-

Posts

13,396 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Thanks, but not yet, Chuck! It's gesso and sand and repeat time now.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

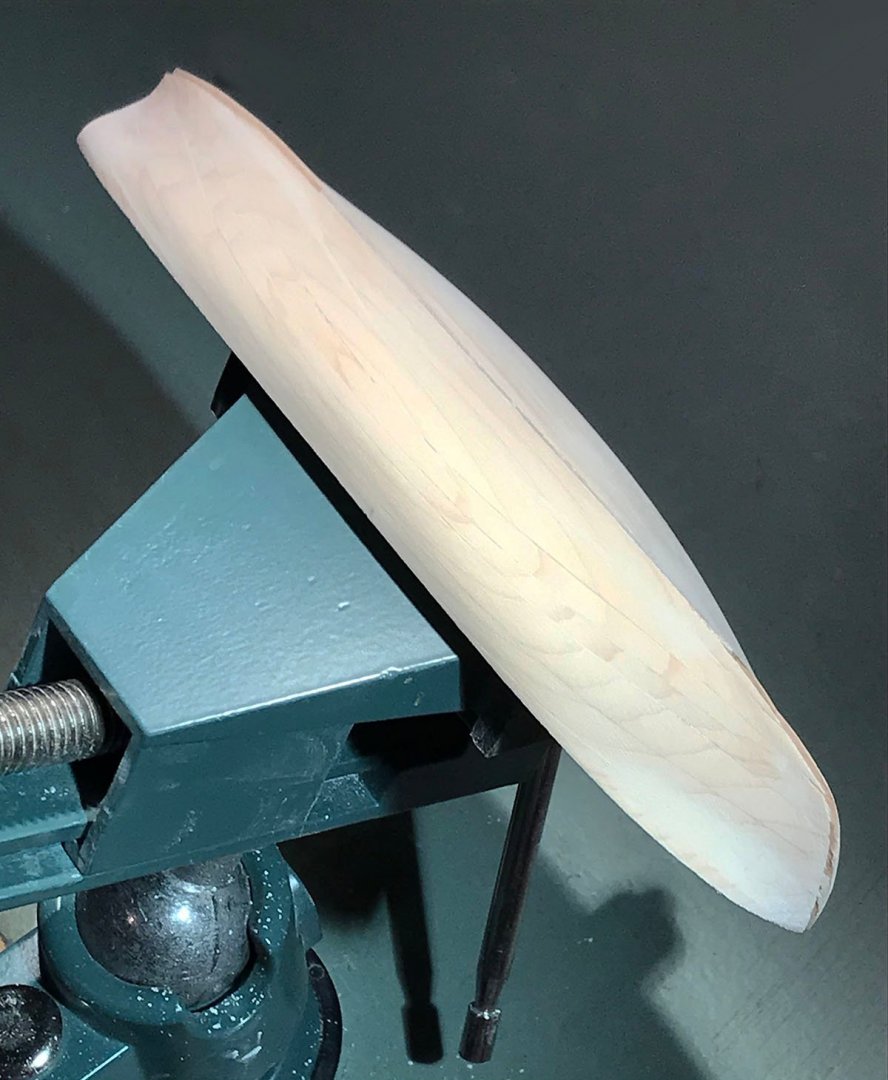

Just about completed the smoothing of the plug. It is worth taking time to refine this even though it isn't part of the model itself. A little filler was required in spots in order to create a smooth fair surface. Next will be several coats of gesso and sanding. The planking runs can then be marked out.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

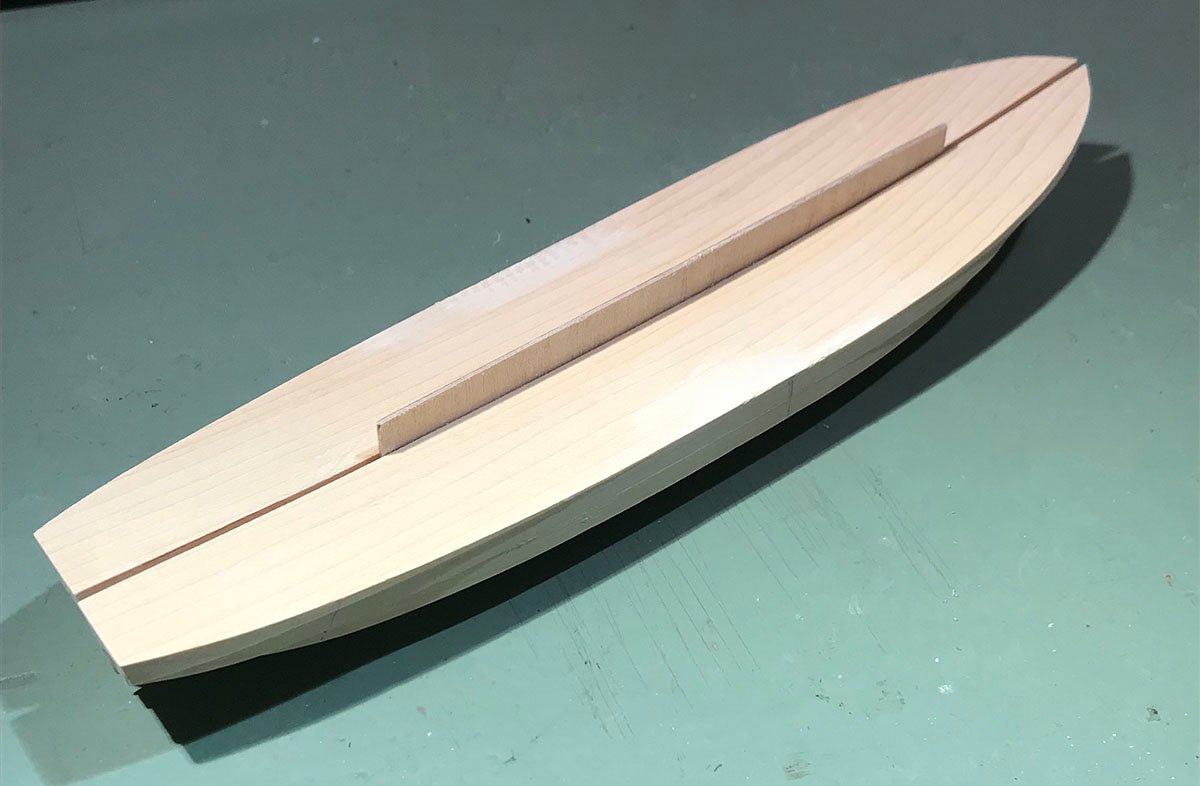

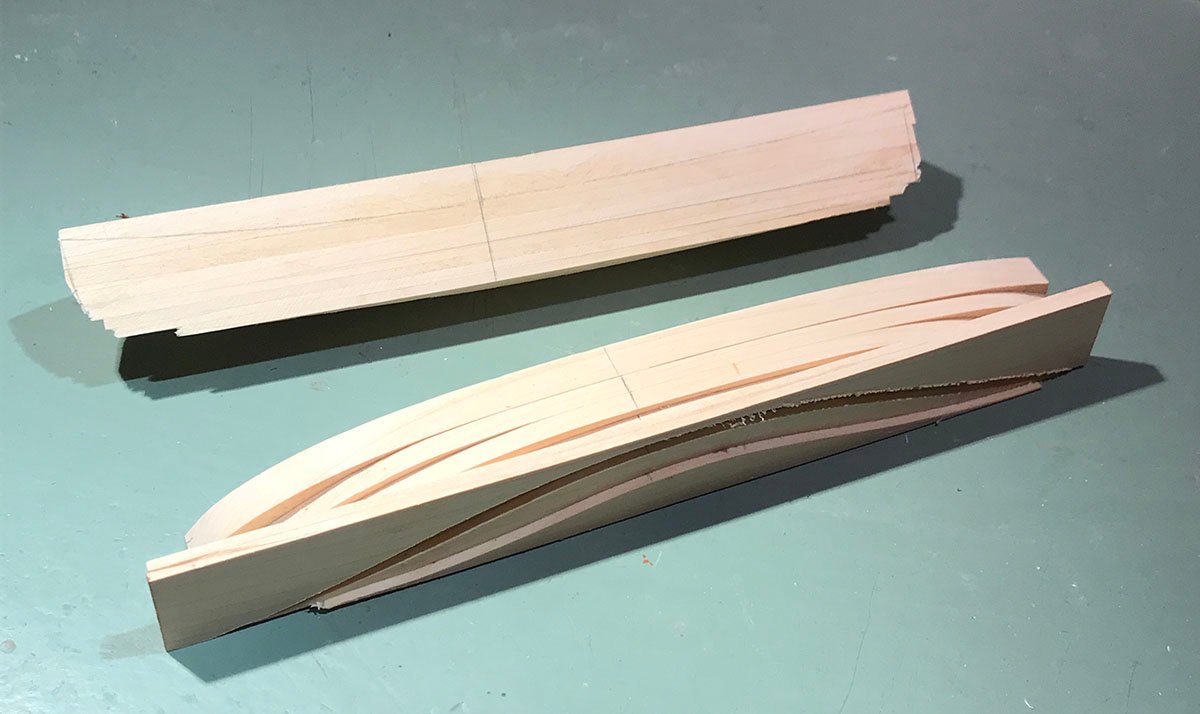

The sheer was sawn out and smoothed using shaped sanding sticks. The half-hulls were then joined with a central 'spine' to allow for the keel/stem/stern post assembly. The projection allows me to clamp the plug in my vise. Shaping then began using a sharp chisel and gouges.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Coming in late to this party, that is a lovely job that you are doing on this, Håkan. Visually the colors work very well.

-

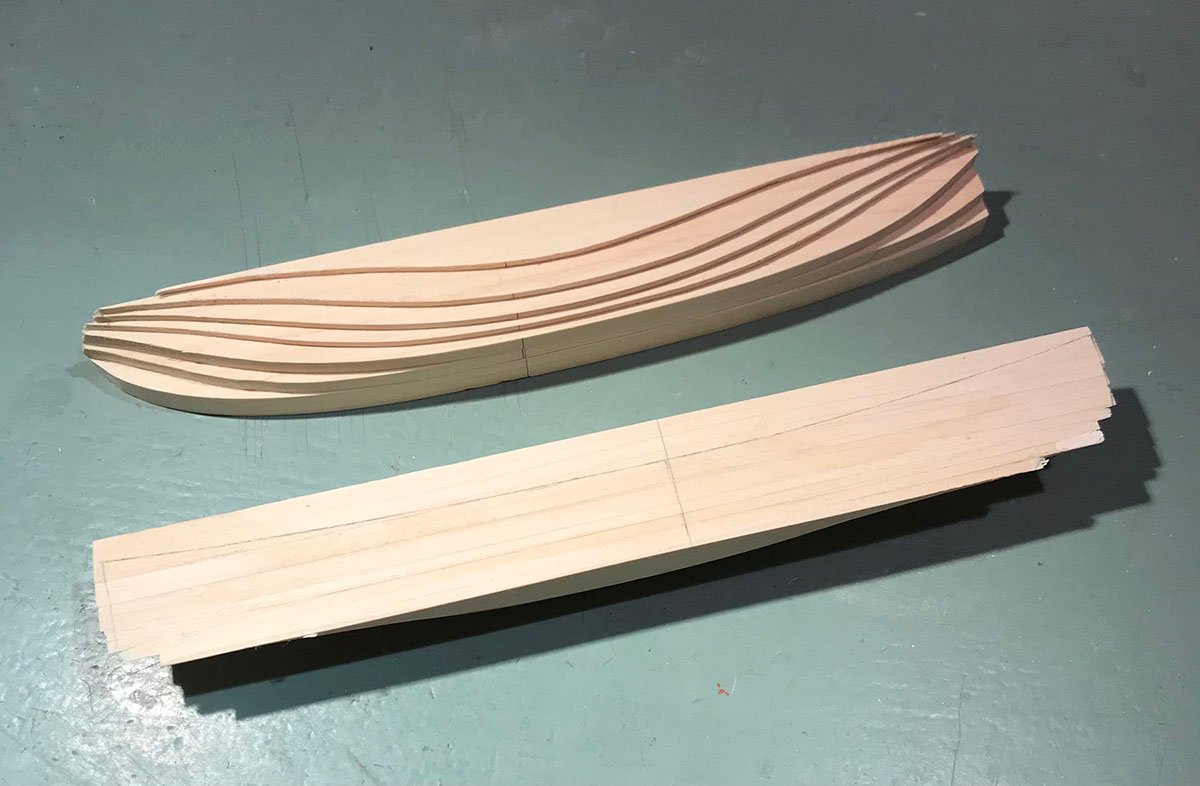

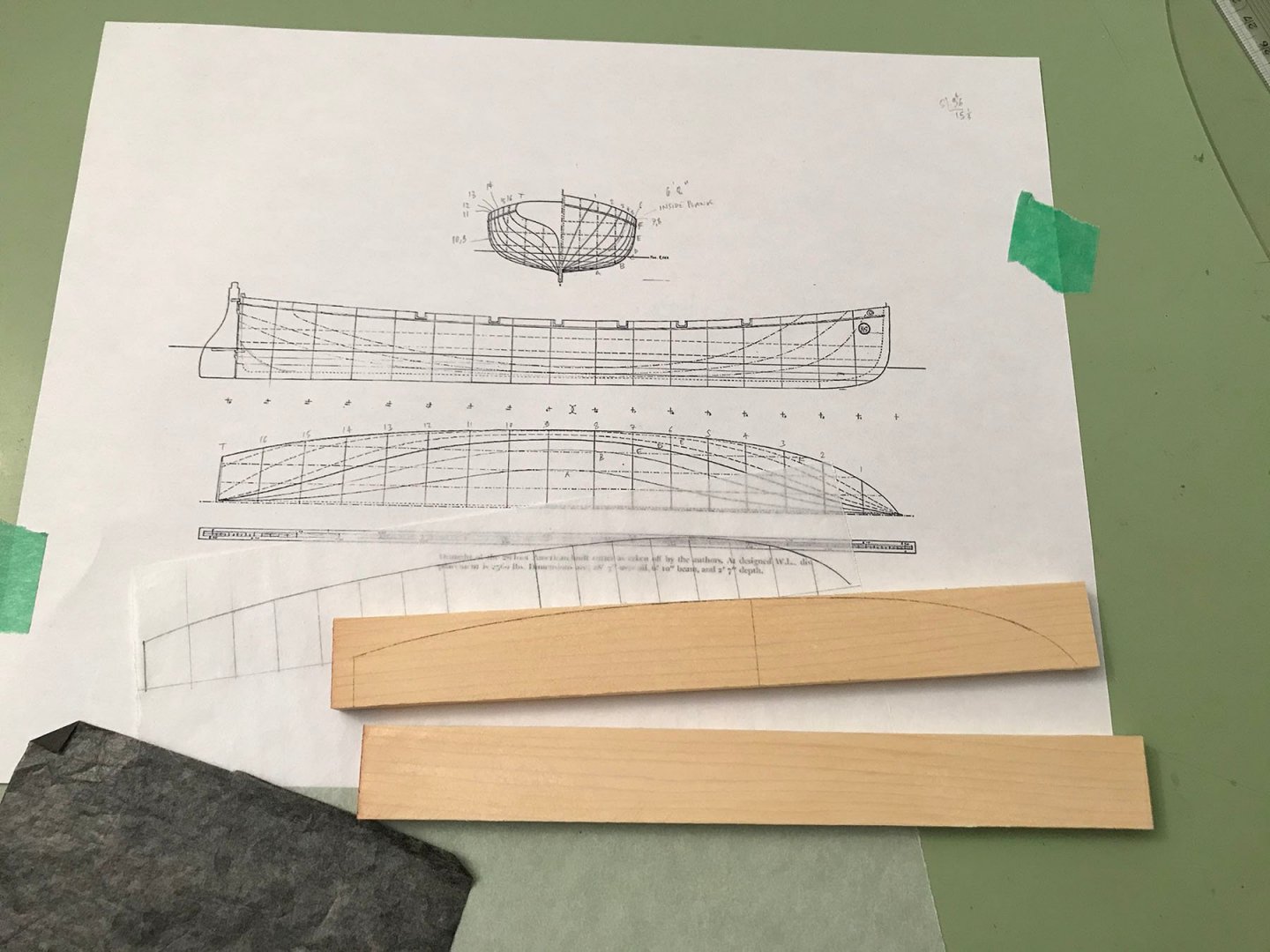

The lifts for the plug have been cut out and glued up. Next, the profile of the boat was marked out on the inner surfaces of the halves. I remembered to keep the off-cuts of the lifts to temporarily glue on again in order to scroll-saw the profiles!

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Thank you kindly, Bruce. That would be much appreciated! If there will be blame to be laid.... It's not often one has the luxury of a specific period small boat photo to refer to. Yes, Håkan, she is definitely carvel planked.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

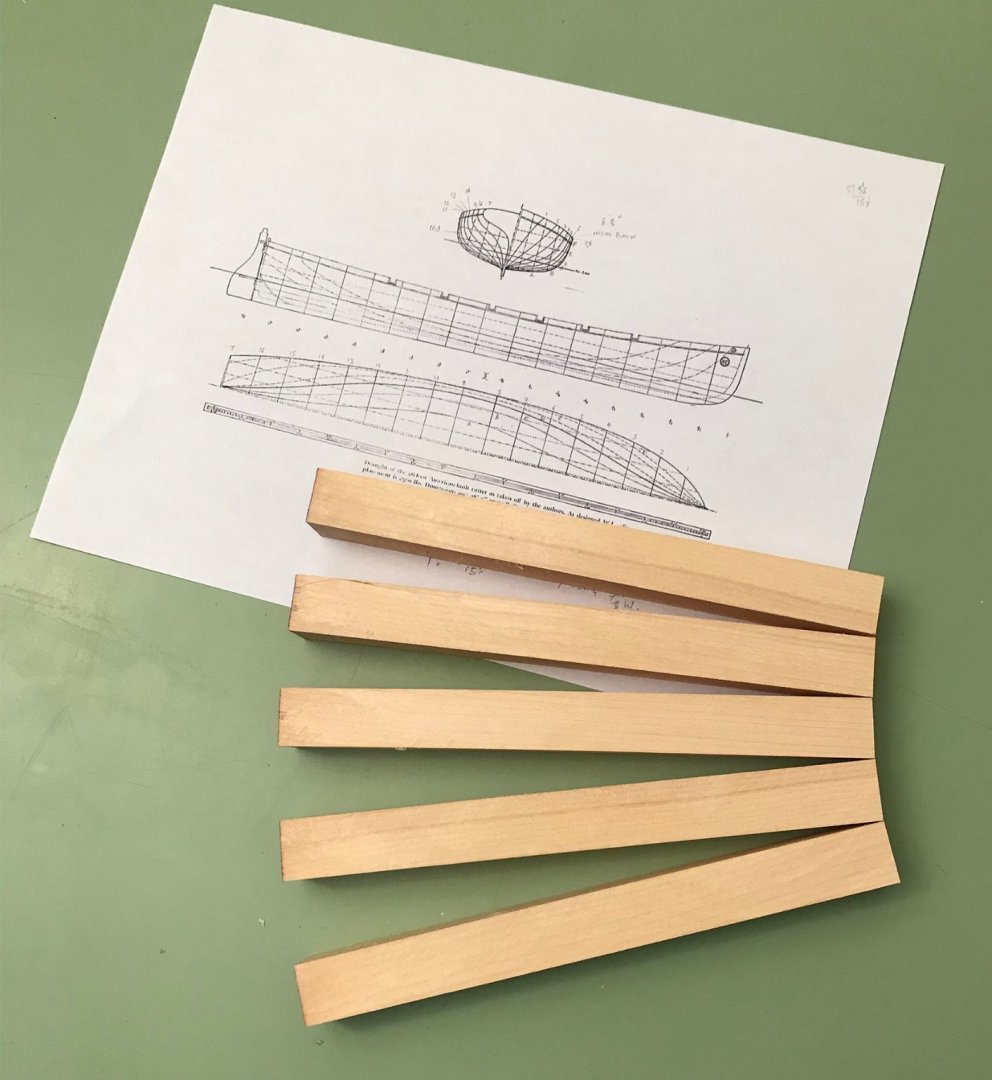

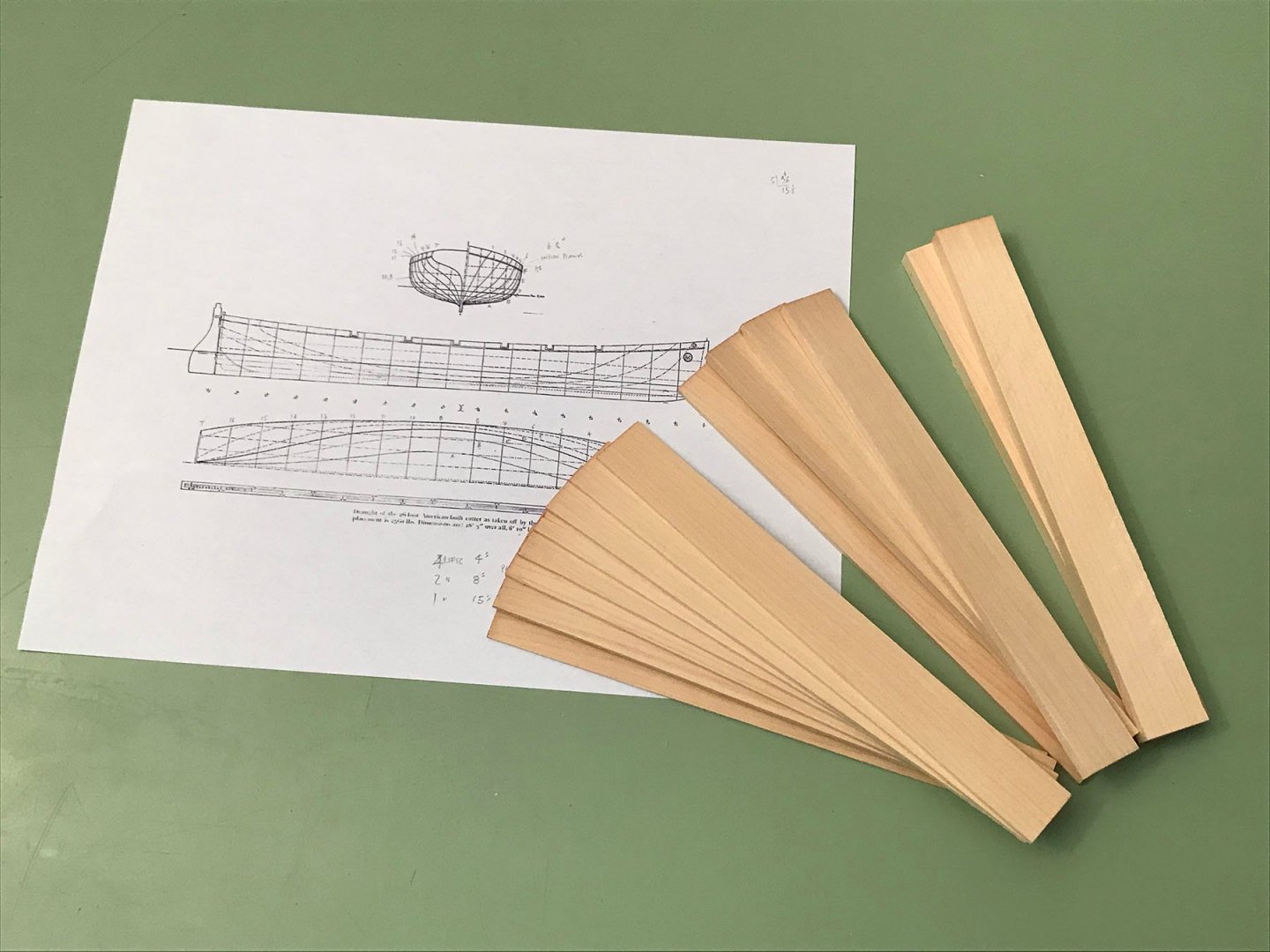

Well, having read the thread on an article seen the drawings and photos about a cutter preserved in Venice, the beautiful form has inspired me to attempt to build a model in 1:48 scale. The first step was to download the photos of the pages in the article that showed the surveyed drawings. These had to be stitched together and distortion removed, which was done in PhotoShop. Then the drawings had to be re-sized to 1:48. Having the overall length, width and depth helped define the reduction required. Once the drawings were to scale, I could begin. The first step was to begin preparing a plug on which to build the hull. Leaves of yellow cedar were cut from blocks (1) and sanded. Four layers a scale 4" thick, two layers 8" and one layer of 15" were needed for each half of the plug. These thicknesses matched the waterlines on the plan (2). Tracing paper was used to transfer the waterlines to the leaves of cedar and laid down using graphite paper (3). The opposite pairs of wood leaves were rubber cemented together before cutting them out on the scroll saw. To be continued!

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

If I may comment; I'm glad that you are having a good time, but reading and understanding the instructions first will prevent frustration!

- 11 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 2 more)

Tagged with:

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

druxey replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

I have a whole box full of different flexible and rigid sanding sticks and blocks. The blocks have convex and concave surfaces in different radii. Great for sanding things like stem pieces or deck beams.- 475 replies

-

Great result, Mike. The hanging of a rudder is so often poorly done with a huge gap between it and the stern post.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Quick! Ask Phineas for his 'shipwright's secrets'!

-

Have you considered turning just a master pattern and casting the guns that you need? That way they would all be identical. As Wefalck points out, your lathe set-up is far from ideal for repetitive miniature work.

-

Well done, Dan. Your client mailed the parts in an ordinary envelope????? At least I'm glad that the aquarium case has gone! She looks great. And now you don't have to smell the ivory any more!

- 95 replies

-

- POW

- Bone model

-

(and 2 more)

Tagged with:

-

Making Knees

druxey replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

You will find, unless building a floating box, that every knee will be slightly different and will need custom fitting. Mass production here won't fit. -

HMS Discovery 1789 by Don Case - 1:48

druxey replied to Don Case's topic in - Build logs for subjects built 1751 - 1800

Each knee will be 'custom', not off the shelf! If you are planning to rig later, there are also a myriad blocks to make.... -

Swan-Class Sloop by Stuglo - FINISHED - 1:48

druxey replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

About ¼" by 3", but I make them in all kinds of sizes depending on the application.- 475 replies

-

I suppose that the wood specie you are using is the issue. You need a dense wood such as pear or Castillo for such items.

-

If you look at the frame pattern, you will see the slot for the deadwood. There are two lines across the top of the slot. The solid line is the fore edge of the frane pair and the dashed line indicates the bevel to allow the frame to sit at the correct height. Does that solve your problem?

- 30 replies

-

Making Knees

druxey replied to Don Case's topic in Building, Framing, Planking and plating a ships hull and deck

Run the grain diagonally so that neither arm is cross-grained.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.