-

Posts

405 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by jpalmer1970

-

-

-

Just a brief update on the latest work on the keel and stem.

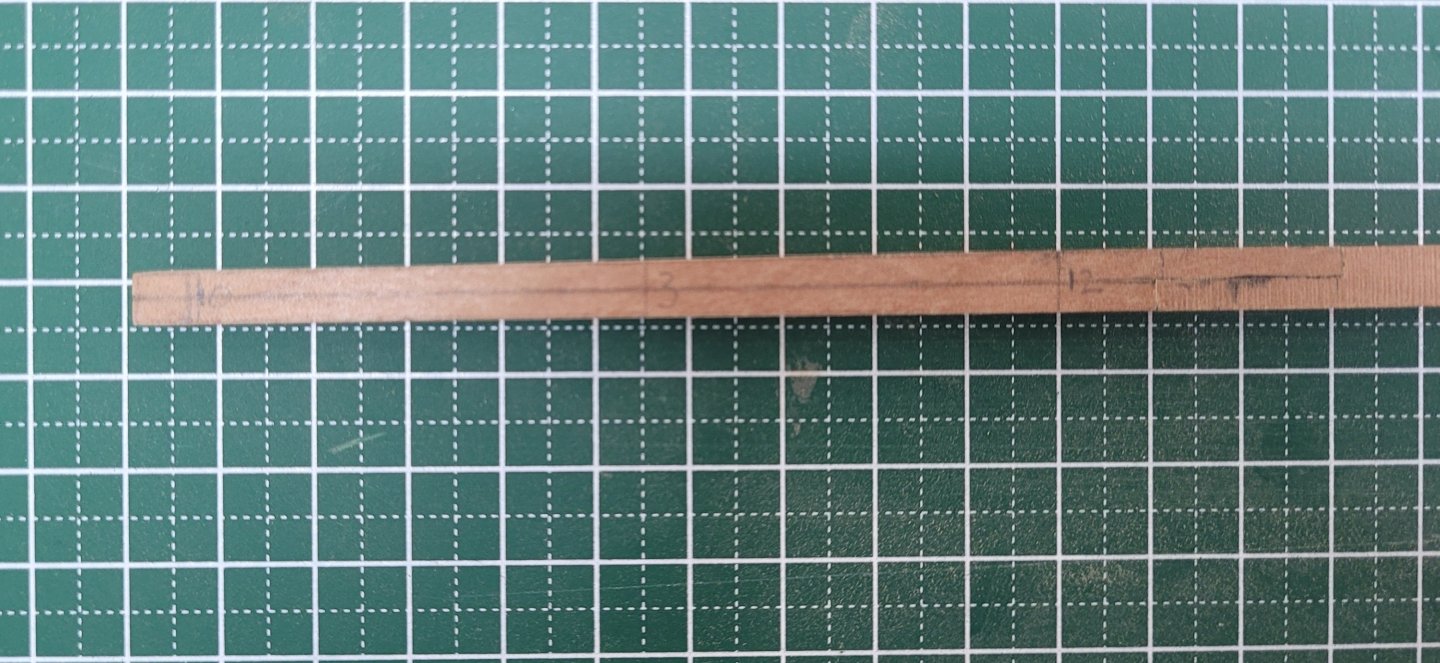

The rear of the keel tapers in width from 12" to 10" and so this was sanded to size. I also drilled the scarph joint with a #75 drill and used 24 gauge copper wire as bolts.

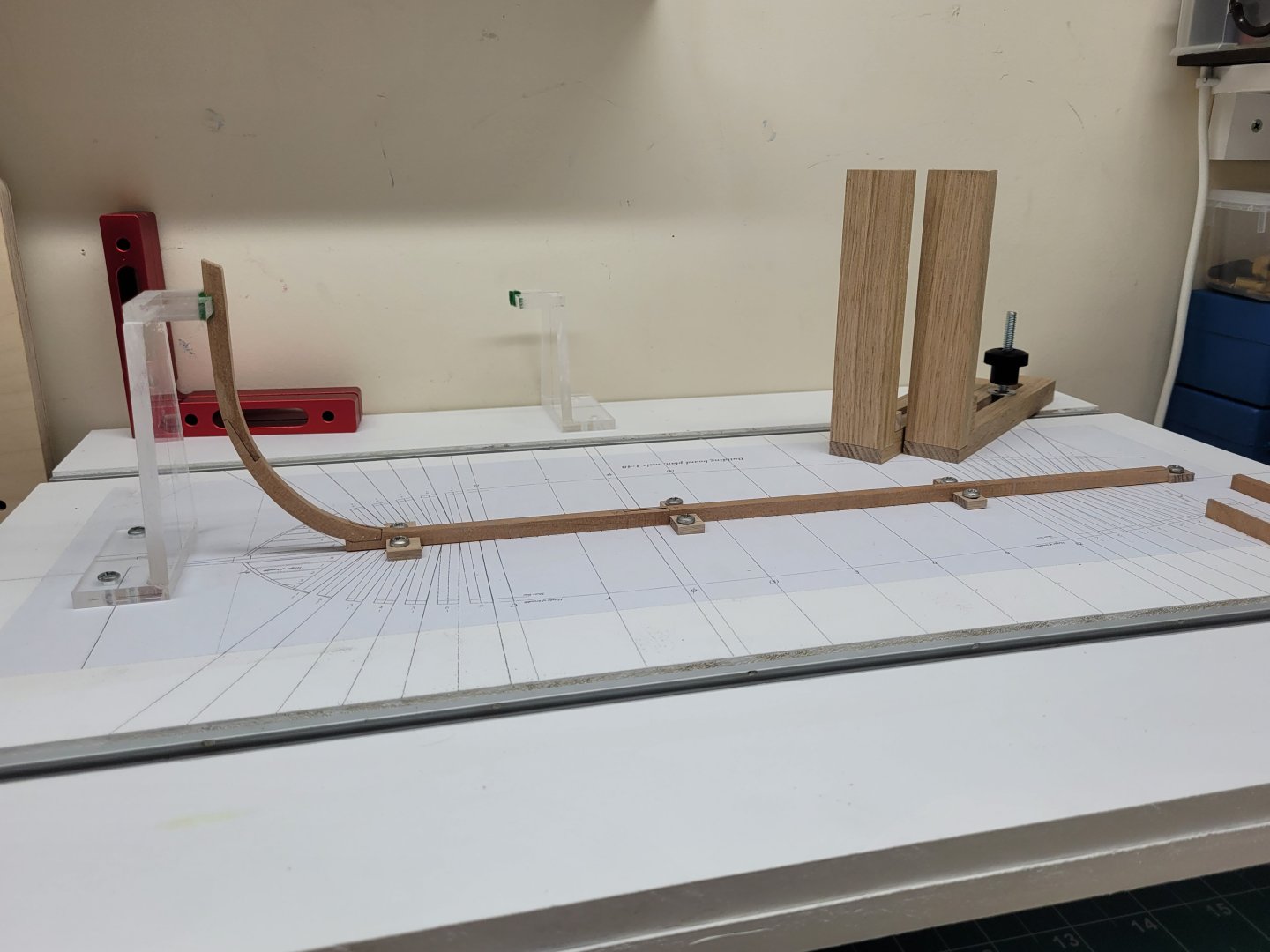

The stem was glued to the front section of the keel at the boxing joint. The front of the keel and the lower part of the stem also taper in width from 12" to 10" and so this was also sanded to size before the boxing joint bolts were added.

At present I haven't glued the forward section of the keel to the rear two pieces as I feel it might be easier to have the keel in two parts whilst I am shaping and fitting the other pieces which fit to it, such as the stepson and the deadwood etc. I am less likely to knock it and damage it if it is in two smaller parts rather than one longer piece. Finally at this stage I fixed the acrylic stem mount to the board.

- Seventynet, Thukydides, JpR62 and 7 others

-

10

10

-

Many thanks, Greg. I must admit I hadn't given any consideration to either of those points about the tissue paper so I am glad you raised those questions! I did some further tests today and I'm pleased to say that the tissue paper I have seems to be colourfast - I didn't have any problems with it either in debonding a join with isotropy alcohol or with adding a coating of wipe on poly, so it looks as though I was lucky 😀

-

I spent a little time this week experimenting with different ways to represent the tarred joints in the keel. I made up some test scarph joint pieces and tried out some of the alternate ways mentioned recently in Pirate Adam's log - black tissue paper, #2B pencil, #5B pencil and dark paint either mixed in the glue or just added to the edges of the joint. The #5B pencil seemed to smudge very easily and I also struggled with the paint option - perhaps I used too much but it just seemed to stain the sides of the join very easily, though I am sure it could easily be cleaned up. The #2B pencil and the black tissue paper both worked well and I felt that given the reddish hue of the myrtle, the tissue paper option seemed to present a cleaner and more defined joint, so that is what I have decided to proceed with.

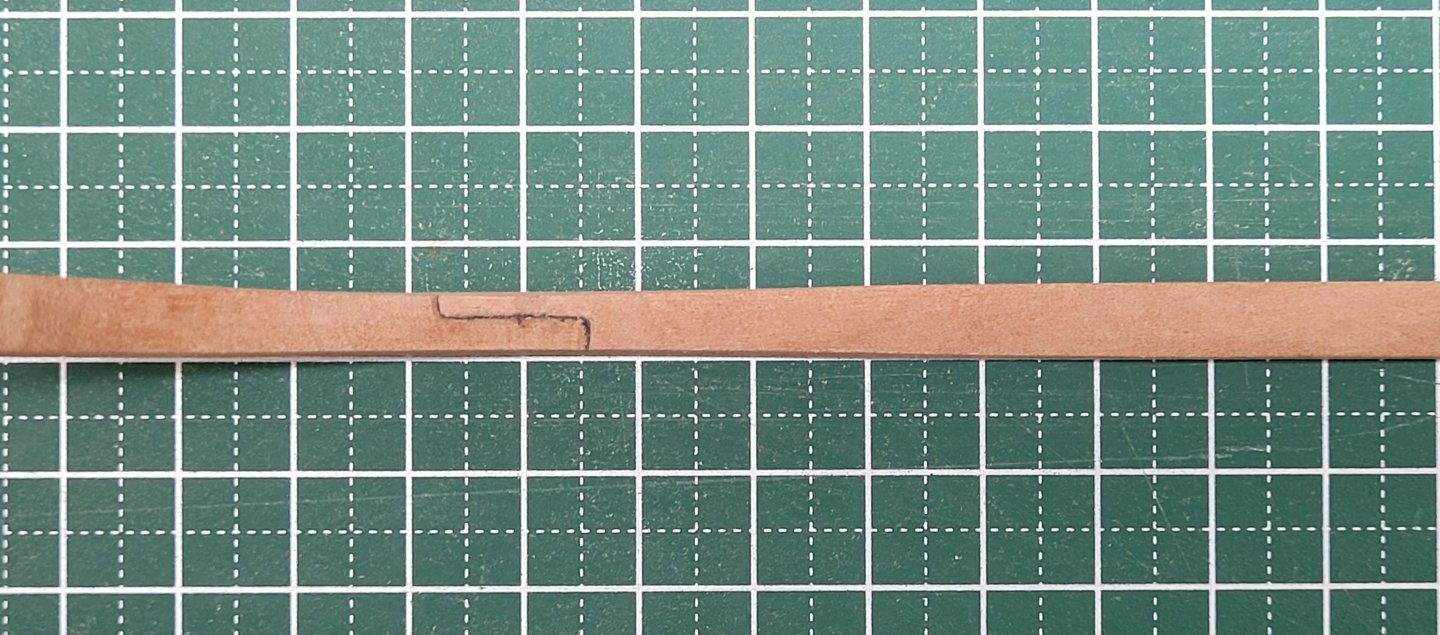

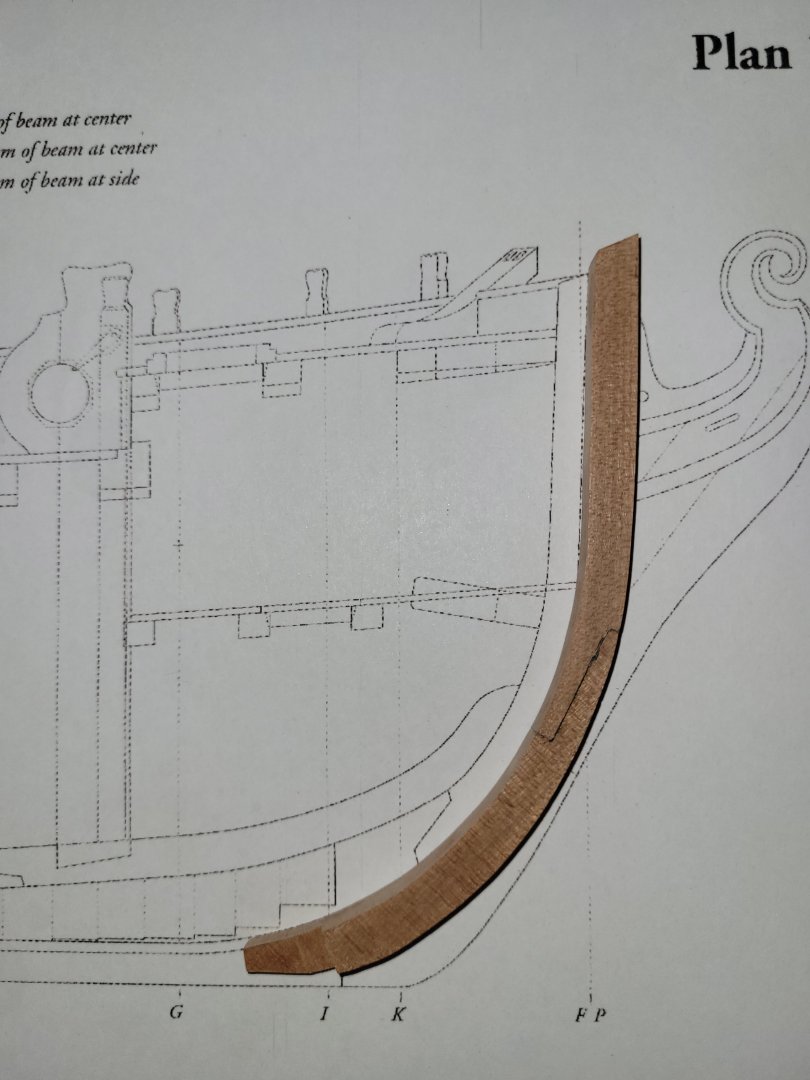

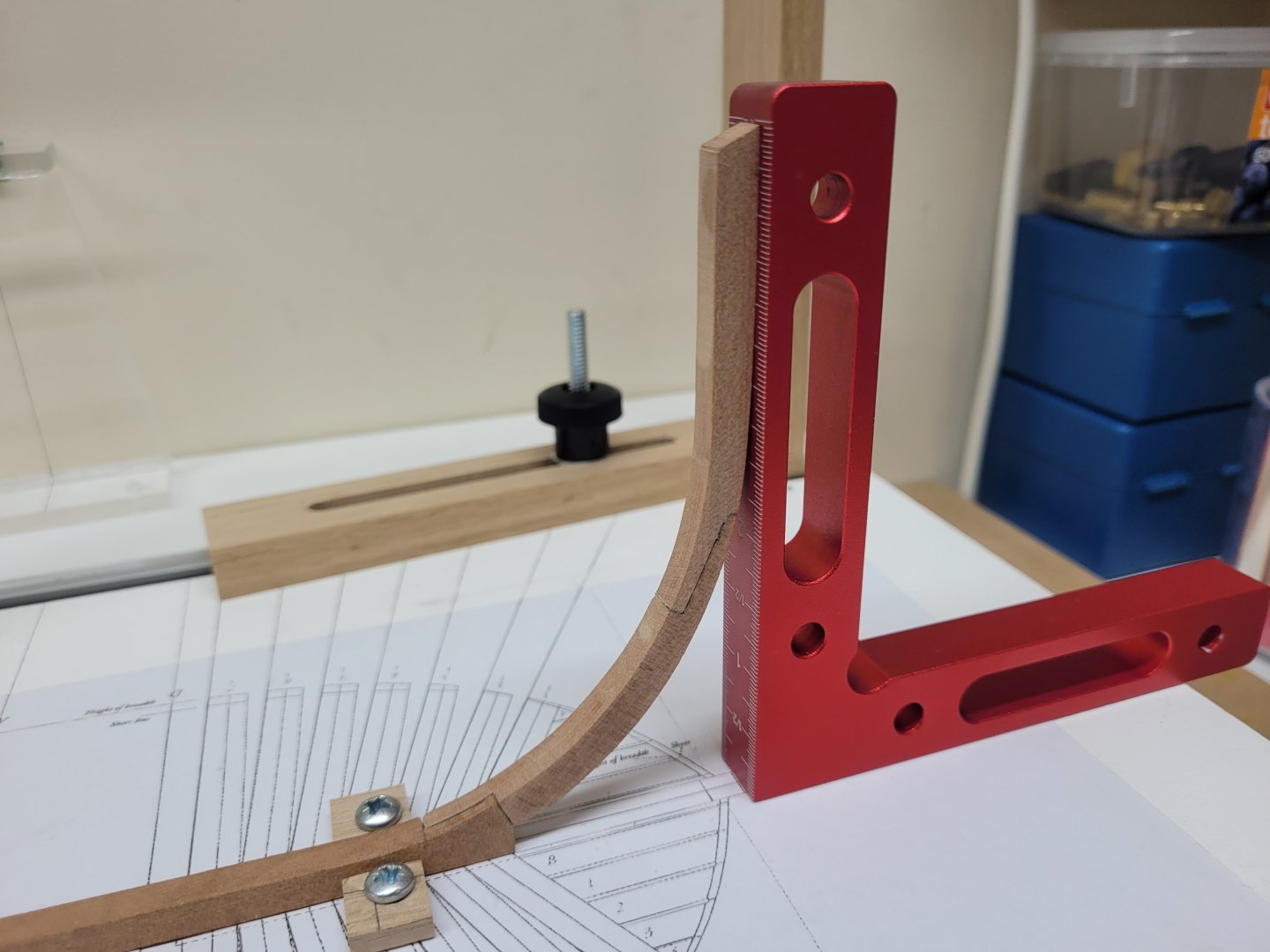

I continued working on the lower stem piece gradually refining the shape so that it matched the plan on both the inside and the outside curve. The upper stem was them mostly shaped to size and then glued to the lower stem with a tissue paper lining to the join. The upper stem was then shaped to blend in with the curve of the lower stem. It seems like a really small achievement but I was very pleased to get these two pieces together and have them both match the shape on the plan - I can at least say now I am building the model, rather than just cutting wood into small pieces! 😀

Here is the joined stem - I still need to add some copper bolts to the joint and then taper the lower section to shape once it has been attached to the keel at the boxing joint. Both the forward and aft ends of the keel taper from 12" to 10".

And here it is just sitting against the boxing joint in the keel to see if I have all the angles correct.

-

Welcome to MSW !! 👍

- Keith Black and mtaylor

-

2

2

-

Just a small update on the latest work.

I firstly purchased some more Australian myrtle from my local supplier - some thinner 10mm sheets and some 45mm deep pieces. Hopefully this stash will keep me going for quite some time. I haven't yet worked out exactly how much wood I need for the frames etc but I plan to have a look at that at some point in the coming weeks.

I also continued working on the keel and stem pieces. The lower and upper stem pieces were cut out of the 12" stock. I actually had to make another lower stem after some wayward sanding of the first attempt but I have now managed to get the two stem pieces to fit together nicely. I shaped the lower stem boxing joint and so far everything seems to be lining up well but I do need to cut out the recess on it for it to fit against the keel. I realised after the fact that it would probably have been easier to make the joint on the lower stem first and use that as a template with which to cut out the boxing joint on the keel, rather than the other way around - but that is one of the learning experiences.

I also cut the three keel sections to length and made the forward scarph joint. I cut this scarph with the table saw and may have gone a hair too deep with my cut but I will need to wait until I decide on how I am going to line the joints to see if it was too much. Tissue paper or thin paper may be enough to 'pad' out the joint perhaps. it won't be noticeable from the side of the keel but I do need to ensure that the joint is strongly glued. I have been reading the discussion on how to simulate the effect of the tarred joints in @Pirate adam's build log of the Crocodile and so i will experiment with the various methods suggested there. As the myrtle has a reddish hue I think a black joint may provide more contrast than a brown one but we will see.

Finally it was good to actually put the keel pieces onto the building board so that it looks like I have made som progress 😀. Nothing is glued or fixed at all so far as there is still much more to do to the keel in the coming weeks.

- Ryland Craze, davec, druxey and 11 others

-

14

14

-

It is interesting to see how Occre want you to progress with this planking and shaping of the bow. Most kits have some sort of central false keel and bulkheads going all the way to the bow into which you might add filler blocks, but I have never seen this before where the first planking terminates well before the bow and the bow section is instead carved from blocks. Endeavour is a very bluff bowed ship and so perhaps that is the reason for this?

Good luck and I'm interested to see how it turns out. 👍

-

Looks like a very interesting project !

-

Thank you for another fantastic build!

- mtaylor and Blue Ensign

-

1

1

-

1

1

-

I have one of these and find it much more useful than a dremel for drilling small holes for eyebolts etc. The slower speed compared to the usual rotary tools (500rpm versus 5000+ rpm) and the small size of the unit allows for more accuracy I think. The drill press is also useful on occasion depending upon what you need to do - I seem to be terrible at drilling straight by hand....

It is basically a motorised pin vise, and not a cheap one at that, but still useful for me.

- mtaylor, thibaultron, Scottish Guy and 1 other

-

4

4

-

-

1 hour ago, allanyed said:

An alternative that I switched to some years ago is to print on full size sheets of label paper. Cut out the drawing of the part somewhere near the lines, peel off the backing and stick on the wood.

That's another good option Allan, especially if you can get easy peel off labels. Some price tags or manufacturers labels are a devil to get off cleanly when the glue is stronger than the strength of the paper!

-

9 hours ago, Stuntflyer said:

In certain cases, rather than shaping each section individually, I just cut the joints accurately and then join the various sections together. After doing that it's easier to get a more accurate outline of the joined parts while the templates are still attached.

That's a great tip - thank Mike.

I have some Elmer's School Glue and various types of glue sticks so I will experiment and see what works best. I guess you need the template to stick well but also come off cleanly when you are finished with the template. Certainly so far from my very limited experience, I think I am finding it easier to work with pieces with paper templates rather than just pencil outlines directly on the wood.

-

9 hours ago, dvm27 said:

You should cut as close to the line as you are comfortable doing without cutting into the line. I used to leave about 1/16" using my scroll saw then sanded to the lines on my disk sander or oscillating spindle sander. After some practice I'm able to cut to within a whisker of the line and that is sufficient. Fairing after the hull is assembled will blend everything together.

Thanks Greg. I appreciate the advice. I need a lot of practice and hopefully experience will eventually come my way 👍

-

-

9 hours ago, VTHokiEE said:

I think that how close you get to the line probably depends on the part. My experience with the frames on my cross section was that I should have left a a good bit more on the parts than I did to account for fairing (maybe leaving 1-2 mm? outside the line to account for fairing)

Thanks - this sounds like very good advice. 👍

-

12 hours ago, targa4403 said:

Apparently the use of this part to extend the lathe bed it not recommended by the manufacturer. I don't know the reason why. Maybe it will affect the performance of the motor? I don't know. I just saw this on the internet. Have you had any issues with the bed extension?

I haven't found any problems so far. I have only used it to extend the length by a few centimetres rather than the whole 450mm though. If you are working on a longer spar or mast it is nice to have the whole length you need to work on available outside the collet to avoid any marring. It also helps ensure the collection isn't holding a tapered piece of the spar which could bring about wobble.

-

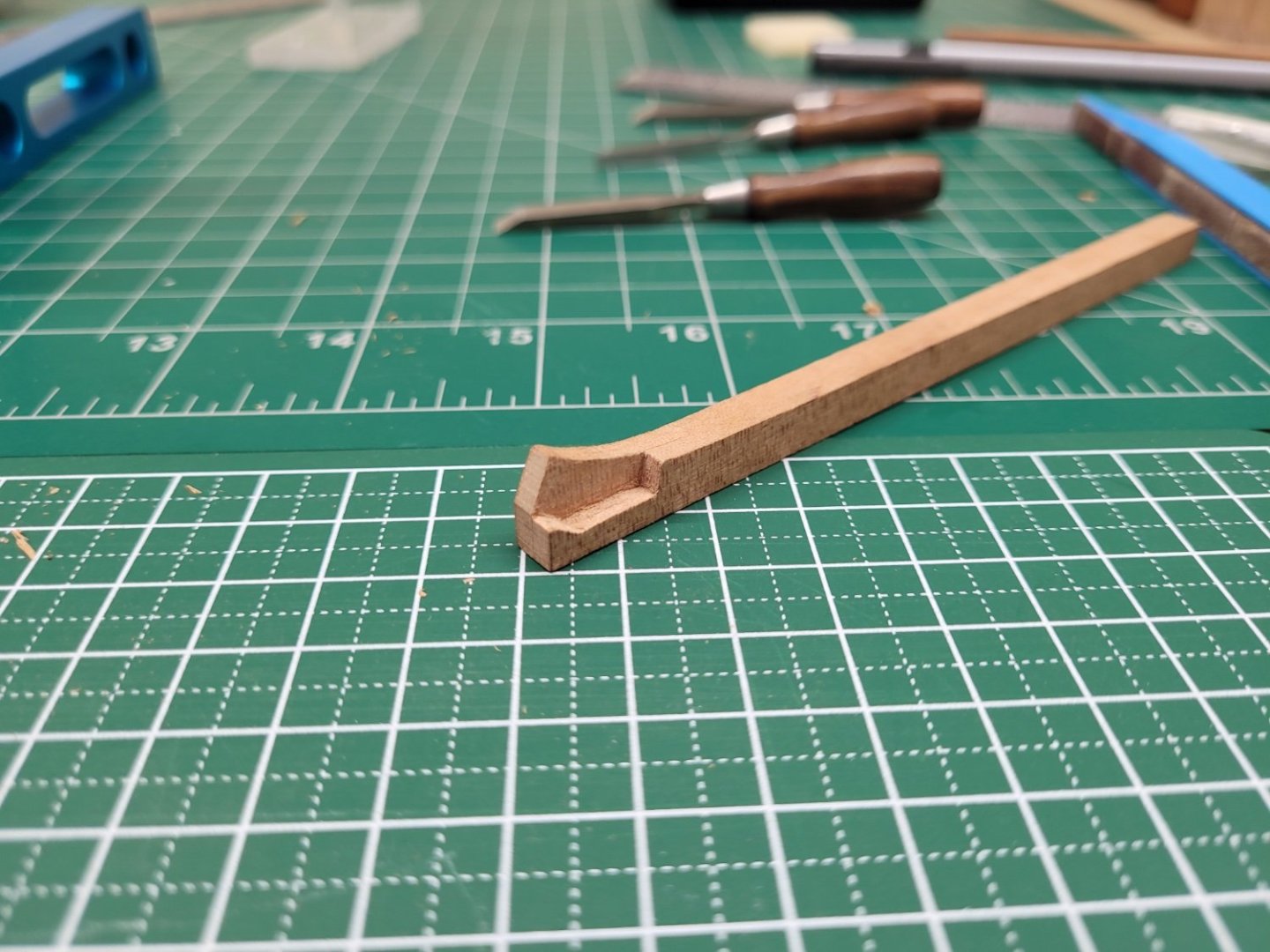

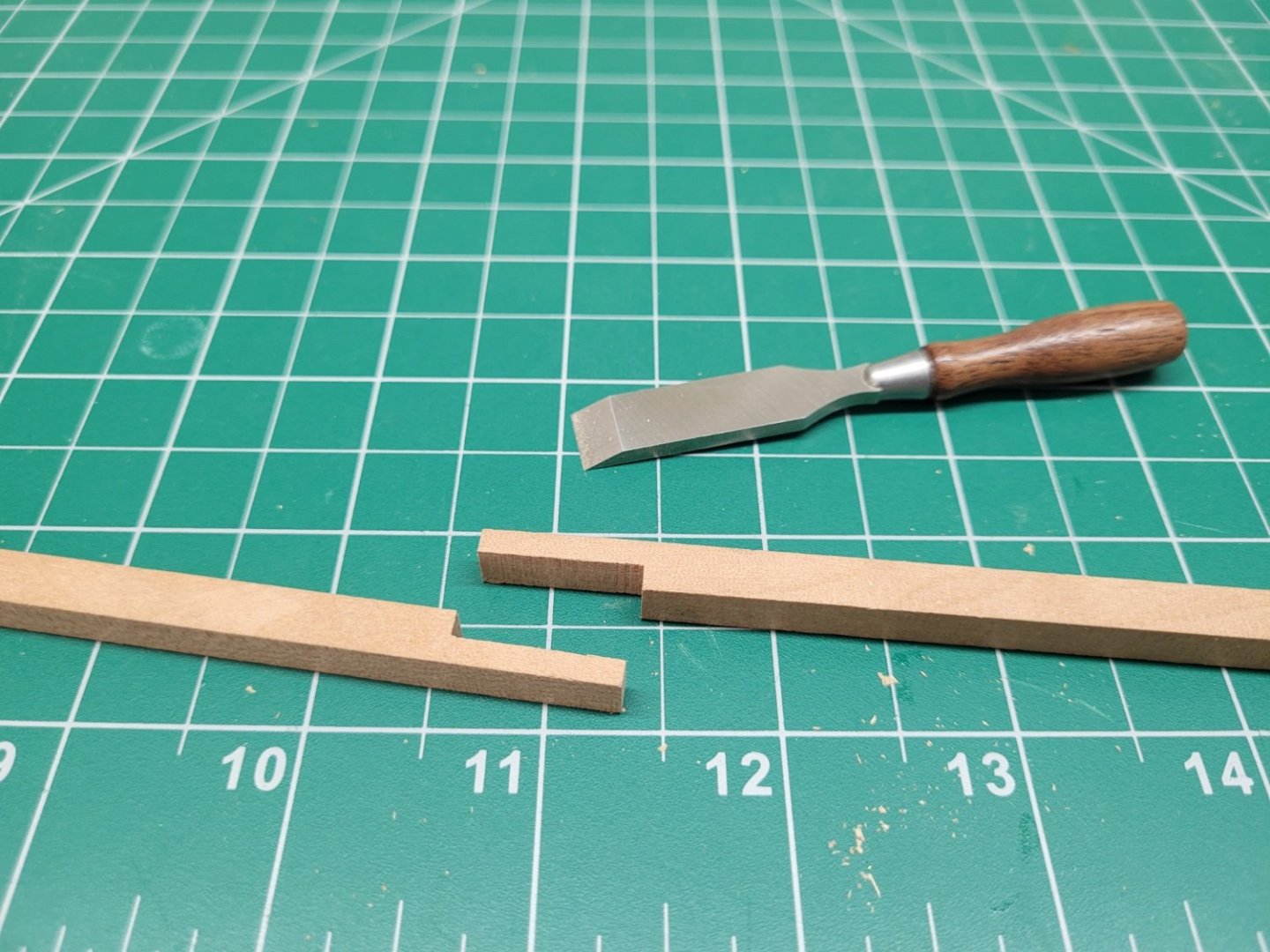

As it is a holiday weekend I was able to spend a little more time on the model. I did cut out the boxing joint on the forward section of the keel with my small chisels but I wasn't happy with the result as I shaved a little too much off the 'tooth' (it probably has a proper name but I'm not sure what it is!) at the end. The temptation just to tidy things up a little is very strong - until you go too far! Consequently I remade that part of the keel again and redid the joint, this time taking much more care with the chisels and only working on specific sections of the joint at a time. The second iteration of the joint was much better that the first attempt and so I'll see how I go when I cut out the lower part of the stem joint before deciding whether this is a keeper. I used my mini mill as a spindle sander to help shape the curved sweep of the top of the piece.

Here is the second version of the forward section of the keel with the boxing joint.

I also cut out the lower and upper stem pieces and the outer keel post from the 12" stock. I experimented with tracing out the shapes on the wood and also gluing templates on the stock before cutting them out on the scroll saw. I'm not sure which is the most accurate way to use going forward but the cut out templates certainly seem to be easier to see, for me at least. I'm also finding difficult to judge how much excess to leave on the piece with the scroll saw - I realise you need to be close enough so you don't have to do too much sanding to shape but at the same time you need to have enough excess to make sure you are not going to end up with an undersized piece. No doubt I will get better at this when I start cutting out the dozens of pieces that make up the frames!

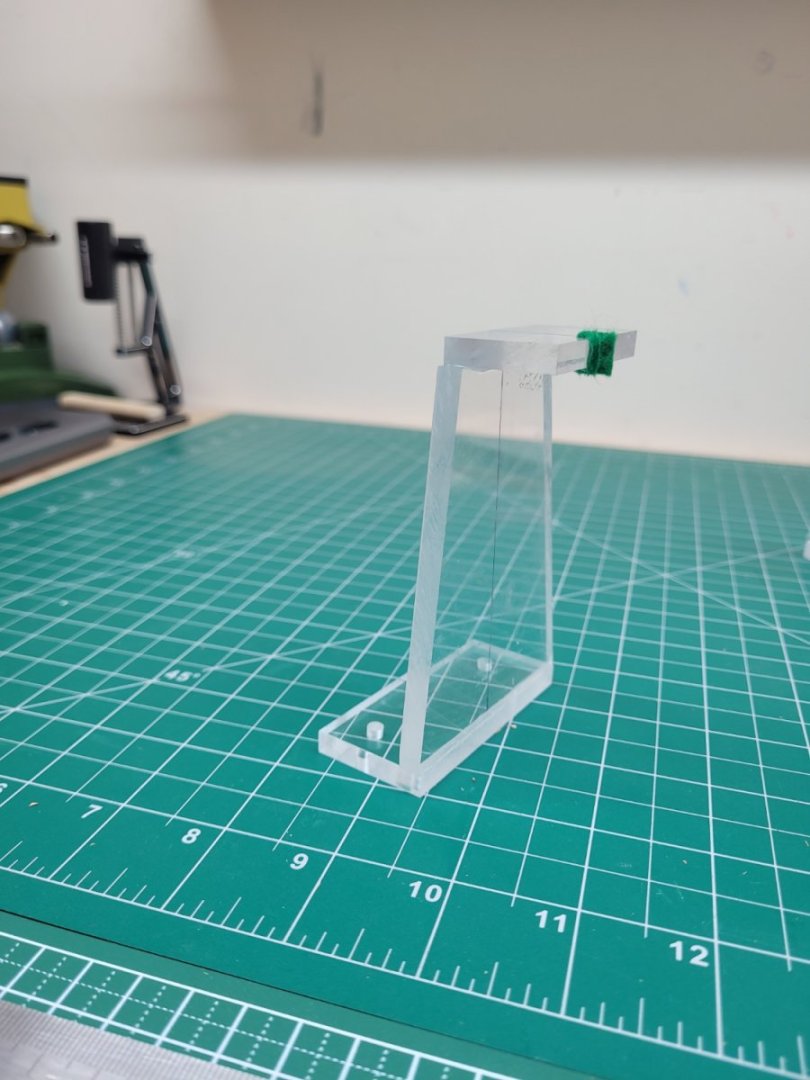

I also used some 6mm acrylic to make the support mounts for the stem and the stern. They may not be the prettiest supports ever but they are square and after lining the cutout with sticky backed felt a 12" timber fits in there nice and securely.

I think the next job will be to trim the keel sections to length and cut the scarph joint for the forward section of the keel.

-

16 hours ago, barkeater said:

I have the Proxxon and use the add on 3 jaw chuck like Rob. The pass-through ability is key as it allows for longer stock and helps avoid whipping.

There is also a 450mm extension bed for the Proxxon DB250 which I have found to come in handy from time to time.

-

This will be interesting to follow. 👍

- mtaylor and Pirate adam

-

1

1

-

1

1

-

Thanks for the support and encouragement everyone.

The artists' varnish doesn't say whether it is water based or not but druxey is no doubt correct. The spray can does indicate it can be used on drawings and artwork but it does mention 'fine art paper' and I guess that is the where the difference comes in. My plans certainly aren't printed on 300lb cold pressed paper and presumably the thickness of the paper is a factor.

-

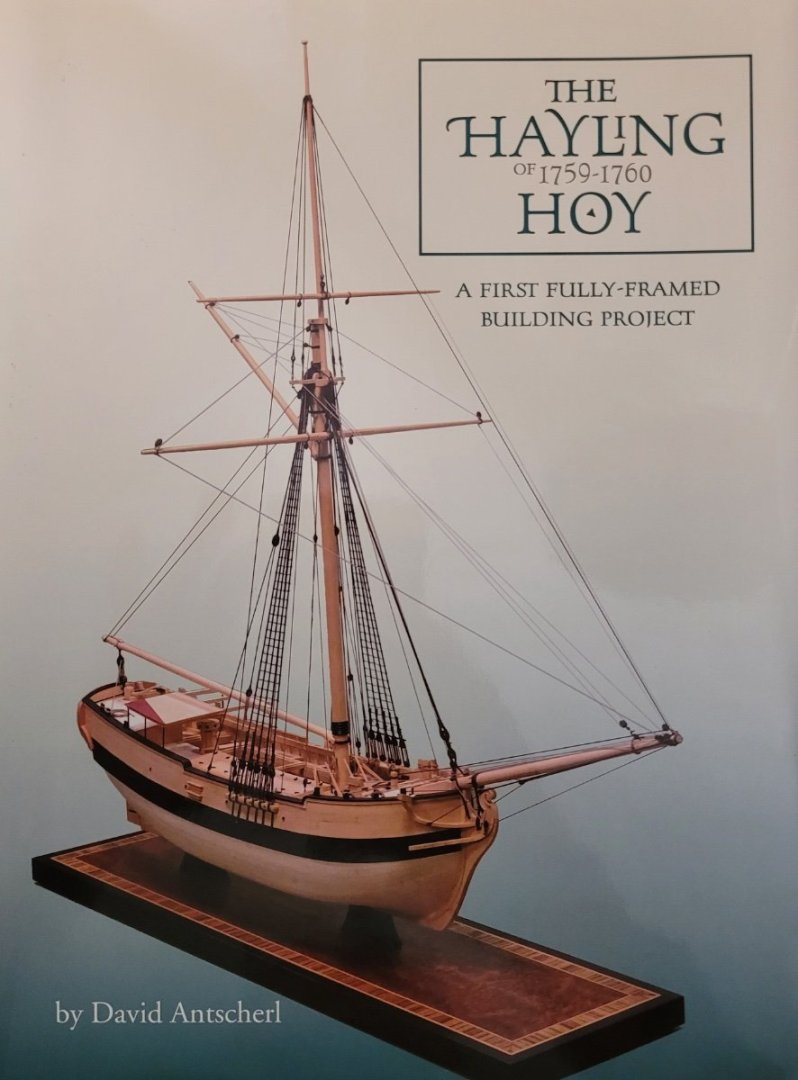

Hello,

Welcome to my build log of the Hayling Hoy. David Antscherl's excellent book on this build says that it is suitable for a first time builder attempting a fully framed model. Well, I am certainly a first time scratch builder and this will be my first fully framed model so I hope he is correct! I decided to attempt this build as I wanted to stretch my skills and techniques and also because I knew it would be a very long project. I really don't have that much spare space to display finished models and so the longer I can keep one on the building board the better! I was impressed and encouraged by previous first time scratch builders who have also attempted this build, notably @Stuntflyer and @Seventynet and I hope I can come up with something that even approaches their excellent work.

I have no background or experience in woodworking and whilst I do own a few of the machines that may help with this build, eg table saw, thicknesser, mill etc I haven't had a great deal of experience using them to date and so this will be a learning experience for me on those tools as well as in regard to the techniques of scratch building a fully framed model. There will be plenty of mistakes and do overs on the way but I'm not worried about that as it will all be a part of the project. I will of course welcome any advice and ideas from people who feel that they would like to contribute. I know I have a lot to learn and I am looking forward to it. Progress is going to be slow as I don't get that much time each week to devote to modelling but hopefully I will keep going forwards!

Being based in Australia I really don't have access to the lovely types of wood I often read about on this forum but there are of course native options. I have decided to use some myrtle that seems to be in readily available supply. So far I have only purchased a couple of small pieces just to get started with. The myrtle seems very like pear wood (to my untutored eye at least) and hopefully will make a lovely coloured model with fine graining.

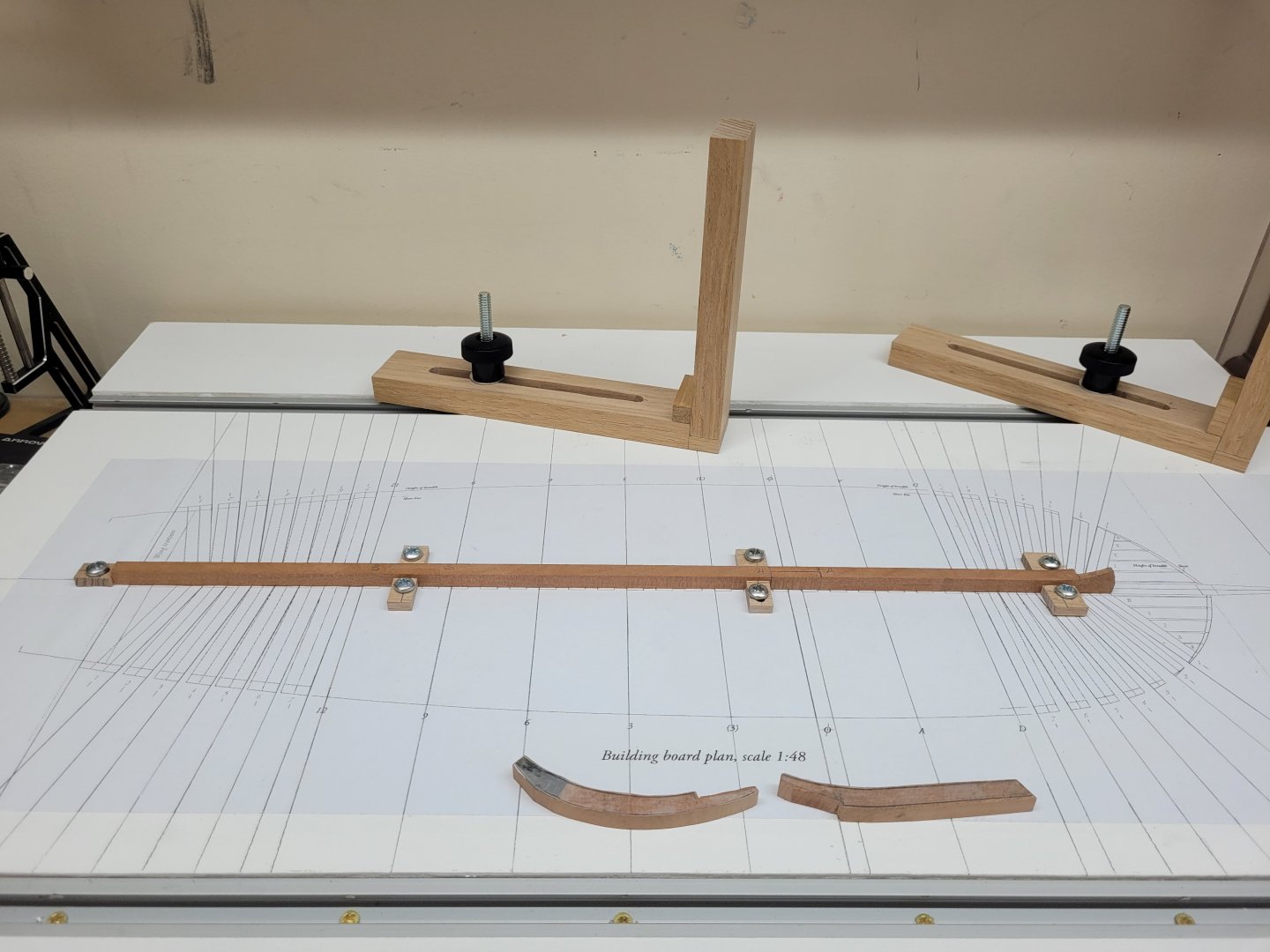

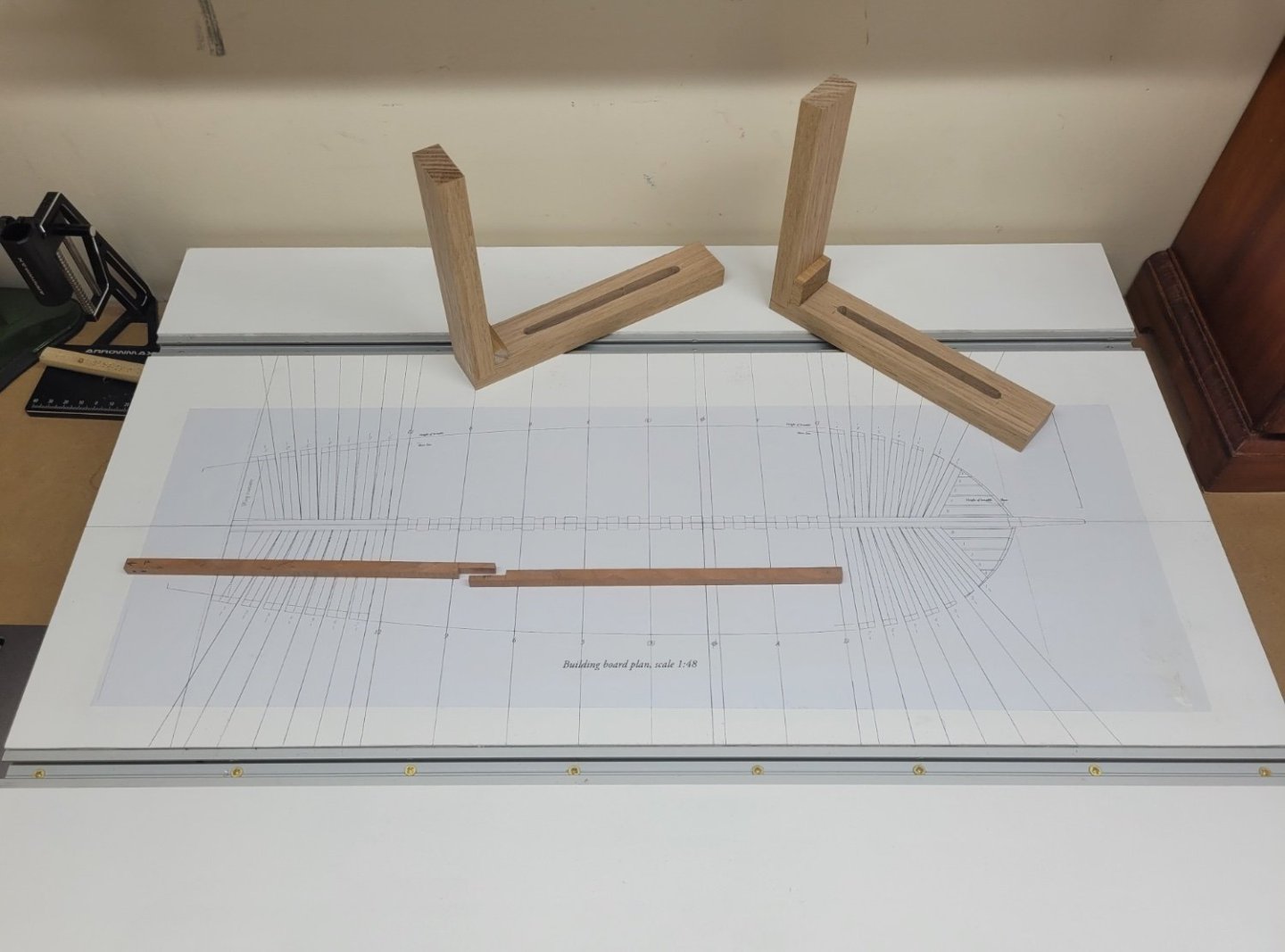

I have spent that last few weeks getting ready to start this project and that included getting the plans copied and making my building board. I used some mdf for the base of the board and added some pine battens underneath. I have seen a couple of builds that use t track as part of the building board and so I decided to copy that idea and I also made some wooden squares to use with the t track. I added a couple of coats of white paint to the board and then glued down the plan using some spray adhesive. It seemed like a good idea to add a coat of artists' varnish over the plan but clearly that was a mistake as it only succeeded in introducing lots of wrinkles - so that wasn't a good start. Either I hadn't glued the plan down sufficiently or the spray varnish just didn't like that particular paper. So off with that plan and on with another copy, this time glued down with lots of Bostick blu stick - and it seems to be sticking well so far. I didn't bother with the varnish this time around. I also extended the lines of the frames out onto the board which should hopefully make things easier to line up and keep square etc down the track.

Today I actually made a start on the build itself and began with cutting out the pieces for the keel. The keel is made of three separate pieces joined with scarps joints. The rear two pieces are simply 12" square lengths and I deliberately made them over long as I wanted to make sure I had plenty of excess to work with in case I made a mess when cutting the scarph joint. The scarph joints were cut on the table saw and then the faces of the cuts tidied up with a small chisel.

Strangely, the keel sections look far from square in that photo above but it must just be the perspective - they are square honestly!

Next job is to tackle the forward section of the keel with the boxing joint.

- Dave boatswain, JpR62, KentM and 24 others

-

27

27

-

That's a great idea for the knotted handrail - excellent work

- AJohnson, Thukydides and Glen McGuire

-

2

2

-

1

1

-

Great work for your first wooden kit Richie. It seems AL have revamped this kit which is good - and hopefully the instructions have been greatly enhanced from the old version. A single layer planked open boat is a challenge for any new builder as you can't hide any planking mistakes under a second layer! Well done with you work so far.

The Hayling Hoy by jpalmer1970 - 1:48 scale - First POF build

in - Build logs for subjects built 1751 - 1800

Posted · Edited by jpalmer1970

Spelling

Hi folks,

I have been puzzling over the plans looking at the sternpost and the inner post and I'm having a bit if difficulty understanding how they are shaped where they meet up with the wing transom. This part of the plan has lots of lines for all of these various parts and I'm not sure sure which one is which!

Here is a scan of part of the plan and it is this area in the red oval that I am struggling with.

The sternpost shape is, I hope fairly obvious, and I have marked it in blue in the scan below. It appears to me to have a little 'hook' where it sits on top of the top of the inner post which is where the rabbet ends I believe. Is that correct, do you think? It is the shape of the top of the inner post that is confusing me the most as it appears that this is where the wing transom sits. I have marked out what I think is the correct shape in red below but looking at the illustrations in David's book the top of his sternpost seems to be complete flat, rather than having that little step? I fear I am missing something here and hopefully that may be obvious to more of you than it is to me!

Any advice and guidance would be most welcome as I would like to get theses pieces cut out of the stock. I thought I had it all sussed out originally but the more I look at them now the more confused I get - so some fresh perspectives from you all will certainly help. Many thanks in advance 🙏