-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Carl, Start a build log with this in the kit area instead of here as this is for introductions by new members.

-

Nice work, Steve. I think you've got this down.

- 48 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Amazing work, my friend. So tiny yet has lots of detail.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Welcome back home, McSpuds. How did the Syren build go?

-

Push sticks, in my opinion are mandatory. I also use feather boards. I got lucky and had one kick back early on and it embedded itself in the wall about 10 feet from the saw. Note that this is a MicroMark table saw. The full size ones I left the anti-kick assembly on the saw and still stood off one side.

-

Model Railway Cars by Canute - 1/87 - HO Scale Rolling Stock

mtaylor replied to Canute's topic in Completed non-ship models

Ken, The attention to the details is impressive. I really never knew that things had went way beyond the old Lionel days or even the more detailed HO stuff of 20 years ago or so. -

Hello John, Welcome to MSW. I find it hard to believe that's a first build. It is just incredible.

-

I'm smiling at the re-work. As for the "blue line", hold off until you get the bulkheads installed and can check the "flow" across the top to it. Better to wait and see than wonder how to put the wood back if it needs to be there. It does appear that the "slot" is also too high but... I'd hold off as long as possible and check the fit after the bulkheads go on.

-

Warped frames

mtaylor replied to jdbondy's topic in Building, Framing, Planking and plating a ships hull and deck

JD, Definitely nose around a bit in the Scratch area. You can also "fudge" a bit and say go to 1/8" on the frames (1/16" per layer) unless you're leaving some frames exposed and going for historical accuracy. The "catch" with Hahn is that his framing is his own not historically accurate. So there's a Catch-22 there. -

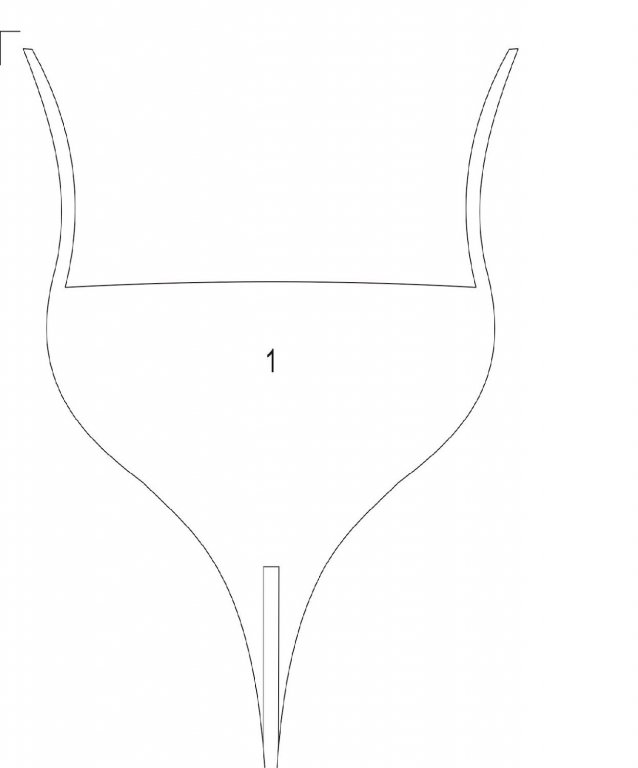

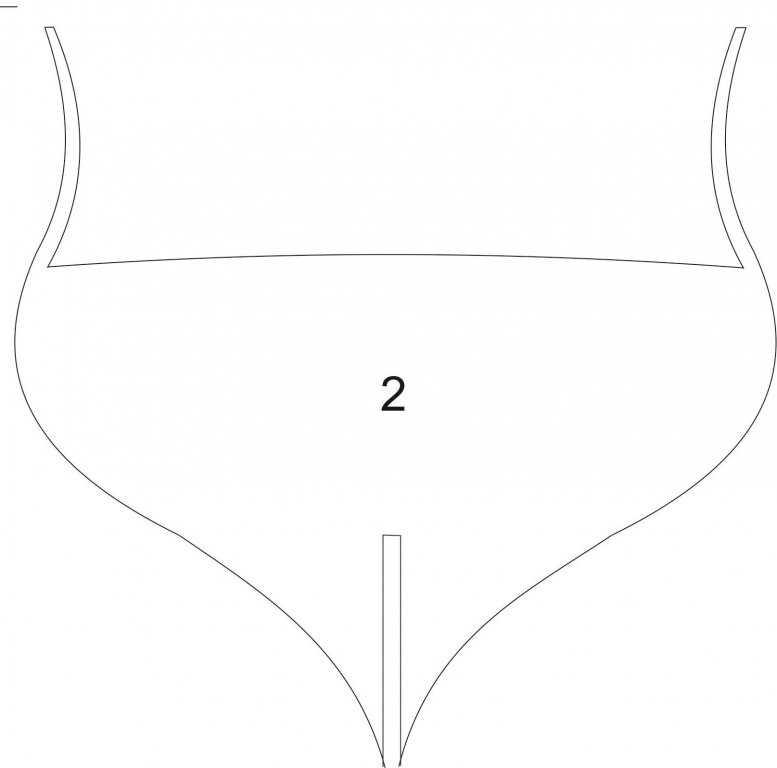

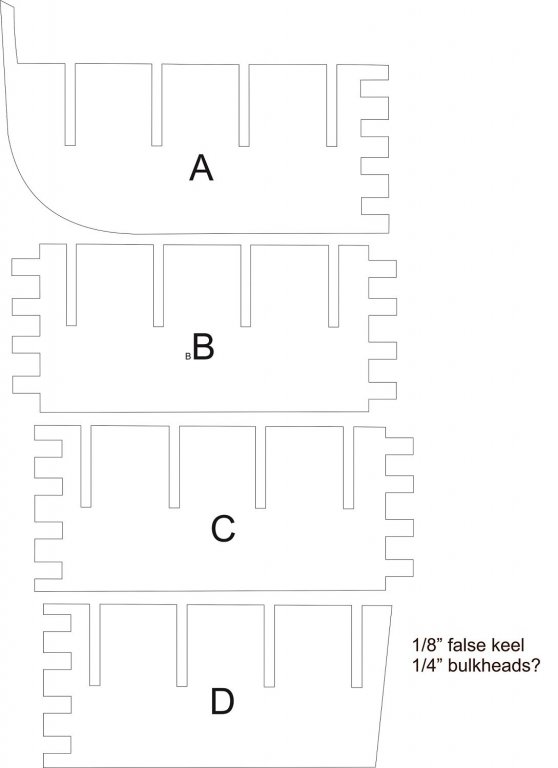

Worked on the false keel today. I'm planning on cutting it from 1/8" ply then affixing it to keel which is 3/16" boxwood. I'll glue and pin it in place. I'll also be gluing and pinning the bow spit, etc. into place. Here's the drawing. I building in interlocking slots to get a good fit and then probably will lay some 1/16' or 1/8" stock to reinforce the joint. Since there's only (roughly) 1 1/4" of free space between bulkheads, it's a bit of squeeze to get reinforment in place. The deeper I go into this, the less my head spins. Next will cutting the bulkheads. That should be fun... there's also some stern framing for the counter. I'm giving thought (not serious yet... keyword "yet" to filling in between the bulkheads and other bit with basswood to give a solid surface for planking. I'm also musing over the thickness of the bulkheads. If I go with the basswood filling, they don't need to be as thick which makes for easier cutting and lowers the cost of the ply.

-

Jo, I think that once you get it apart, I'd sand/file slowly and carefully and checking often, the area in part 16 where the keel sits. The other photos look like the keel is pretty square so just a bit fine tuning the stern post. I'd start by rotating part 16 on the plans and then mark where the keel notch needs to be filed and do the filing.

-

Looks great from here also, Kevin. I'm not going to "like" that broken line post though.

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

It's great to see you back and on the Constellation again, Jerry.

- 553 replies

-

- sloop of war

- constellation

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.