-

Posts

1,054 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Thistle17

-

Hobby saw with larger table top

Thistle17 replied to ONEVW's topic in Modeling tools and Workshop Equipment

Thanks Jim. Final questions: Outside of shipping how long is the retrofit time? Are there any alignment querks/needs to remount to align with the arbot? All I send is the table top sans the fence rails but with the rail mount blocks right? Joe -

I too am building Cheerful. As I rate myself higher than a "newbie", but by no means a professional, there is so much to learn and do that is relatively intracate on this model it bears proceeding with a good deal of respect even though it is a kit of a higher level with quality components. I am detailing out the deck fittings at this point. It might be of use to you to know that the decking I found harder than the hull planking. I think one of its characteristics is that there is no denying its quality assessment as it stares at you. Also beware the widlass is tricky. About 60 parts of small dimensions where tolerance build up becomes a large factor. The good news is that once you reach this level of the build it gets even more satisfying. Joe

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It is hard to imagine what you can create to top this for your next model offering. Joe

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

In terms of accuracy don't let your engineering mind take you over the edge. That is my background as well and I know the feeling. From an accuracy standpoint I offer that you will be just fine. Keep in mind that there are very few rectilenear elements on a ship or boat as compared to a house. If you want to increase your accuracy beyond your adjustable square then treat yourself to a set of engineering squares (fixed blade, varied sizes). They are relatively cheap and they remove the variabiluty of your run of the mill adjustable version. I use them all the time in both woodworking and modeling. Joe

-

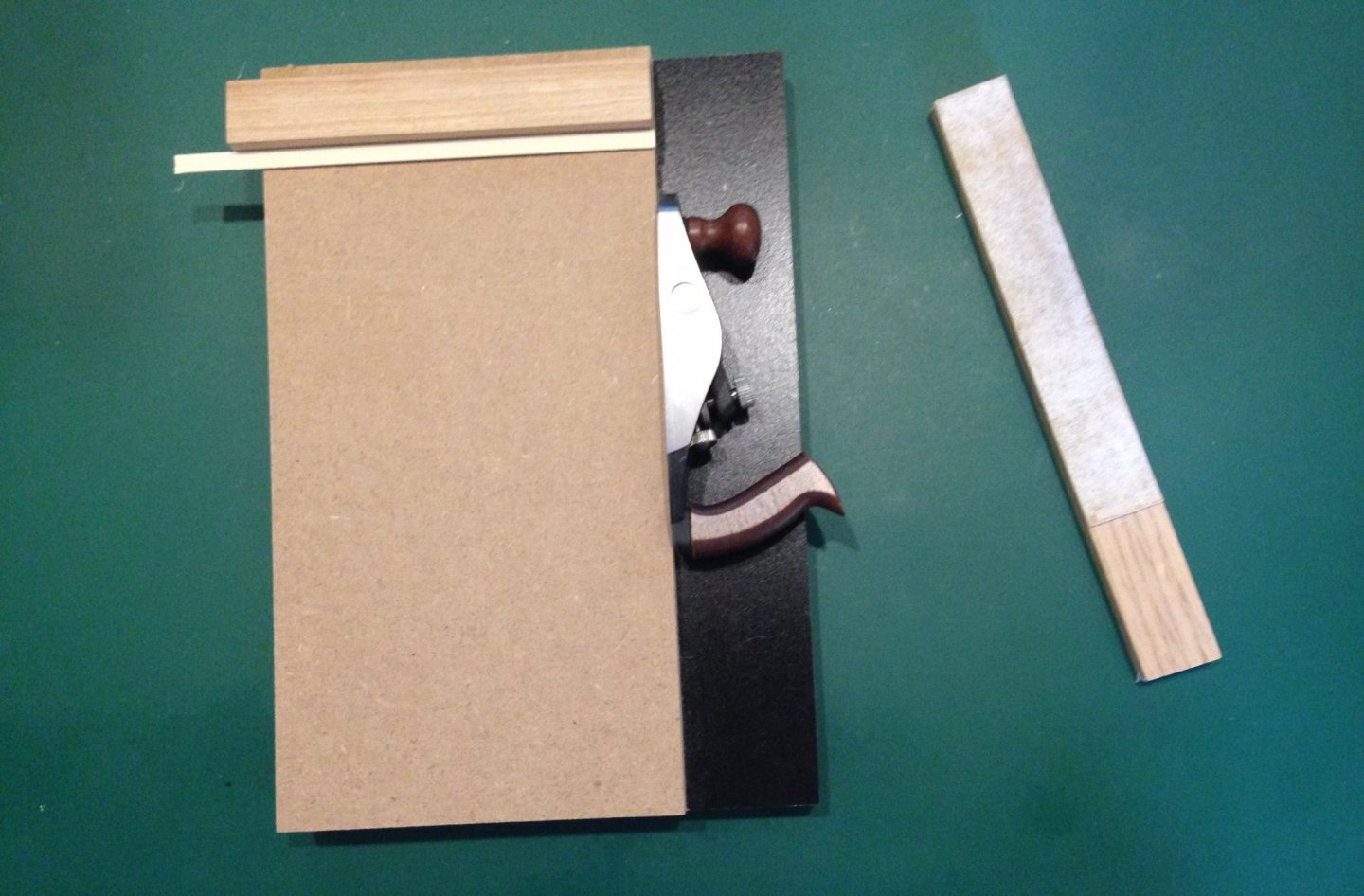

It is not uncommon to need to refine angle cuts. I wish I had thought of this jig when planking the gun pports of Cheerful. Initially I had thought I would create another jig for the truing of angled cuts but after thinking that one jig might fit both applications and inspecting the commerical one shown earlier it struck me to make a small change to version 1.0. Version 1.1 utilizes the Byrnes sander mitre positioned as shown. I milled a 0.49 slot that yields a tight fit for the bar just deep enough to enable the mitre fence to sit flush with the jig surface. The slot is snug as I did not want the bar to wander into the trimming area. In this position one can trim just about any desired angle in either direction. I will modify the mitre fence by adding a wooden fence that will extend to the trim edge of the jig. I perceive it will need to be slidable to the trim edge especially if one chooses to use a low angle plane to prevent exit breakout. Joe

-

Practically speaking the only elements of the jig I suggest that need to be true are the : the shooting edge where the plane rides and the perpendicular placement of the cross piece or stop. This is easily accomplished with a square to align the pieces. Even a drafting square can help with the alignment. Joe

-

Acoarond I am certainly not an expert on traditional building methods but this just sounds counter intuitive. I think I understand the reasoning owing to the fact that it is very difficult to lay up decking and waterways for a fully framed hull or even a plank on bulkhead version would be a feat. Also given that most vessels were planked inboard why would one go to the trouble when it is all going to be hidden. Not to mention trying to recreate the form of the hull above decks afterwards. Joe

-

Byrnes saw blade biting...update with pic

Thistle17 replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

When "cover" is referenced I have assumed you mean the table insert for the saw blade. If so I would suggest the following from my careless experience. I installed a new blade which had an existing table insert that matched the prior blade kerf. I turned on the saw and it was slightly hitting the side of the insert. I stopped and opened the saw up and to my dismay the saw blade was not sitting flush on the mandrel. The act of reinstalling it correctly did not fix the problem as the blade had slightly distorted. That new blade was rendered useless. Joe -

It is not a coincidence that we all need a tool akin to those suggested here for all types of square cuts or even angle cuts. I made this simple one out of cut offs of MDF. It is modeled after my wood working shooting board. One can use either a low angle plane with a sharp, sharp blade or even sand paper glued to a stick. The plane is the Lee Valley Block plane. I am working on a similar version for angled fine tuning that will incorporate my mitre fence from my Byrnes sander. Joe

-

I am sure you know but just for the sake of it wood swells across its width i.e. perpendicular to its fiber cells. So don't glue them in until you are sure they are completely dry if you go this route. Look on this site for alternate measures for planking. I think you may find these methods preferable. Joe

-

Our group got to see Rusty's model in person last weekend. It is such a warm and rich appearing rendition in pear wood. His execution is skillful aaaaaaaaand all the more so as we remind ourselves that to this point it is all scratch! Joe

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I'm curious. It would seem you are just a few steps from creating of say a DXF file to have your parts machined via laser or cnc routing. is there a reason you didn't go that route? Joe

- 58 replies

-

I too am in the process of building Cheerful in the original boxwood material as offered early on. I haven't posted a build because I have gotten so far behind it is almost anti-climatic to report on it. I will say that after some false starts with planking and the like I am now at the deck level adding detail. So to give you some encouragement it is finally starting to get exciting to work on her as fleeting as that may be. Don't lose heart and as Chuck all too often emphasizes take your time. Joe

-

Your build is coming along just fine. It too was my first build from an AJ Fisher kit that was a solid hull. Plenty of on-line pictures to help guide you and if I recall there was a book out on its build that may be of help. Of course most of the recent info is of II. And I notice that much of the deck "furniture" is for safety or comfort conformance. I did use Erik Ronnberg Jr's manual of Benjamin Latham as a guide as I viewed him as an authority. I have a question for you. When you speak of her as a racer what do you mean. It was my understanding that the original Bluenose raced against some American vessels of the same "class" to see which was the fastest. It is my understanding she was never converted to be a racer as such. Joe

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

This is such a magical trip you are taking us on as your build advances. Absolutely love it! Adding figures and creating the environment adds so much viewing interest. Two years ago we had a member of the Rochester Museum and Science Center in to give a talk on his work on a diorama restoration of early Rochester NY down by the falls (which was the city epicenter for a time). He related they wanted as accurate a depiction of the population represented so they went back to historical records and gleaned enough information to include people of color in the new display. Kudos to you Jond for your similar work! Joe

- 69 replies

-

- diorama

- Glad Tidings

-

(and 2 more)

Tagged with:

-

Thank you for sharing this latest tip Mike. You make the road ahead less difficult! Joe

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Check this site out for properties of this wood. https://www.woodworkerssource.com/show_tree_wood.php?wood=Staudtia stipitata Given what I read I only offer that this wood is going to be difficult to edge bend given its density and reference comparison to maple. You may have to resort to soaking in water or alcohol. I would try a sample piece before I go too far. Chuck Passaro also recommends heat to edge bend in the area of the curve. Joe

-

turning a manual mill in to a CNC mill

Thistle17 replied to garyshipwright's topic in Modeling tools and Workshop Equipment

I forgot to mention that you can get a healthy dose of knowledge from this individual's email and postings. He is quite the CNC enthusiast. Bob Warfield from CNCCookbook <bob@cnccookbook.com> Joe -

turning a manual mill in to a CNC mill

Thistle17 replied to garyshipwright's topic in Modeling tools and Workshop Equipment

At the outset let me say I am not trained as a machinist. Having said that I did invest in the Sherline Mill with DRO capability. I love the machine! I also invested in a Sainsmart 3018 Pro to try to teach myself and my grandson who is in college studying Mechanical Engineering to give him some early hands on exposure to this type of tooling. Firstly let me say I do not recommend that CNC system. It is a learning tool. What I would offer is that we had such a disappointing entry into the CNC world via this product. However as painful a startup as it was, we learned quite a bit about the entire environment. Here are my thoughts: invest in a turn key system of both hardware and software (CAD/CAM) if you don't want to spend all your energy and time stitching together a system. From the standpoint of a machine paying for itself one should have other projects other than ship modeling as Ron suggests. Depending on what software front end (CAD software) you choose, and there are plenty, there can be a steep learning curve for the more powerful/useful ones. Even some of the better ones are freeware to the home user. The more powerful systems (CAD/CAM) allow one to even scan in images, import certain types of files, like DXF files and even with conversion JPEG images. But you may have to learn how to debug and edit 'g code' to have it produce what you want. There is a caution on the import of the more common DXF files. Certain DXF files that were meant for a laser system may need significant editing to have them run a router based system. Node discontinuities are the problem for the most part. These are just a few thoughts that I/we had to learn the hard way' We did this over 2 months of summer trail and error. What made it fun I was spending quality time with my grandson! If all this doesn't deter you please keep this thread alive and we all can learn and contribute with you. Joe -

How did I ever miss this build log! In reading earlier posts I can only say that I appreciate your sense of the what elements of your work bring satisfaction and those that don't that haunt you. I can relate and at times i find it a curse in this model building pursuit. Nonetheless your work is inspiring and a joy to now follow. Your work is excellent. If you are ever in the Rochester area we have a small model group. Our web site is www.modelshipwrightguildwny.org. Although we have members from Syracuse and Buffalo (and even Lisbon Portugal) it would be a trek to have you attend one of our meetings. You may be interested to know that the Niagara Model's group will be holding an open house in June of this year just over the border. They have some fantastic modelers. We plan to attend. Look under the topical heading dealing with model club news and events to learn more. Joe

-

Byrne's saw advice needed.....

Thistle17 replied to CPDDET's topic in Modeling tools and Workshop Equipment

The larger table is still available but not advertised. I inquired about 6 months ago and he would supply it. The rub as I recall was that I had to ship my present table top to him for the rework. I have yet to do so as it is in use for a project. I still wish to do it but can't free up the top. As Mike says check with Jim. Joe -

Byrne's saw advice needed.....

Thistle17 replied to CPDDET's topic in Modeling tools and Workshop Equipment

I agree with Mike on the crosscut sled it is an excellent accessory. As I posted before regarding the tiling table and I must qualify once again I have never used it. However intuitively I am troubled by the "mechanics of the piece being cut tendency to "fall" in the direction of the blade. I would never do so on my full size table saw and as a matter of safety I never cut say a 45 degree cut with the piece trapped between the table and thetilted saw blade. Rather I cut the angle on the opposite side of the blade. I am open to being corrected so please I invite feedback to the contrary. Joe -

I don't know why I missed this MSW thread before but in reading through the progression of the build, not with standing the full scale "model", it is such a beauty and like others like Michael you are gifted! I have such a fondness for small craft. Perhaps it is because of their basic beauty or maybe it is just their fundamental essence and grace. Joe

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.