-

Posts

4,303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

Thanks, Why did you use white for the rigging? A stupid beginners mistake (I got this kit for free (but without rigging) and had to improvise Which colors did you use and what manufacturer makes them? Tamiya matte colors What wood oil or stains did you work with? matte varnish, the color is old oak

- 63 replies

-

- vasa

- billing boats

-

(and 1 more)

Tagged with:

-

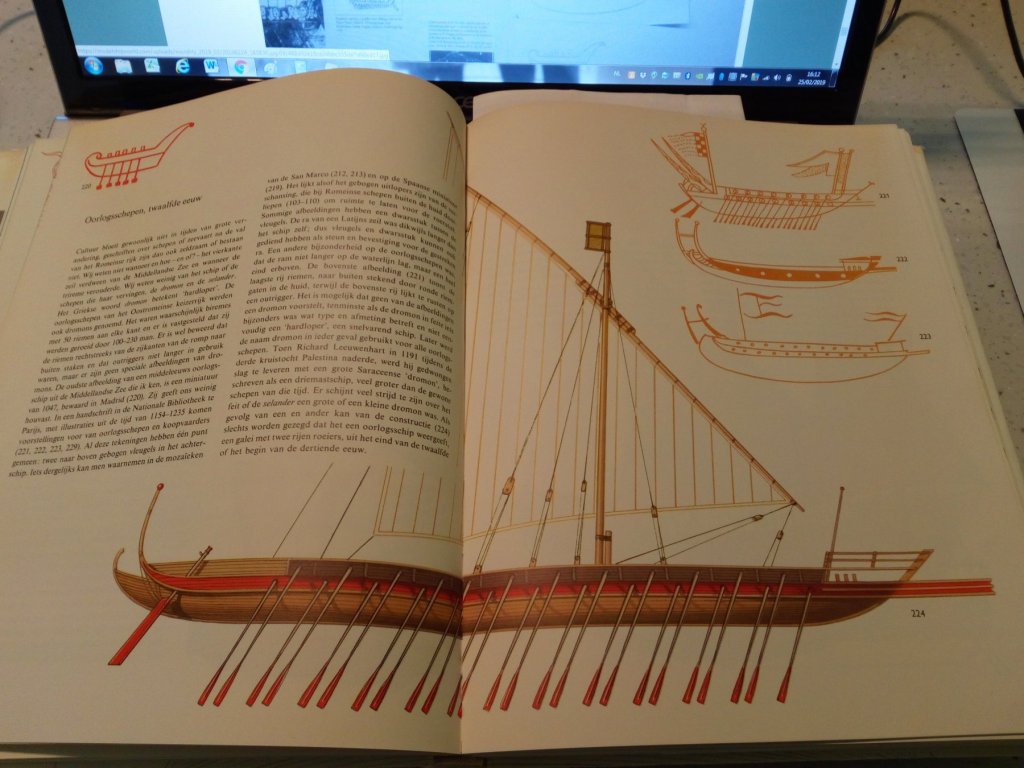

Do not know much about dromons. But the best option seems to be to lower the forecastle. And a horizontal deck looks the most logical. Greetings Patrick

-

Small update, The inside is painted and the waterway is ready. This work me took more time than expected. Thanks for following.

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

Thanks Vossiewulf, I have been working on this ship for a few years now. Nobody knows what this really looked like. And most of the "detailed drawings" of this ship were actually drawn a few centuries later. Probably it was not a real warship but an armed merchantman. Paint schemes are the choice of the builder. None (brown wooden hull), red green white (English) Yellow red (Spanish). Nobody can say that you're wrong (or correct). In the years that this ship sailed over the oceans it will probably have been repainted a few times. And if you are thousands of miles from home, you have to paint with what you have found from the Spaniards ... What is reasonably certain : Below the water line it is almost certainly white (the white stuff) Inside of the gun gates certainly no red (ordinary wood color, brown) Wales certainly not black, that came into use later Greetings Patrick

-

Great work. With all builds of the Revenge, the triangles and stripes on the hull are always beautifully painted. But I have never seen how this is done. How do you do this? With my Golden Hind, I had to cut masking tape for hours before I could start painting

-

And thank you for the link. greetings, patrick

-

Greetings from Belgium

-

Why not move the hole of the ladder a little to the left. Now this is still possible.

- 21 replies

-

Welcome to MSW and good luck with the exercises for walking again.

-

Welcome to MSW. Very good for a 40+ year project

-

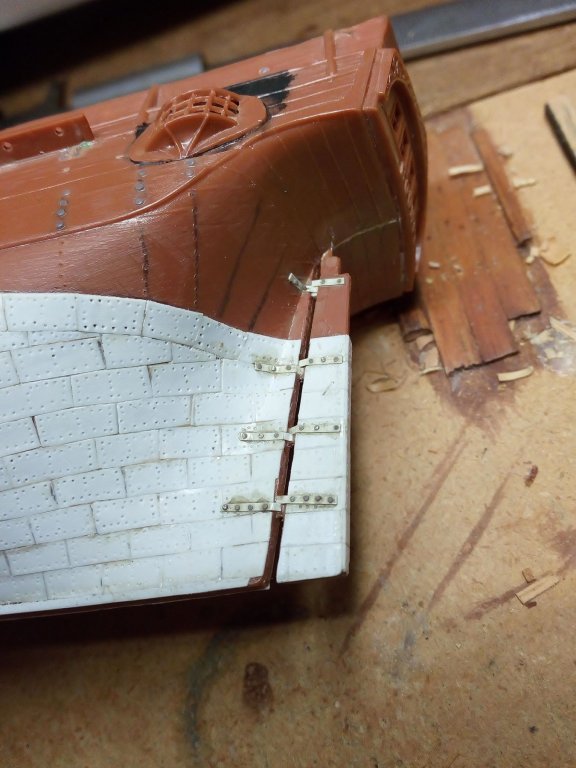

update, The copper sheeting is ready. The rudder now has 4 hinges as it should be (The model had only 3 hinges). The railing has been removed again, it was not really what it was supposed to be. Tested with a metal color, can be okay. to be continued, thanks for following ( Shipyard closed in the summer, on hold until october, november 2019)

-

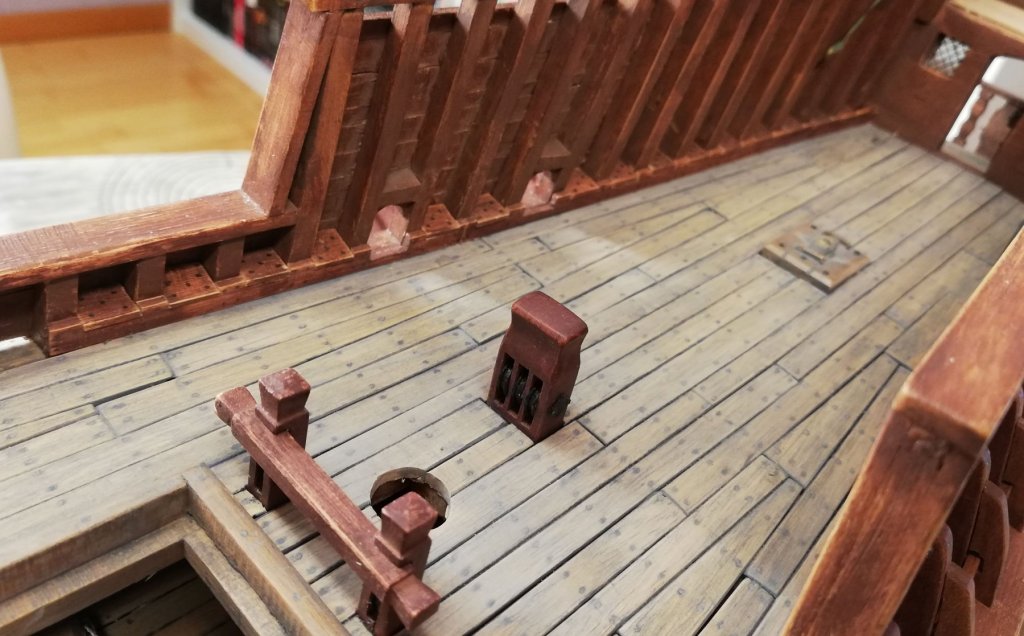

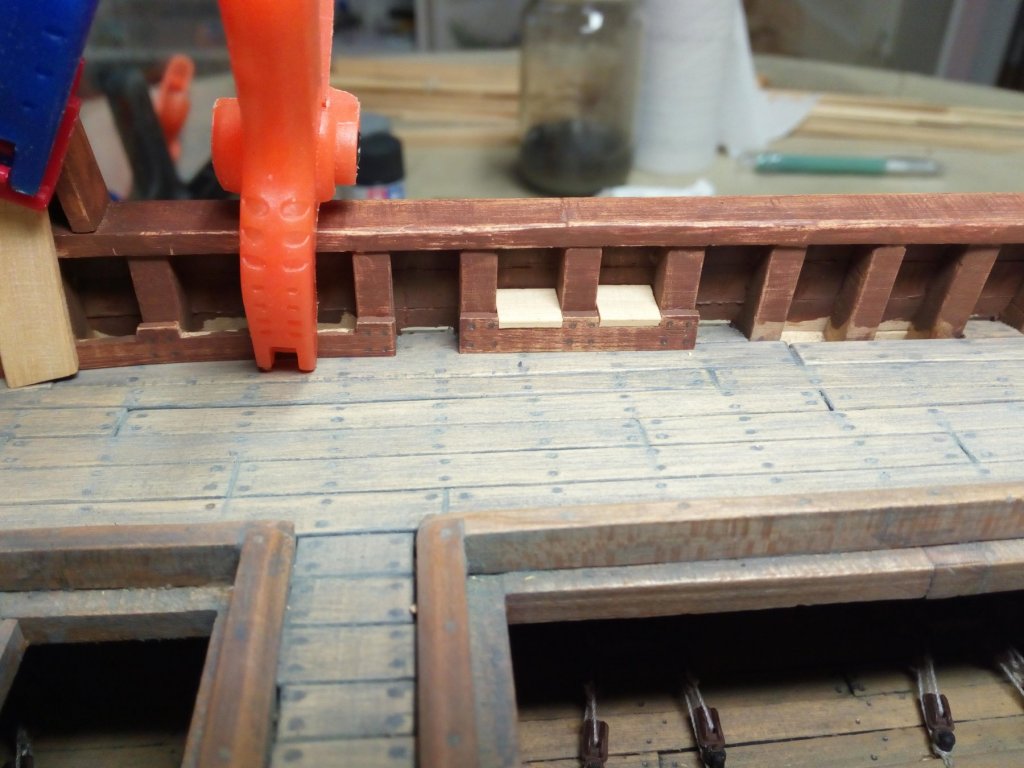

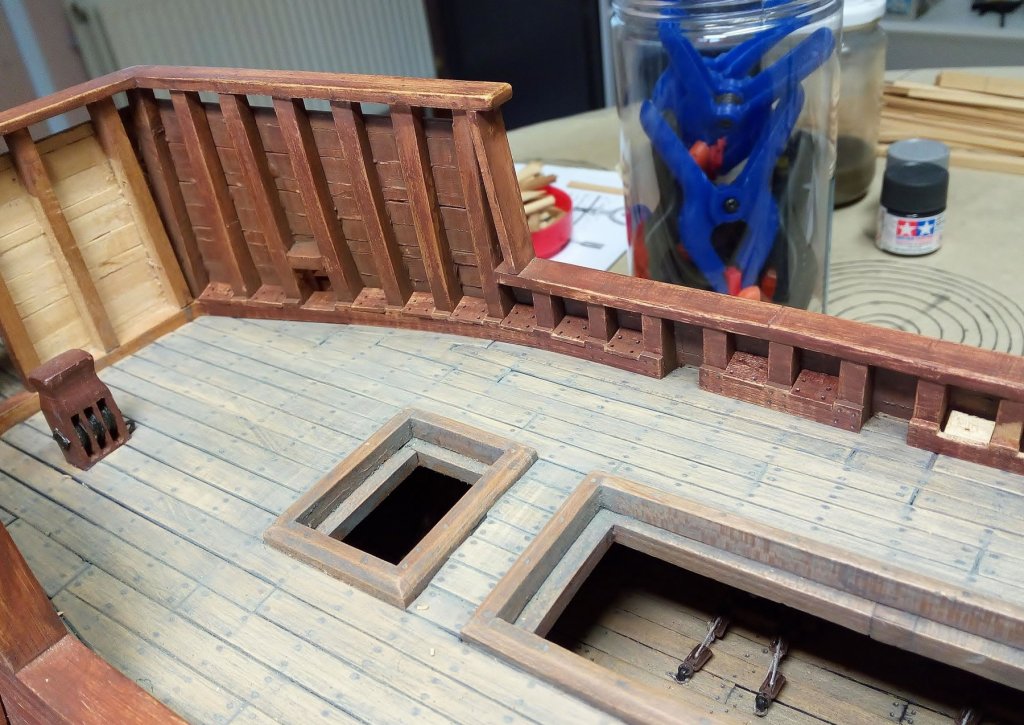

Hello, Today i started with the installation of a waterway on this deck. With the following models as examples : Batavia replica and the san Juan whaler. First I paint the inside painting (had to do this much earlier, that would have worked easier) All parts are first painted and detailed before assembling. Fillerblocks are used to make the horizontal parts easier to glue. In the meantime, a second (plastic) shipyard has unexpectedly been started up. This is why this shipyard sometimes has a delay. This was going to be something quick and easy. But has become something like a semi scratch. Thanks for following

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

We once visited the Tirpitz muzeum in Alta norway. On the site of this museum there is an interesting film with a Tirpitz in grey color and various other color schemes https://www.tirpitz-museum.no/#home

-

Hello, and welcome to MSW. Greetings from Belgium

-

Looks great. Enjoy the Stella Artois, you've earned it.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Thanks. I used sheet of 0.2mm thickness. Too thick for this scale, of course. But the result is not that bad. .

-

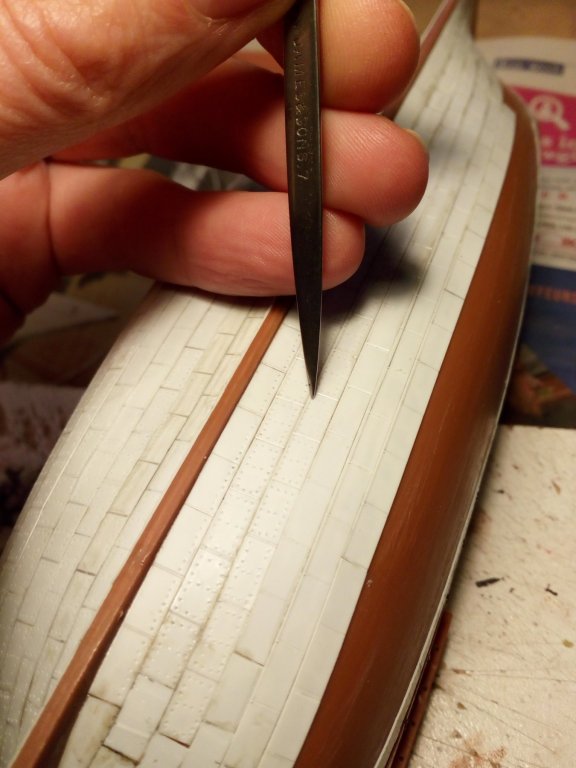

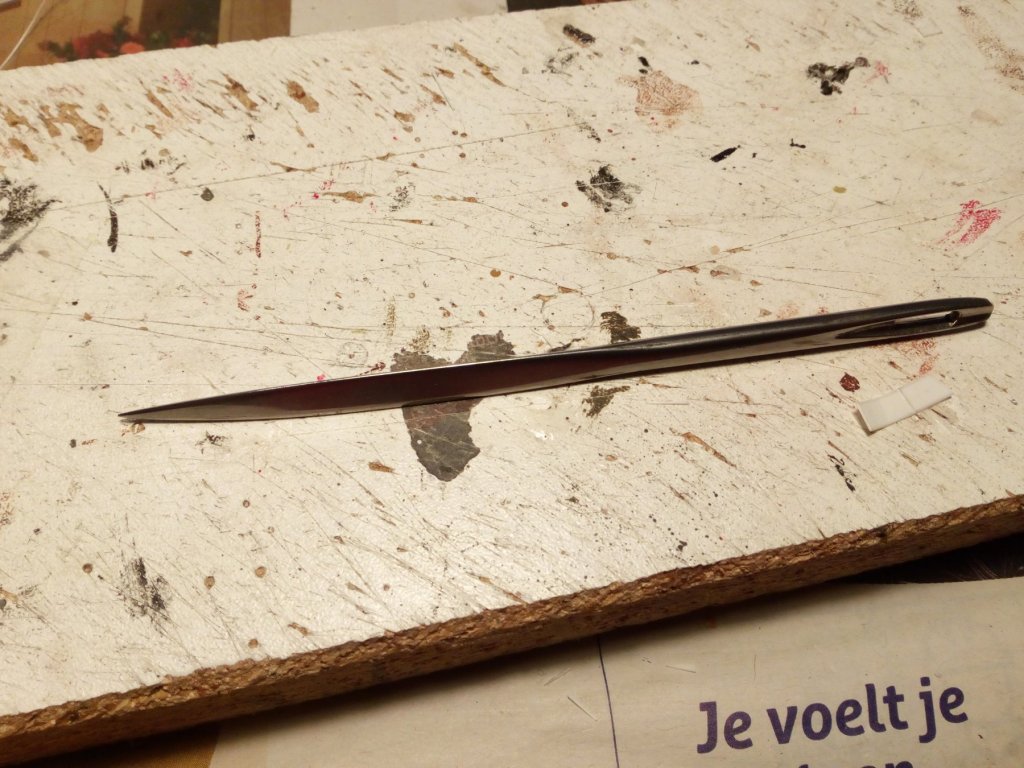

The copper sheeting has been slightly sanded. Now I have started to apply imitation nails. I use a large steel needle for this. Work in progres, still much to do and new hinges must also be made for the rudder. Thanks for following

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.899a429b75385d42ebd53bc783453fb5.jpg)