-

Posts

3,004 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glenn-UK

-

-

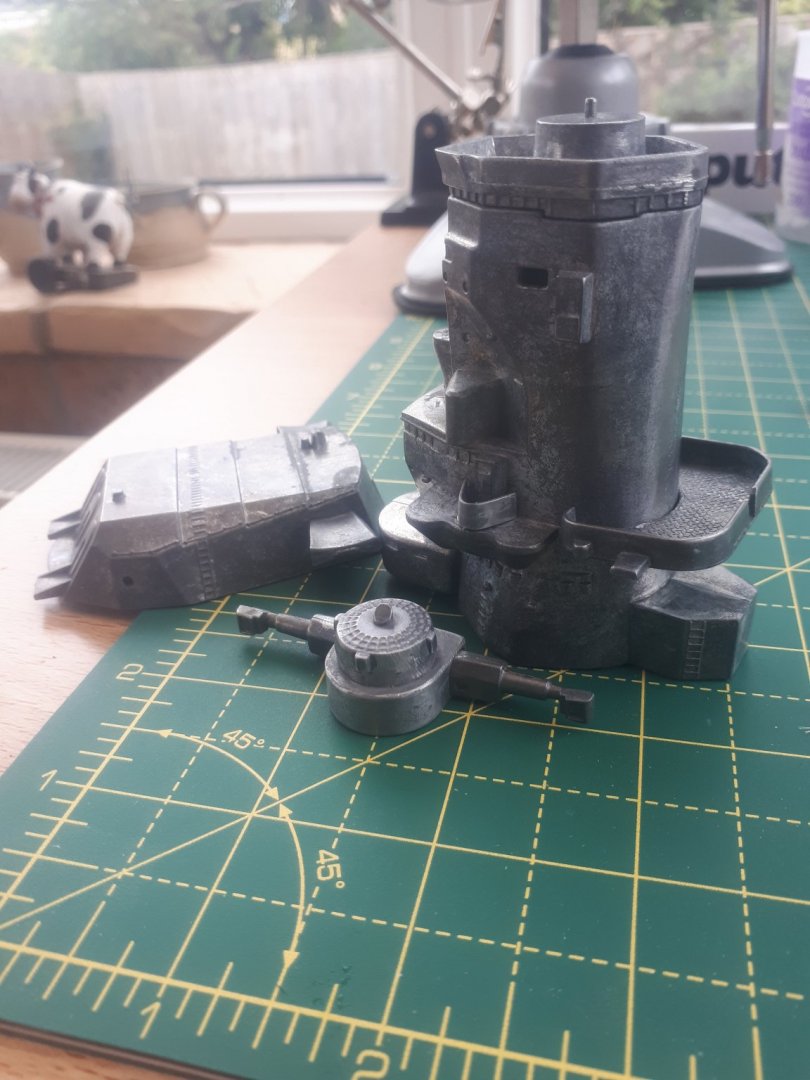

I have sorted out the issue with the gun range finder and using epoxy resin, fitted both parts to the main gun assembly.

I also fitted the flag signalling deck to the bridge assembly. This took a bit of time to get correctly positioned. I made a small wooden jig to aid the clamping of the deck as the epoxy resin cured.

I tested fitted the range finders to the command post, they required a bit of filing before the could be located in the fixing holes.

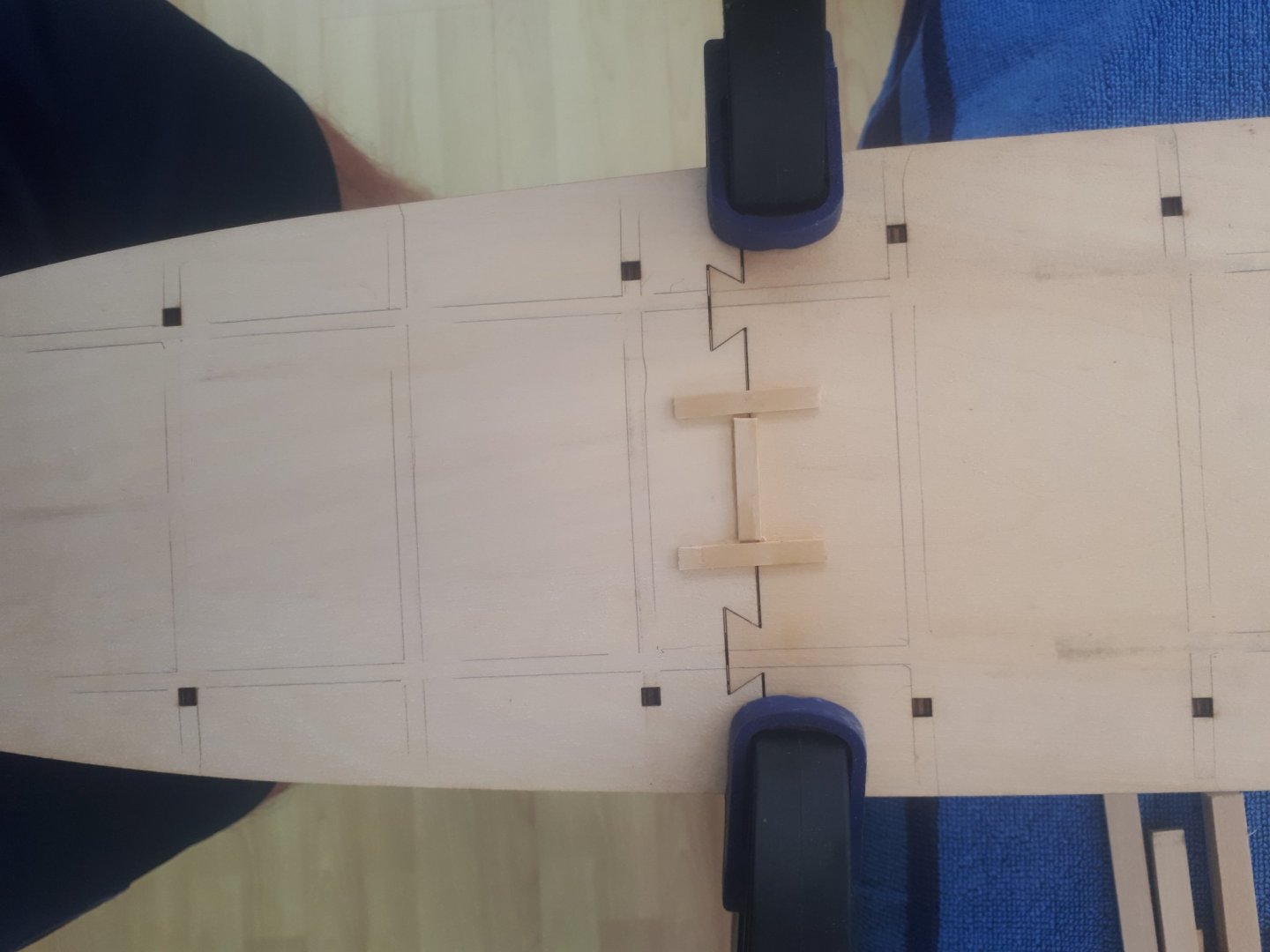

I added a some small wooden strips to help fix the warping issue with the base plate and also applied some wood glue and clamped the two edges. I also marked the position of the bulkheads and support frames to assist me to correctly pin the bulkhead.

Finally I clamped the warped keel support, after I had soaked it in water. This seems to have sorted the problem.

- VTHokiEE, Landlubber Mike, JeffT and 5 others

-

8

8

-

6 hours ago, yvesvidal said:

Very interesting kit. I will be following your efforts with interest.

Obviously, this model will be top-heavy, due to the amount of white metal on the superstructure.

Yves

There is quite a bit of wood required for the hull assembly, especially when the hull and deck planking has been added which I think will balance the weight between the hull and the die cast super structures.

- yvesvidal, mtaylor, Old Collingwood and 3 others

-

6

6

-

Today I have started the build in earnest.

First task was to dry fit the hull parts. Everything went together without any issues and the Yamato is going to be a big model.

There are two parts which are warped however. One is one of the base plates which can be rectified when the bulkheads are glued and pinned in place.

The other part is keel of stern part. I will probably have have to straighten this piece before it is fitted in place.

I fixed the bridge misalignment issue. This turned out to be an easy task as I was able to file a little bit off the locating pins.

I also looked at the first big gun. There are a couple of minor issues that needs to be addressed. The first one is the wooden based plate is a tad to big and a couple of the edges need to be trimmed.

The second issue is one of the two range finders does not fit in the slot provided so will require a bit of filing to sort that out.

-

51 minutes ago, maaaslo said:

this is weird way of building superstructures. i know its cheap, but seeing your example, i would tend to think that probably more common than one would welcome in such expensive toy...

well, you certainly took some challenge head on.

It is not a cheap kit to buy, looking at other examples of this build, there are not too many build issues to contend with. There is a lot more detail to add to the bridge and the slight misalignment would not be noticeable when complete. However better to correct it, if possible, in my opinion.

-

First problem encountered. There is a slight alignment issue with the bridge assembly due to position of the locator pins. It is only a fraction out but it does not look right as the right side is lower than the left. I have a few different options in mind to sort this out which I will experiment with.

-

Starting a new project which is bit of a departure from my previous projects. I have bought (and received) the full kit for the 1/250 scale model of the IJN Yamato.

This is mixture of standard wooden hull construction, photo etched parts and die cast metal parts for the superstructures and guns, etc.

I have had to sort through the delivery and I believe I have received all the parts, there were 90 different packs. The kit does not include a build manual but this is available on line in pdf format as 22 separate files. I have printed out the first 12 files.

I have been following the progress made by John Builds Iconic Military Models on his YouTube channel, who is currently building this model. This is going to be a great help. There is also an official build log on the Model Space forum which will also be checked from time to time.

The first picture is the first 16 packs, 4 packs required per build file document.

The next picture shows my workstation which is ready for me to start work.

-

I have the proxon lathe and it has been an invaluable tool for production of masts, yards, booms, etc.

-

I have not done an update for a while. I have decided to take a different approach and I plan to only part rig the build. The rigging instructions are very easy to follow but with my poor near vision, and my extra large hands I'm been finding it a challenge.

Also I have a new project starting shortly with a 1 / 250 scale build of the Yamato.

- egkb, JpR62, Edwardkenway and 5 others

-

8

8

-

-

Just now, Suzdal said:

What was your solution ? I hope to build the "Flirt" as my next project.

Richard

I taper the edge of the thread but cutting at approx. 45 degrees across the thread which really helps. I normally run a 0.6mm micro drill through the 3mm block holes which seems OK for the most part but I have increased the micro drill bit size to 0.7mm when the thread is 0.25mm which seems to have done the trick.

-

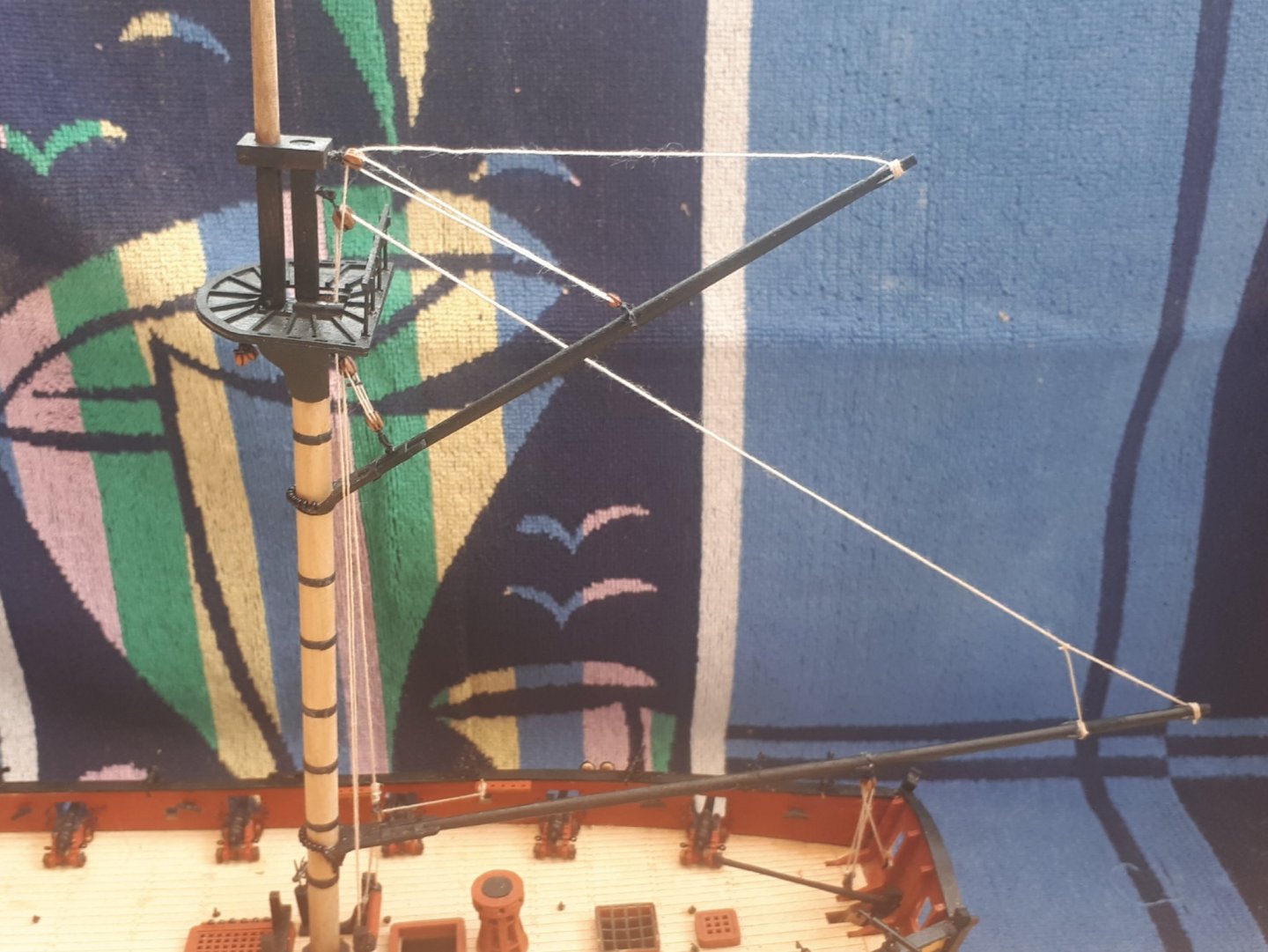

I have now finished adding the boom and gaff. I did have to redo the boom because I made a fundamental rigging error with the boom topping lift rigging, as I took it through the wrong double block on the main mast.

I did find it difficult threading the 0.25mm natural thread through the 3mm single blocks even when the end was hardened with ca, but eventually found a workable solution.

As I have said before I'm not very good at rigging, or taking photo's but I'm getting a bit better at the rigging.

- DelF, KARAVOKIRIS, GrandpaPhil and 4 others

-

7

7

-

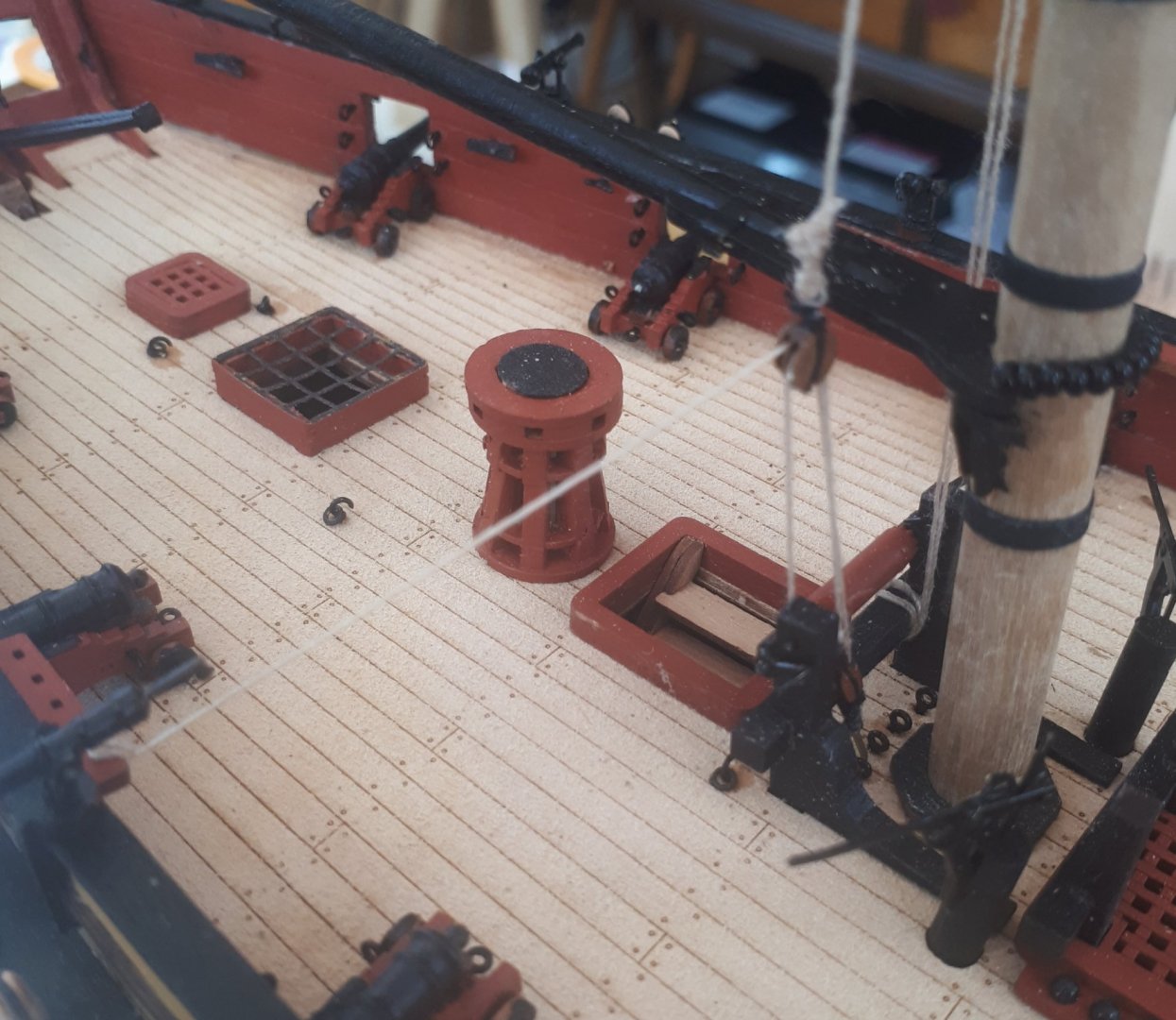

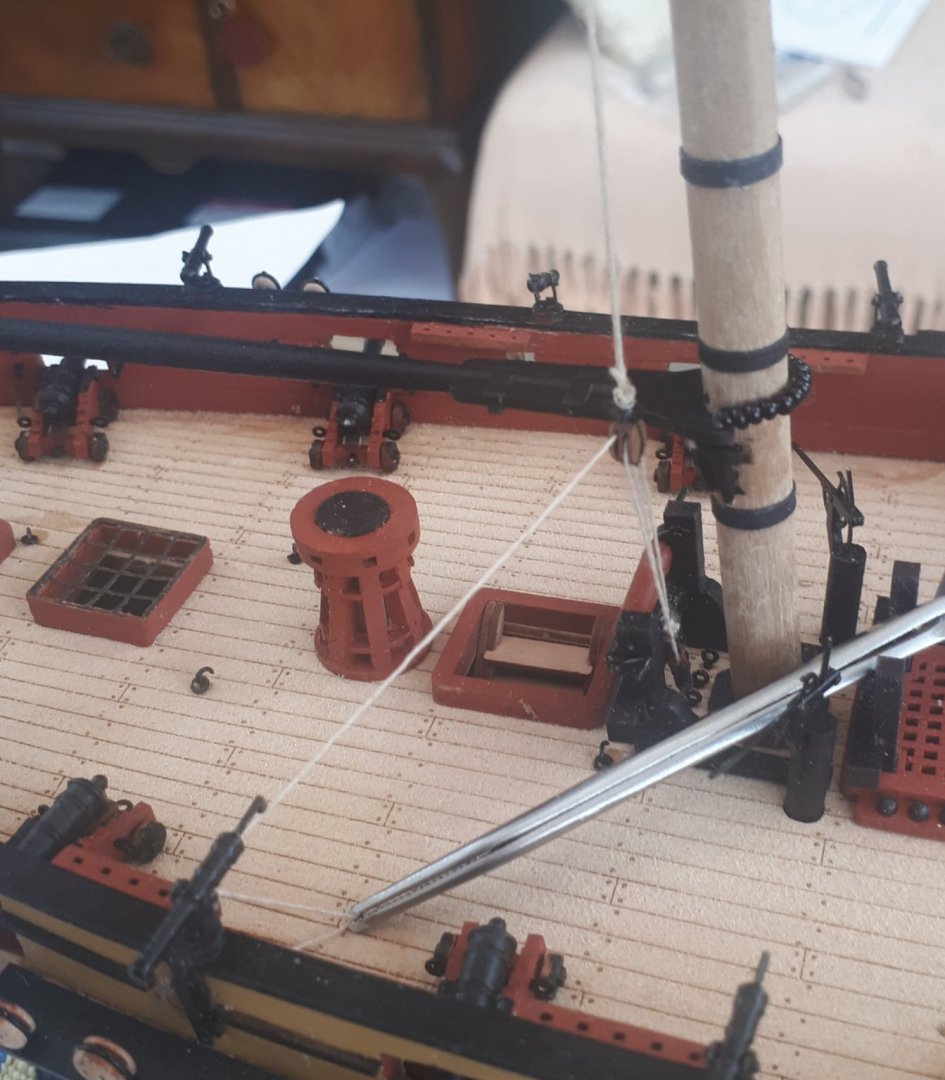

My progress is slow at the moment. I have finally installed both the rudder and the main mast so today I started work on adding the boom prior to fitting the shrouds.

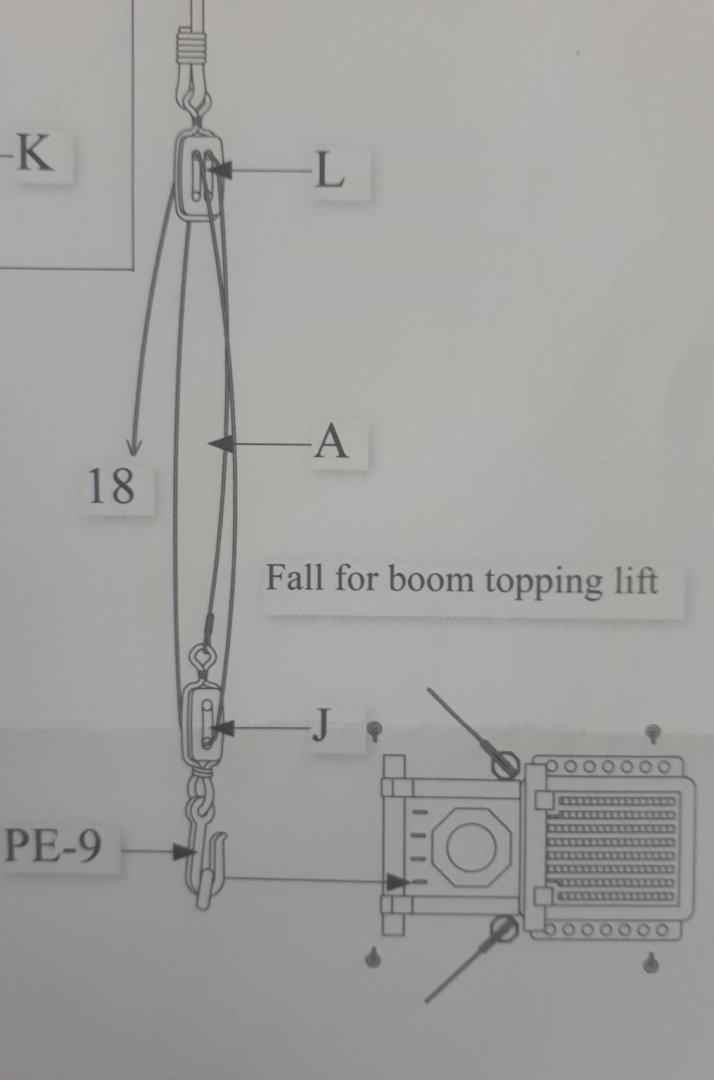

As can be seen from the plan sheet there is a nice double block assembly required for the boom topping lift.

This took a little bit of time and effort to get the loops on the blocks, but it was not as difficult as I first feared and the boom was fitted and the topping lift added without to many problems. I just need to finish off belaying the drop. I have positioned it around the belaying pin, but I needed to take a break so will come back to it tomorrow to finish it off and add the other boom rigging. I will also add and rig the gaff in the next few days before I start work on the main mast shrouds.

I realised that I had not fitted the cleats to the stern patterns so it was a bit tricky drilling the holes with the tiller and cannons in situ, but I took my time and managed it without incident.

- egkb, Jonny 007, Edwardkenway and 5 others

-

8

8

-

-

I have continued work on Speedy, at a much slower pace due to the nice weather which means working in the garden. Also I do not enjoy the shroud work and I can always find a good reason to put off starting.

I have finished making the main mast and will start with the standing rigging over the next few days. According to the manual and rigging plans I should start with the shrouds. However when looking at the build photos the gaff and boom were fitted to the main mast by Chris prior to the shrouds. I think this makes sense as space will be limited once the shrouds have been added.

- ErnieL, JpR62, GrandpaPhil and 4 others

-

7

7

-

28 minutes ago, DavidG said:

I follow the below diagram for attaching the deadeyes.

Your diagram is similar to the method used in Donnie's YouTube video and as shown Lennarth's excellent book. I did struggle to replicate this. I think I need to spend some time practising to be able to rig in this manner. I know what I did was not correct and looks a bit messy but it the best I can do at the moment.

The biggest problem I had was the catharpins, but after much swearing, several refits I got to a workable solution for this build.

-

Adding the futtock staves, catharpins and futtock shrouds to the foremast shrouds turned out to be more difficult and complicated that I expected.

Rigging the shrouds was a fairly straight forward task. The futtock stave did not appear to be that complicated but I soon ran into problems when adding the catharpins with unwanted twisting of the shroud. After several attempts to get it sorted I finally managed to get it looking passable so was able to add the futtock shrouds.

The completed lower foremast shroud rigging is not great, 2 of 10 at best as can be seen from the photos below. As far as I am concerned the task is now complete and will be acceptable once the rest of the rigging is complete. I hope to do a bit better when I start to rig the main mast shrouds, futtocks, etc.

- Edwardkenway, egkb, GrandpaPhil and 5 others

-

8

8

-

8 hours ago, glbarlow said:

"Tie a loop with one loose clove hitch slide it to get close, out the deadeye in use your jig to set the distance....."

Thanks for this. I have just tried the clove hitch method on a test piece, looks better and seems to be more manageable. I will try this on my actual shrouds and I report back in due course.

Donnie's YouTube method replicates what is illustrated in Lennarth's excellent rigging book and I have concluded it is too complicated for me for the time being.

-

I'm not very happy with how the shrouds are looking. It is clear I'm not very good at this rigging lark. I have now taken the decision to start again. I need to practice how to seize the shrouds around the deadeyes neatly, I was getting better when I did the one on the right in the attached picture.

The problem I have is wrapping the seizing around the shroud without it unwrapping and looking a mess. They make it look so easy on the YouTube videos. I think I will use black thread as used in Donnie's video's rather than natural.

- GrandpaPhil, Edwardkenway and egkb

-

3

3

-

-

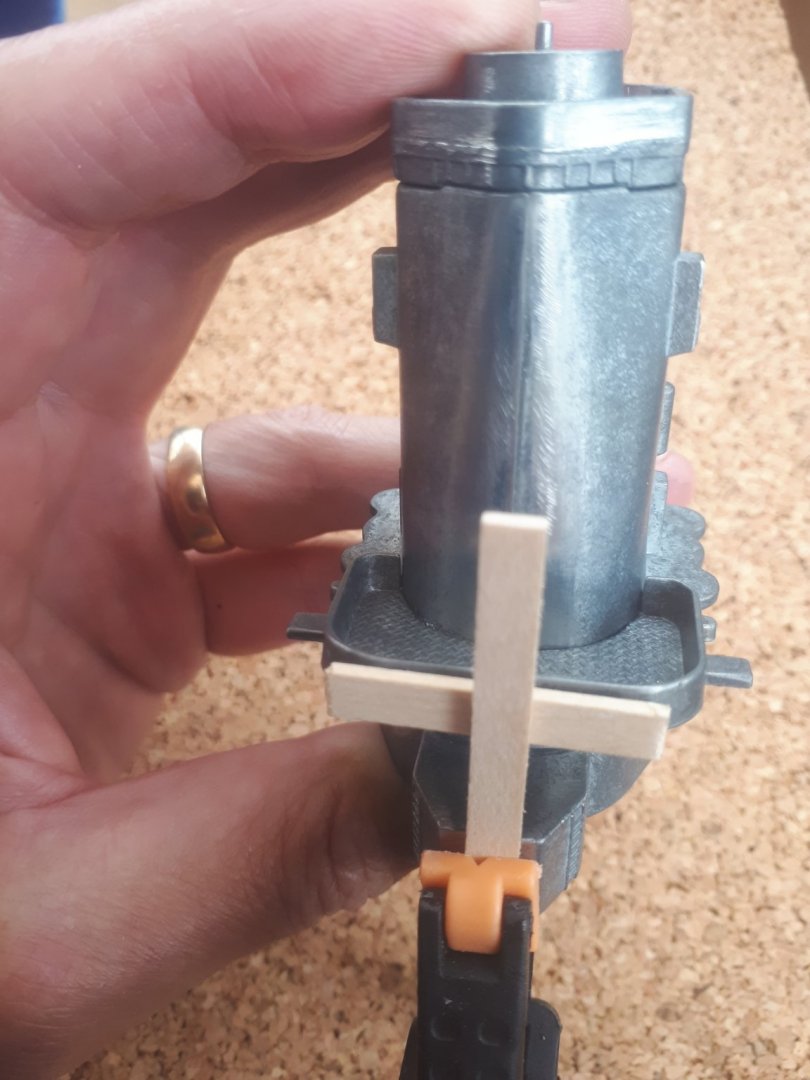

I have finally started with adding the shrouds.

I used a brass jig to set the gap.

Deadeye seized to shroud. I by in large followed the method shown in Donnie Driskell YouTube video for ths task.

As the shroud line was tensioned when the lanyard was added the top deadeye ended up a tad lower than I would prefer. The bottom edge of the shroud deadeye is about level with the top of the bulwark capping. I'm undecided as to leave as is or to start again, but I currently edging towards leave as is.

- egkb, Edwardkenway and Jeff-E

-

3

3

-

- DelF, Rudolf and EricWilliamMarshall

-

3

3

-

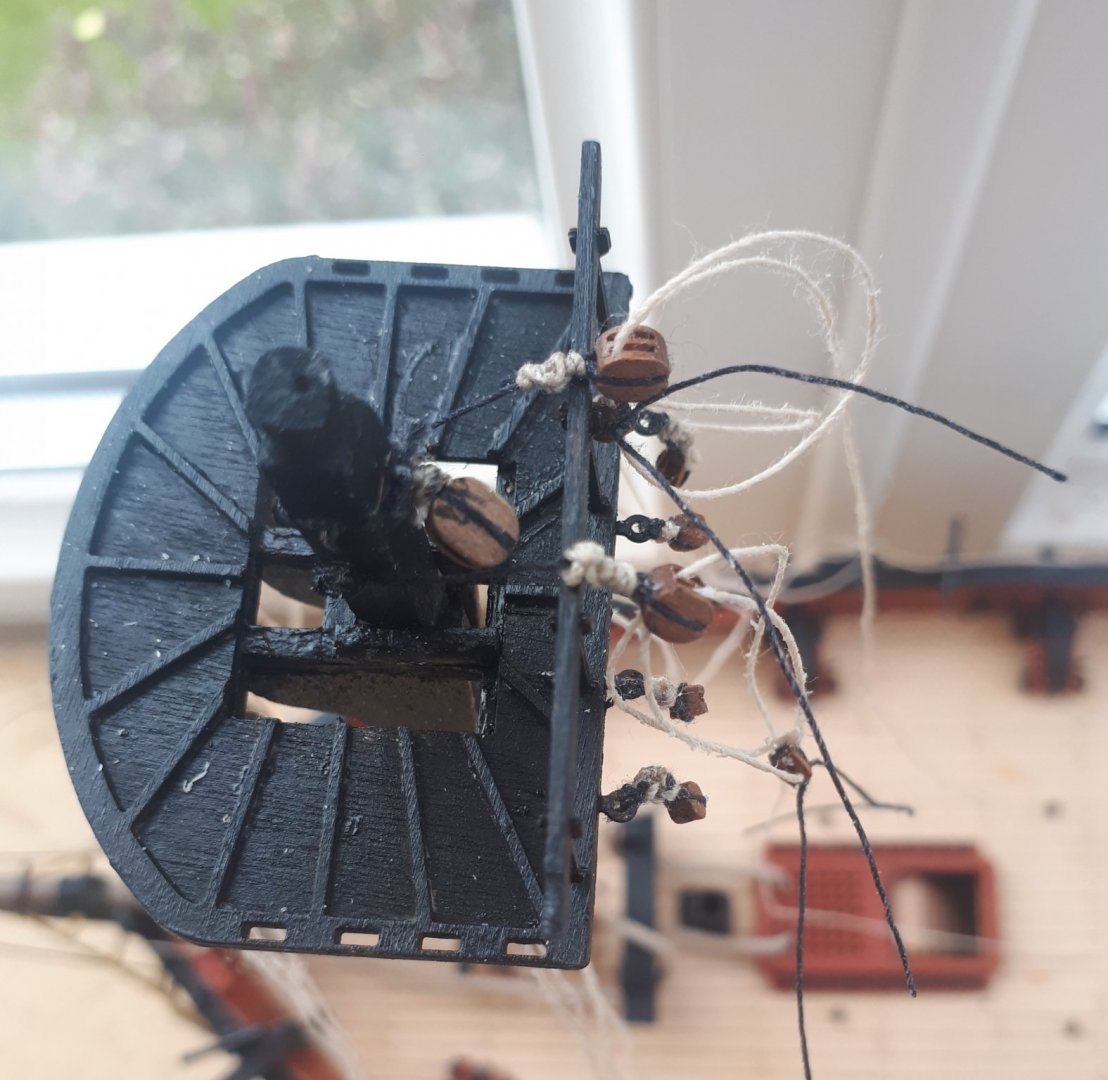

I have now started work on rigging the Fore Mast. I was going to follow the instructions and start with adding the shrouds, which is standard practice. When completing the fore mast tops I fitted the 18 blocks, a mix of single 3mm and 4mm doubles. When studying the rigging plans I noted that these blocks would be used for the mast stays, lifts, sheets, clews and the spritsail yard braces. Furthermore access to 14 blocks of these blocks may be tricky given that would be located on the underside of the fore mast top and would be partly obscured by the shrouds.

Therefore I decided to add the 0.1 and 0.25mm natural thread in these blocks, before adding the shrouds. As noted by the "Other Glenn" in an earlier post my Foremast now looks like a shaggy Christmas tree as can be seen in the photos below. I now believe I can fix the fore mast in place and start adding the shrouds.

After the threads have been tided

The blocks that are dangling over the stanchions are the two double blocks that that hang lose and they are (I believe) the two mast stays (or tyes). I have included the single 3mm single blocks in this rigging stage so they are ready to be fixed to the main (lowest) yard.

Adding the 0.25mm thread through 3mm single blocks is a bit of a challenge but is doable with a bit of care and patience. My method was to

a) Apply beeswax to the thread

b) Stiffen the end of the thread using ca.

c) Make a diagonal cut across the stiffened end to made a pointed end.

- egkb, Richard44 and GrandpaPhil

-

3

3

-

-

I have been working on the foremast today making sure everything is ready before I start adding the shrouds. I realised I had not added any of the hooks and eyebolts to the deck. I drilled the holes and fitted them as per the plan sheet. If I had my time again I would pre drilled the deck assembly before it was fitted. Doing it after all the deck items had been fitted made it a bit tricky but I did manage it without incident. I also glued the cannon balls in place.

Before I started the shrouds I noted that the Fore Top assembly required 16 off block adding. I decided to complete this before gluing the Fore Top assembly to the lower fore mast.

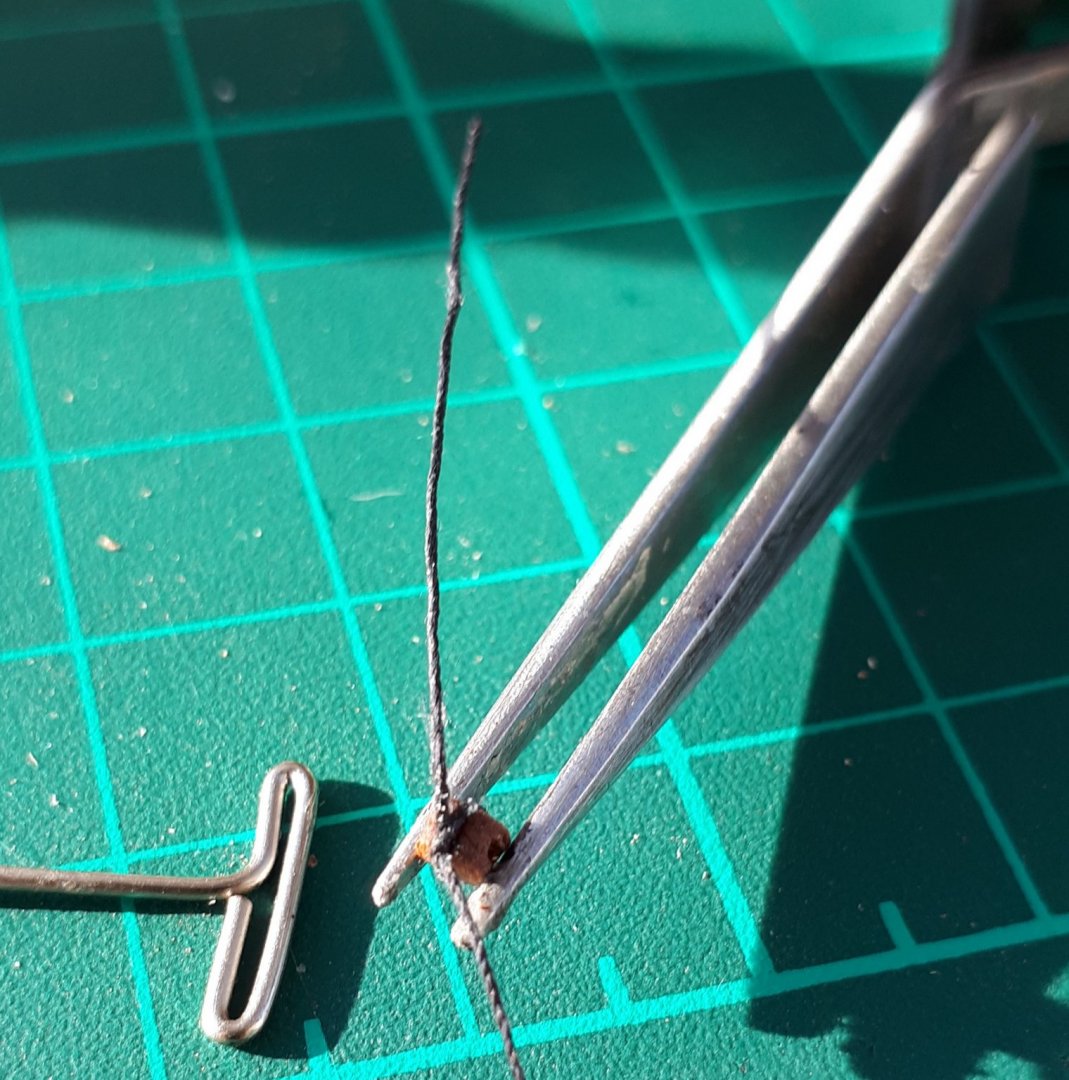

I thought I would share my current method to rig these blocks. I did try the method shown on J Brent's YouTube video which I think is a great method but I could not seem to get to grips with it. I don't think my method is the best or correct method but is one that works really well for me.

Step 1 - I check the holes in the block are clear, using a 0.5mm micro drill bit.

Step 2 - I place the block in my reverse action tweezers and add the black thread, carefully positioning the half hitch knot to one end of the block before adding a touch of ca glue.

Step 3 - This is where I could do with a second set reverse action tweezers, which I have now ordered. I hold the block in one set of tweezers (with a croc clip as these are not reverse action). I hold the black thread ends fairly taut using my reverse action tweezers. I then add the whipping using some natural thread, I normally try to whip the thread 3 or 4 times. Finally I add a touch of ca and trim away the excess natural thread.

Step 4 - I thread both ends of the black thread the eyebolt (in opposite directions) and secure with two half hitch knots, one either side of the eye bolt. I add a touch of ca before trimming away the excess thread. As you will note from the following picture I'm not very good at taking photos.

- egkb, DelF, GrandpaPhil and 1 other

-

4

4

IJN Yamato by Glenn-UK - FINISHED - DeAgostini & Model Space - 1/250 Scale

in - Kit build logs for subjects built from 1901 - Present Day

Posted

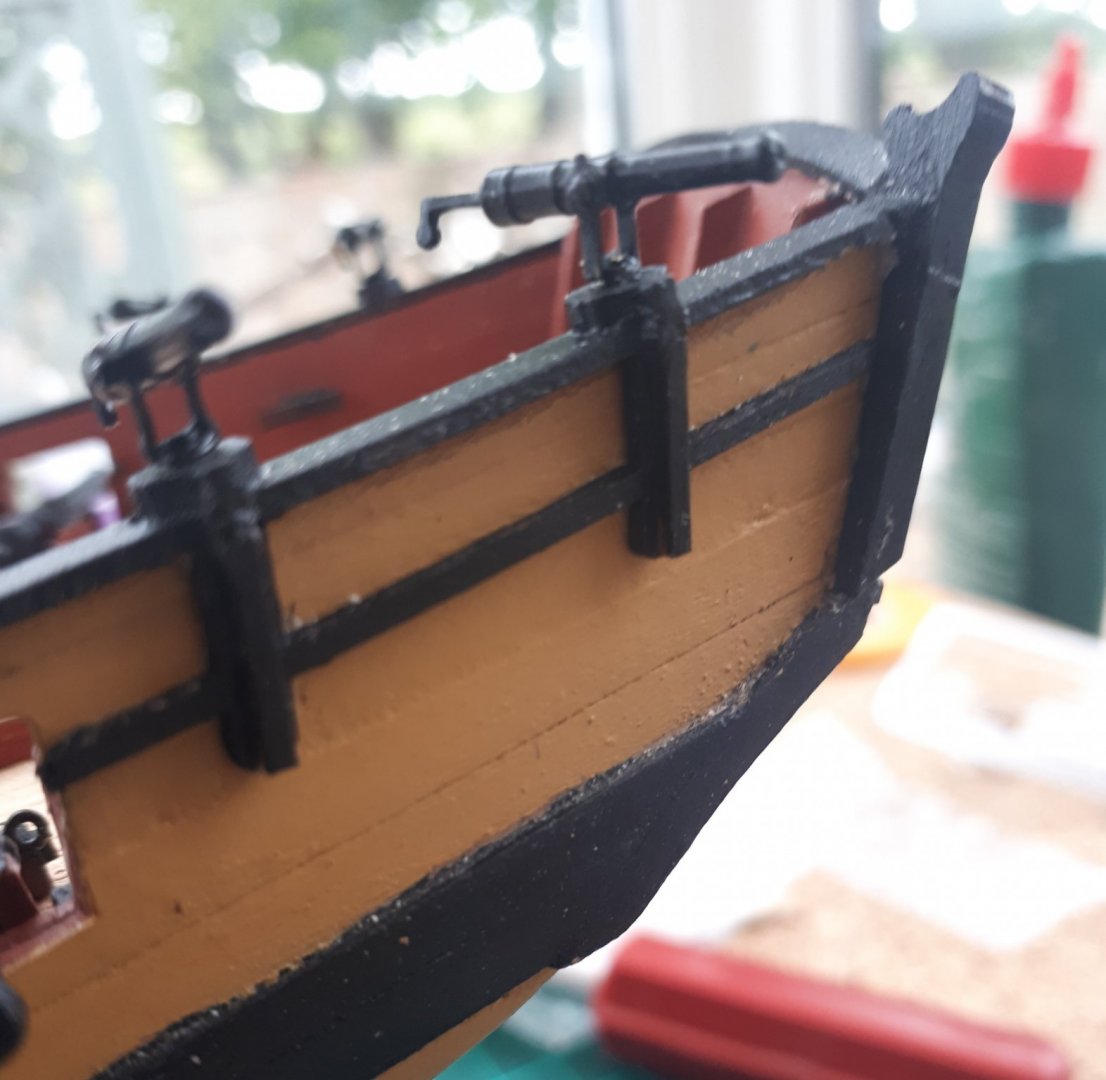

More work undertaken today on the bridge and hull

Bridge Work

I have added some more bridge parts. I made another small wooden jig (10mm one edge and 11mm the other edge) to support one piece as the epoxy resin sets.

Hull Assembly

I have now glued the majority of the hull bulkheads in place. I still have a slight issue with the warped keel support piece but it is almost straight. I'm just giving it one more clamping (after soaking in water).