-

Posts

629 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Matt D

-

Welcome aboard, Steve! I also cut out my own bulkheads. Twice. Be sure that your print outs are scaled at 100%. I didn't pay enough attention the first time and had the whole set put together before I realized it was about 95% of the size it should have been. So I started over. If I had it to do over again, I'd have been more careful about making sure each bulkhead was centered and that my bulkheads were perfectly symmetrical. Also, put a test batton along the wale marking line on both sides and make sure they look good. That's all the unsolicited advice I have for now. I hope you have fun with this build. It's a great project and I'm happy to watch another one come together.

-

That looks like a terrific start, Gregg! I’ve read that Model Shipways will send replacement parts for anything missing or broken. As I understand it, if you mess something up on your own, they’ll replace it for you. They have a good reputation for their customer service. So don’t hold back if you have missing parts.

- 29 replies

-

- Model Shipways

- muscongus bay lobster smack

-

(and 1 more)

Tagged with:

-

Those are some nice looking clove hitches. Are you able to do this with your fingers or does it take tweezers?

- 382 replies

-

- Vanguard Models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

It looks like you're in a lot of trouble, there. Next you'll have to walk the plank! They look excellent, Glenn.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well that stinks, Justin. I’m sorry that happened. I’ve had it happen several times that I’m trying to slowly creep up on “just enough” sanding and somehow overshot by a mile. It’s painful. I also know the feeling of trying to carefully remove a piece and instead wrecking the whole thing. The good part is that you have this frame making business down pat, so your new set will be terrific. I’m looking forward to seeing it.

-

Your ship is looking great! I wish you the best in your health issue. Coming up short in your build is the railing. In some logs, including mine, builders have used spacers to set the posts evenly. I want to warn you that doing so poses a high risk of creating stacked tolerance errors. If you look closely at mine, you’ll see that the railings are off from one side to the other near mid-ship. I corrected it as well as I could at the time, but the step really shows off the error. Do think carefully about how to get the spacing right while keeping both sides the same. If I had mine to do over, I would have marked the post locations and checked side to side instead of trying to just use a spacer to set them.

-

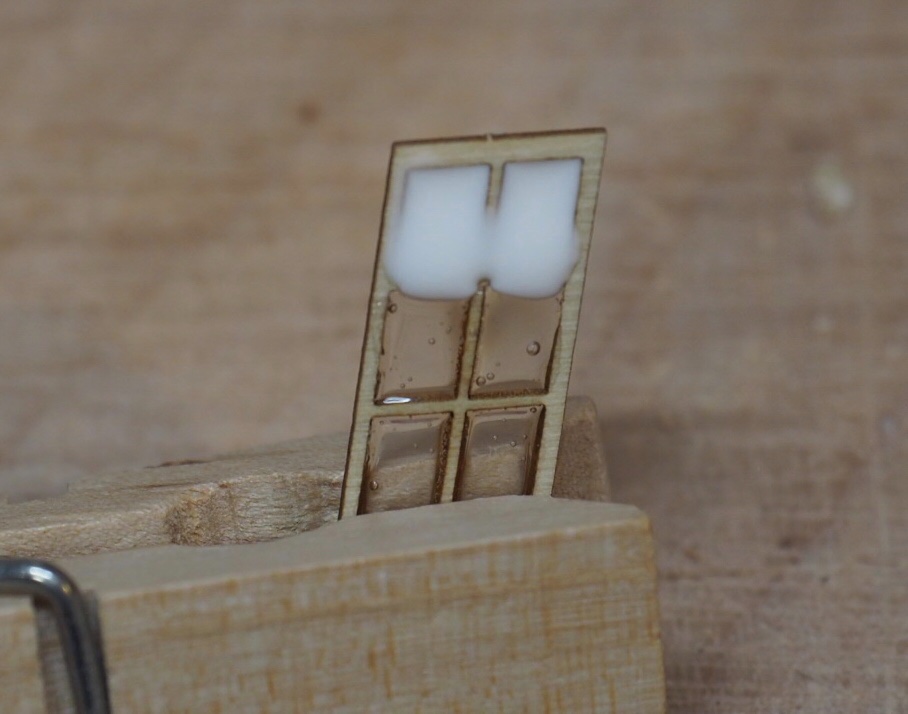

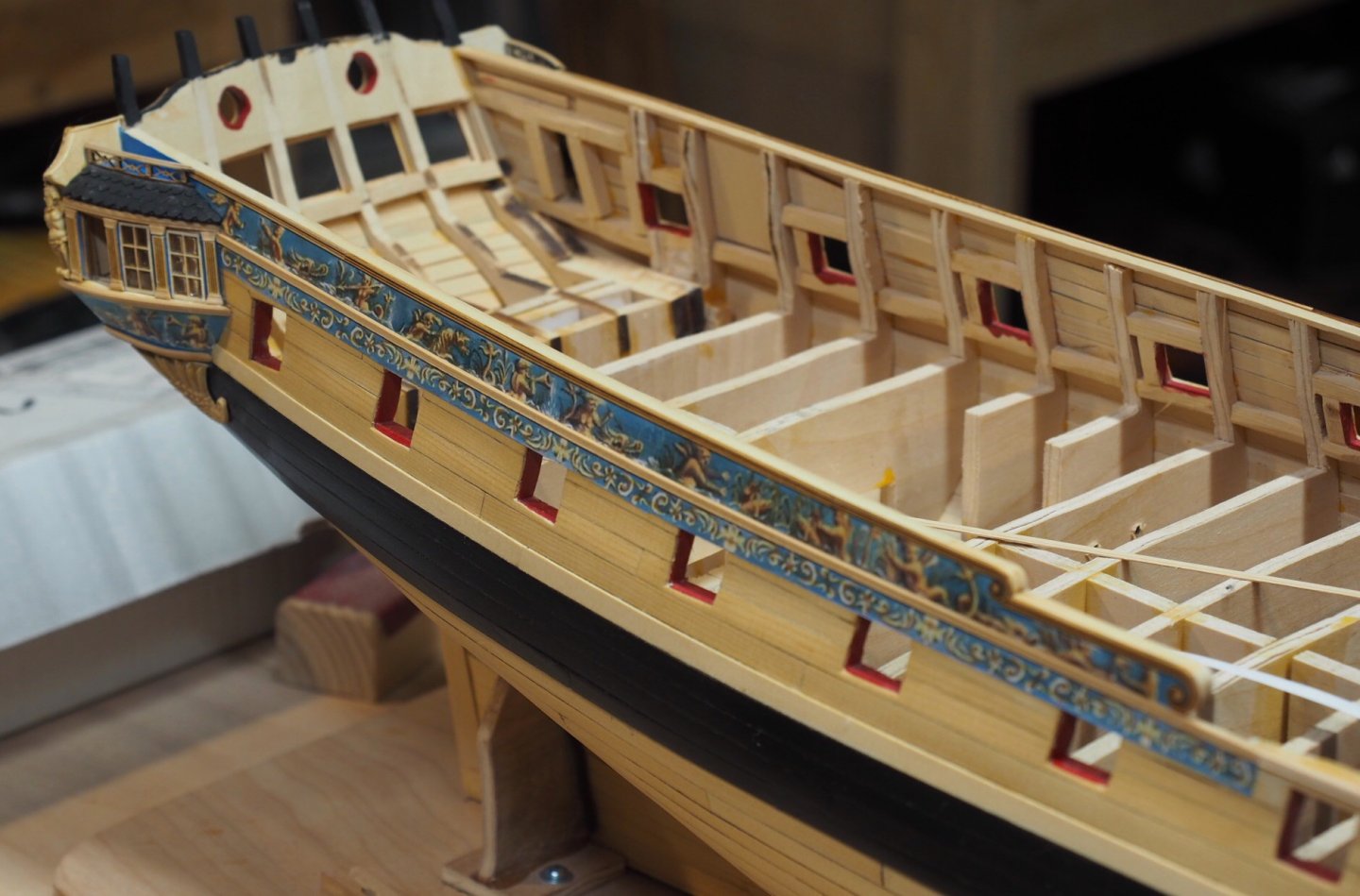

I’m working at a snail’s pace on chapter 3, inching my way to completion. I really like working with the friezes and I’m pretty happy with how my moldings are turning out. I’ve also completed the q gallery roof railings. And I took a page out of Bob’s build log and used Micro Kristal Klear for the windows. I really like how they look and it seems like it reinforces the delicate frames. Thanks for showing that, @rafine!

-

Wow! That looks amazing. Is that a crew of three I see in there? Was it a lot to handle with all of those sails or just a matter of setting them and staying on course for a while?

- 108 replies

-

- leon

- brigantine

-

(and 1 more)

Tagged with:

-

Hi Chuck. I decided to add this as a new topic, but it may be covered elsewhere. Feel free to delete if this post is superfluous. Which cannon barrels and carriages should we use on the Winnie? I thought about buying them today with my Chapter 4 order, but couldn't tell for certain which ones to buy for the main deck. Obviously, it's too soon to mount them permanently, but I thought it would be nice to test fit them. Or are they not available yet? Thank you!

-

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)

Hello from a newbie with L plates on!

Matt D replied to Pirategirl's topic in New member Introductions

Welcome to MSW, Jas! This group is helpful and kind. It can seem intimidating to post your work, but you’ll get real help and very nice comments about your work. People here like to answer questions and share their experience to help others, so please don’t ever feel like you shouldn’t ask questions or solicit opinions about what you’re doing. Also, if there’s a kit worth building, you can learn about it here. -

Welcome to MSW, Smellycat. I’m sorry that your dad is gone. My dad was a Vietnam War veteran, too. I hope your restoration goes well.

-

.thumb.jpg.6d6ee4bdbfaac2c58ecc77e7b80ae374.jpg)

Need plans and instructions for Virginia 1819

Matt D replied to Phinatic74's topic in Wood ship model kits

I had read in a recent AL Virginia 1819 build log that they only include the CD now. I haven’t seen the CD, but my guess is that the files are PDFs. If that’s the case, then you probably just need to print them 1:1. If you need a larger printer, try FedEx Office or Office Depot or someplace similar. One benefit is that you can print the manual larger, which is great if you have old eyes like I do. -

JR, I too suffer from FOMO. I have to constantly restrain myself from buying kits I’m not ready to build. By not ready, I mean I’m already working on a model and don’t really want to try to have two going. There are pluses and minuses to that. Occasionally, kits are discontinued and can’t be found later. But it looks to me like more often than not, the most desirable kits get upgraded or get fixed if they previously had problems. So it’s better to wait and assume that anything I missed out on was probably a bad kit anyway. I feel like right now is an exciting time for kit or semi-kit (semi-scratch) builders because of the new products coming out from Syren, Vanguard, and CAFmodel. So I don’t want a mountain of kits clogging up my shelf when I know there are more interesting things coming by the time I’m ready to build them. With regard to prices, it seems to me that kit prices go up as a function of size, detail, and quality of materials.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.