-

Posts

4,891 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

The stand looks great Sjors, and a nice touch with the name plate. Coppering looks to be coming along nicely too.

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Thanks very much Alan, Augie, Sjors, Mobbsie, Ian and Mark, and also all of the "likes".

-

Slog - sorry for the bum steer on the Coptic markers, but good to know they have at least been tested now. On paints, you should be able to use acrylic paints, like Winsor and Newton. Buy them in tubes and thin with water (ie squeeze some out and drag some water into it on the palette). Using paints in this way, you can mix your colours to get an exact match, and thinned to your desired consistency. If you're not sure how to use something, it's always worth checking out You tube - I invariably find a few videos of people demonstrating exactly what I'm after. It might not be in our field of modelling, but the techniques are generally the same. Painting is one are where there are plenty of video tutorials. Don't ask me how I know!

-

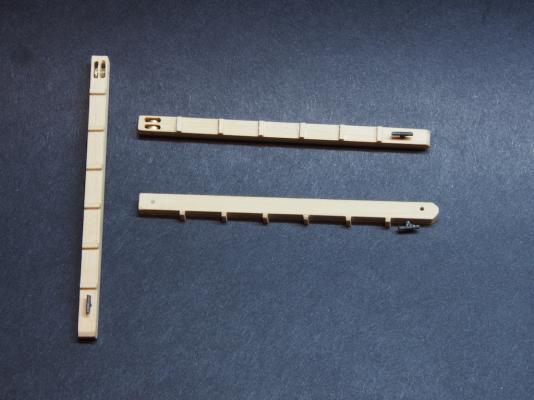

Cutters Ver 2.5 continued.... Only a minor update today. I've been painting the hulls for the last week or so. Decided to break out the airbrush for this job and after six coats of white paint on top of the gesso undercoat, plus one coat of clear Satincote (one more to come), here's a quick sneak peak at the outside of one of the hulls - just to prove that progress is being made As soon as I get another coat of Satincote on the external hulls, I'll move onto the interior, painting that in yellow ochre before proceeding with the fit out. This painting lark is a slow process! In between watching paint dry, I've been working on the quarter davits to carry these Cutters. I've mainly been working from the diagrams and description in Longridge for these. The basic structure is boxwood, with working brass sheaves held in place with a copper wire pin. I also manufactured the cleat for the base of each davit by silver soldering brass wire into a T-section and then cutting/filing to shape. These have been blackened and placed temporarily in place for the photo. The davits will be painted black prior to final fitting. At the base of the davit, I have manufactured separately some brass swivel/hinge plates to attach the davits to the hull - these aren't shown in the photo below, but will be fitted in due course. So here's what they look like (only 3 of the 4 davits shown in the pic):

-

Ah, so you finally got off the Chatham Dockyard bus Sjors - exactly a year since we took that photo.

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Great to see son progress Slog. Looking good. Those Pitt Pens look like the answer to your prayers alright. Along similar lines, you might want to try out some Coptic markers, which you'll find in any art supply store. I've no idea if they will be suitable, but the Pitt pens prompted my memory. They come in a really large colour range too.

-

Congrats Mark. Take a bow and have an adult beverage or three. She's looking mighty fine Sir!

-

More excellent work Mobbsie - and nothing boring about it my friend! Fabulous looking yards, and I love those blocks I just worked out that it was exactly one year ago last weekend that we had a wonderful weekend together visiting Chatham and Portsmouth, and of course Chateau Mobbsie. Still the highlight of the whole holiday for me.

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Beautiful symmetry there Bob. I haven't tried it myself, but Sculpey might be a good option to try - at least you can put some more on if you take off too much! I know that Brian C used it for his decorations on his Fubbs, and they seem to have turned out very well indeed.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Good idea to break it up like that Ray - they can become a little tedious! The ratlines look great so far - nice and evenly spaced.

- 536 replies

-

- diana

- caldercraft

-

(and 1 more)

Tagged with:

-

Nice set-up Mike. At least with the Admiral having her own part of the room, you can't be accused of 'abandoning' her for your hobby!

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

WOW! That looks superb Augie. Hope you and the Admiral have a great holiday - I can't believe its now exactly a year since we did the same. Where are you headed?

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Sweet! That looks superb Sjors. Now just lift your game and do better on the starboard side will you? :P

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Hi Ian, It may have seemed simple to you, but your descriptive post on the manufacture of your die to make the cap squares was particularly educational for those of us who remain metal-work neophytes (or in my case, luddites). I am DEFINITELY copying this to my "great ideas" folder! (I might have to call this folder SIFI - Stealing Ideas From Ian ) Would you mind posting a picture of your railroad riveting tool in action? I'm intrigued by this.

-

Dave has it right Ed! What a wonderful description of a relatively simple solution to a complex problem. And while I say "simple", I for one would never have worked out that remedy by myself. Thanks for your continued sharing and instruction of techniques Ed - your contribution to this forum and Shipmodelling in general is beyond description.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.