-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

David, There's been quite a few who have used silkspan. John Tilley, in this article also suggests it: http://modelshipworldforum.com/resources/Rigging_and_Sails/ScaleSails.pdf It's an old article and many of the links are dead but it's still valuable for the techniques.

-

Great looking launch, Matt. The details really make it pop!

- 425 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Rock on, Popeye. I guess I'm surprised by the concept of a green net but then, I'm not a fisherman in the ship sense. Or any sense now that I think about it....

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

Fantastic work, Augie. Other than that..; I'm pretty speechless.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

What a great idea... I like it as I think (not sure yet) I have chicken coops to do.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Hi JP, Will you be bashing or doing an out-of-the-box? If you're going to bash, have a look here: http://ancre.fr/en/monographies-en/20-monographie-de-la-renommee-fregate-de-8-1744.html#/langue-anglais There's photos of the completed model per the ANCRE plans which point out at least one error. La Renomme didn't have "billboards" like the English ships but the entire bow section above the wales had heavier planking. As I understand it, this is pretty good kit of her.

-

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Congratulations, Captain. Great looking vessel and properly fitted out.

- 625 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Sweet work, Popeye. That air horn is perfect. As is everything else.

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

H.M.S. Victory, Heller, 1/100, Onward and Upwards.

mtaylor replied to Izzy Madd's topic in Plastic model kits

I suspected you had a faceplate for your ropewalk because of the 4 additional holes. Thanks for the explanation of the extra gear. That makes perfect sense to me. The ports don't follow the waies, they follow the deck. Thus the yellow stripe is between the wales and follows them. If you look at the real beast, some of the lids actually have the extra thickness so that when they're closed the main wale is unbroken. That's part of what they were, defense against small arms fire for the gunners. In foul weather, a canvas tarp was put over them (on some ships) and on others, the hammocks went below. -

I thought it got answered here: http://modelshipworld.com/index.php/topic/9614-how-is-the-pudding-spar-attached/

-

Ouch... didn't "like" that post as I know how frustrating that can be.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Sweet update, Popeye. She's almost there.....

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

H.M.S. Victory, Heller, 1/100, Onward and Upwards.

mtaylor replied to Izzy Madd's topic in Plastic model kits

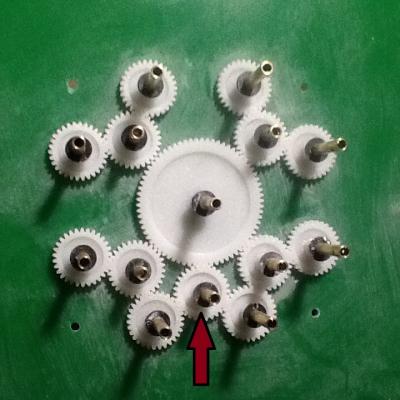

Izzy, I'm not sure but I think you've go one too many gears.... this might account for the drain on the dilithium crystals. -

That's good news, Grant. Carry on but don't chase the staff for a few more days.

- 456 replies

-

- finished

- bomb ketch

-

(and 2 more)

Tagged with:

-

Grant, Modelbuilders and those who draw many of the plans usually seem to simplify things. From everything I've seen, it usually a "block" with a sheave mounting in or atop the bulwark. I'd think that if it were just a hole, that's inviting wear on the line. Maybe a really small ship might just have a hole...

-

Looks great on the base which has just a bit of a weathered look to it. Seemingly proper, in my mind. Good luck on tomorrow and that was great news on the prostate.

-

Specifications for Construction of U.S. Navy Ship Models

mtaylor replied to Rob Wood's topic in Nautical/Naval History

Hmm... interesting discussion. I wonder also about some of the new technologies and the longevity of them. Such as 3D printing. The metal might or might not hold up but what about the plastics? Some 3D people I've run across are touting "bio-degradable" plastics because apparently there's a bunch of waste generated. This might be fine for quick prototyping but not much else, yet they want everyone to go that direction.- 16 replies

-

- Specifications

- US Navy ship models

-

(and 1 more)

Tagged with:

-

Best wishes on the surgery, Grant. I'm sure it will go well and yes, the quality pharmaceuticals do help a lot. My admiral has had multiple hip and shoulder replacements and it seems like the procedures have improved vastly, even in the last few years.

- 456 replies

-

- finished

- bomb ketch

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.