-

Posts

1,437 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Mike Y

-

-

-

Thank you, Gary! Welcome to the log

- Omega1234, mtaylor, FriedClams and 1 other

-

4

4

-

-

-

It may comfort you that the builders of a full-size replica of the same period (see http://modelshipworld.com/index.php/topic/12395-replica-poltava-1712-russian-ship-of-the-line ) also used lamination for the internal planking in the bow, where curves are steep. And some outside curves as well.

So it is definitely not cheating!

-

May we see photos of the other completed model, please? It looks more interesting than the wall!

It is a Model Shipways Pinnace kit, designed by Chuck. The build log is in the signature, here: http://modelshipworld.com/index.php?/topic/4954-21ft-english-pinnace-by-mike-y-model-shipways-124/

Incidentally, this is the only finished model I have so far

After the Pinnace, I started a longboat out of boxwood (the link is in the signature as well), and the hull planking is mostly ready (1-2 strakes left), but the build is on hold because I started the Oliver Cromwell build

After the Pinnace, I started a longboat out of boxwood (the link is in the signature as well), and the hull planking is mostly ready (1-2 strakes left), but the build is on hold because I started the Oliver Cromwell build

-

Alan, John, Druxey, Patrick, Christian - thanks for the feedback!

And a happy New Year everybody!

Possibly a thin felt gasket glued on the inside edge to keep the dust out?

You could employ a more traditional floating base... a open backed box that slips over the strong support that is bolted to the wall.

That way if someone looks underneath they see a finished face.

A set of strong magnets (or screws) could secure the "box" to the "support".

Yes, haven't really planned the dust protection yet - some felt-like material will be used between the wall (the wall has a rough texture) and the back side of the case.

As for the base - underside of the base would be left unfinished simply due to economical reasons - it is a lot of wood needed to cover it, and nobody will bend that low anyway. And kids who will see it - will appreciate the view on the internal structure and some electrical wires

Happy New Year! I like your concept for the case, especially those complicated joints. My only comment would be to have a back-surface incorporated into the case as opposed to relying on the bare wall. But, that's just my opinion.

Yes, was thinking about it, but it is so hard to decide what that back-surface should be. I was thinking about a milky-opaque plexiglas, some plywood with veneer on top of it, mirror, etc. Ended up with just a bare wall, it should look nicer and also provide more volume. Due to the location of the case, I can't make it wide (people will bump into it), so it is fairly "flat", so the visual volume matters.

And if these estimates would be wrong - it should be easy to retrofit any sort of the back material later (just sticking the correctly sized rectangle to the wall behind the case).

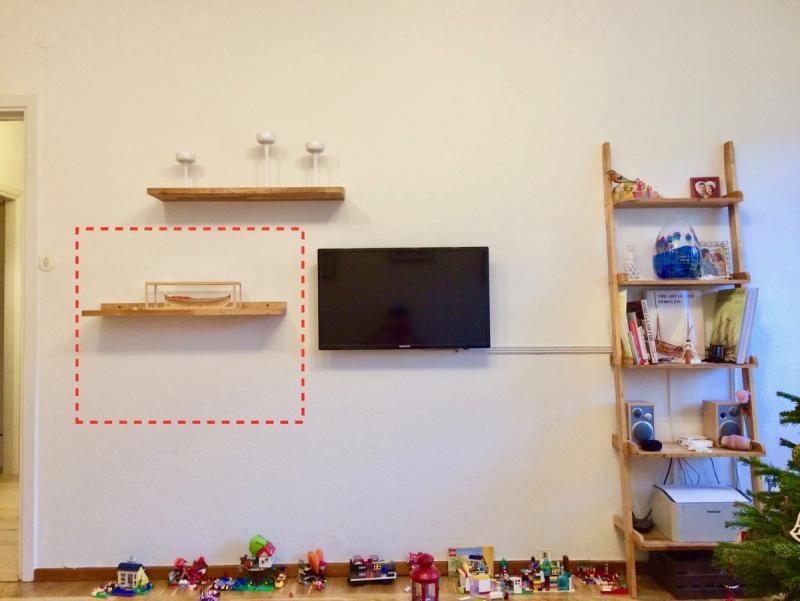

For the background, here is the wall where the display case would be mounted. It will replace the floating shelf with the pinnace model, so here is the dashed line of the estimated location:

The wall close-up (it is a simple painted wallpaper):

Since this is a super common wall colour (already known as "Stockholm white"), I am quite certain that even if we move to another apartment - the wall texture and colour would be the same

- FriedClams, AON, mtaylor and 4 others

-

7

7

-

Thanks for the nice comments and likes!

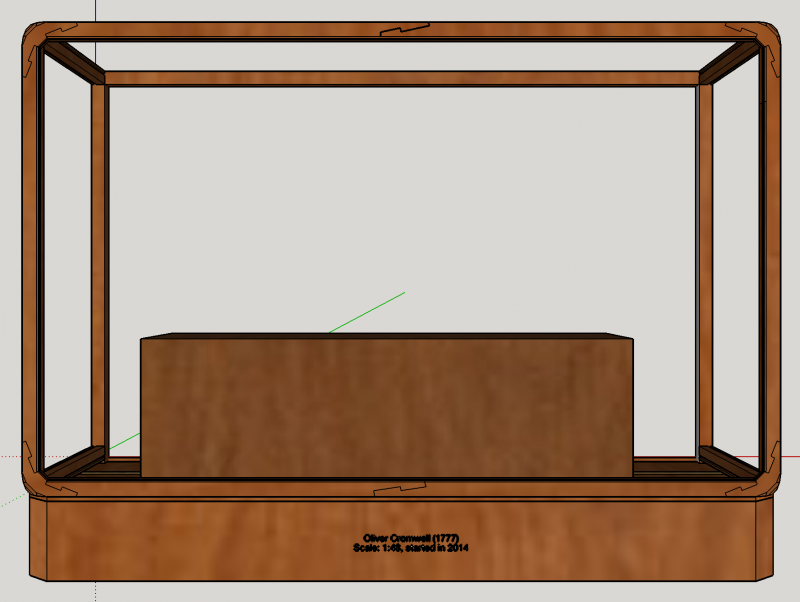

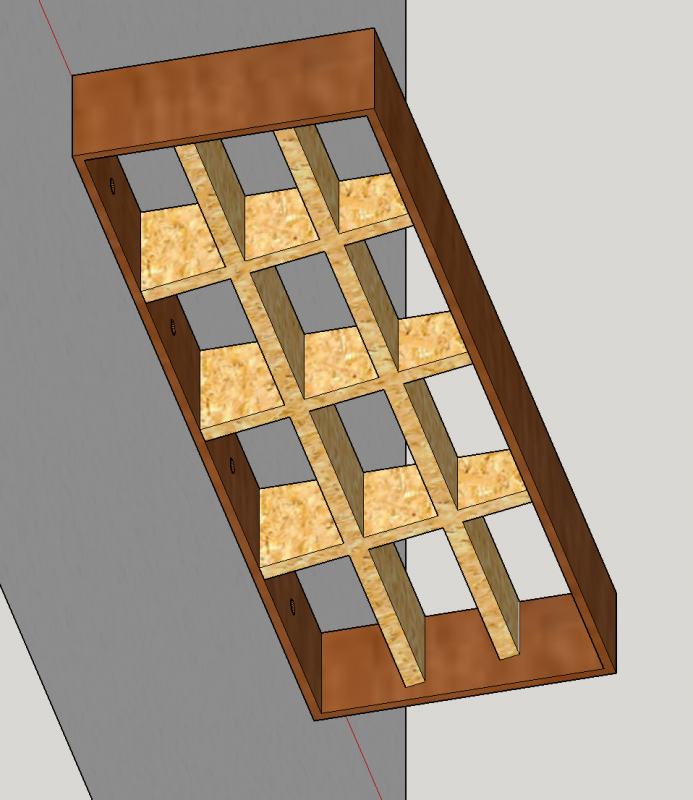

Finished a draft version of the display case sketch. Would appreciate the critics, it would be cheaper to correct the design issues now than later!

Basic characteristics: 100cm wide, 80cm high and 30cm deep (40' wide, 31' high, 12' deep). Plexiglas (3mm thick) would be used instead of glass (for safety and weight reasons). No glass on the back side, it would be mounted to the wall and the background would be a white wall.

Made out of the same swiss pear as the model. The frame would be made out of square pear stock 2x2cm (13/16').

Here is the overview first:

Front:

(yes, I love scarf joints

)

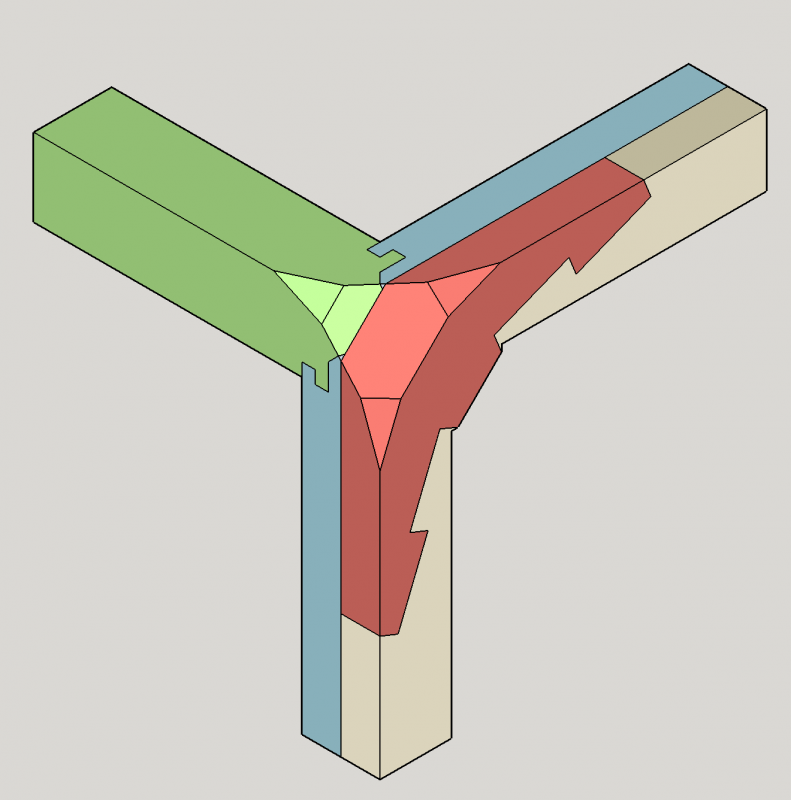

)Isometric:

(Please ignore the joints in the back, I had no energy to draw them properly, but they be a mirrored copy of the front joints).

The load bearing part is hidden by the "skirt", and is made out of thick plywood bolted to the wall with Big Strong Bolts. Any sort of electrical stuff would be hidden in that cavities as well.

Plywood is covered by the pear "skirt" with a model description carved on it (or inlayed).

The top part of the case would be attached to the wall as well, with hidden screws, but will not take any weight.

Tricky part is the the way it would be opened. Since I will keep model in it and get it out every time I want to work on it, the opening mechanism should be easy to use (multiple times per week). Also, due to asymmetrical nature of the model, I want guests to be able to get it out easily to see the other side.

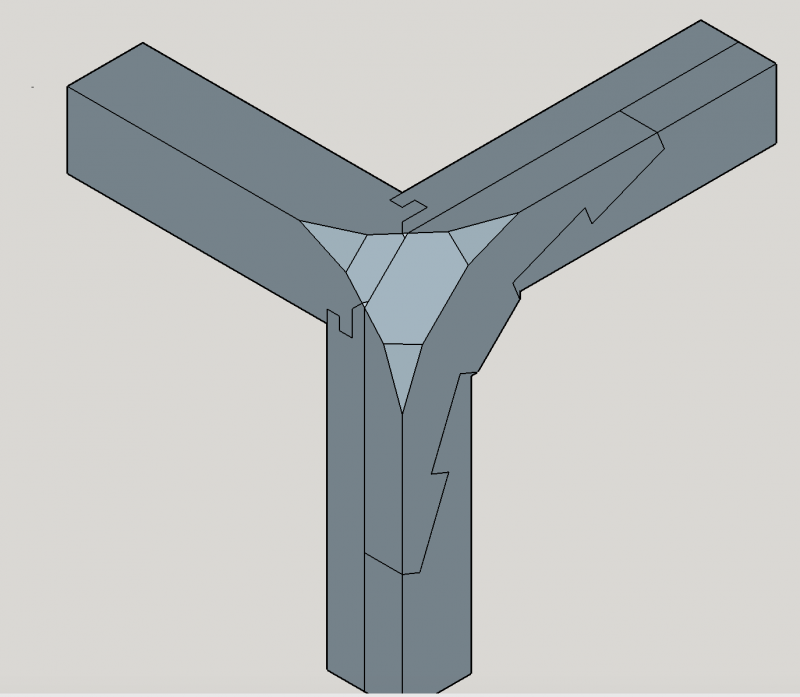

So the front window is detachable and is held by strong magnets. That means that front frame is split into two parts - one is 1cm thick and hold everything together, and another is also 1cm thick and holds the front glass.

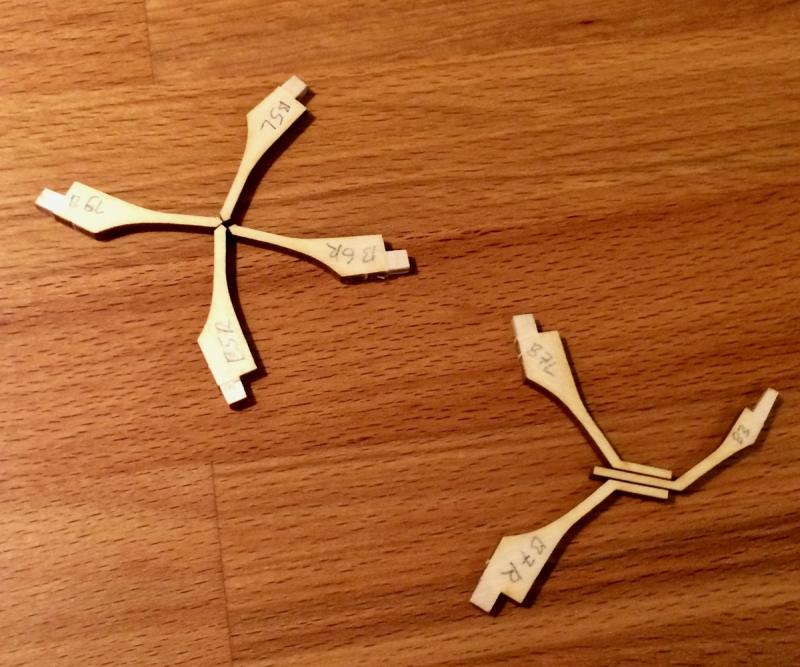

Front frame joints look like this (a bit complicated, but it is a sort of decorative joint, I want it to look nice)

Or a multi-colored version of the same joint, each color is a different wood piece:

There would be a groove inside front part of the front frame, to provide an additional support for the top glass and its frame, since otherwise it would be only supported from sides and will sag over time.

Would appreciate corrections if I forgot to over-think something in this design!

Is the plexiglas thick enough? I accounted for the wood movement, grooves for the glass are deeper to allow wood to shrink and breathe a bit.

Is the plexiglas thick enough? I accounted for the wood movement, grooves for the glass are deeper to allow wood to shrink and breathe a bit. Is the base construction strong enough?

- John Cheevers, Canute, -Dallen and 19 others

-

22

22

-

-

-

Finally the sawdust has been made! Your model gave me a lot of the inspiration, very happy to see it taking shape again! Might deserve to be renamed to "Phoenix"?

Should be in line with the Swan naming convention!

Should be in line with the Swan naming convention!The building board is great! What do you use to fix the model when working upside down?

- Trussben, AnobiumPunctatum, mtaylor and 2 others

-

5

5

-

Yes, I draw a boxwood nails. Requires a nice straight grained piece to cut the strips from, but works fine after some practice. Also works as a reliable mood measurement tool. One must be totally calm when using it - otherwise the piece will snap somewhere in the small hole

- ChadB, thibaultron, Canute and 3 others

-

6

6

-

Mike Y is working up the "Cromwell" with Lumberyard wood: http://modelshipworld.com/index.php/topic/7297-oliver-cromwell-by-mike-y-148-1777-pof-hahn-style/?hl=%2Bdlumberyard+%2Bkits#entry215467

Appreciate the note, but I use Lumberyard jig and plans, however replacing all wood with the one from Arkowood. See my whining in the first few pages of the log (page 2 and 3), there are clear photos, the conclusion is up to you.

Lumberyard has a good inventory, but when ordering - please be super pedantic about what you need. Things like

1) Allowed amount and severity of defects in the wood you get

2) Finishing sanding grit. That was a bummer for me - I ordered a milled wood and got something so rough that needed thickness planer / sander or a lot of time wasted on tedious sanding. With a totally different thickness in the end

3) Wood type. I wanted "swiss pear and boxwood" - got a non-swiss (not kiln dried) pear for the frames, which has a different colour. Not saying this is better or worse, but it is definitely not something that I expected

So, I guess, with all that precautions they could be used. However, there are many new suppliers - the famous one is Crown Timberyard that provides a dramatically different quality and no need for sanding / re-milling. Stuff is just perfect out of the box and looks exactly like you expect.

Lumberyard have a much better selection of woods though, so if you have a tools to mill your own wood (or, at least, to thickness it) - they could be used for less popular woods bought in some rough form (sheets, billets).

Sorry for getting that dirty laundry out, but with the lack of a proper "rating" system and such a limited amount of wood suppliers, guess it is better to share.

- mtaylor, -Dallen, Captain Poison and 6 others

-

9

9

-

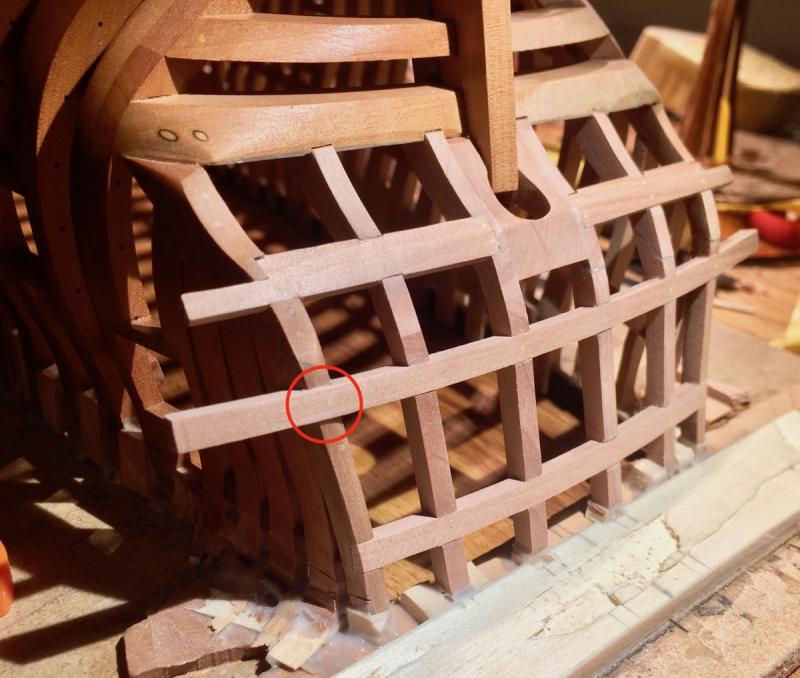

Finally finished the transom.

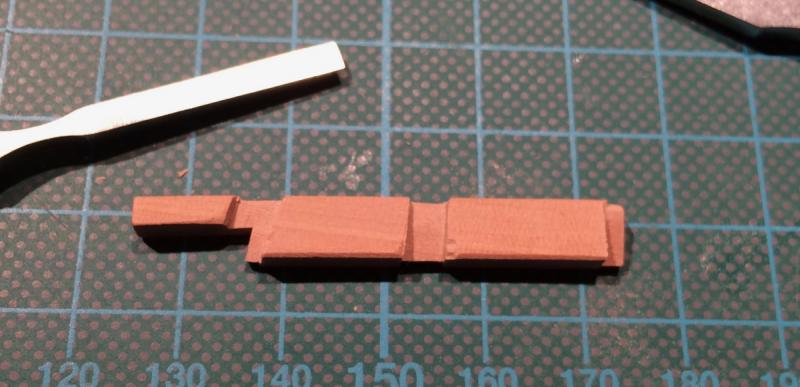

Last set of notches (aka "macro is brutal")

Horizontal piece also got some of them, on a weird angles:

Glued in, treenailed and masked for fairing:

Fairing was easy, because the smooth curve of the transom allowed to use the plane:

Faired. I made one mistake, one joint is too shallow, so can't fair this junction properly - the wood is too thin and will fall off

Too late and painful to fix, decided to leave it as is. Eventually this will become a part of the quarter gallery, so it will be less visible:

Put the oil on it (that was fun, so many surfaces to carefully oil and so many are crossing each other). Can't wait for it to dry, sorry for reflexes due to wet oil!

Note that due to a different grain orientation, oil resulted in different colours for different groups of timbers. Light "along the grain", medium dark "diagonal grain" and very dark "cross grain". It is all made literally made of the same piece of wood, I promise! Wood is magic

Not everything aligned as it should, but I started with a not very symmetrical transom, at least haven't made it worse. Will pay much more attention to the proper alignment in the next build!

Now I am taking a short break - will shift attention to the jewellery box I promised to admiral, and then will come back to this log with a display case for the model. The model is far from being complete, but it does not stop from displaying it properly, and will definitely help to keep the dust off.

-

Small note on treenails: I use the same method as you, and after some practice it works fairly ok. But it is more efficient to use a long strip of wood instead of a short ones - you spend roughly the same time per strip, but get much longer treenail material in the end

Great log, thanks for posting!

-

The progress photos are very interesting! Thanks for taking your time to start the log, it is very educating.

- mtaylor and aviaamator

-

2

2

-

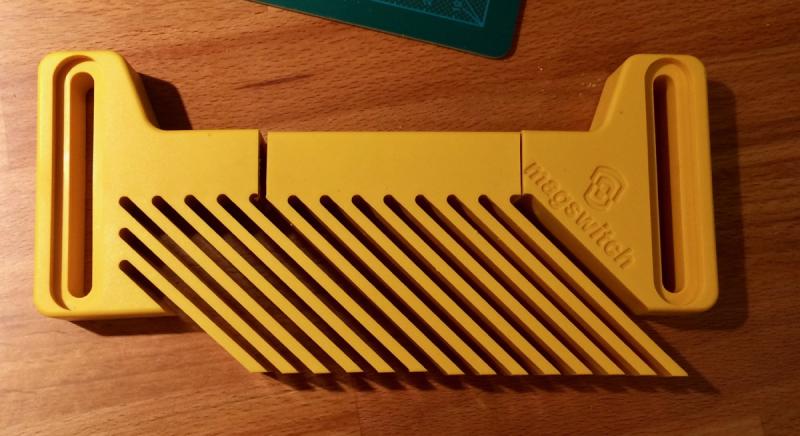

Wanted a featherboard for the table saw. Magswitch looked really good: https://www.amazon.com/Magswitch-Table-Feather-Universal-Model/dp/B001DSZ7EC

But I forgot that my table top is aluminum, not iron. So magnets are not working on it

So I bought this attachment, because I really liked the material (and it also includes all the hardware, bolts and knobs)

https://www.amazon.com/Magswitch-Vertical-Featherboard-Attachment/dp/B006SJH0SW

It was, obviously, too large for my saw, so I shortened it a bit, cutting off a long middle section and gluing the remaining parts with epoxy, reinforced with a wooden block inside the featherboard:

After squaring and shortening the bolts, it was a perfect fit and it works like a charm:

-

How do you use the spokeshaves in this hobby, if not a secret? They are designed to make some round and curved shapes, right? But I can hardly find parts in the model where a spokeshave can be used.. Or I totally miss the idea?

- PeteB, Seventynet, Canute and 3 others

-

6

6

-

So precise for such a small size! You definitely have a sharp eye and a steady hand!

- bdgiantman2, giampieroricci, PeteB and 1 other

-

4

4

-

Roger, these chisels are used a bit differently - shaving and cutting the wood with a finger pressure, not with the mallet. Due to their size, they are much easier to work with comparing to the full size chisels - which are just too long. I have both fullsize and miniature chisels, and haven't used the fullsize ones on the model for a while.

Might be subjective though.

- mtaylor, Canute, Seventynet and 8 others

-

11

11

-

Semi-offtopic: got a bit distracted from the build with an idea of doing some small-scale woodworking (jewerly boxes, that kind of stuff). Part of the plan is to also build a nice display case for the Cromwell. The model looks quite nice even when not finished, plus in the case it would be better protected from dust. Plus it is better to build a case while you have an itch to do it

Ordered few boards of some basic hardwoods - walnut, cherry, maple. While the wood dealer is milling them to desired dimensions, took some small piece of scrap to practice with milling my own wood. This was a walnut from the edge of a trunk, with a bit of sapwood.

Everything is sooo out of scale

My tools are tiny. So I can only build tiny boxes.

My tools are tiny. So I can only build tiny boxes. The piece I got was not square and not symmetrical. Obviously, I do not have a jointer, so squared it on a table saw.

Of course, the saw is too small, so finished squaring with a plane. Which was also super small. That felt, hm, awkward for sure!

Resawing this piece into planks on Proxxon bandsaw was just pathetic. Super slow even on a max speed and the sound was disgusting. The bandsaw was definitely not up to the task.

But after passing it through planer the wood turned out to be beautiful. Very deep walnut pores and grain, but guess that is a feature?

That contrast of sapwood and heartwood is striking, something I can use on some box to create a nice effect if matching the boards correctly.

Walnut on stained white oak.. I turning into a wood junkie...

- mtaylor, tkay11, aviaamator and 11 others

-

14

14

-

From both: thank you for the comments, it is really nice!

This weekend Daria asked me to find a time to build together, I was really happy she asked for it. Also, this time I tried to maintain a slower pace - the build sessions are supposed to be a moments of calm enjoyment, no rush. But it is harder with kid, since her attention span is quite short and she is typically rushing things. So trying to slow down

Fiddly bits in the transom. It is funny that this kit build reached the same milestone (hull is ready, building transom) after 4-5 hours, while it took 2 years to get there with my main fully framed build

Daria loves to think these are a pieces of the puzzle that can fit together. She might enjoy the Things Perfectly Fitting Into Other Things tumblr eventually

Gluing the side timbers with some sort of filling blocks. Everything is carefully notched and well thought trough, this kit is great! Daria got the concept of "parallel alignment" and played a lot with parallel machinist clamp.

Installation is tricky, but was fairly successful in the end:

Transom is ready. There are some gaps, but I in this build it is better to make mistake instead of chasing perfect quality:

(nevermind the glue, will clean it up when dry)

Clamping was very tricky because transom is not square and not parallel, so I did it myself.

So far, that kit is quite kid-friendly. Except the fact that every single part fits too tight and notches should be extended with a file. Bleh!

I take all the nasty parts (filing, filing, filing, filing), and she gets all the fun parts (assembly, measurements, clamping). Not fair!

-

Mike Y,That's my test project and there are some specifics need to be improved.The blog Maybe released after the project is completed.The project of Zeehaen is some preparation or test for HMS Cumberland 1774 -i want to make my drawings by 2d/3d technology and CNC engraving machine to process parts.

hjx, it is much more fun to share the progress - please start the log while the project is not yet completed!

I am sure lots of people would be interested in a CNC build. Even a tiny photos you attached look excellent!

I am sure lots of people would be interested in a CNC build. Even a tiny photos you attached look excellent!P.S: Chris, sorry for skewing your discussion!

-

Hm, for me it works without any extra jigs - I bend pear even with 3-4mm thickness by simply:

1) Boil a full kettle of water

2) When it is done - open the lid and dip the piece into the boiling water while it is still boiling. Of course, it is super hot inside the kettle, so use tweezers to hold the wood piece

3) Wait 15-20 sec

4) Done! Take the piece out, bend and clamp to shape

5) Wash the kettle and pretend you never did it in a first place

Super simple and no problems. Of course, it will be hard to do with long pieces, but super long pieces are typically out of scale anyway, right?

I found that for best results it is important to dip when water is still boiling. Maybe it is all that air bubbles and vibration that helps to relax the wood fibers? Just a guess..

At least experimentally - it works better than just dipping in hot water when bubbles are gone, and much faster then using steam.

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

in - Build logs for subjects built 1751 - 1800

Posted

Semi-offtopic. Finished the jewelry box, the build log is here if somebody is interested: http://imgur.com/a/7fNCc

That was an interesting practice, took longer than expected. Totally new skill of turning a non-square non-flat warped piece of wood and making it square, flat and parallel on all sides. Jointing and planing, something not frequently used in the ship modelling!

Also, my standard way of "cutting an oversized part and sanding it to shape later on" does not work on that scale, so there were much more careful calculations and cutting to final dimensions from the first attempt. Well, maybe shaving 0.5mm from some risky pieces with the block plane..

First time I used OSMO Polyx (http://www.osmouk.com/sitechapter.cfm?chapter=82&page=247) as a wood finish. It is surprisingly good - dries fast, easy to apply, the end result is really strong. Will test it on a small scale, might be a good finish for the model. Anybody has an experience with OSMO as a ship modelling finish?