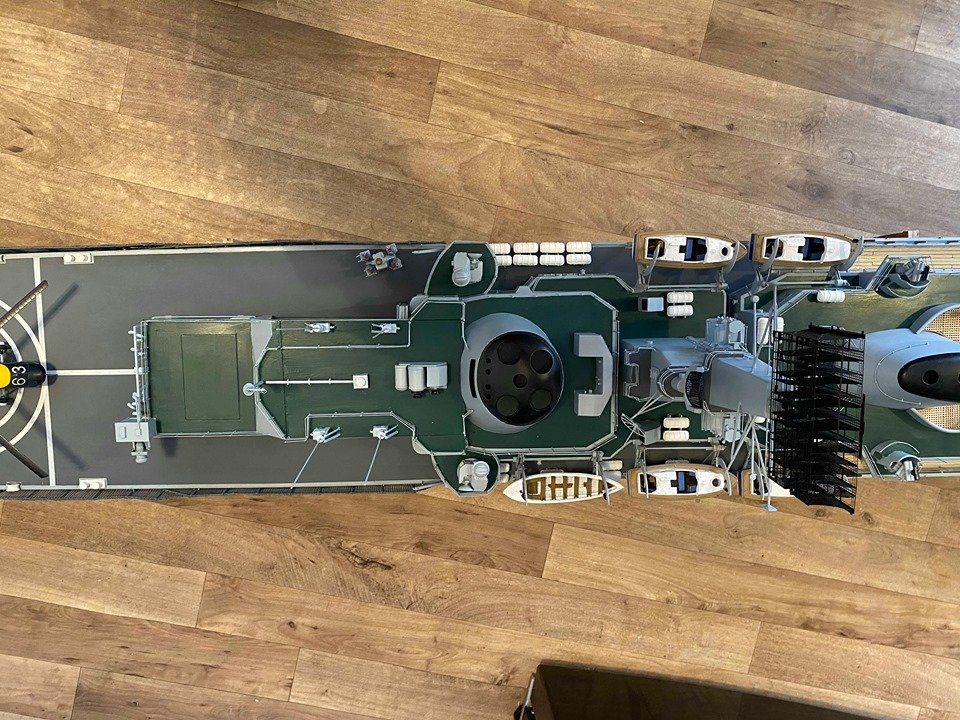

Good evening everyone, yep two posts in one day and LOL i have still got 12 working days left put everything on that i have made up for a photo tonight, so i can start to work out how i am going to achieve making her look like a working boat, next month should be back to the hull and do some catch up work with that, i would say she is about 50% built now, but then on top of that there is all the clutter to be made the bridge walkway railings still need to be adjusted, as they form the handles on the steps leading down

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

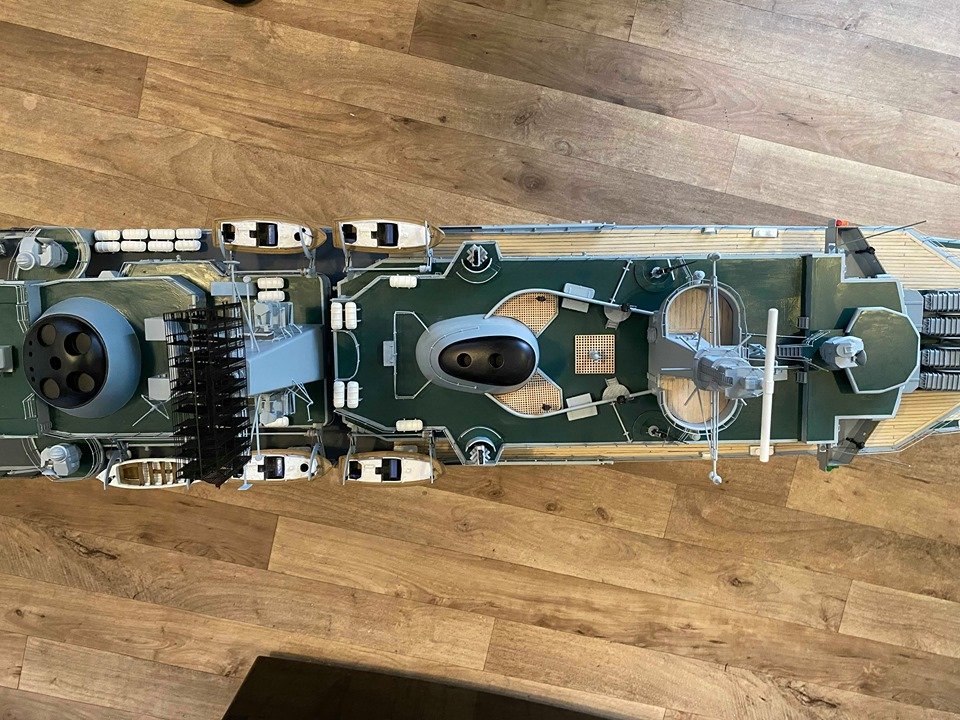

Good morning everyone made the other side walkway this morning, and put the netting over the rai;ing set that sits on top of the cod oil house, then put a matt white primer over it all nothing is in its final position yet, an still needs more work to make it look presentable

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

Good afternoon everyone Using my last 3 days of holiday, before i finish working on the 31st January, so i can now plan my projects and get back into regular posting again Bridge walkway the railings provided in the kit were not good enough for this so i have made my own, its another of those projects that takes time, but unable to complete until i work out howmuch room is available, as it is quite tight for space behind the bridge

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

enjoy your break, im about to take one as well, to allow myself more time to do more boat building

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.57ef2d7eb945af26f93fec8d09ab8457.jpg)