-

Posts

5,962 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Ah the fix of the weekly update. Simply stunning work Glenn. That is some very clean, crisp and well executed joinery. cheers Pat

-

Thanks Popeye and John. Managed to fix one of the yards (stunsail booms but not the other yet ). Thanks for the compliment John, coming from you it is much appreciated. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Your riggers have been very busy Dave; nice work - double rum ration for them i would suggest! cheers pat

-

I thought you needed a few more beers to celebrate this lovely model. cheers Pat

- 268 replies

-

Some beautifully executed detail work there Danny cheers Pat

- 268 replies

-

Very nice Greg, those armour bands came up very well indeed. cheers Pat

- 342 replies

-

- dreadnought

- zvezda

-

(and 2 more)

Tagged with:

-

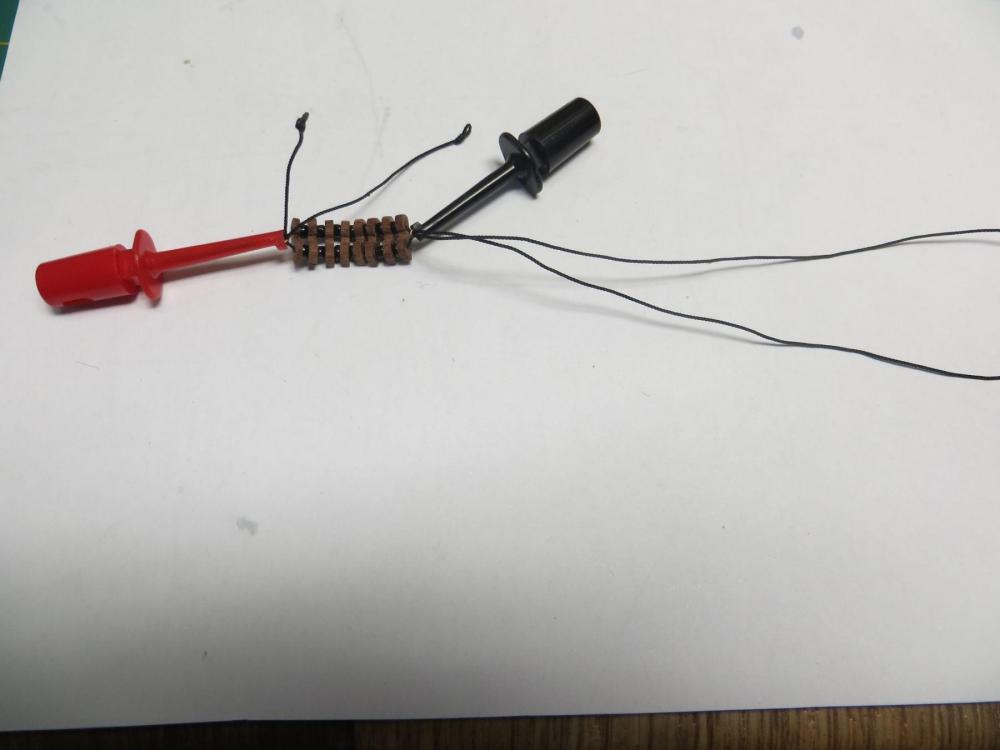

Hi, are the clips I use as shown here what you are after. These come in various sizes and available at electronics stores and the like (as Geoff/Aussie posted). I find them very handy as they are easy to use and very light but grip strongly. Just take care if you have pre-wetted the line with diluted glue as it may develop a kink. cheers Pat

-

Hi Mark and Druxey, why would the lead lining go so high, especially if the railings are open - no way to use it as a cistern unless the lining went up the same height against the rails also? If a storage area, it might have been a wood lining to prevent minor damage but I would have thought the ship's side would have been sufficient for that? Just my two cent's for what it is worth cheers Pat

-

Thanks Mark, Per and Dave; and all for the likes. It was a quiet BD but just what you need as the good doctor says above. That's the two most complex yards in place now so hopefully the others will not take as long. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

You're going along rapidly Greg; that PE looks good where you have used it so far. Those baseboards look a treat, especially with the grain showing the way it does. cheers Pat

- 342 replies

-

- dreadnought

- zvezda

-

(and 2 more)

Tagged with:

-

THE 74-GUN SHIP by Jeronimo

BANYAN replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

I had missed your latest build log Karl, beautiful work - but we have come to expect that from you. cheers Pat- 194 replies

-

Thanks all for comments and birthday wishes - appreciated. John, no need to paste mate but thanks anyway. I was aware of inner and outer tricing lines, and interpret the same way. My intention is to show one tackle hanging from the pendant with both tricing lines fitted; the remainder will be the outer tricing only with the tackle hauled taut (pendant pulled in along the yard, but I don't think I will seize it also. WRT the positioning, AOTS shows two shroud blocks fitted one above the other on the leading shroud of each set at about the cheek level, one for inner and one for outer. I think I will stay with the AOTS as I have also used that belay plan for the running rigging else where( Braces leads for example) and the lead works nicely for the shroud cleats. Thanks for the heads-up mate, much appreciated. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

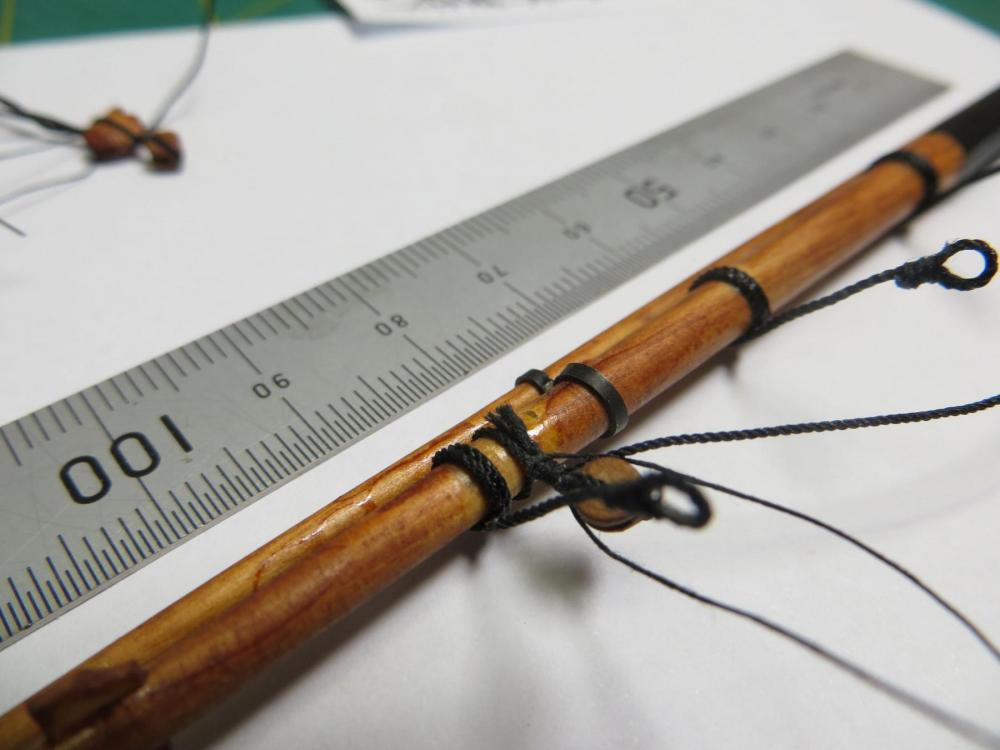

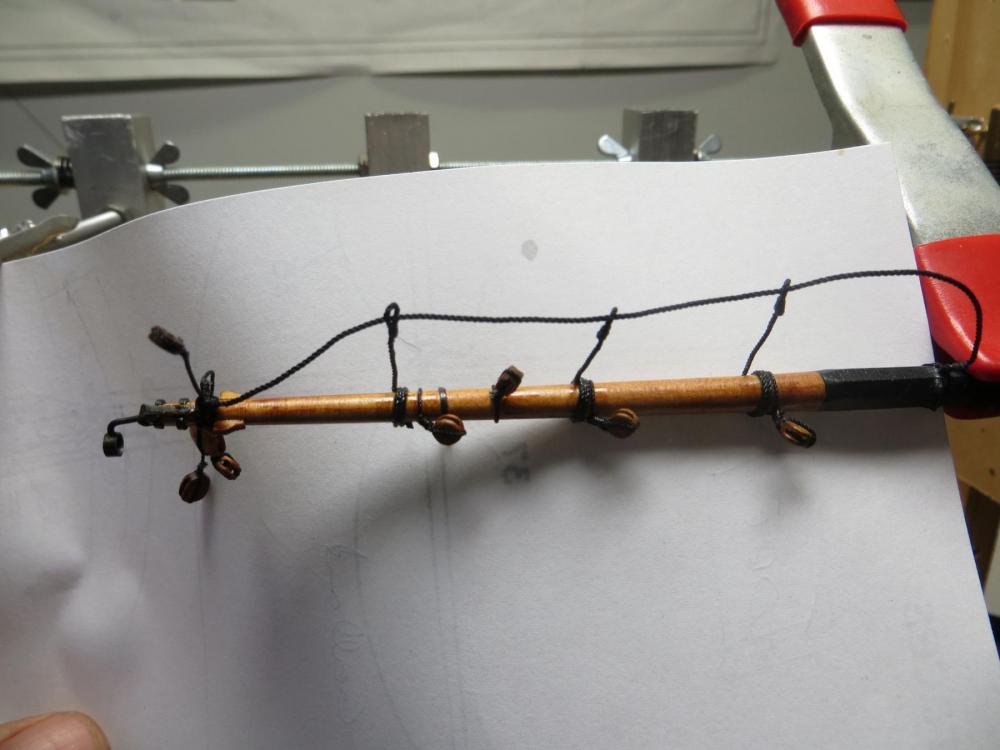

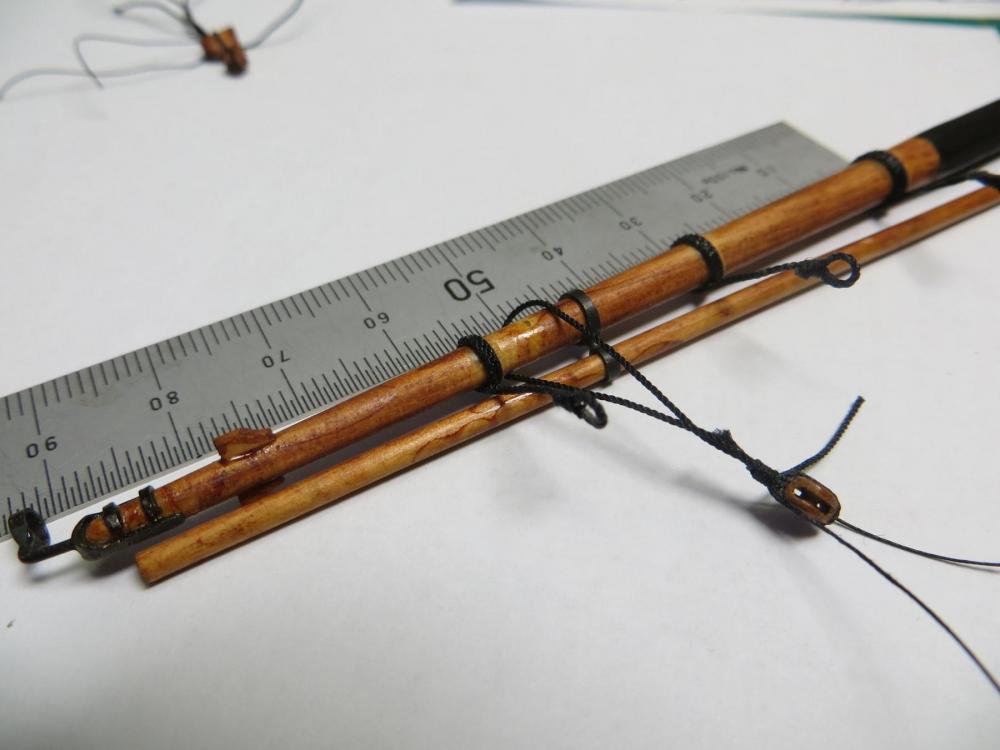

Second instalment. The rigging is slackened to allow the jeers to be lowered about half way down the mast, I seize the slings around the yard. I then prepare the parrel off the yard and fit it after the yard has been slung and raised a little closer to the tops. After tightening it I haul the completed yard. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi folks, next instalment (if the site lets me - third attempt - seems Win 10 and Internet and this site causes BSODs - I have tried three different browsers!!!!). This posts starts with the yard fitted with the stirrups and hardware (from earlier posts). All blocks etc are prerigged with running loops, with the loop large enough to fit over the stirrups etc without causing damage etc. [edit: ignore the stain run on the stunsail boom, that wipes off very easy - I let its it for a while for the stain to penetrate the wood which is Huon Pine with natural oils, so it takes the stain a little time to penetrate] cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

It's the screw-ups we learn from Mark; thanks for posting them. At least with the "death star" recutting/shaping is a tad easier We also have to remember that the macro-photos also make things look worse than they really are to the eye. cheers Pat

-

Thanks John, appreciated. Last night I found two small blocks seized to the leading edge of each fore shroud (Main and Fore) in the AOTS running rigging overall drawing. Very faint lines which turned out to be (according to the AOTS) lead blocks for the tricing lines which ten led to the foremost shroud cleats for belaying. I'll check those two other reference you provided and decide from there. Many thanks mate, for this and pointing out my error (or should I blame the dockies? ). Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.