-

Posts

1,042 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Thistle17

-

-

Here it is August 22 and it is finally going to happen i.e. I will deliver the table and the sails tomorrow.

Last week there were torrential downpours in the Finger Lakes area of NY state that made the dirt road ( better described as a cow path) up the hillside improbable. Nearly 70 homes were destroyed or heavily damaged one lake over from Canandiagua Lake nearby. Cars, some homes and propane tanks were washed into Seneca Lake. As you may know these lakes were carved out by the last glacial period and for the most part are surrounded by high hills making runoff a major problem when such an event occurs.

In the mean time I have assembled the new model stand and completed some last minute touch ups to the model. I hope to deliver that over the next 2 weeks.

-

Here is what I would do at first blush. Check the keel or false keel against the prints. If you find it correct I would infill the inside of the stem and modify the outboard edge of it to have a uniform stem along its form. If the stem is correct then work the false keel. at the point of disagreement in a similar manner.

Joe

- grsjax and thibaultron

-

2

2

-

Bare Koala if you have the notion to go full scale someday take the time to visit this web site Acorn to Arabella and follow the saga of building a 38 foot ketch. While many of the structural components in model building are no different when you go full scale the "horsepower and ingenuity" needed is a different story.

Joe

- Bare_Koala, mtaylor and Canute

-

3

3

-

-

From my experience I would add the rip fence extension and the miter extension at a minimum. If you have the $$$ add in the sliding table as it allows one to make cross cut parts repeatedly and safely. I have yet to find need for the tilting extension table as a surrogate for the absence of a tilting arbor.

Joe

-

Hard to believe it is now August and I have yet to deliver the model. That is the bad news but there is some good news. The table is done and is scheduled to be delivered this week. The table is 5 feet long and 2 feet wide and will fit the model nicely. The model will be named "Herself" which has been the request of the owner so the plaque will be made up this week at a local trophy shop. "Herself" has been de-masted and all rigging is tagged for hopefully easy re-rigging. The table and sails will travel separate from the boat as my vehicle just isn't big enough for all. I have also developed a build log in note book form for the owner in the event future work is needed. Materials (wood, adhesives, paint etc.) has been documented.

The model does look a bit anemic at this point as you will observe. Apart from function sails do make a difference!

- mtaylor, CDW, Captain Poison and 1 other

-

4

4

-

Mark welcome to this forum and the world of ship modeling. I hope you find it engrossing and worth the investment. There will be anguish and quiet satisfaction along the way. It is part of the journey but always know that is normal.

I have built the Bluenose from the original A.J. Fisher of the 1980s and it was my first endeavor. Yes there was some do overs but the lessons learned carries on . She is a beautiful model.

Joe

-

Here is a somewhat better view of the transom work. The thrust ports have been installed at the waterline and intermediate lateral and vertical re-enforcement has been added to the area. We are nibbling away at the build spending just a few hours each week, currently focused on the transom and fairing/filling the bulkheads forward of station 8 and bow which has been built out with with balsa fillers. This area is still a bit rough but should be "picture ready" next week.

The photo doesn't depict the transom gentle contour and vertical angle but hopefully with the skin added next time one will get a better idea of the aft section of the hull.

-

Modeling work on the PBR has been creeping along this summer with vacations and all. Over the last 2 weeks we have had volunteers come in and work on the transom area and preparing the aft part of the hull for final skinning. The first picture shows the bulkwark excess material cut away from the stern up to station 8. A flush cutting hand saw was used to pare down the bulkwarks to the floor. There was negligible deflection of the bulkheads when the excess was removed. By measurement it was less than a 1/16 inch. This will be compensated for when the deck is in place. The second picture is of the transom frames glued in and trued. We will be "skinning" the transom next visit and move forward to start the bow fairing which has been filled in with balsa blocking.

By any standard things still looking a bit "raw" but I predict that that will quickly change as the skin is applied. Hopefully we will have this done for our opening meeting in September and we can get others on board for sub assemblies.

- BLACK VIKING, Valeriy V, Canute and 4 others

-

7

7

-

I seemed to have lost the Winne project baseline build definition. I had assumed you were doing a beta build to prove out the design for Chuck/Syren. Is this not the case? The question arises (over the laser work) as I had assumed I was witnessing a true beta build. I hope this is clear.

Joe

- FrankWouts, Martin W, mtaylor and 2 others

-

5

5

-

Yes Wefalck as I understand it is designed so. I can't tell you how impressed I am with the design of the machine, the accessories offered and the service of Sherline. and I thank you for your 90 degree suggestions. I will certainly put them to good use.

I logged on just now to extol the virtues further of this tool. In making a table for the Atlantis model I have had to bring on line another router table to fashion the legs. I bought a 1/4" aluminum mounting plate that was supposed to fit my router and allow a built in lift from the table top. When I assembled the plate and router I ran into an interference problem for the lift tool and the router plate, pre-drilled access point. I thought about filing the plate and living with a functional albeit awful looking access hole. In the "now what am I going to do" moment I thought of the vertical mill. It took a little bit of thinking but within just a few passes I had a clearance hole I could be pleased to look at time and time again.

This is just more testimony of this wonderful tool!

Joe

-

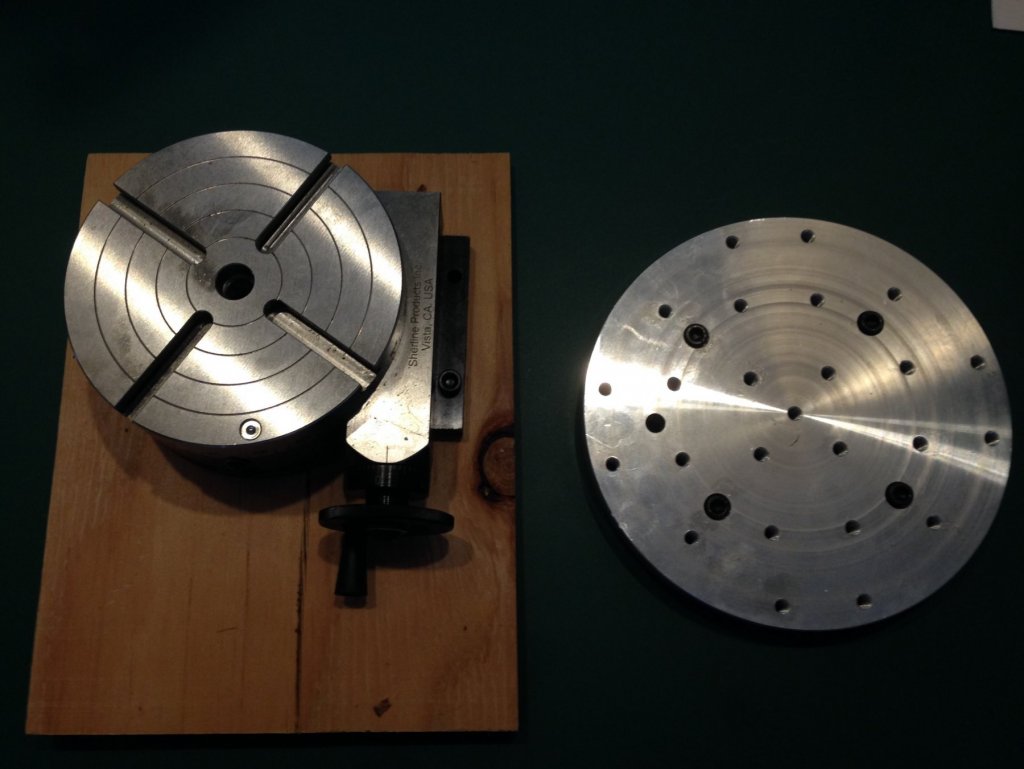

Someone had said to me on this thread that I would invest as much in accessories as in the original cost of the mill. I think I am going down that rabbit hole. I just purchased the Sherline rotary table for my mill. I also purchased the tooling plate as well. Interestingly the rotary table was on sale on their web site so that was fortuitous. The 2 other recommendations they make to further increase the versatility of the mill is to add in the right angle support (for the rotary table) and the right angle tail stock attachment. Now I can see the usefulness of both but I would appreciate hearing from others on how useful these elements are.

Joe

-

Michael as I follow your reconstruction I can't help reflecting on those "passers by" that will casually observe your incredible work. I think but a few will appreciate the talent, ingenuity and work you are accomplishing. I certainly do!

Joe

- cog, popeye the sailor, druxey and 4 others

-

7

7

-

Only additional comment I would make at this point is that your work product is museum quality in my opinion!

In regard to trailboards. If you are considering relief carving I would suggest laser etching. I witnessed a very convincing demonstration of laser etch, at reduced power, that inscribed a beautiful stern banner on a model part. A drawing was scanned into Corel Draw and converted to a laser file that was compatible with the unit. Just a thought.

Joe

- mtaylor, thibaultron, Mahuna and 3 others

-

6

6

-

You are not alone with losses like this. We all share the experience. I have had luck with the internet seeking even parts for a model from a defunct manufacturer. So broaden your search to forums out there. There has to be someone who can help.

Oh and" Y'all gonna love it here" as they used to say to me (a Yankee) when I lived in Texas.

Joe

-

I just completed what I believe will be the stand for the model. As I am anxious to work the table itself I have to get past this element hastily to deliver the model soon. Nothing is glued up yet and the assembly parts need final sanding. As I stood back and evaluated the stand I did realize one element I may have to revisit. Although the environment where this unit will live is a controlled environment temperature and humidity swings can't be guaranteed. I might say the same for the model. The stand uprights are about 6" wide and I think over time they may blow out the delicate trim around them. I hate making service calls! Hmm!

Joe

-

I finally met with the client today. It is the first time she has seen it. Modestly I say she loved it! That made my day!

We decided it is prudent to step the masts and reassemble it at its new home about 35 miles south of Rochester. While that will require about a 2 day effort at the site, it is the safe way to its new home. All running and standing rigging will be identified and its termination points will be identified as well.

I am now working on a stand for the model and it is being done in mahogany trim and a maple platform. With the trim it will mimic the deck treatment and should not be a detraction.

I have pulled out the lumber for the table and that will be started and hopefully finished not too long after the stand. Since the environment where the model is going is rustic (yet nicely done) I am using quarter sawn Douglas Fir for the table. The face grain is beautiful but the side grain is a bit distracting so the legs have to be made as 4 separate wedges glued together. The rest of the table will be straight forward apron and top construction.

As a final touch a plaque will be made for the model and named by the owner. Then I will have my first build declared a finished product!

Joe

- mtaylor, druxey and Roger Pellett

-

3

3

-

In an earlier life I was in real time software development. There was a saying within the team; "You can tell much about the developer by the sharpness of his tools". That fits so well when I witness your work. Jig making is an art form of itself.It goes beyond creating a single point object as it has to be flexible, adaptable and of course useful beyond a single objective. You bring it to such an astounding level of utility.

Joe

-

Mike you are truly gifted and prolific! I am also amazed at your beautiful photographs. They tell the story in such splendor. May I ask what camera you are using?

Joe

- Canute, mtaylor, aviaamator and 1 other

-

4

4

-

Jeff I am not an expert at planking but have learned a lot from those better than myself. In reading your post I have to presume you are trying to avoid spiling or at the least, minimize it. I have tried Chuck's method of heating and force bending the planks with less than good results. In the demo he did in his video I think (guess) he was using 3/64 planking (a fat 1mm). Wood doesn't bend in 3 planes as I have been taught so that may be a good limit to keep in mind.

In my mind spiling is unavoidable but can be mastered. I have been tutored by a fine modeler and have been allowed to capture his NRG presentation of a number of years back on our web site. It is in our RESOURCES segment under SHOP NOTES Part II on Planking. Our web site is www.modelshipwrightguildwny.org. His pictorial presentation is easily understood. Mind you we are not the first nor last word on hull planking but you may find the references within helpful.

My 4 cents.

Joe

- Canute, JohnLea, Seventynet and 2 others

-

5

5

-

Shean it may be a long drive but if you can attend the July 28th seminar in the flyerI referenced, it may be a good way for you to meet everyone. The title of the seminar is a bit misleading as it will be a pretty complete expose' on how he built the Sultanah for the country of Oman's new museum. It is a 1:24 scale model of incredible work. It may be worth the trip for you. Do let us know as we have a few more seats available and it is right off exit 45 on the NYS Thruway.

Joe

-

Thanks Chuck I will behave myself and do my best to do this project justice.

Joe

- mtaylor, Canute, thibaultron and 1 other

-

4

4

-

Nice design, nice assembly support, nice product. Simply put VERY NICE. This should be a fun build and not a career in its making!

One question; when it is ready to release do you plan on releasing to all those who have signed on for the group build all together or are they going to be "put in your store window" and it will be a first come first served" basis? Just wondering given the Barge experience.

Joe

- thibaultron and Canute

-

2

2

-

Shean!

We have a group of modelers in Rochester NY. Please visit our site www.modelshipwrightguildwny.org to get a sense of who we are. If you are near we would certainly enjoy your participation as we have all levels of skill and interests in the group. We have a member in Syracuse and one in Buffalo. They commute to our monthly meetings. We also have a member in Lisbon Portugal that will be coming to the US to give a seminar on July 28th (see our EVENTS and TOPICS OF INTEREST on the web site to learn more). If you can make it, there would be a warm welcome awaiting you!

If you wish

Joe

Recommendations For A Good Milling Machine

in Modeling tools and Workshop Equipment

Posted · Edited by Thistle17

Now this has nothing to do with ship modeling, but if you will, it has everything to do with the versatility of the Sherline Mill. Recently I bought the 4" rotary table and tooling plate for the mill as my first accessory. From several sources I had read how useful it is and this immediately proved to be so.

Now I am not a skilled machinist so you folk that are, will probably consider this elementary, but for a novice like me every use of the mill is a discovery and eye widening lesson in use. The rotary table can be mounted to cross slide in a traditional manner or can be mounted 90 degrees to the cross slide/table. This does require an additional part which I have yet to order. Sherline also offers a tail piece to mount in a similar manner.

I had to make a 3" wide collar for a repair of a glass table top that was damaged in a wind storm. I used a 5" piece of Delrin bolted to a sacrificial plate which in turn was bolted to the tooling plate I had also ordered. I reasoned that if I centered the desired piece on the rotary table assembly and positioned it so that it was dead centered to the milling head tooling I could then index it in the 'X' axis 1 1/2" away (never touching the 'Y' positioning) I could cut an acceptable disc and receiving hole in the stock piece with accuracy and ease.

Again this is just more testimony into the applications of the Sherline Vertical Mill. This machine is a joy to use so if you are holding back in its purchase....DON'T, it is such a great machine!

Joe