-

Posts

9,490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Lad

-

Nice to see you back at work, Danny! John

- 62 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

Hey, Mobbsie - at least you drew one game!! John

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

You're right, Bob - it does almost look like matting. Very nice! John

- 196 replies

-

- higaki kaisen

- woody joe

-

(and 1 more)

Tagged with:

-

She really looks beautiful, Remco (both the ship and the kitten) - just keep a close eye on Pebbles the part napper! John

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

I thought you were only one-eyed when it came to football, mate! I hope the eye is OK. John

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Your local brick yard has done you proud, Augie! John

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Bob, you certainly put your eight hours to good use. She's looking 'ichiban'. John

- 196 replies

-

- higaki kaisen

- woody joe

-

(and 1 more)

Tagged with:

-

Congratulations, Ollie - very well done, mate! She looks absolutely first class. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Bulkhead Fairing Questions

Jim Lad replied to Jon219's topic in Building, Framing, Planking and plating a ships hull and deck

If you're going to fully plank the hull then a shim, if needed, can be of virtually anything as it won't be seen. Whether or not a shim would need steaming or soaking would depend on the type of wood and thickness you need. Give it a go and see what happens. John -

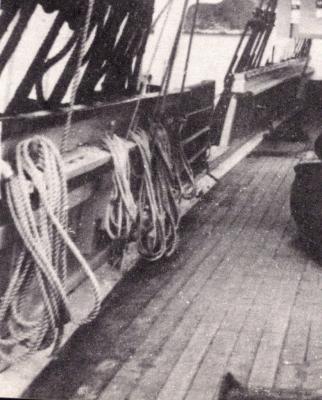

Alister, Both these photos show ships in port. The following photo is of a ship at sea (Loch Tay 1869). John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Sorry, Piet, but I don't see the fuse screwed into the nose of that shell for the deck gun! John

-

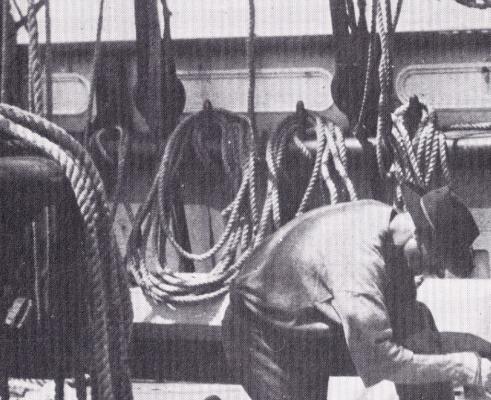

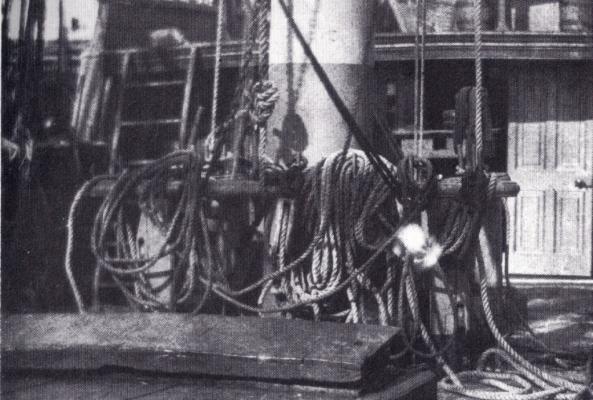

Ollie, I assume that the style of your coils is as per the kit instructions and indeed you will see a lot of models on the forum with coils made up exactly like that. You'll also see such coils on many modern replicas and restored ships, however the traditional method of make up coils was a simple coil dropped over the pin, as you will see in many contemporary photos of old sailing ships. The photos below date from the 1840's (first photo) and 1850's (second photo) and shown perhaps not in brilliant clarity, what I mean. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Ollie, your only problem now is that your next models have to be of a size to fit the other shelves. John

- 803 replies

-

- colonial cutter

- modellers shipyard

-

(and 1 more)

Tagged with:

-

Very nice, Augie. As for the stove base, simply order a couple of hundred very tiny bricks from your local brick yard! John

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Harriet McGregor by Boccherini

Jim Lad replied to Boccherini's topic in - Build logs for subjects built 1851 - 1900

Very nice indeed, mate! John -

When you have the time, Michael. We're a patient mob! John

- 2,214 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.