-

Posts

1,557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Mike Y

-

-

Semi-offtopic: got a bit distracted from the build with an idea of doing some small-scale woodworking (jewerly boxes, that kind of stuff). Part of the plan is to also build a nice display case for the Cromwell. The model looks quite nice even when not finished, plus in the case it would be better protected from dust. Plus it is better to build a case while you have an itch to do it

Ordered few boards of some basic hardwoods - walnut, cherry, maple. While the wood dealer is milling them to desired dimensions, took some small piece of scrap to practice with milling my own wood. This was a walnut from the edge of a trunk, with a bit of sapwood.

Everything is sooo out of scale

My tools are tiny. So I can only build tiny boxes.

My tools are tiny. So I can only build tiny boxes. The piece I got was not square and not symmetrical. Obviously, I do not have a jointer, so squared it on a table saw.

Of course, the saw is too small, so finished squaring with a plane. Which was also super small. That felt, hm, awkward for sure!

Resawing this piece into planks on Proxxon bandsaw was just pathetic. Super slow even on a max speed and the sound was disgusting. The bandsaw was definitely not up to the task.

But after passing it through planer the wood turned out to be beautiful. Very deep walnut pores and grain, but guess that is a feature?

That contrast of sapwood and heartwood is striking, something I can use on some box to create a nice effect if matching the boards correctly.

Walnut on stained white oak.. I turning into a wood junkie...

- tkay11, FriedClams, aviaamator and 11 others

-

14

14

-

From both: thank you for the comments, it is really nice!

This weekend Daria asked me to find a time to build together, I was really happy she asked for it. Also, this time I tried to maintain a slower pace - the build sessions are supposed to be a moments of calm enjoyment, no rush. But it is harder with kid, since her attention span is quite short and she is typically rushing things. So trying to slow down

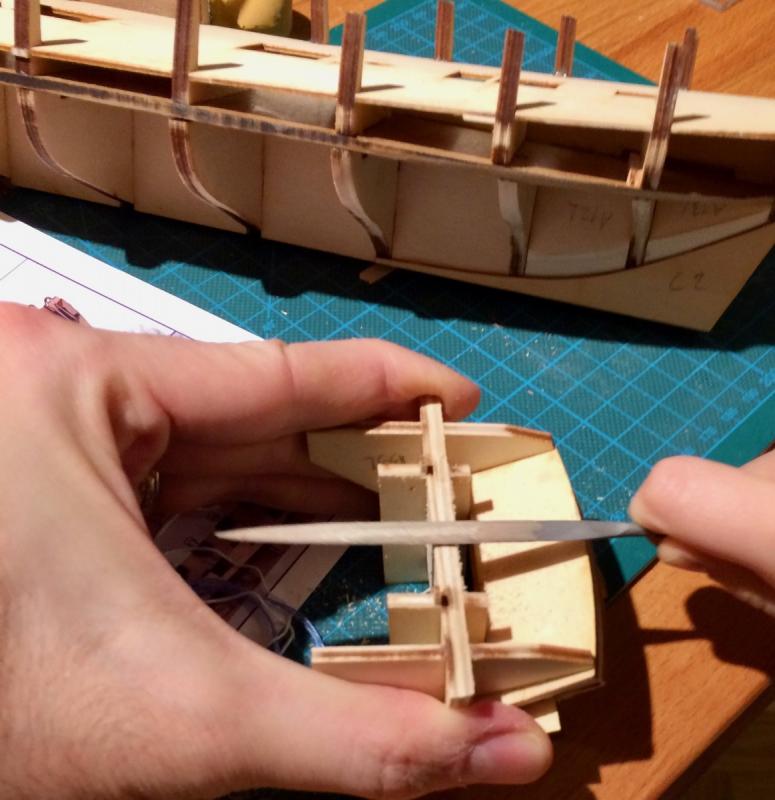

Fiddly bits in the transom. It is funny that this kit build reached the same milestone (hull is ready, building transom) after 4-5 hours, while it took 2 years to get there with my main fully framed build

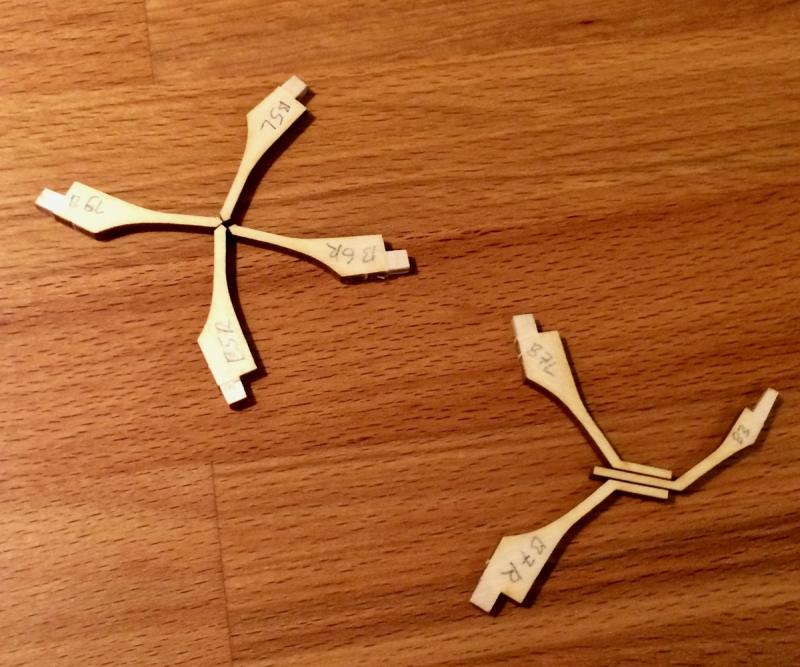

Daria loves to think these are a pieces of the puzzle that can fit together. She might enjoy the Things Perfectly Fitting Into Other Things tumblr eventually

Gluing the side timbers with some sort of filling blocks. Everything is carefully notched and well thought trough, this kit is great! Daria got the concept of "parallel alignment" and played a lot with parallel machinist clamp.

Installation is tricky, but was fairly successful in the end:

Transom is ready. There are some gaps, but I in this build it is better to make mistake instead of chasing perfect quality:

(nevermind the glue, will clean it up when dry)

Clamping was very tricky because transom is not square and not parallel, so I did it myself.

So far, that kit is quite kid-friendly. Except the fact that every single part fits too tight and notches should be extended with a file. Bleh!

I take all the nasty parts (filing, filing, filing, filing), and she gets all the fun parts (assembly, measurements, clamping). Not fair!

- GrantGoodale, piter56, archjofo and 13 others

-

16

16

-

Mike Y,That's my test project and there are some specifics need to be improved.The blog Maybe released after the project is completed.The project of Zeehaen is some preparation or test for HMS Cumberland 1774 -i want to make my drawings by 2d/3d technology and CNC engraving machine to process parts.

hjx, it is much more fun to share the progress - please start the log while the project is not yet completed!

I am sure lots of people would be interested in a CNC build. Even a tiny photos you attached look excellent!

I am sure lots of people would be interested in a CNC build. Even a tiny photos you attached look excellent!P.S: Chris, sorry for skewing your discussion!

-

Hm, for me it works without any extra jigs - I bend pear even with 3-4mm thickness by simply:

1) Boil a full kettle of water

2) When it is done - open the lid and dip the piece into the boiling water while it is still boiling. Of course, it is super hot inside the kettle, so use tweezers to hold the wood piece

3) Wait 15-20 sec

4) Done! Take the piece out, bend and clamp to shape

5) Wash the kettle and pretend you never did it in a first place

Super simple and no problems. Of course, it will be hard to do with long pieces, but super long pieces are typically out of scale anyway, right?

I found that for best results it is important to dip when water is still boiling. Maybe it is all that air bubbles and vibration that helps to relax the wood fibers? Just a guess..

At least experimentally - it works better than just dipping in hot water when bubbles are gone, and much faster then using steam.

-

-

-

-

-

It actually looks very nice with that grain! Feels like that "flower growing through asphalt" pictures. Rough wood - and a gentle flower emerging through it

With a proper backstory, this piece could be more interesting than something carved on a "proper" wood where grain is barely visible.

And the pimple is a nice touch, not a thing to get rid of!

- WackoWolf, aviaamator, mtaylor and 3 others

-

6

6

-

-

-

Eeeh, what? Already done? So quick?

Your productivity is incredible, especially combined with the highest quality and careful planning and research. Bravo!

Looking forward for the next project

-

1) Yes, lots of them, just look on the shaft diameter - anything between 1 and 3.2mm will fit

2) No problems, it can even handle aluminum. Just a matter to the cut depth. I am usually using it with hardwoods (pear and castello), they should be harder than plywood

3) The table surface dimensions is 7x21cm, do not have any experience with trying to fit larger pieces onto it.

- mtaylor, WackoWolf, Seventynet and 2 others

-

5

5

-

Mike:

Progress was a bit slow because I got a bit sick, so no modelling due to the quarantine mode enforced at home.

Assembling the transom. I have hard time figuring out what these parts are, because in the true spirit of POB kits this area is going to be fully planked and its internal structure is totally different from the real ships.

Tricky part to fit, it has a dozen notches that need to be enlarged to fit properly. Lot of filing!

Now it is a time to fair the hull! That goes easy, because parts are cut with a good precision, so fairing is truly minimal, everything fits perfectly. I was doing it only because Daria loves the process of turning rough hull into the smooth hull. Fairing was not really necessary.

This part was lots of fun! Using compressor to get rid of the dust after fairing. Ended up playing with an air flow for a good 15 minutes

Transom continued:

Filing to ensure a good fit to the deck:

I let Daria figure out the right way to clamp the transom to the hull, and she figured it out!

Looks like a ship!

Now it's time for important stuff!

-

-

With the Proxxon, you can only use very small cutters, which break easily.

Agree with the rest, it is only a question of cost. If one can afford Sherline instead of Proxxon - there are very few reasons to advocate for Proxxon (well, maybe speed, but that's it).

However, if cost is an issue, Proxxon seems to be on the level that is decent enough and problem-free.

But may I respectfully disagree with this note about the cutters?

The proxxon mill accepts cutters with the shaft diameter up to 3.2mm, so there are plenty of aftermarket bits that can fit into it. And even the proxxon cutters are quite strong and sharp, I abused them a lot and haven't managed to break even the 1mm one. I am talking about this cutter set:

- aviaamator, mtaylor, tkay11 and 3 others

-

6

6

-

Tim, you made me blush

One thing to keep in mind when making a decision. Bare mill is hardly usable, you need a basic set of accessories:

1) Clamps to fix parts flat to the table

2) Precision vice to fix parts square to the table

3) Basic set of sharp cutters

4) Rotary table (considered basic for our hobby, milling capstan / wheel / anything round-ish is less convenient without it).

For Proxxon, #1 is included out of the box, and the rest will cost you $137. Together with the mill ($242), the whole package is $380, so roughly $400.

Sherline plus similar pack of accessories would be roughly 2x-2.5x more.

So if you look for just a "good enough" mill - MF70 should be ok and is used by a lot of great level modellers in Europe. I used it for a year already, and had zero issues with it, nothing I can presume as negative. Steady, reasonably quiet, precise! Well, maybe the wheels could have been a bit bigger...

No maintenance really, I never needed to adjust / maintain / lubricate / tune anything in it after the initial setup.

No maintenance really, I never needed to adjust / maintain / lubricate / tune anything in it after the initial setup.But no doubt that Sherline is a more "adult" mill, that have a better customisation possibilities. I am just whining because I can't afford it (slap 25% extra on it to get the european price of sherline).

-

Depends on your definition of "mini". Proxxon MF70 is the smallest, which is the key if you do not have a workshop. It is a really good piece of machinery, way better than most of the other proxxon machinery. I am supper happy with it. Also much cheaper than Sherline. But it is harder to customise it (fewer accessories), and the working area is obviously smaller (see "mini").

- Jase, mtaylor, genericDave and 3 others

-

6

6

-

They are one of my main tools (that chisels and a miniature block plane), I use them more or less every time I work on the model.

I am super happy with them! It is a nice tool and a very high quality metal, sharping is quite rare. Both are pretty sharp just out of the box.

Now I know how good tools look like

The only nuance to keep in mind - due to the size, you can't use any full-size honing guide. So either you need to make a guide yourself (block of wood, etc), or use this one: http://richardkell.co.uk/honingECom.htm (guide #1)

The guide seems to be available in US as well, just google. First result: http://www.garrettwade.com/kell-british-made-deluxe-honing-guides-gp.html

-

My daughter has her own table, but we build on mine, it is larger and all tools are closer

Will try acrylic as well!

I guess in depends on the desired look. I do not want to imitate ebony 1:1, I actually like when black wales are a little bit fuzzy, in this case the grain raised by water based dye is a feature, not a bug. Acrylic will hide the grain? Will see. Scrap wood experiments are a way to go!

I guess in depends on the desired look. I do not want to imitate ebony 1:1, I actually like when black wales are a little bit fuzzy, in this case the grain raised by water based dye is a feature, not a bug. Acrylic will hide the grain? Will see. Scrap wood experiments are a way to go!- Omega1234, cog, aviaamator and 2 others

-

5

5

-

-

Thanks everybody for likes and comments!

The transom is slowly progressing, but due to pre-christmas chaos I am not sure I will finish it this year..

Why don't you use simple oil color? I've made different tests as preparation for my build and happy with the results. It's important to use a good quality color (Schminke, Lucas ar two German brands for example). Than you can work with very thin layers of color

The honest answer is "because I am really bad in painting and know nothing about different types of paint". Most of the models where I saw really nice wales used wood dye, so I decided to go this way. There are enough variations even with dyes, if I will start trying various paints - I will end up overcomplicating it and getting crazy with dozens of test pieces spread around my apartment

-

I can only dream about having any sort of workshop... But there is one thing that you might consider - height adjustable table. I was a bit reluctant to spend money on it, but once I got it - it is really a joy to use. It is super handy!

And nowadays you can buy a frame for it for quite a good price - http://www.ikea.com/us/en/catalog/products/50263225/#/80263224

(table top of your choice could be bought separately, or there are versions with top included). It is really steady and stable, btw. Especially if you put a heavy top on it!

I use it very frequently, basically every time I switch to another operation that requires a different height. It definitely worth it.

It would be a good addition to your shop, especially for the "clean" area, where the actual model is assembled.

- thibaultron, druxey, mtaylor and 3 others

-

6

6

-

Hello Mike Y. It's a very elegant line model at the same time as nice, the choice is a great success, I like it a lot ... and the work you're doing extraordinary.

You "HAPPY" with capital letters. A hug, Liberto

Liberto, thank you! It is really nice to hear that from a man behind such a masterpiece as yours! Hug!

Miniature Hand Tools

in Modeling tools and Workshop Equipment

Posted · Edited by Mike Y

Roger, these chisels are used a bit differently - shaving and cutting the wood with a finger pressure, not with the mallet. Due to their size, they are much easier to work with comparing to the full size chisels - which are just too long. I have both fullsize and miniature chisels, and haven't used the fullsize ones on the model for a while.

Might be subjective though.