-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

And great creative design it is. Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Steve I am glad that I have been of help regarding these mechanisms. Gary, thank you for your kind words. I have been very fortunate in my working career inasmuch that I have always been able to work doing the things I enjoy doing the most. The interesting thing is that while I worked building models commercially I did not have much interest in building models for myself. I have a tendency to work in spurts and am very focused during these times, I think it has a lot to do with solving ways to accomplish the next part. currently I am procrastinating about what part to tackle next. A little bit of "model-makers block" Michael

-

An amazing amount of work Nils. Quite and education sorting out all the control points and leads in that forest of lines. Michael

-

Nice depiction of some working tools in the emblem on the cover. I am also interested in the small chisels they look beautiful. Michael

-

Mark Thank you for your instruction, I did anticipate it coming. Michael

- 2,215 replies

-

Fantastic work there Patrick, I am assuming you will be fluffing up the pillows in the master bed suit ;~) Michael

-

Nice work on the sail Dan I am taking notes . Michael

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

I appreciate your candid comment Ed. I was a bit surprised by the gloss, perhaps most by the degree of it more than the fact that it is glossy. I can also appreciate your need to not dally over these things too long when dead lines loom. I think that we come up against the whole issue again of scaling nature with regard to the finishes we impart on our models. sort of reminds me in a way of the old comment about if we scaled the earth down to the size of a billiard ball it would be much smoother than a billiard ball. I hope that you will not be upset later that you are not completely satisfied now, later. Regards Michael

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Toni Thank you for taking the time to share the display case set up. The mahogany cases lend such a great sense of timeless quality to the visual presentation of your work. Being able to reflect on your development and having the ability to see where you have been with regard to the ships you have built. The pysanky display is amazing as well. I cannot imagine how many hours you have spent doing all the work in those cases. Prolific seems to pale as a descriptor. Thank you again for sharing. Michael

- 1,449 replies

-

I find that this is one of the more engaging aspects of going to the craft stores, What can this be used for? is the song running through my head. Michael

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

Chopping block work table

michael mott replied to qwerty2008's topic in Modeling tools and Workshop Equipment

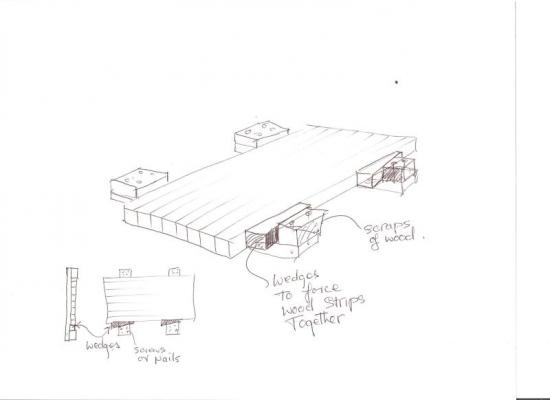

Lextin, another way to clamp the pieces once you have cleaned the old glue off is to use a couple of pieces of wood like this simple wood clamps made from scrap. once the glue is set knock out the wedges and the clamps can be taken apart for some other use. Michael -

hi Scott, a great start I will be following along. I am looking forward to seeing your steam plant come together as well. Michael

- 33 replies

-

- sanson

- artesania latina

-

(and 1 more)

Tagged with:

-

Mark in my case it was a commercial melt pot that was electric, the chap I worked for was a bit unscrupulous and would cheap out on the quality of the metal sometimes, I wont go into the details of one event that scared the .... out of me! there was metal all over the room. I went home early that day after giving him an earful. Michael

-

Mark your first attempts at casting look great, That said I thought that Druxey's comment about casting the barrel muzzle up was the way I would have approached it, one other thought that occurs to me is to make the bottom of your pouring sprue (gate) a smooth curve rather than the right angles that you have done in your first one. The venting looks good to me. something you might try is to leave the vents off until you start to cast especially with the pewter, and as you test the pours you can use a sharp #11 blade to cut v groove vents from the trunnions and begin with small almost no holes and increase them till the right flow occurs. sometimes a little back pressure helps to fill the area right next to the main body rather than a fast flow. The talcum powder helps a great deal with the metal, I had a small muslin bag that I used to fill with talc and used it to dust the moulds the casting worked best when the moulds had warmed up after a few runs, so you will notice that the casting improves usually with the 2nd 3rd 4th pours and so on until the mould reaches its optimal working temp. I spent many evenings of my boyhood casting costume jewelery in 12 inch circular centrifugal moulds, that were made by vulcanizing them in a metal shell under great pressure. The casting machine had a turntable that was like a record turntable with 6 counterbalance weights that would apply pressure to the steel plate on top of the two halves of the mould, there was no speed control as such but I learned by trial and error what speeds and speed of pour into the central cavity. I used to get paid 3 shillings per gross and there were eight to twelve pieces per mould depending on the particular shape. I used to cast 3 gross per evening (guitar callouses couldn't hold a candle to mine in those days) When I had my own business building models I had the commercial casting equipment but eventually sold it because i didn't use it much. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.