-

Posts

1,323 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tigersteve

-

- 165 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

In the second round of installing the oarlocks, I used a straight edge to draw a line roughly in the center of the caprail in the locations where the oarlocks would be placed. I then used a small file to draw two equally spaced perpendicular lines. This method worked much better for me. Not perfect but I'm getting used to drilling these tiny holes! Repainting the caprail was not fun. I wanted to see how Minwax Polycrylic(water based) satin would look over the paint job. I think it provided a little more sheen than the Minwax WOP. It certainly dries quicker and no time to buff to dull the shine. It's a little more shine than I want, but I think I may accept it, as the idea of painting it again is exhausting. The rudder setup is just about done. The tiller has been shaped and stained. I will install on the next updates. I think I'll work on the oars next. Steve

- 165 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

It's getting there. Eventually it will just come together. Keep working on it until you're happy. Steve

- 258 replies

-

- harriet lane

- model shipways

-

(and 1 more)

Tagged with:

-

Bob- thank you. It looks great. I have to stop fiddling with the oarlocks on mine so I can move forward!! Steve

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Nice work. I'll follow along. Steve

- 128 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

-

Wow- painting already! Seems like you just started on this project. Awesome! Steve

- 162 replies

-

- dirty dozen

- fishing

-

(and 2 more)

Tagged with:

-

Samueljr added sails to his: http://modelshipworld.com/index.php/topic/4559-18th-century-longboat-by-samueljr-finished/?fromsearch=1 Steve

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I can't wait to see what you decide. I think if you wanted to you could finely sand the layers of WOP off and still stain. So don't rule that out if you had it in mind. Test it on scrap first, of course. Not an expert, but I'm learning about these minwax products as I go. Really enjoying your build. Steve

-

No rush. Just wanted to see what the other part of your rigging looked like. I'm in the midst of repainting my caprail and touchup as well. Not close to rigging yet. Thank you for your reply. Steve

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Bob- it looks great! Very excited about this:) Can you take a photo of the top of the mast for us? Steve

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Just found your log and skimmed through it. Nice work on this kit! Steve

- 164 replies

-

- model shipways

- armed virginia sloop

-

(and 2 more)

Tagged with:

-

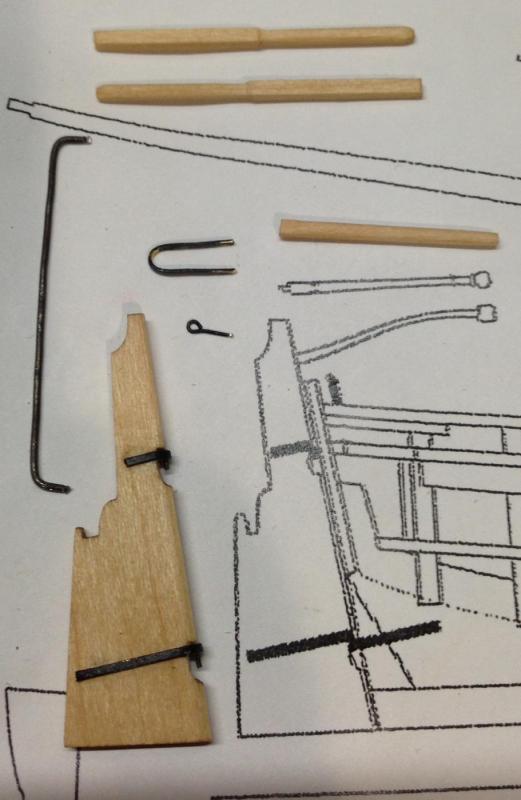

Thanks Chuck and everyone for all the likes! In the middle of another redo with the oarlocks. I had them installed but I rushed it a bit so naturally it has to be redone. Probably a week to correct this with the filling of holes, sanding, painting, etc. Here's some photos of other progress: belay pins painted (photo of the paint used). Pleasantly surprised by the quality of this paint. Metal work for the rudder and such is shown along with the horse and windlass handles on the side for now while the caprail gets repainted and oarlocks installed. Steve

- 165 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Glad you decided on the wood for the deck. What are you using for the hull planking? Sorry if you've answered this already. Steve

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

Check out Chuck's planking videos too http://modelshipworld.com/index.php/topic/13850-chucks-planking-videos/ The curve of the sheer is up to you but you need to leave a little room at the bow for the caprail and also some room at the transom. You'll see that on the plans. I spent the most time on this build on planning and marking off the hull before I started bending planks. Steve

-

I agree the gradual soaking, bending, drying then repeating worked for me. I had a couple planks with kinks and they showed after the stain so if that happens don't use them and redo unless you are painting below waterline. It really is a learning process and you will figure out what works for you. Bob F shows the method for marking off the sheer from the plans. He also explains the tick strip method which many of us used. Steve

-

The paint work looks very clean. I like it. Steve

- 742 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

It was tricky to install the windlass. I ended up sanding until it fit into position. Originally, I wanted to add that detail but I was afraid to cut into the risers. Also I wanted to keep moving forward. The drill bit that I had for drilling the hole for the wire broke so I could not add the wire. I ended up gluing it in place. Also knew adding the wire would be very difficult. Steve

-

I think this one is going to be a good one. Lol What makes this kit so expensive? Is it because of the amount of walnut wood included? Anyone know? Steve

- 231 replies

-

- model shipways

- armed virginia sloop

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.