-

Posts

4,669 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by augie

-

I'll be checking back here as well. Nice job!

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Good stuff, Popeye! Hey, instead of a picture, how about a small section of a map to look like a chart of the coast?

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

That was quick, my friend. The color will settle in with time. She seems to grow with every update --- and now 4 boats!!!

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Thanks, Popeye. Be interested to see if it takes paint well. Keep us posted.

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

Seeing that last plank go in brings a big smile for today. Go do some 'drillin' and fillin' !! Gorgeous!

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

A lot of fine details coming together. Wish I could help on the 'black box'.......access to a chain locker???? Are you using that thin liquid glue on the styrene?

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

The method suggested by Bill works very well. An additional benefit is that the line going through the hole doesn't stick out in front of the pin rail and make it hard for you to attach the pre-made coil. Just be absolutely sure you have the right tension on the line before you glue in the pin.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Lots of things going on there! That 'unflattering photo' looks great from here!

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

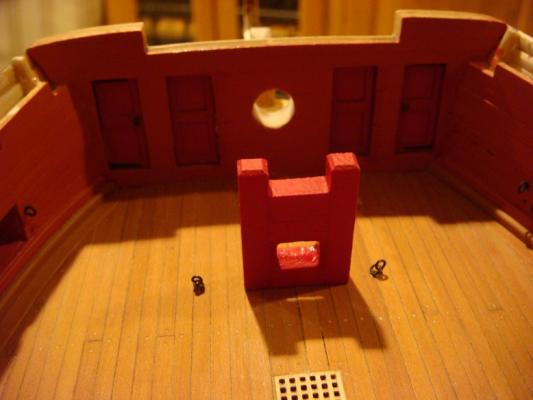

Haven't really made enough progress for a proper update but there's something important I need to point out ... and now is the time. The bulkhead beakhead doors were made the usual way by laminating 3 sections together, thinning them down, applying the finish and hardware. They required only minor adjustments to fit the openings properly. The two outermost doors will be covered by the roundhouses down the road. Next, we fabricated the bowsprit step out of 3/16 and 1/4" strips. After painting, it was securely pinned to the deck: OK, here's what I wanted to discuss. The bowsprit hole in the beakhead is quite a bit undersized for the bowsprit. The bowsprit will be tapered but the hole still needs to be enlarged. With the stem already in place, getting the proper angle and size on that hole is somewhat problematic. Also, the next steps will include installing additional deck fittings as well as forecastle deck beams which will largely cover the bowsprit step. I could visualize painting myself into a corner and being unable to properly fit the bowsprit 6 months from now. So I fabricated and aligned this NOW and I'd strongly suggest you do something similar. If you check Rusty's great Confed log you'll see that he left off the upper part of the stem (that which holds the figurehead) at this point ----that would give you room to work. But I didn't think that far ahead. I don't like breaking out my dad's old Craftsman 1/2" drill for work on a 1:64 ship model. So I slowly enlarged the hole using slightly tapered sticks (old paint brush handles) wrapped in sandpaper. Yes, it's just this side of Neanderthal (and slow) but it works..... and nothing got destroyed in the process. Here's what we have: The bowsprit has a tenon cut in to sit nicely in the step. That will need to be painted red just prior to final installation. Didn't mean to bore anyone with this as I'm sure you all know it's good to think ahead. But now my conscience is clear.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

A week? Maybe ---- maybe not!!! Just keep in mind that each piece of wood has it's own mind so if the first doesn't work, try another. I know Dirk used something he called 'Bendable Beech' but I'm not sure it's from Earth.

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Really coming together now John!

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

-

Hey guys...lighten up. Augie is not a 'master'. Syren was essentially my first ship. I just keep good notes It's always good to get Chuck's blessing when you get blown off course a bit. And now we can all breath a sigh of relief. Also heed his advice that the final sanding of those lintels comes after the planks are laid so you have some strength there. I'm really glad the 'new' Syren crew is enjoying the build. Back in the Dark Ages (MSW 1.0), we had a Syren thread and when you opened it you saw about 12 ongoing projects.....one better than the next. Hope you've checked some of that out. Of course we now have Dirk who keeps setting the bar higher for everyone!

-

Great work, Sal. Hull looks spectacular. Transom shaping up. Don't you just love the dummy canon idea? If I recall, the cap strip over the top of the transom comes next. Be very patient here. May take one or two extra trys but it can be done!

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I have the utmost respect for the folks who roll out the mills and lathes to turn this kind of thing out. But seeing it done this way ---- and so beautifully ---- brings a smile that lasts all day. Really first rate, mate.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks to all for stopping by once again. John - yes, the details are fun......if sometimes a bit frustrating. Rich -- no, the pumps don't work. But at my elevation, no need to worry. I know there are many craftsmen on board who wouldn't rest until they did !!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

The quarterdeck details, beams, carlings and knees have been completed: With that, we bid fare thee well to the stern and turn our attention to the long forgotten bow. Before tearing into it, I've prepared the beams and knees to go under the forecastle deck. These will be set as we install the bow details:

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.