-

Posts

1,190 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AntonyUK

-

Hi Keith. Mark is spot on with his advice All the ships I have been on do not have any ropes on the deck. They are long coiled and tied with thin lashing and stored on the belaying pin that is used to that that preticular rope is tied to. The only exception to this is when the ropes are being inspected and then they are in coils for short ropes and snaked along the deck for the long ropes. I know there are a lot of photos out there ... but that in for ceremony purpose and not done in normal practice. Regards Antony.

-

Hi Remco. As always truly Exelent craftsmanship with everything. Regards Antony.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Hi Steve. Yes you can fill the Bow section if you want...It will make the planking better. I use balsa blocks the same thickness as the gaps between the bulkheads. Dry fit first and mark both sides to show the excess to be trimmed off. Trim off the excess leaving a little spare to be sanded later. Glue them in place. And sand the contours. Hatchttepartworks is a pain. I still have only got parts 1 to 3. Not happy with them. Regards Antony.

- 40 replies

-

- hatchette

- black pearl

-

(and 1 more)

Tagged with:

-

Hi Andy. She is looking very nice. And very nice work on the masting. Regards Antony.

- 188 replies

-

- constitution

- mamoli

-

(and 2 more)

Tagged with:

-

Hi Divarty. Just catching up with your build The deadeyes are looking Exelent and the whipping is very neat. And yes take your time with the rigging and as you say One step at a time. If you are not sure what goes where just ask. Regards Antony.

-

Xebec by mij - FINISHED - 1:60 scale

AntonyUK replied to mij's topic in - Build logs for subjects built 1751 - 1800

Hi Mij. The ship is progressing very nicely. That method of shaping and cutting the cannon carages is used a lot by the me people on this site. Worked for me as well Please keep the photos coming. This build is interesting as I like the shape of the ship and the style. Regards Antony. -

Hello Garward. That's a very nice set of cannons you have created. And to have a gold award shows the standard of your workmanship. Congratulations on winning and thank you for sharing this with us. Regards Antony.

- 50 replies

-

- cannon

- le fleuron

-

(and 1 more)

Tagged with:

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

AntonyUK replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Hello Doris. Your work is stunning to say the least. Many fellow modellers have said and complemented you on your creation. I cannot find words that match what I am looking at My jaw is dropped to my chest... My eyes have become dilated... Mouth stuck for words...( wife likes this bit ) Looking forward to your next post. Regards Antony.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi welcome to MSW. Time spent preparing is well spent and makes the second layer much easer and lookes better. Don't sand too much as the first layers are thin. Put filler in the shallows areas and sand excess. As far as the ships boats go... Look here http://www.cornwallmodelboats.co.uk/acatalog/amati_boats_oars.html They do many others but thease look very nice and come in three sizes 70mm . 90mm and 105 mm. All the best Antony?

-

Hello Al. Read your build log through today.. In the start you were not quite sure on your capabilitys to build the AL Bounty. Since then your conference has grown like the model and she is something to be proud of Your are looking at the build as if you have been scratch building for many years. With solutions that many on this forum would not have thought of. And a big thank you for posting the log as its nice to read and watch modeller and ship grow together. Regards Antony.

- 265 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Hi shipmates. Thanks for your words of encouragement and likes. Upper deck timbers are now cut and ready for assembly. Will take take a few photos tomorow. Thanks for looking in Regards Antony.

- 209 replies

-

Hello Hans. The Falmouth is a nice ship and from what I read they produce good quality kits. I do have a question... Why import into Norway from the US when you can get it direct from Euromodel . Much less postage and no inport duties. I will be catching up on your build from time to time. Regards Antony.

-

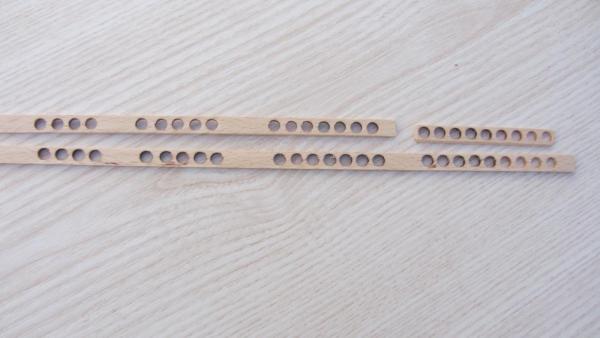

Hello shipmates. Well its time for another small update. Today while working on the topdeck I made a template for the hanging knees. But to my horror I forgot to add then on the middle deck So managed to cut them out and add them to the middle deck. First time I have used super glue on a model ship. And yes I did remember them on the Orlop Deck. Also made up the racks. Hope to get in another few hours later on this week. First its the main beams and all the other timber to be cut down to size. Will post later this week Regards Antony.

- 209 replies

-

Xebec by mij - FINISHED - 1:60 scale

AntonyUK replied to mij's topic in - Build logs for subjects built 1751 - 1800

HI Mij. Nice work on the rudder hindge and the carving are master piece. The Eagle in the photo with the dolphins looks real good.. But looking at the carving on the stern it looks like a camera flash has taken away it's curves. A thought... Try a light stain to bring out the depth of the carvings. And by the way they are by far better than my carvings.. Too embarrassed to post photos Regards Antony. -

Hi. If you are not doing a build log ): then can you do a mini kit review.. I.E. laser cutting, wood quality, instructions, and other bits. Many thanks Antony.

-

Poll

AntonyUK replied to Ulises Victoria's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Hi. When pins are not used for other things they are kept in the holes. Regards Antony -

Xebec by mij - FINISHED - 1:60 scale

AntonyUK replied to mij's topic in - Build logs for subjects built 1751 - 1800

Hi Mij. Duplicate post.. Lagging . Regards Antony. -

Xebec by mij - FINISHED - 1:60 scale

AntonyUK replied to mij's topic in - Build logs for subjects built 1751 - 1800

Hi Mij. Love the little water dragons And the ship is progressing very nicely. Regards Antony. -

Здравствуйте. Исключительное качество и навыки, используемые на вашем, чтобы строить. Качество законченной древесины - превосходный . Looking вперед к больше с наилучшими пожеланиями Энтони Hello. Exceptional quality and skills used on your build. The quality of the finished timber is excellent . Looking forward to more Regards Antony

- 56 replies

-

- bonhomme richard

- finished

-

(and 1 more)

Tagged with:

-

Hi Andy. POF ... Scratch build your Victory. Or even a cross section of the Victory. Consider using laser cutting or water jet cutting for the frames. There are many small company's out there in the UK that will do it for you. I use adobe Illustrater to design the parts then group then on to the area of the sheet and send the file to the cutters. Several company's on EBay UK that will do this service. Ebay listing number. 390791206653 181327979894 111290072017 121297122252 Doing it using this method means very little work with power tools and no Noise. As far as I know there are no POF kits in the UK. Regards Antony. Edited ... Added eBay numbers

-

Hello Alex. Truly outstanding work. Regards Antony.

- 227 replies

-

- cumberland

- 74 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.