-

Posts

2,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

Looking REALLY good Mark, glad your having fun!! I'm not sure after learning to frame the right way up I could do it upside down! More power to ya! Ben

-

That's really nice work on the stern framing, as Greg says they have really good symmetry. Ben

- 1,449 replies

-

Hi Mike, I shall also follow along with your build. Ben

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Well Augie, you DID it and it came out great - well done mate! It's a fun little project on its own isn't it?? Now just get that deck planking down and you will of passed my Confed and then I can look to you and your log for advice when I finally get back to mine! ( just having too much fun with framing on Pegasus for that to happen any time soon but you never know, your work may spur me into action!) Ben

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Nice to see you back Andy, and nice to see her in primer. ( tamiya primer is what I used to prime the metal parts on my Confed, gives a nice thin basecoat ) Ben

- 382 replies

-

- stadacona

- sylvan scale models

-

(and 1 more)

Tagged with:

-

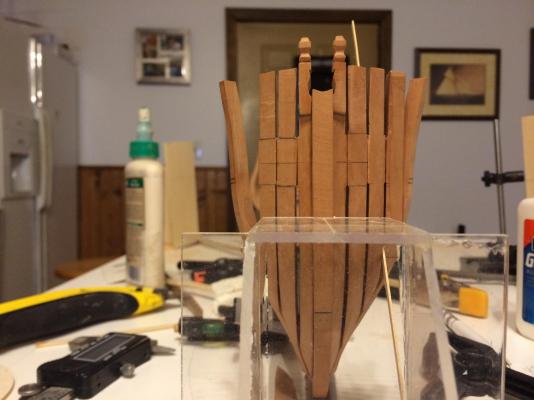

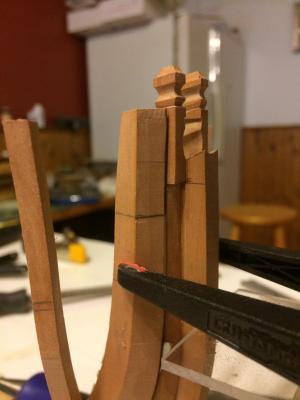

Hey Rusty, I'm struggling here even if it doesn't look like it! Greg - good idea on testing out the hawse holes as well. Ben

- 889 replies

-

I continue to work on the Hawse timbers, but the pieces you see will end up in the scrap bin and be redone, I decided to just keep practicing with them so when I do make the real ones they should be much better. Hope to get it completed by next weekend. Ben

- 889 replies

-

Some great work Bob, you really have made a beautiful model but can I ask if you are going to rig her or stump masts?? Ben

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Just came across you build log, and wow!! Great research and craftsmanship. I shall follow avidly from now on. Ben

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

-

Kat, we have an admin on this site called Chuck Passaro, he does extensive work using Sculpy for ship decorations, He even posted a practicum of how he uses it on the NRG website www.thenrg.org under the ship modeling resources shop notes. Take a look or drop Chuck a PM, I'm sure he'd be happy to offer some advice. Ben

-

Aha! The dark side is going to claim Sjors as well! Ben

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Sorry to hear some of the wood supplied is not so good, I'm sure you will manage with it. Ben

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Thanks for looking in Mike, the TFFM books are great references for any build IMO. Ben

- 889 replies

-

- 889 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.