-

Posts

4,100 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Landlubber Mike

-

-

Very nice! Another beauty!

- lmagna, Old Collingwood, Jack12477 and 4 others

-

7

7

-

-

-

-

Coming along really nicely. I like how the anchors are stored on this ship, cool look to it.

- thibaultron, mtaylor and Canute

-

3

3

-

Hey Glen, I'm in for another great ride if you'll have me. I love your ingenuity and creativity when it comes to the stands for your SIB builds - this one looks great! That wood is gorgeous, a fitting complement to the SIB build

- Glen McGuire, Keith Black and mtaylor

-

2

2

-

1

1

-

This is such an epic, incredible project. Really nice job!

- mtaylor, Jeff T, FriedClams and 4 others

-

7

7

-

-

Superb work Bob as always. Very nice!

-

Really nicely done BE. Your artistic touches make an already nice kit even nicer.

- mtaylor, hollowneck and Blue Ensign

-

2

2

-

1

1

-

-

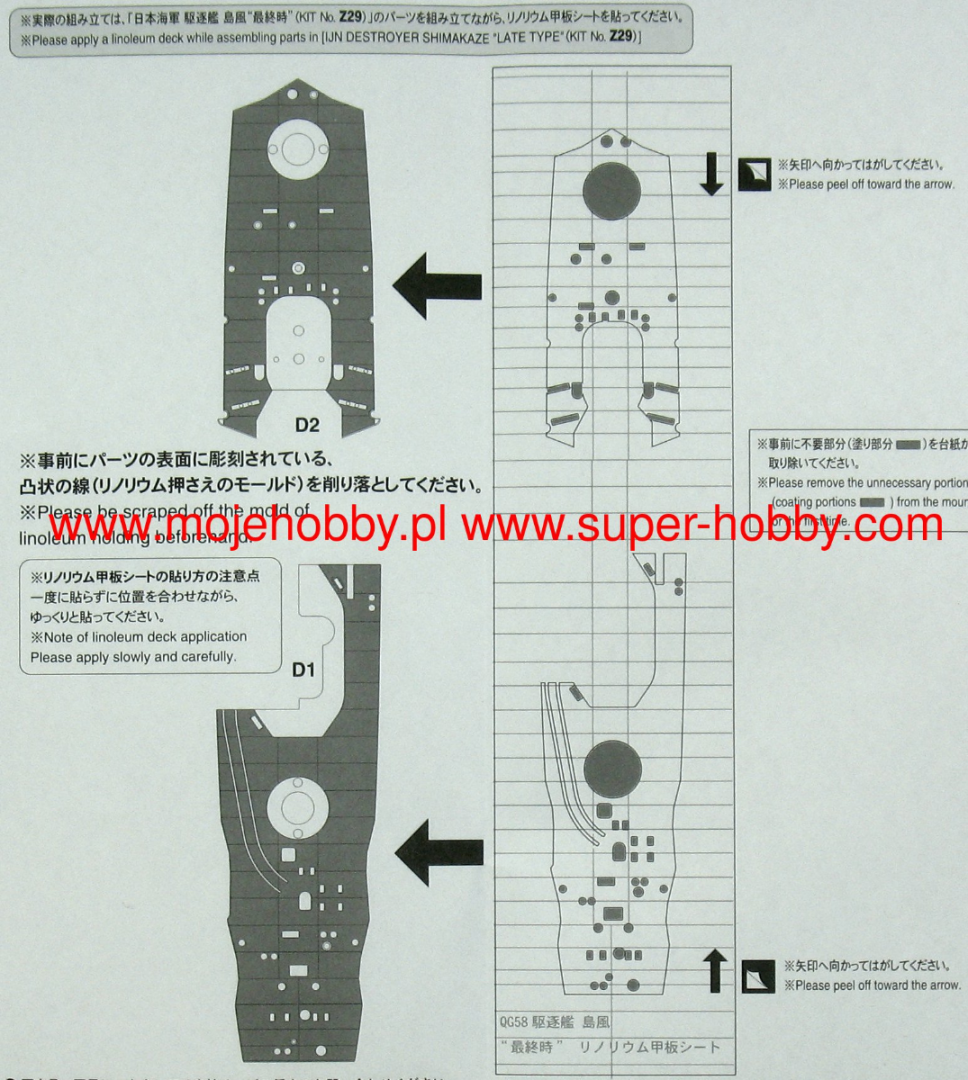

For the linoleum deck, there were raised lines for the brass deck hold downs. The Hasegawa instructions specifically said to scrape those off (translation in the instructions was a bit wonky), so I went ahead and did so. That seems to be a different situation than a scribed deck where for the most part, the deck is fairly smooth with just slight indents. I suppose if your instructions don't say anything, you can lay the wooden deck on top just to get a sense as to whether it would make the deck too high?

Here are the instructions for the linoleum deck - maybe your deck instructions have something similar?

-

-

Doesn't the Hasegawa deck instructions tell you whether you need to cut or sand away the plastic details? I had good instructions on sticking on the linoleum deck appliqué on my Hasegawa destroyer.

- Canute, mtaylor and Cap'n Snack

-

3

3

-

Looking great Tim! I've always loved the Mikasa. I have the 1/700 Hasegawa kit with the Infini upgrade which I'll tackle sometime down the road.

On the PE guns, I think they are usually worth it as the barrels don't need to be drilled out unlike the kit plastic ones which need to be drilled out or thinned. That's where you get your bang for the buck.

- lmagna, king derelict, Canute and 2 others

-

5

5

-

-

Sorry, thanks Roger for the clarification. Sherline also make a follower rest which clamps on the saddle/cross-slide and does exactly what Roger says:

- mtaylor, thibaultron and Bob Cleek

-

3

3

-

Would be a shame if those books are no longer published. I've been using the TFFM extensively on my Pegasus build, and have a few others on the shelf. Just glad I decided to buy the Sussex book a couple of months ago before things closed down.

-

That's really nicely done Mike. Love the colors you used. I'm sure the prior owner is looking down with a big smile of satisfaction.

- mtdoramike, mtaylor, popeye the sailor and 2 others

-

4

4

-

1

1

-

All that girder and railing work is spectacular - fantastic job!

- Old Collingwood, lmagna, mtaylor and 2 others

-

5

5

-

I used to have a Proxxon DB250, but sold it to buy a Sherline lathe to be able to turn metal and have more flexibility for turning projects in general (larger sized, etc.). The Proxxon was a really nice tool though. It made turning the masts and spars on my Badger a breeze.

There is a hole that goes through the headstock so longer pieces are not necessarily a problem. I'm not sure of the diameter of that hole though. If that's what Proxxon refers to as the spindle bore, then that hole is 13/32" or 10mm. It might be too small if you are looking to turn a mast of a larger model (remember, it's a circle, so you won't be able to turn square stock that is 10mm x 10mm). It's been a while, but I think that may have been another reason I upgraded to a Sherline.

You can deal with that potentially by buying the extended bed for the Proxxon so you are not relying on the hole in the headstock. The only thing I'm not sure about is whether there is a way to steady a longer piece on the extended bed so that it doesn't deflect out when you are applying tools. This is the steady rest Sherline sells for its lathe to give an idea of what I'm talking about. I haven't had the need to use it yet, but you see how the brass bars keep the stock from deflecting too much when applying cutting tools - particularly where the stock is very thin and has flex to it.

Overall, I think for the vast majority of kits, the Proxxon is just fine. If you find the need to turn a larger diameter piece, you could always pre-shape the square stock into an octagon using a jig and small hand plane, and then use the Proxxon.

Hope that helps.

- mtaylor, AlleyCat, thibaultron and 1 other

-

4

4

-

-

Another fantastic model Greg, congratulations! I actually went on the Navsource site the other day to look up other Casablanca class escort carriers to see if there were any cool pictures I could represent similar to what you did with the Thetis Bay. Very creative on your part!

What's next?

-

Greg, is the warping a common effect? I have a few kits with wooden stick-on decks and heard of this problem.

Is it remedied by pretreating the model with a gloss coat - I.e., does the deck’s adhesive bond better to a gloss coat than plastic? And in your experience, is it a good idea to use additional glue and not just rely on the adhesive?

Thanks in advance!

- mtaylor, thibaultron, Canute and 2 others

-

5

5

P-51 B/C by Egilman - FINISHED - Revell - 1/32nd scale - Rub n Buff finish test build; Experiment Completed

in Non-ship/categorised builds

Posted · Edited by Landlubber Mike

I'm away for a couple of weeks and Egilman turns out a stunner. Nice job!! Great work with that reflective finish, wow!

If you don't mind, and forgive me if I missed it when reading your blog, but what paints did you use for the aluminum color? And for the aluminum fuselage versus aluminum painted bottom of the wings, did you use the same paint/color, and just buff out the one on the fuselage to make them different? Or did you use different colors? Alclad for example has a ton of aluminum finishes.