-

Posts

5,613 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by James H

-

-

12 minutes ago, BobG said:

James, I saw a photo of this boat that you posted in the coronavirus topic that showed you tapering the planks and installing them.

I have a couple of simple questions about the plank tapering process that you use. Do you always taper the plank on the bottom edge only and then glue that tapered plank to the previous one so that the untapered, top edge meets the tapered bottom edge of the previous plank? I assume that the top edge of the planks are never tapered, only the bottom edges? Is that correct?

Secondly, do you chamfer the edge of the plank before installing it if necessary? If so, how do you typically decide if the top edge of the plank needs to be chamfered? Do you chamfer the whole plank from end to end or just in places that seem necessary?

Newbie questions...thanks very much.

Hi Bob,

I run the plank along the previous and where it stops flowing naturally and looks like it wants to run over the previous, I make a pencil mark. I then take a look at the end of the plank and see the overlap of the previous and mark it. Those marks are then joined up and cut to add a taper. Where the curve of the bulkhead demands it, I will bevel the top edge of the new plank so it butts up close.

It probably isn't the best and most accurate way of doing it, and yes, I have to fit stealers into some gaps, but with the second layer, I'll make sure that anything like that is hidden under the painted area.

I really should learn how Chuck does it so it's a little neater, but it works well on this and other painted hulls.

-

-

-

3 hours ago, Javlin said:

I will be out of pocket it looks for a few days a week #19 got me maybe being admitted to a hospital later today looks like pneumonia may of already started in the r/lung and I started feeling ruff Sunday.This is the second time this build has been stopped due to illness last was in 2015.

PLEASE stay safe. Let us know how you go.

-

9 minutes ago, NewbyMark said:

Looks another very nice kit from Chris. Do you know when this would be available for purchase?

I think the plan is around 2 months.

- popeye the sailor, mtaylor and BobG

-

3

3

-

The school I work at closed today due to a confirmed case of coronavirus, and even though it will partially reopen in 2 days, after a deep clean, at-risk staff such as myself who has an underlying health condition, have been told to stay away for a month. Well, I couldn't waste any workshop time, so I got straight into the man cave and worked on Lady Isabella. Amati's sanding block had its baptism of fire when I faired the bulkheads in readiness for the planks. Thanks to previously bevelling the pre-engraved bulkheads, doing the rest only took about an hour, and in that short time I also got something to eat!

The pearwood keel is presented in three parts which plug into the false keel. The lower keel and stern keel part are now glued into he hull. Even though you can't really get this wrong, the kit supplies some MDF clamps to slide over the assembly to ensure all is straight and even. In these photos, you can see the stem keel section in place, but at this stage, it must only be dry-fitted to test.

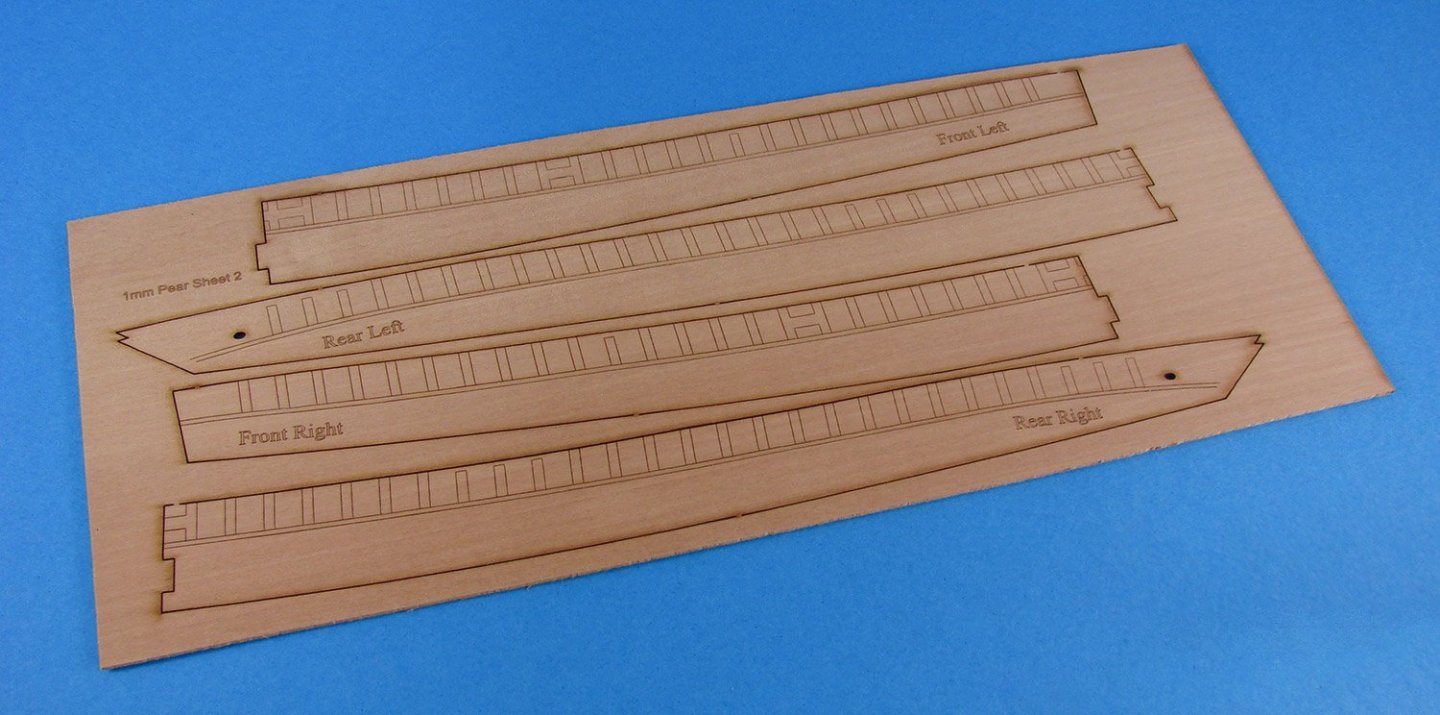

The pear bulwarks are supplied in two parts per side and are engraved on the inner faces. Engraving is for the timberhead and lower/upper deck levels. These parts are 1mm and need to be soaked in water for 5 minutes before they can be manipulated. There is a slot on the stern keel into where the bulwark slides. All parts were wet-fitted to the hull and left to dry before removing.

All parts are now fitted to the hull with Titebond glue, making sure the deck level is correct along the length. It's worth mentioning there is also a slot in the stem keep for the bulwark, but this isn't critical because the bulwarks are left slightly long to allow for any variation that the modeller might accidentally introduce. Some brass pins were pushed into the lower edges of the bulwark so the properly touched the bulkheads. Clamps were used above decks.

Whilst this lot was drying, I thought I'd work on the superstructure. There are some little pear pegs that fit into the MDF core. These are pushed into place and then the external pear fascias are glued. The fit is a little tight but that's so you get everything properly aligned.

Next.....planking.

- DelF, Haliburton, hollowneck and 18 others

-

21

21

-

Amazing work! I hope you'll create a gallery album, if you haven't done already.

-

-

-

3 minutes ago, BobG said:

I agree. There are lots of period warships to choose from but these working boats are, I feel, an underrepresented segment of good, quality model ship kits. They are wonderful boats with important and interesting histories and they come in all kinds of interesting and often unusual and colorful designs. I would love to see more of them from Chris in the future.

I absolutely agree. It's a lovely build too, with everything doing exactly as it should in terms of fit.

Fishing boats are my guilty little passion. There's a romanticism about them and the hard lives of the crews who bring us our fish suppers.

-

-

10 minutes ago, hollowneck said:

Your thread indicates that your HMS Victory production prototype is "imminent." Can you please give me a best (informed) guess as to how imminent, imminent is?🤔😂

Ok....Amati will, theoretically, have the laser and PE stuff at the beginning of April, so if all goes to plan, I should have for latest mid-April. BUT....who knows what curveballs coronavirus will throw at us. It's already caused a slight delay, and that was before a nationwide lockdown.

-

5 minutes ago, yvesvidal said:

Very nice start. It is always exciting to discover a new model from Chris Watton.

Could you post a picture of the finished model, or at least what it is supposed to look like?

Thanks

Yves

I will when I've finished it 🤣

Here's a pic of a very old model of one of these.

-

Evening all!

Well, I wasn't going to post a log of this until it was either quite advanced or finished. However, I figured that I could well have some serious free time coming my way courtesy of coronavirus, so I may as well spend some time and get this online. This model is a production prototype of Chris Watton's forthcoming 1:64 Zulu-class herring fisher, 'Lady Isabella'.

From Wikipedia (https://en.wikipedia.org/wiki/Scottish_east_coast_fishery)

QuoteThe Zulu

In 1879, Lossiemouth fisherman, William "Dad" Campbell came up with a radical design for his new boat. It had the vertical stem of the Fifie and the steeply raked stern of the Skaffie, and he called this boat Nonesuch, registration number INS 2118. She was relatively small, 52 feet (16 m) overall with a 39-foot keel length (12 m). The Nonesuch had her registration closed on 12 January 1901 after having been broken up. The Zulu War raging in South Africa at the time gave the name to this new class of boat.

The Zulu boats were built to the carvel method of planking. The shape of the Zulus gave the boats a long deck but a shorter keel, which greatly improved their manoeuvrability. Zulus were two-masted boats and carried three sails - a dipping lug fore, a standing lug mizzen and a jib. The sails were very heavy and difficult to haul, and the masts had to be very long and strong. Masts could be 60 feet (18 m) tall on boats of 80 feet (24 m) in length. Their design produced very fast boats that became invaluable to herring fishing fleets. They got to the fishing grounds quickly and returned swiftly with the catch. Because of these qualities, the Zulus rapidly became very popular along the entire east coast. As the 20th century approached, steam capstans were introduced, and this made the hauling of the sails and nets much easier for the crews. One of the best of those was the capstans patented and built by MacDonald Brothers of Portsoy, in 1908.

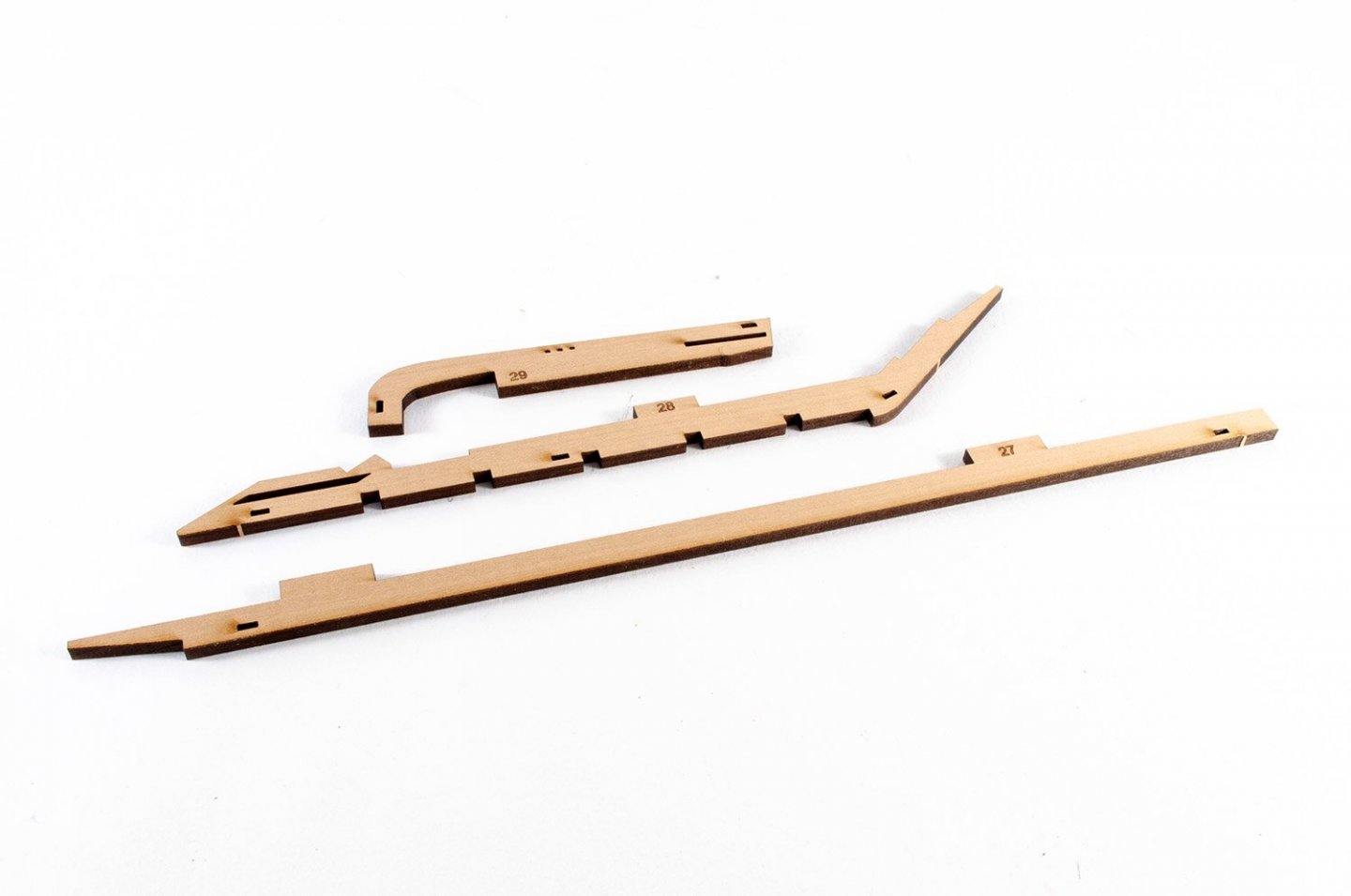

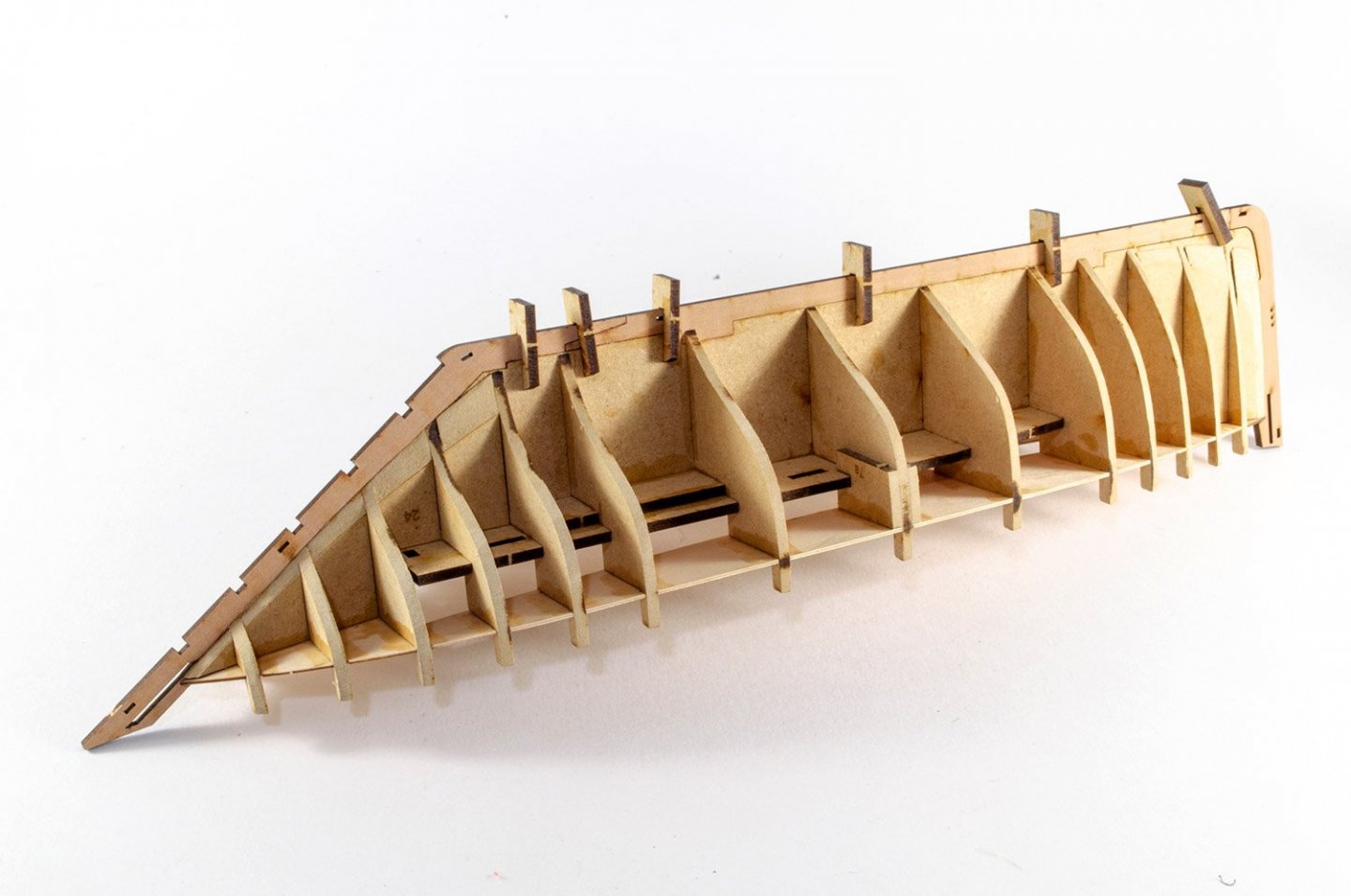

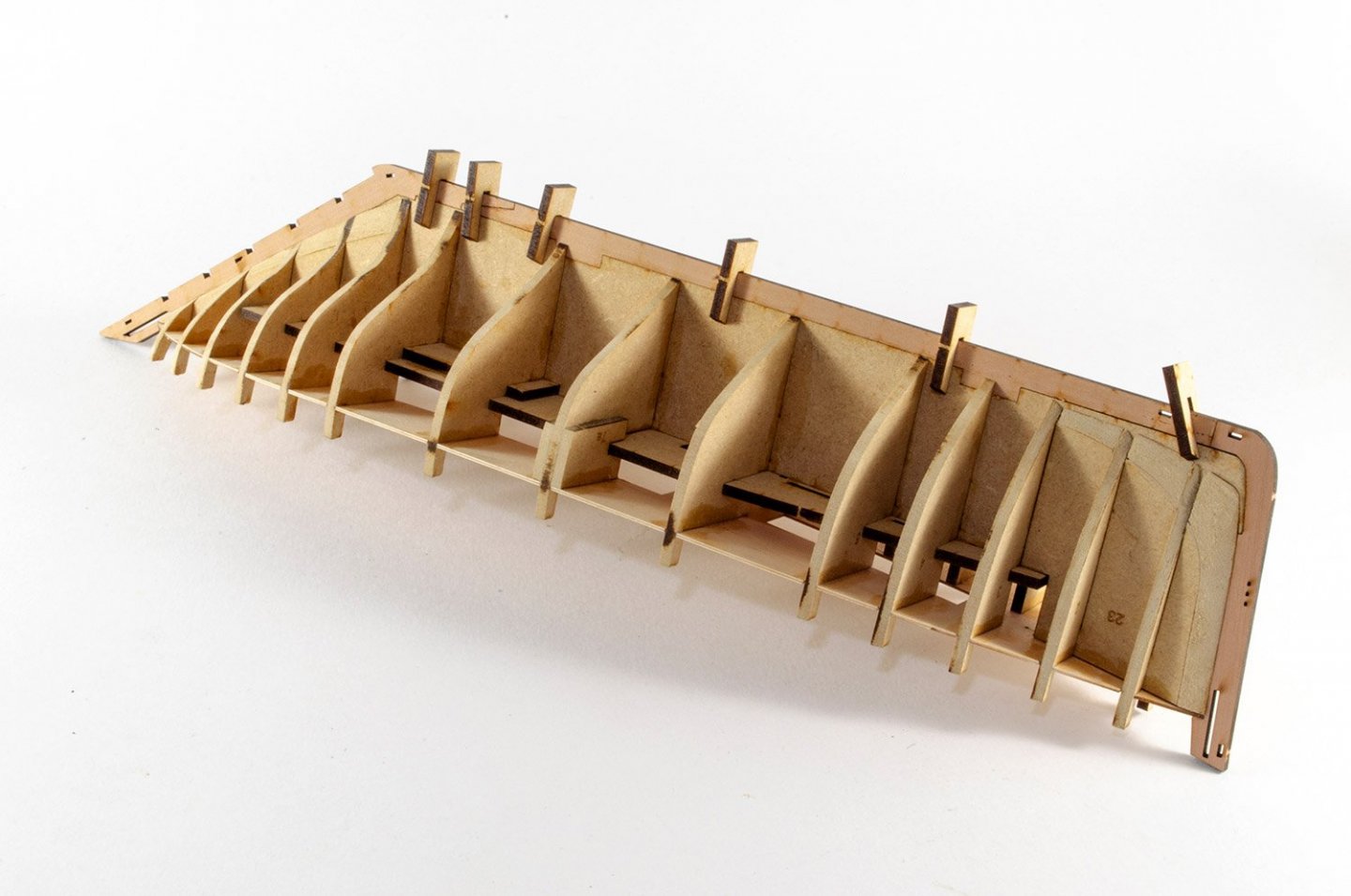

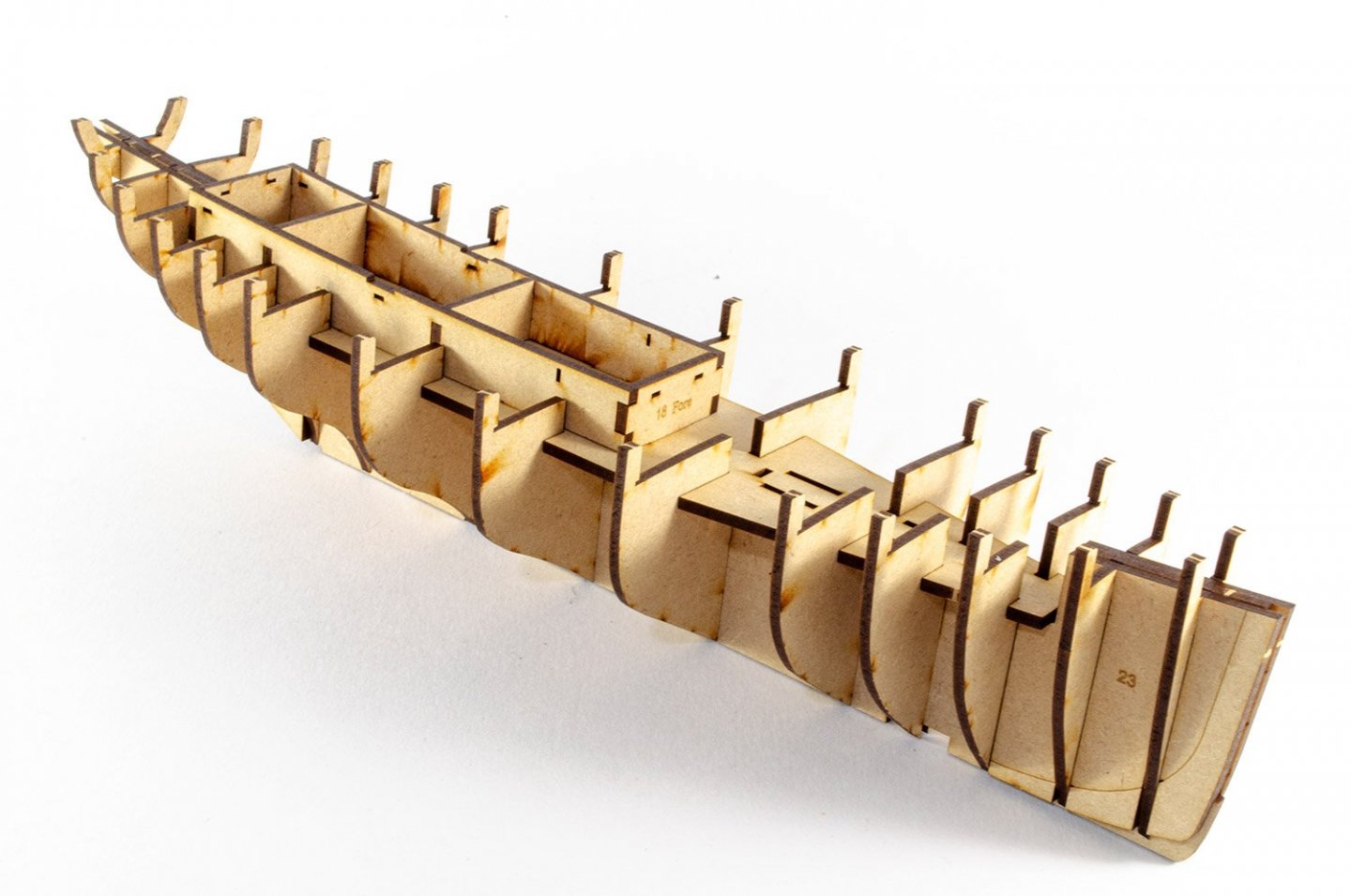

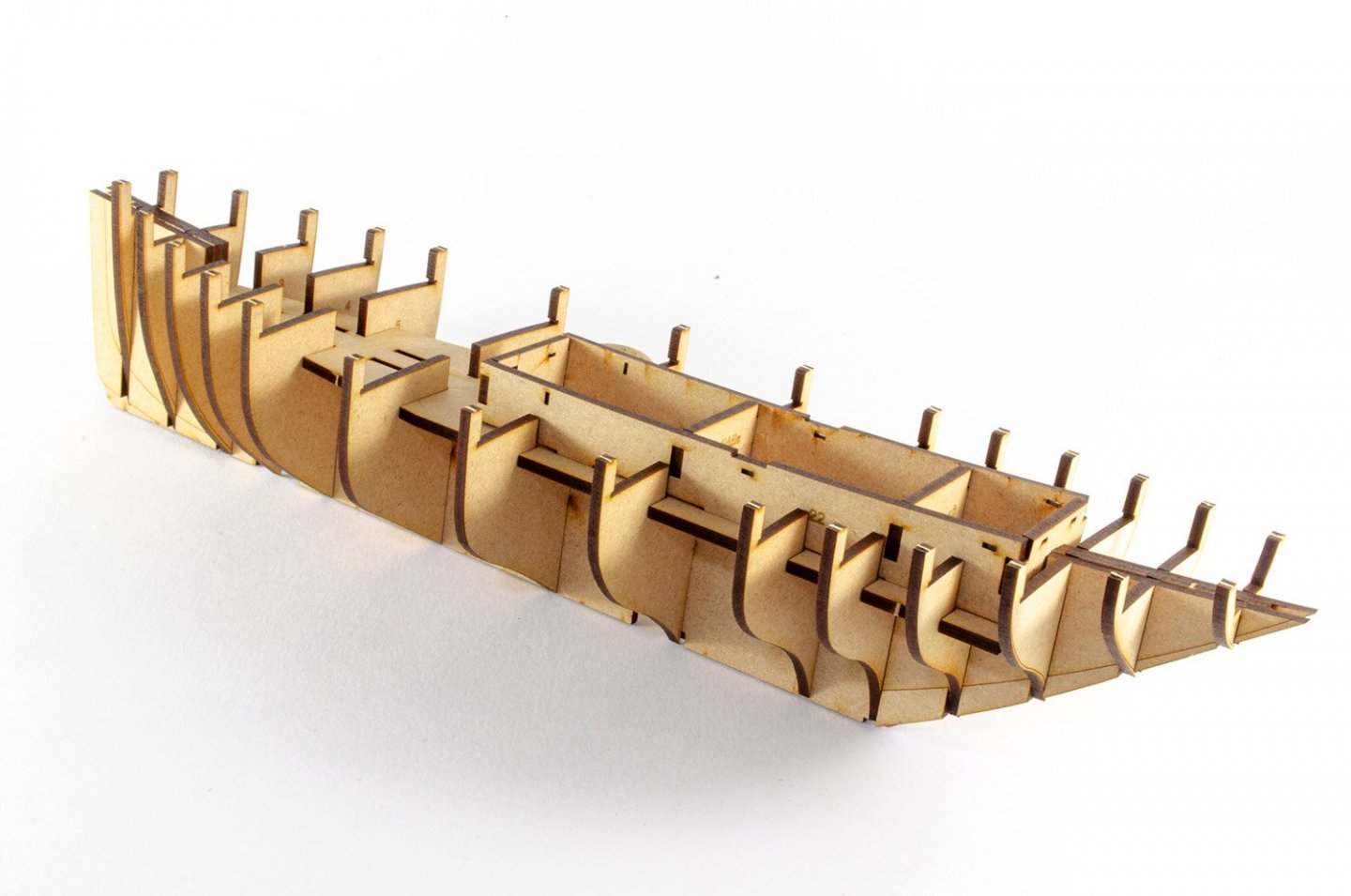

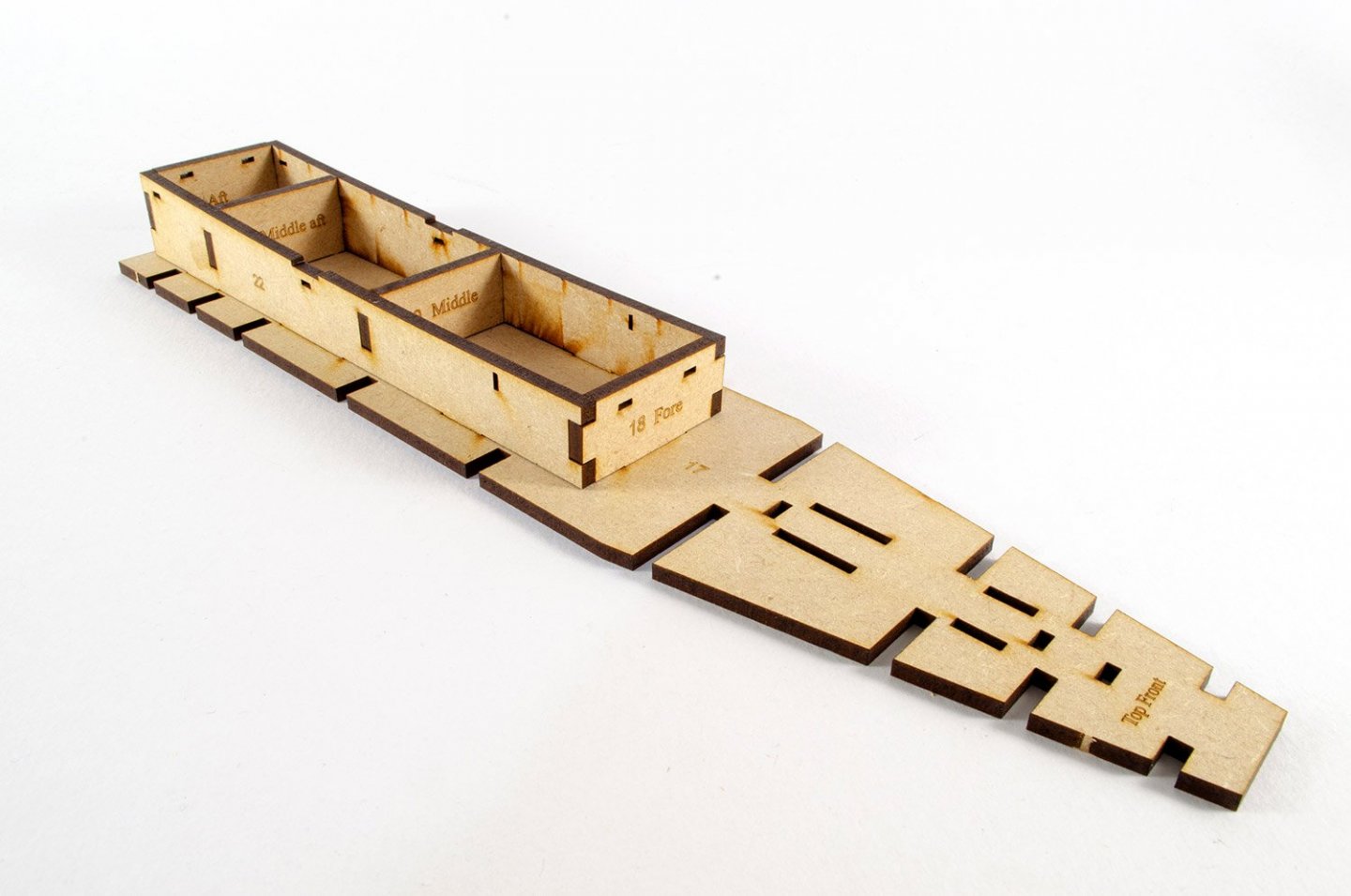

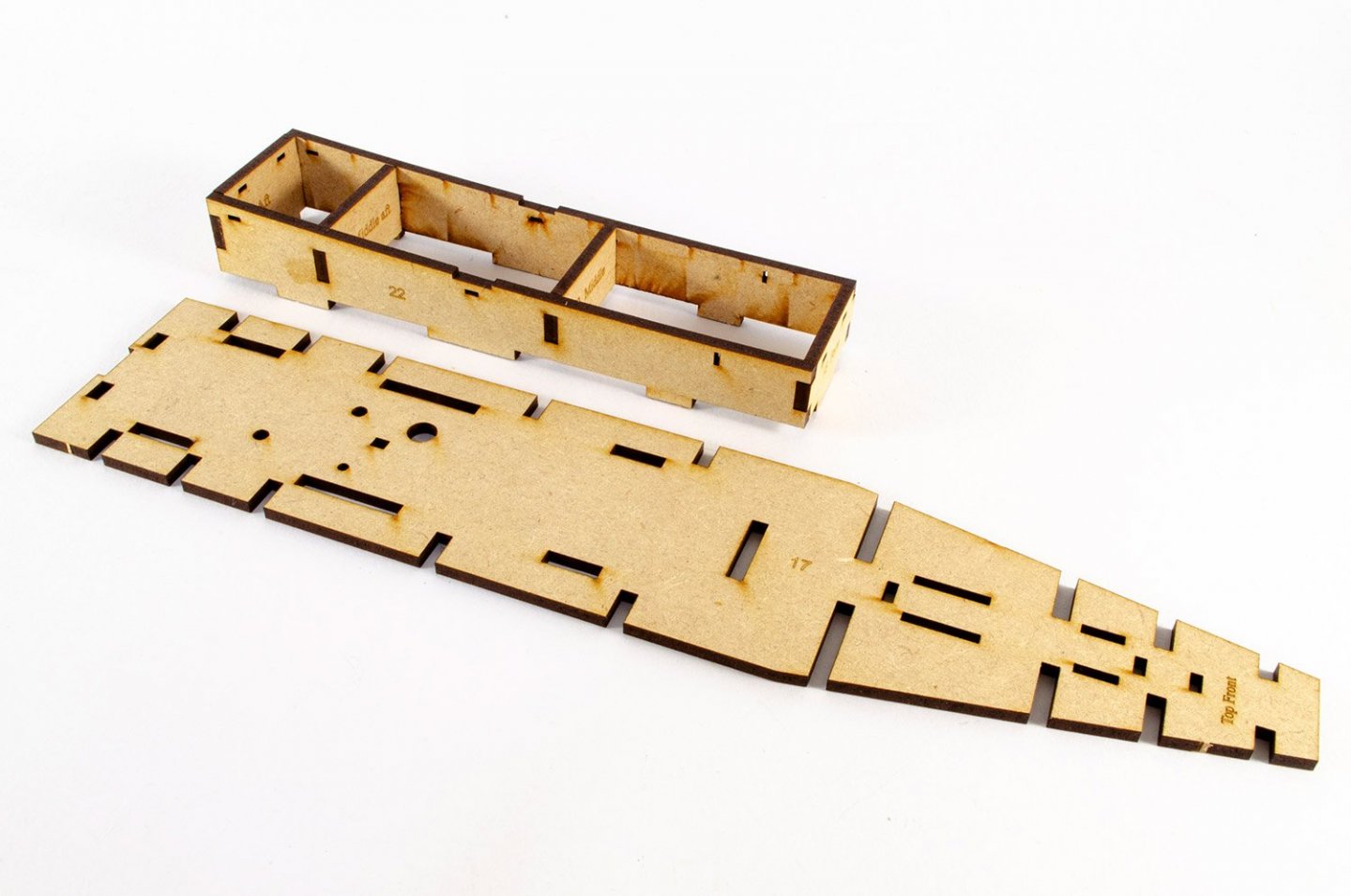

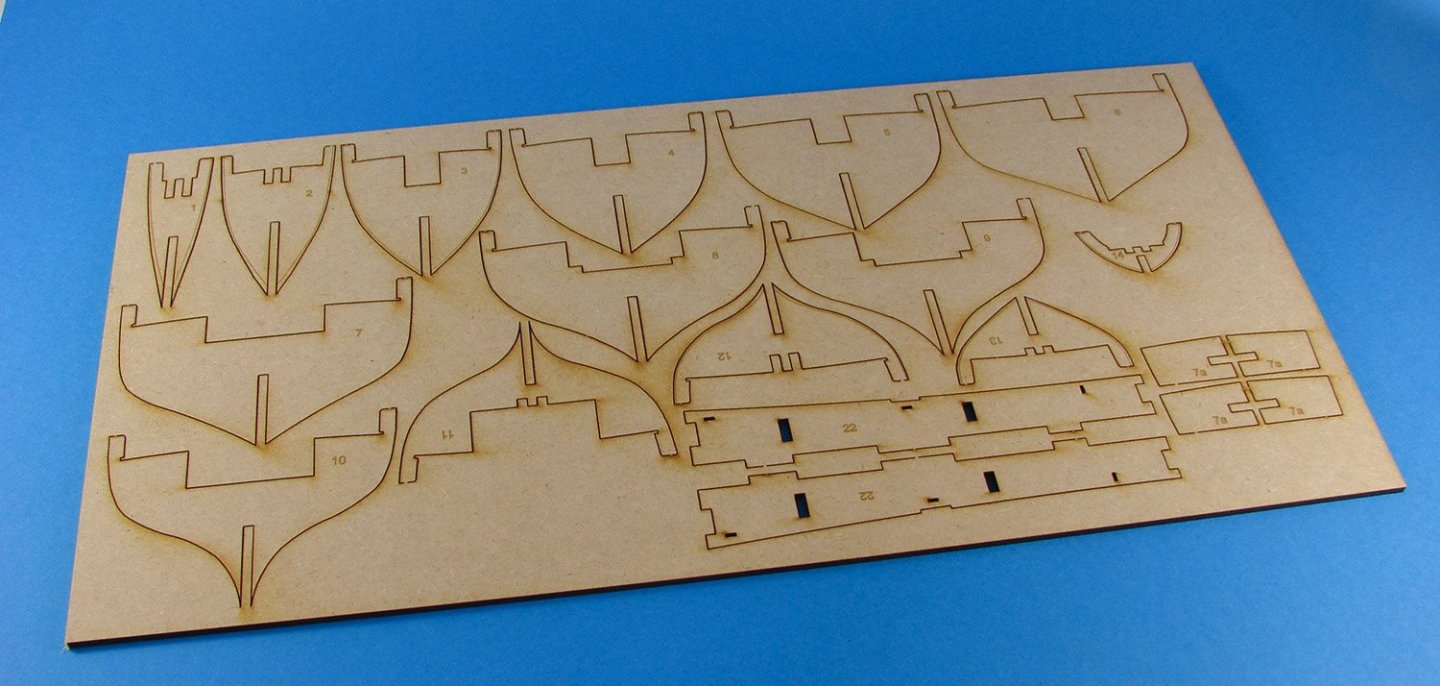

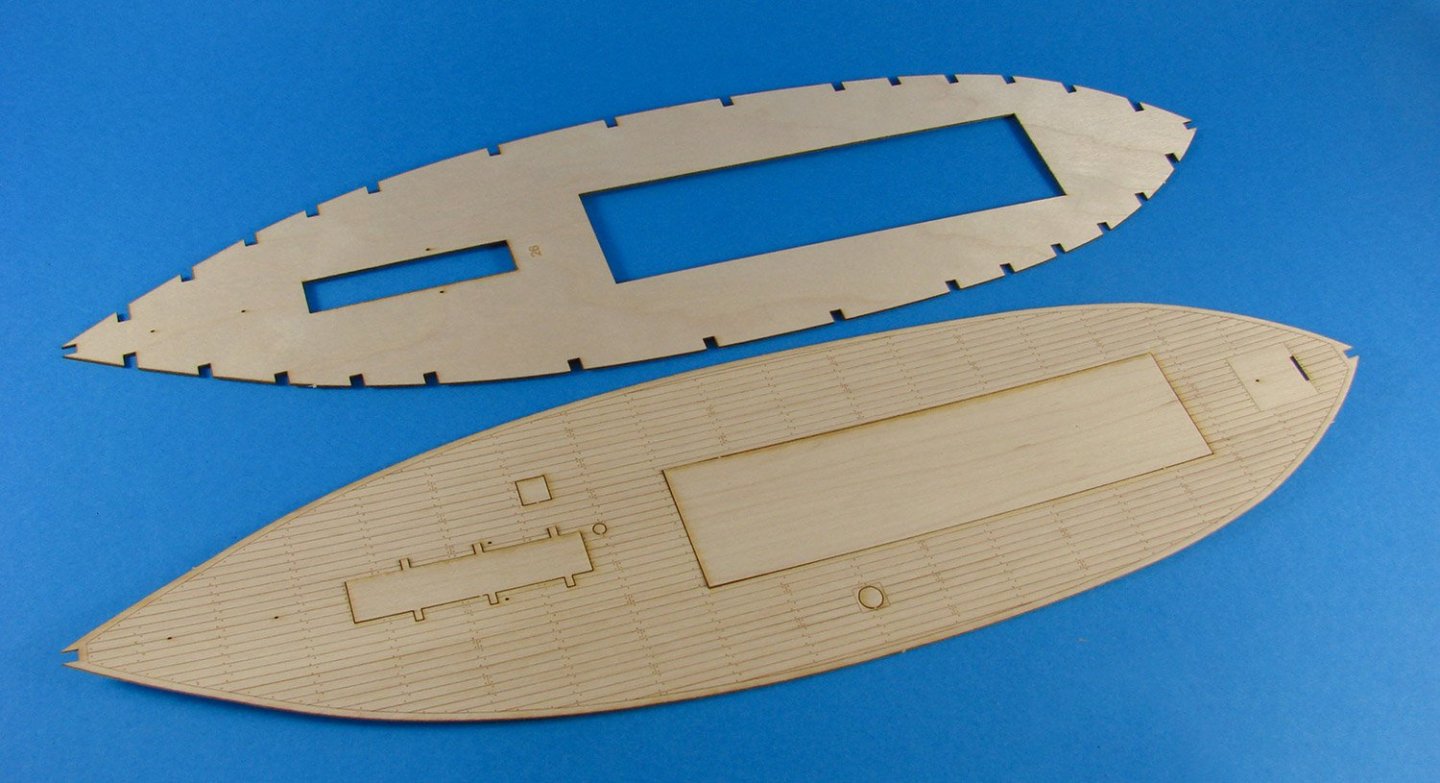

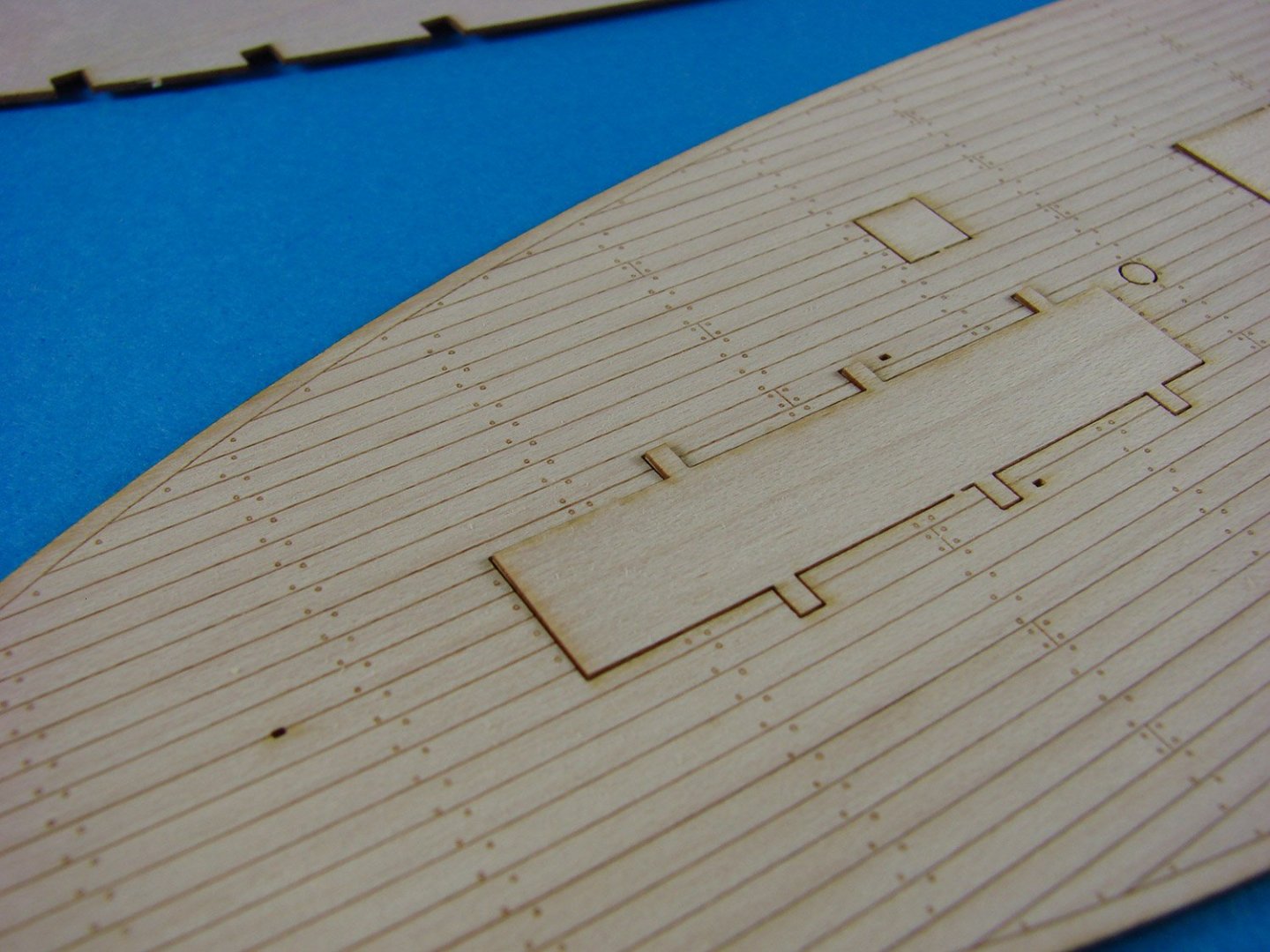

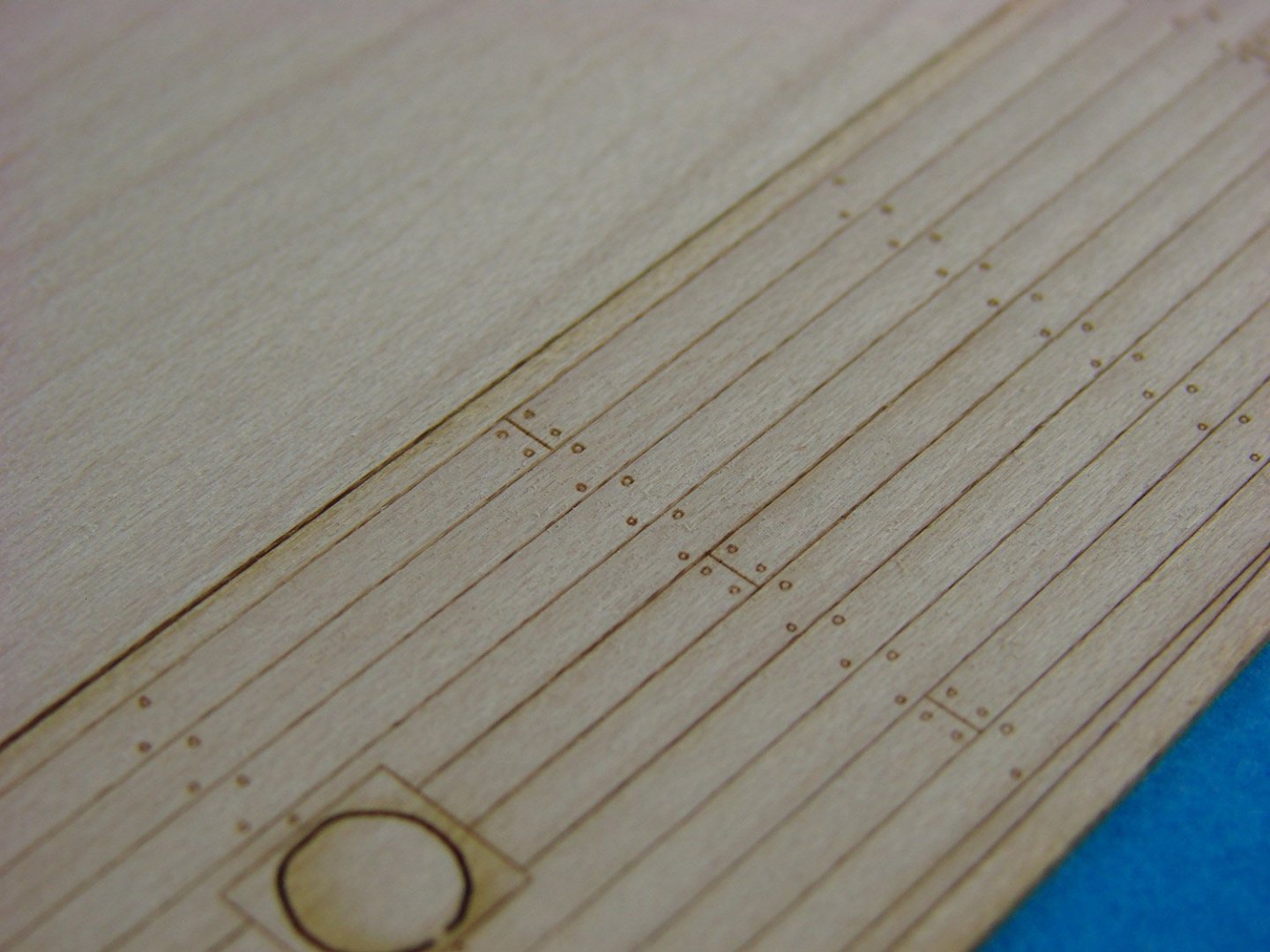

Here are some of Chris's photos of these very parts:

Here is my recent preview of this model, as the kit I received wasn't a finished product (no box, manual, sails, rig blocks and cord etc)

Ok, on with the show...

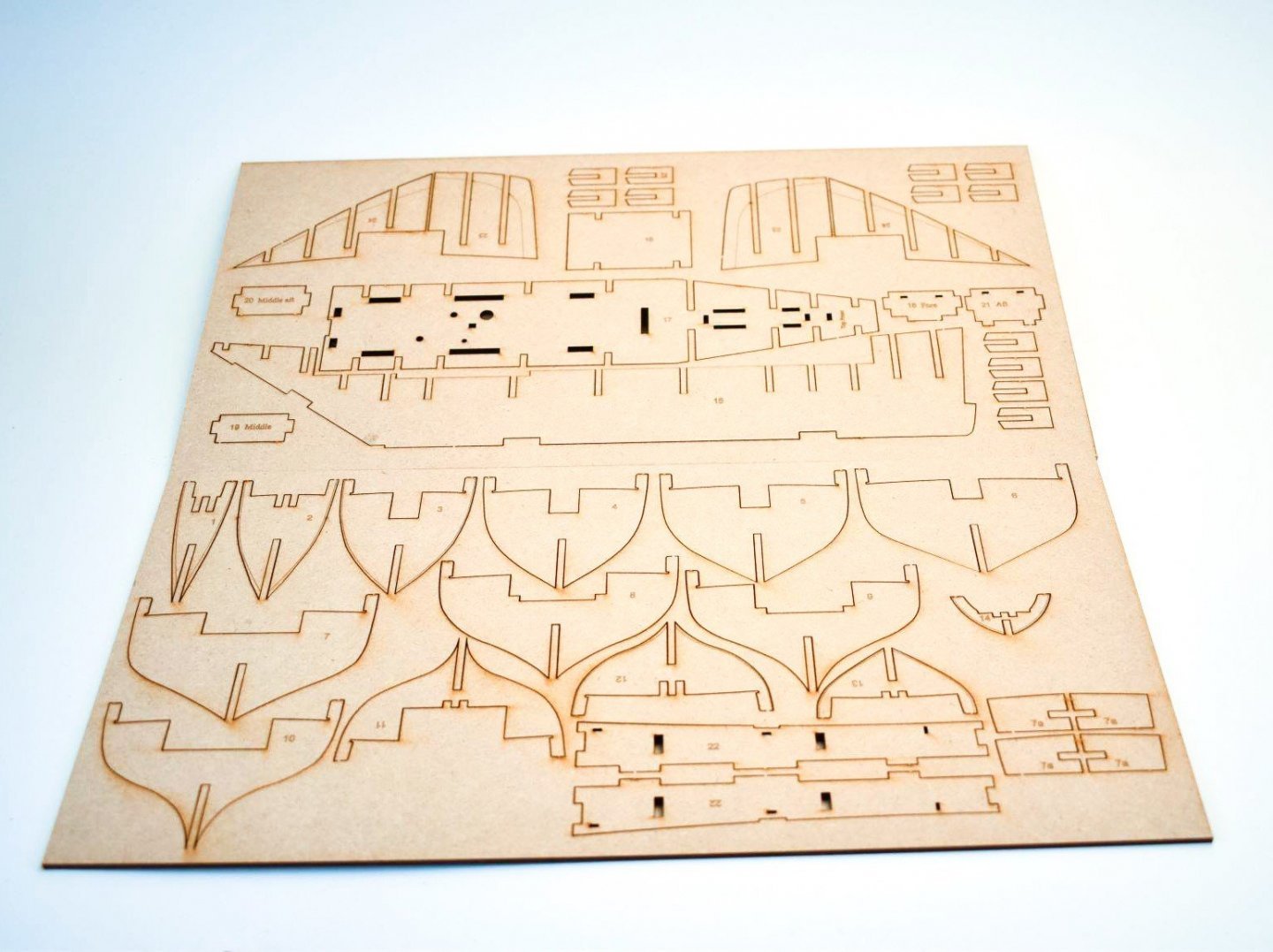

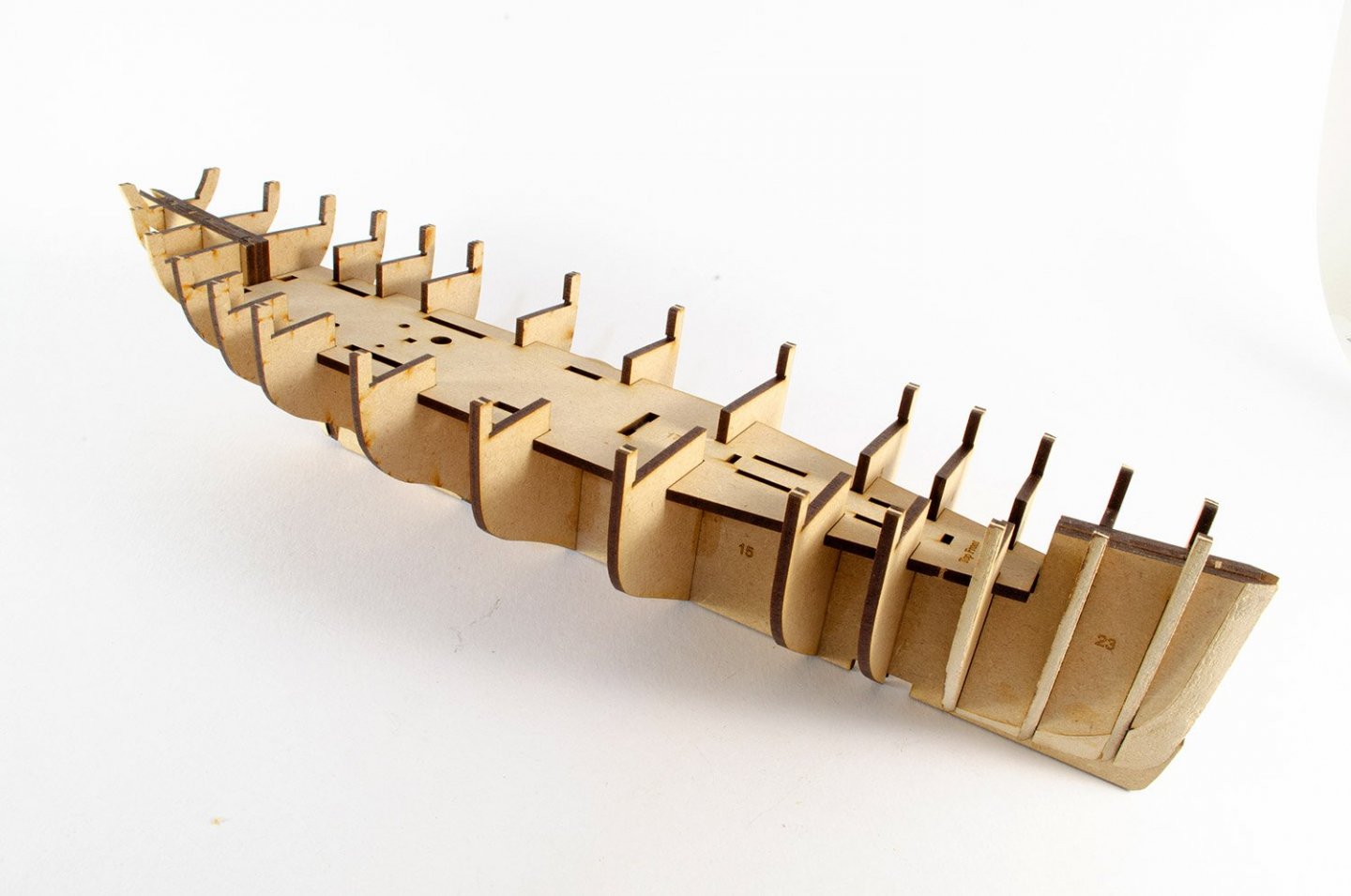

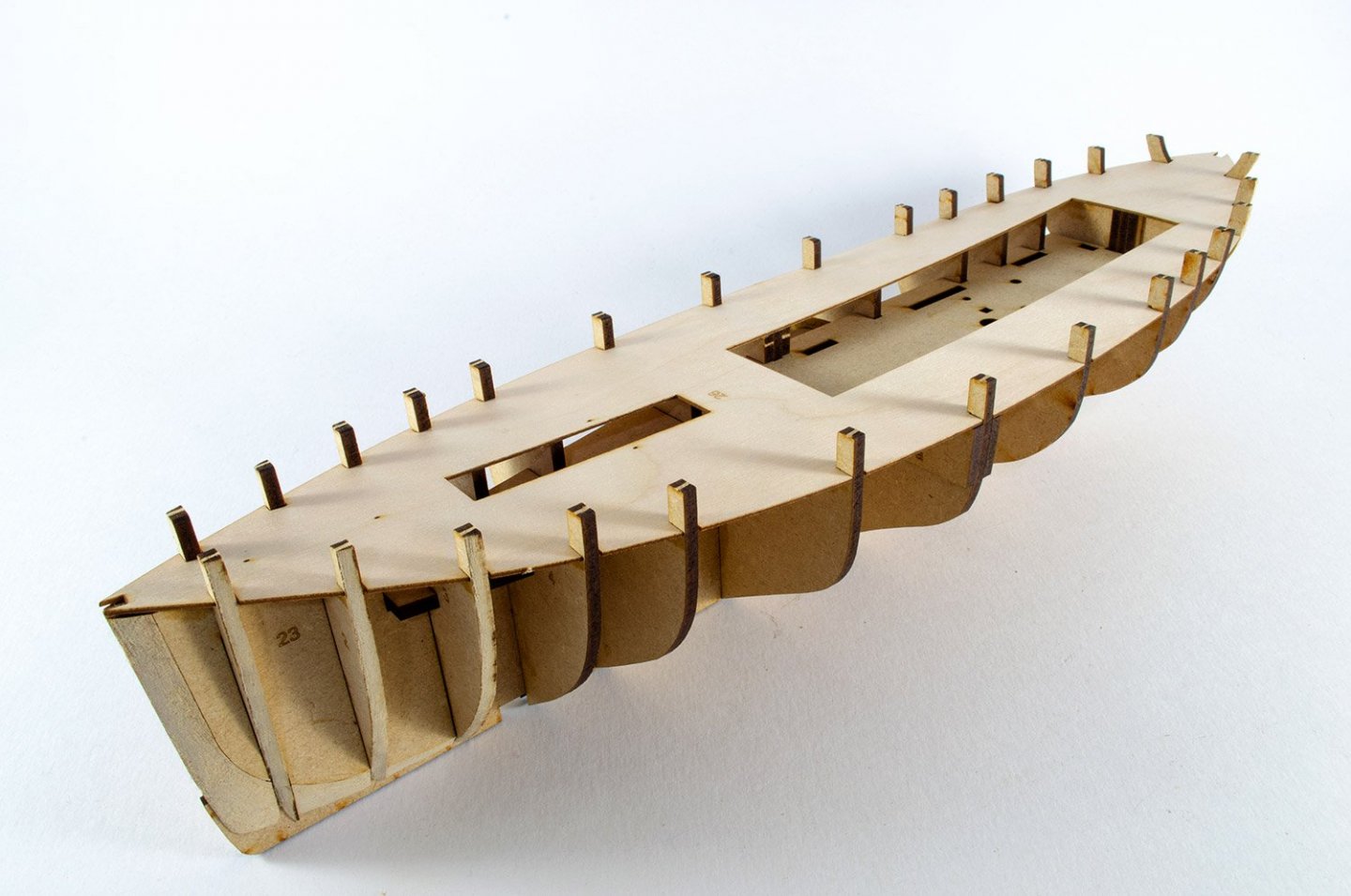

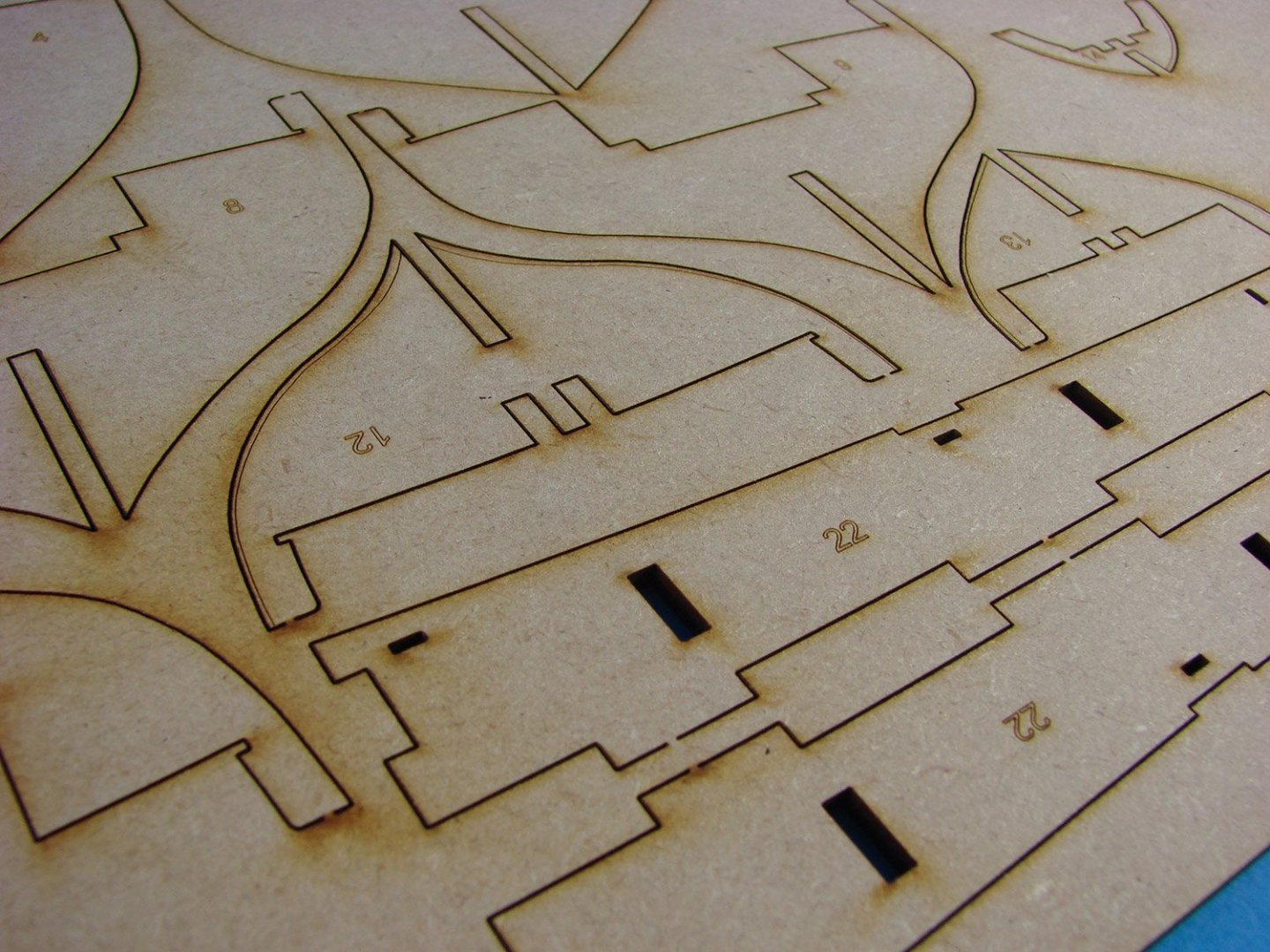

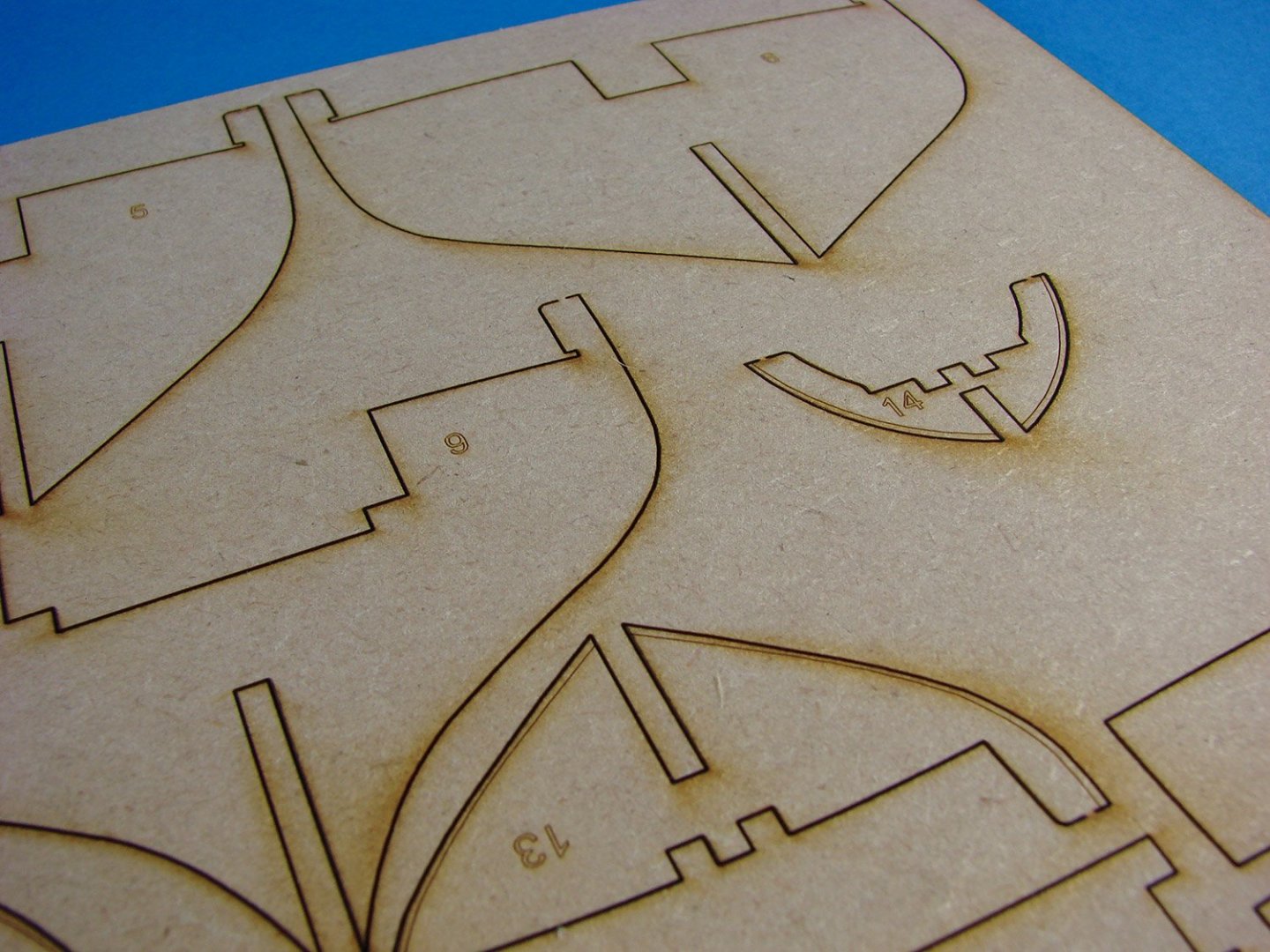

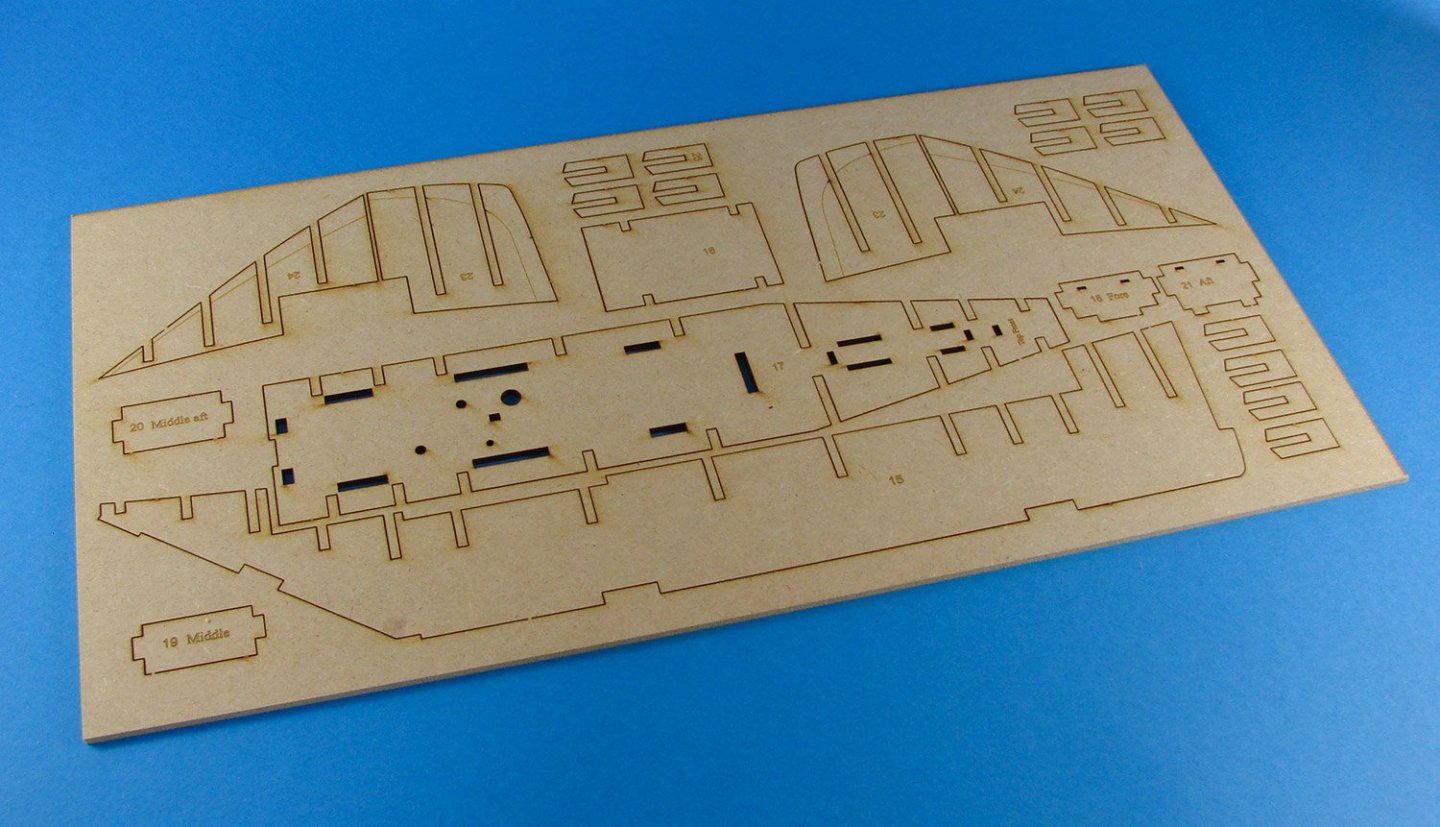

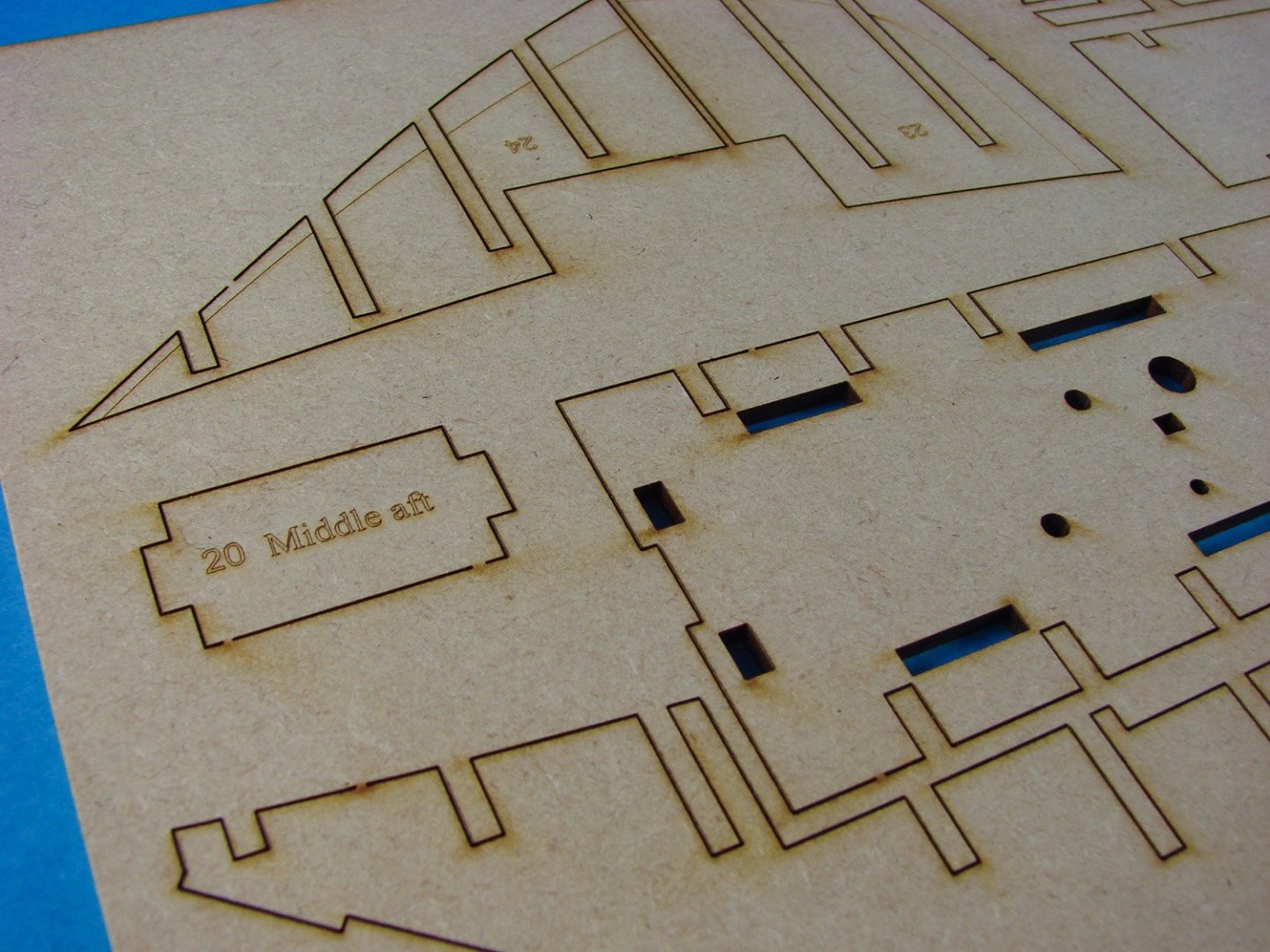

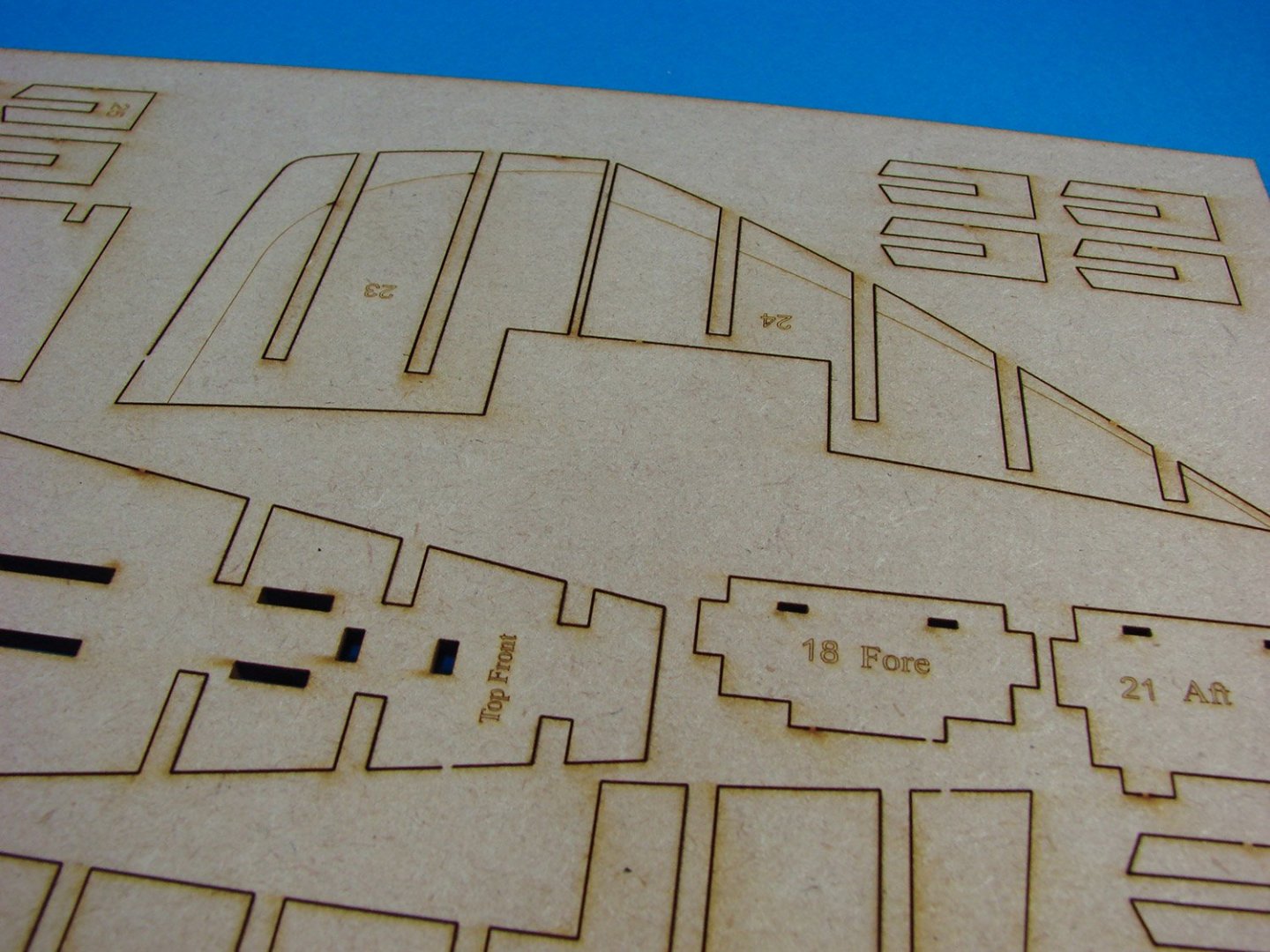

First of all, all MDF parts were removed from the two sheets. All parts are laser-engraved with numbers and some writing, so they are easy to identify. You'll also note some engraved bevelling lines on some bulkheads too. You'll tend to find that the tags that hold the parts to their sheets, are positioned in unobtrusive positions, such as the top of the bulkheads which will eventually be cut away. With all parts removed I did a quick test fit of the main parts.

Before any work starts, the superstructure needs to be assembled. To do this, it needs to be put together and glued while sat on top of the false lower deck. This is only to make sure everything is square, and it must not be glued to that part. Note some parts have engraved labels to help orientate them. I mostly use Titebond glue for my work.

It was now the turn of the bulkheads to be paid a little attention. Those which have a more acute bevel are engraved as such. Using a Dremel, I removed all the excess material from them on a sedate 9000RPM speed. The Dremel is also used to grind the MDF to the bearding lines on the infilled parts.

All bulkheads are now glued into position on the false keel, but this time I use white glue (Evo Stick PVA) as this dries more slowly than Titebond, and allows me some wiggle room until all parts are in place. The kit is made so tolerances are reasonably tight, so you can't really get anything wrong here. The false lower deck has text on it to define the upper side.

Chris has selected birch ply for the main deck lower surface. This makes it quite pliable. This is important because you need to be able to flex it slightly at this stage. Each bulkhead has the temporary timberheads notched. The deck slides into these to there's no reason to pin it at the edges. The deck just snaps into position perfectly and site perfectly across the top of the bulkheads.

I didn't do a test fit of that deck. I figured that once in place, it wasn't coming out again to easily, so I decided to paint some Titebond around the joints from the underside.

I almost forgot to add the reinforcement pieces 7a to either side of bulkhead 7. It didn't matter too much though as fitting them afterwards meant that I could slide them right in underneath the deck and bang into the perfect position.

More soon!

- Kevin, egkb, popeye the sailor and 16 others

-

19

19

-

What unusual construction. Very much enjoying this build.

-

What a great looking kit. Never seen paints included before either.

Looks a very classy release! 😍

- mtaylor, Ekis, thibaultron and 2 others

-

5

5

-

2 minutes ago, mugje said:

I like the slim lines of this vessel very much! Nice looking kit

You are almost wonder if a kit doesn't get to easy with all the little helpful extra's like the precut rabbet etc.

But I like the innovative way Chris Watton is designing his new kits.

Technically, it's not pre-cut, but a simple and very effective method of construction that creates it.

-

18 minutes ago, VTHokiEE said:

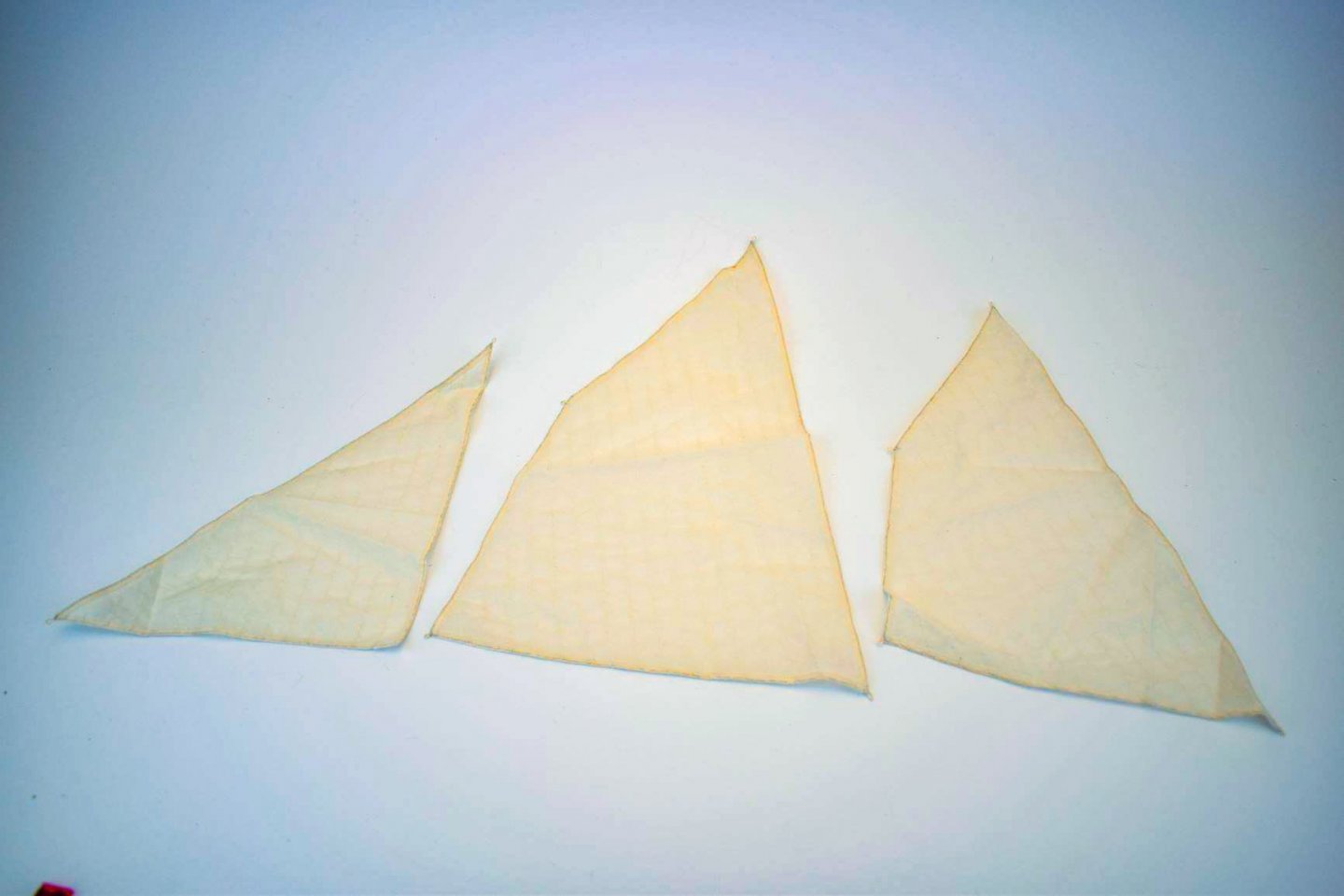

Are the sails going to be pre-sewn? Are you planning on using them in your build (or is Chris, I’m curious what they will look like)?

Being an amateur the differences of wood frequently escape me (aside from the “that looks nice” aspect). What visually would be different between the decks? Given the potential beginner market it may be a good idea to do side by side pictures so that a novice has a better idea of what the upgrade means to them (or maybe it’s simply me 🙂).

I’m looking forward to the two builds!

Sails will be an option, but the first sample set just landed. Here you are....

For deck differences, the prototype Fifie has the maple veneer deck, and Chris's Zulu has the 1mm limewood deck, but hard to tell the slightly different colours and closer grain on the maple, compared to limewood

- GrandpaPhil, VTHokiEE, tkay11 and 3 others

-

6

6

-

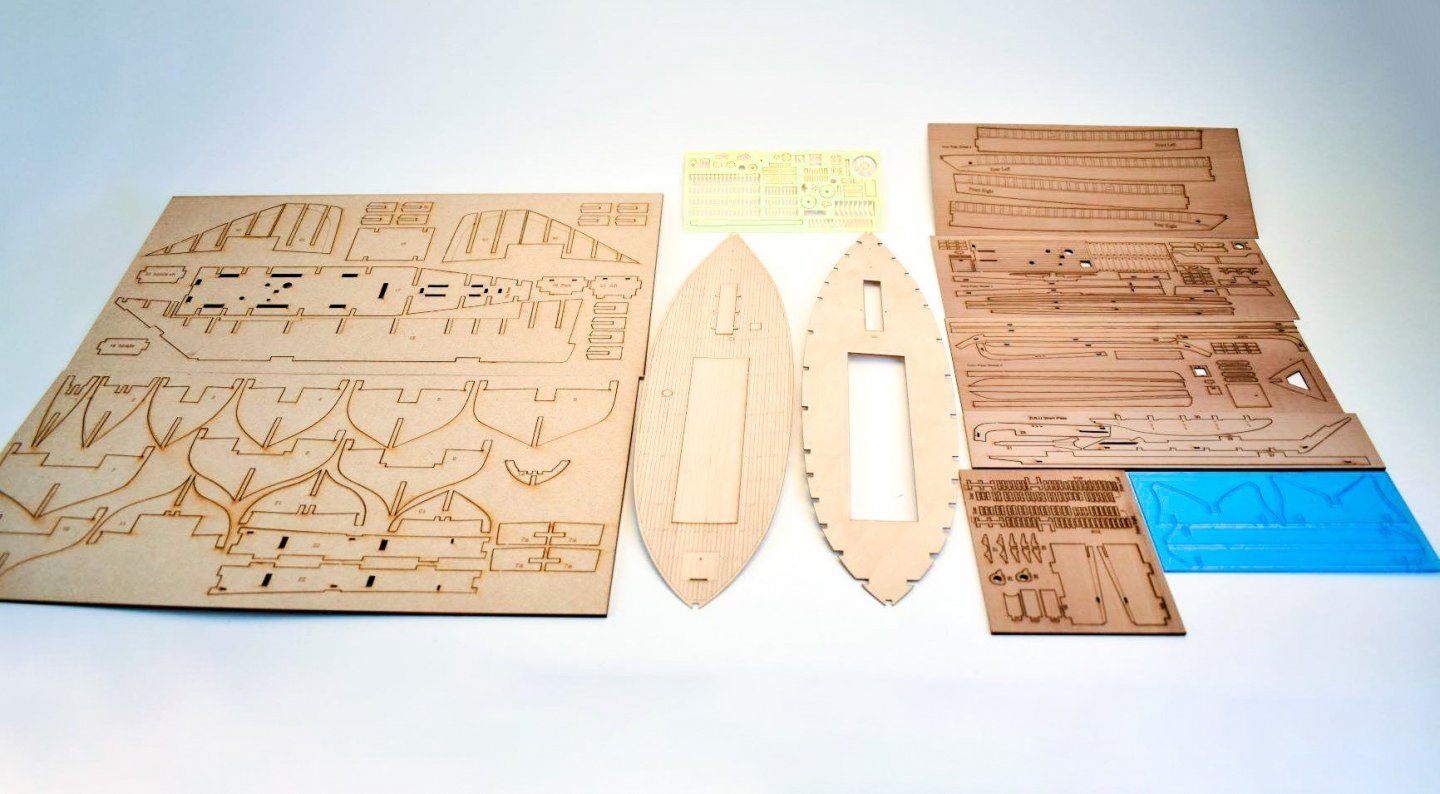

1:64 Zulu Fishing Boat - KIT PREVIEW

Vanguard Models

**Coming soon**Vanguard Models are currently around 2 months (give or take) from releasing two new kits which are suitable for both beginner and expert alike, but of course engineered to help those who want to try their hand at modelling a ship/boat in timber. Both models are in 1:64 and both are working vessels; fishing boats. These are the Zulu and Fifie class of vessel which tended to operate around the south-eastern coast of Scotland, mainly as herring fishers. If you know Chris's style of design, then you'll see it here in this preview kit I have for the Zulu.

This is a preview only and isn't designed to be a review. It's simply to show you the basic box contents before Chris finishes the kit. Firstly, it isn't a finished-boxed product, being sent to me in a regular shipper box. It also has no instructions and no plans at this stage, and rigging blocks/cord/sails will be with me later. My own build which Chris wants to use for a box-art photo, will be made using his prototype photos that I'm currently editing for his instruction manual. Sails will be provided as an extra, should the modeller want them. Many don't use sails, so you'll not pay for something you won't use when you buy the initial kit. Despite the model also being pitched at newcomers and novices, no poor quality materials have been used. You get pear in this kit, with an option to buy with a maple deck instead of lime.

The Zulu contains:

- 2 x 3mm MDF sheets

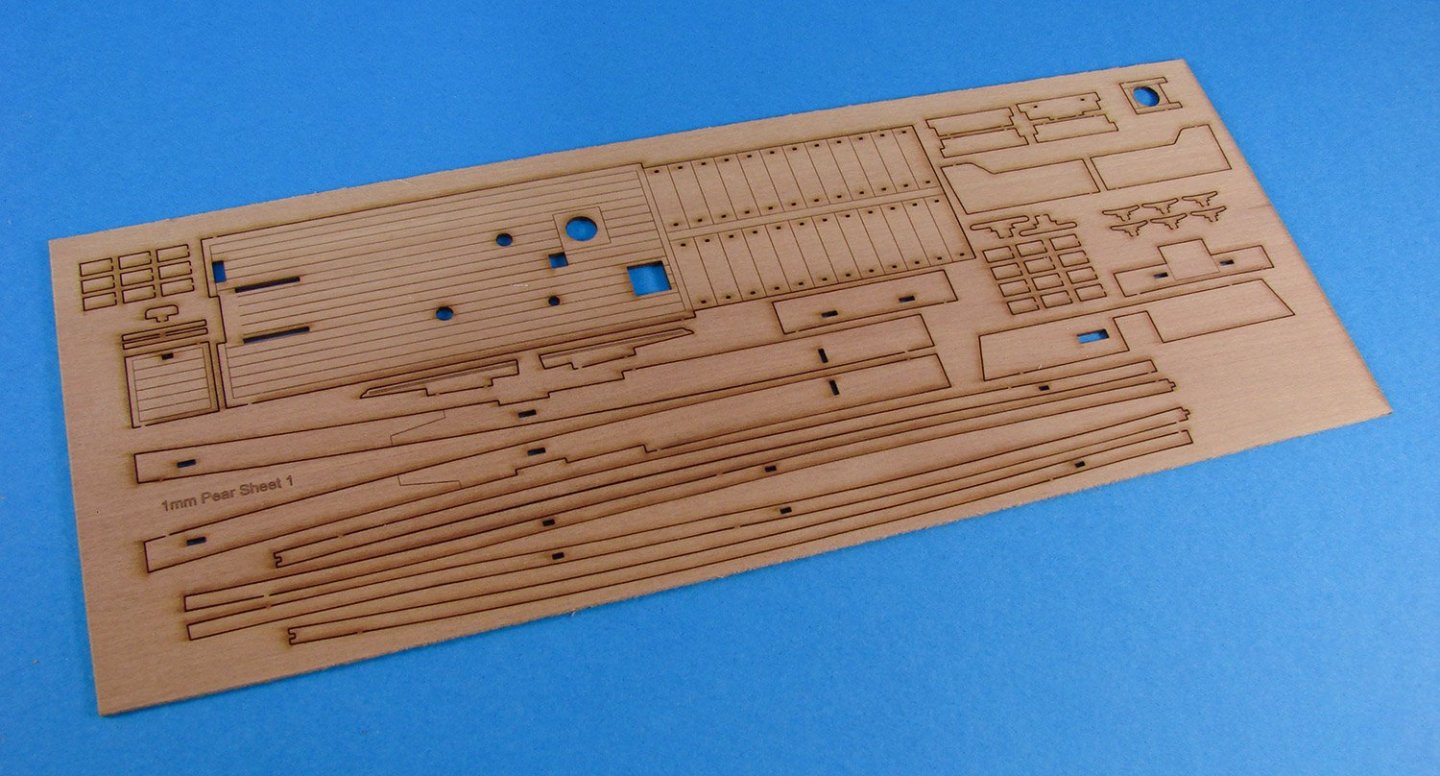

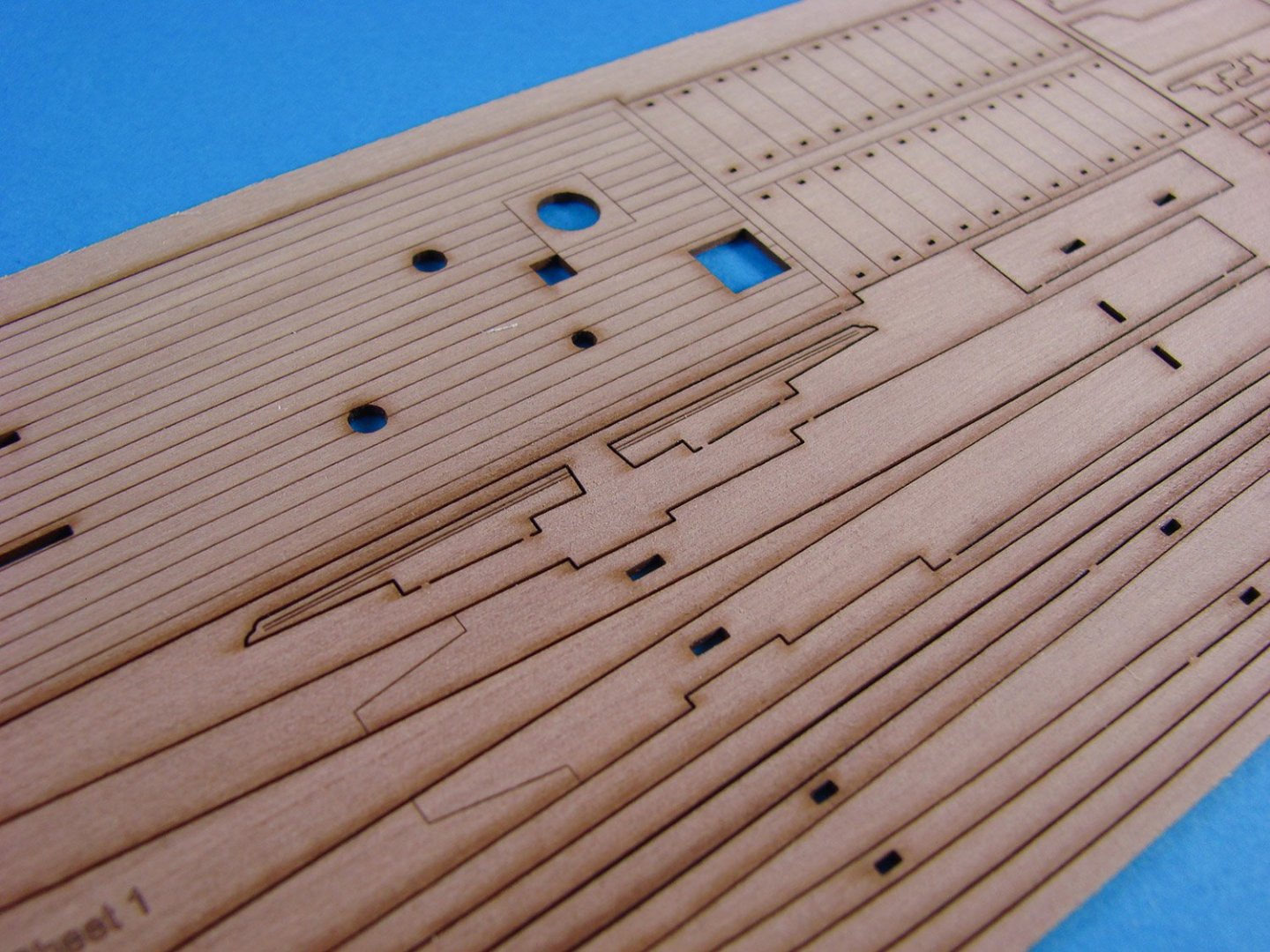

- 3 x 1mm pear sheets

- 1 x 2mm pear sheet

- 1 x 3mm pear sheet

- 1 x 2mm acetate sheet

- 1 x 0.8mm ply (single part)

- 1 x 0.7mm maple or lime wood laser cut/engraved deck (lime is standard)

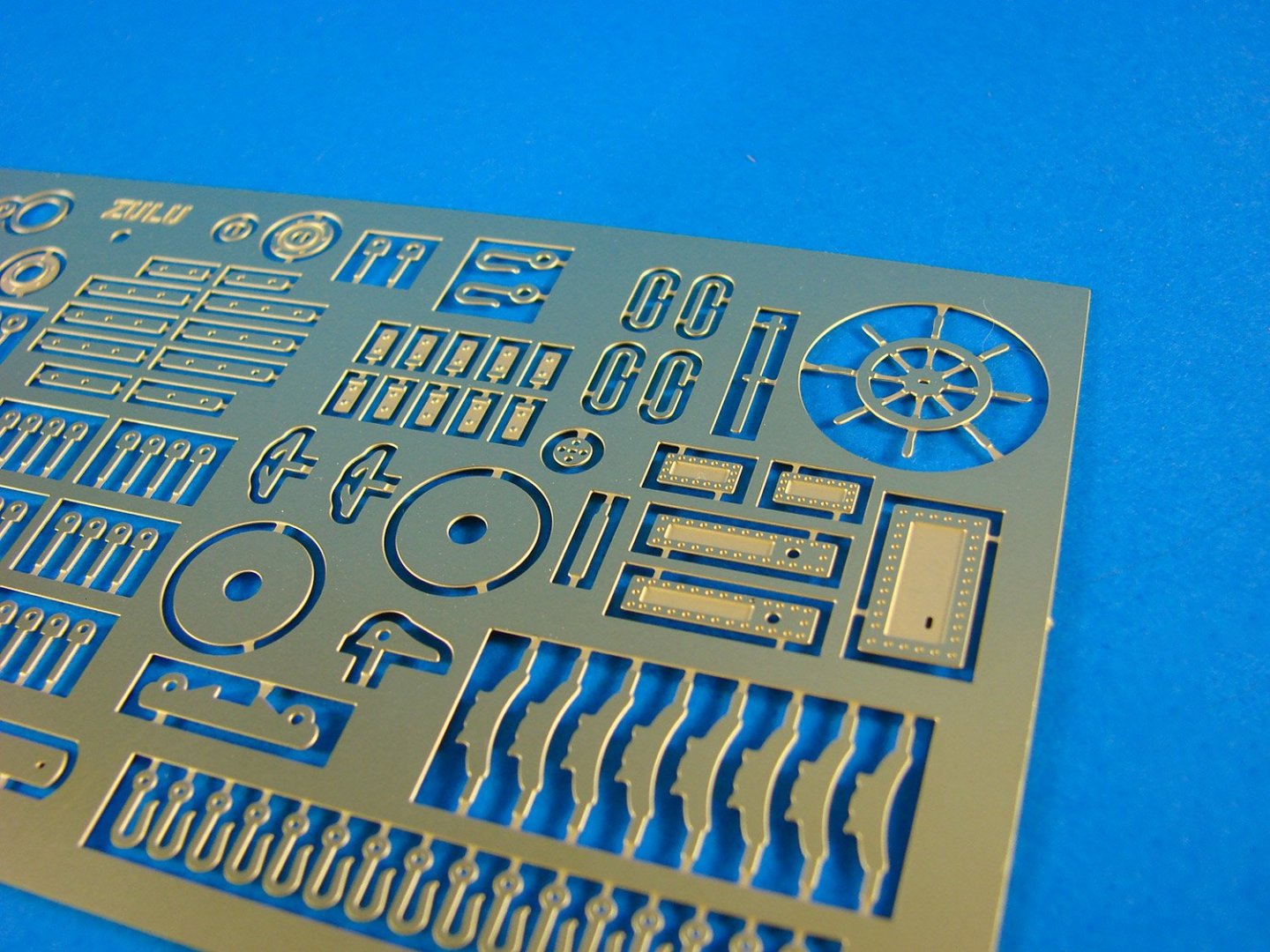

- 1 x 0.4mm PE sheet

- Timber strip

- Metal tubing

Not seen in this photo are the rigging blocks and cord, and the optional sails.

MDF Sheets

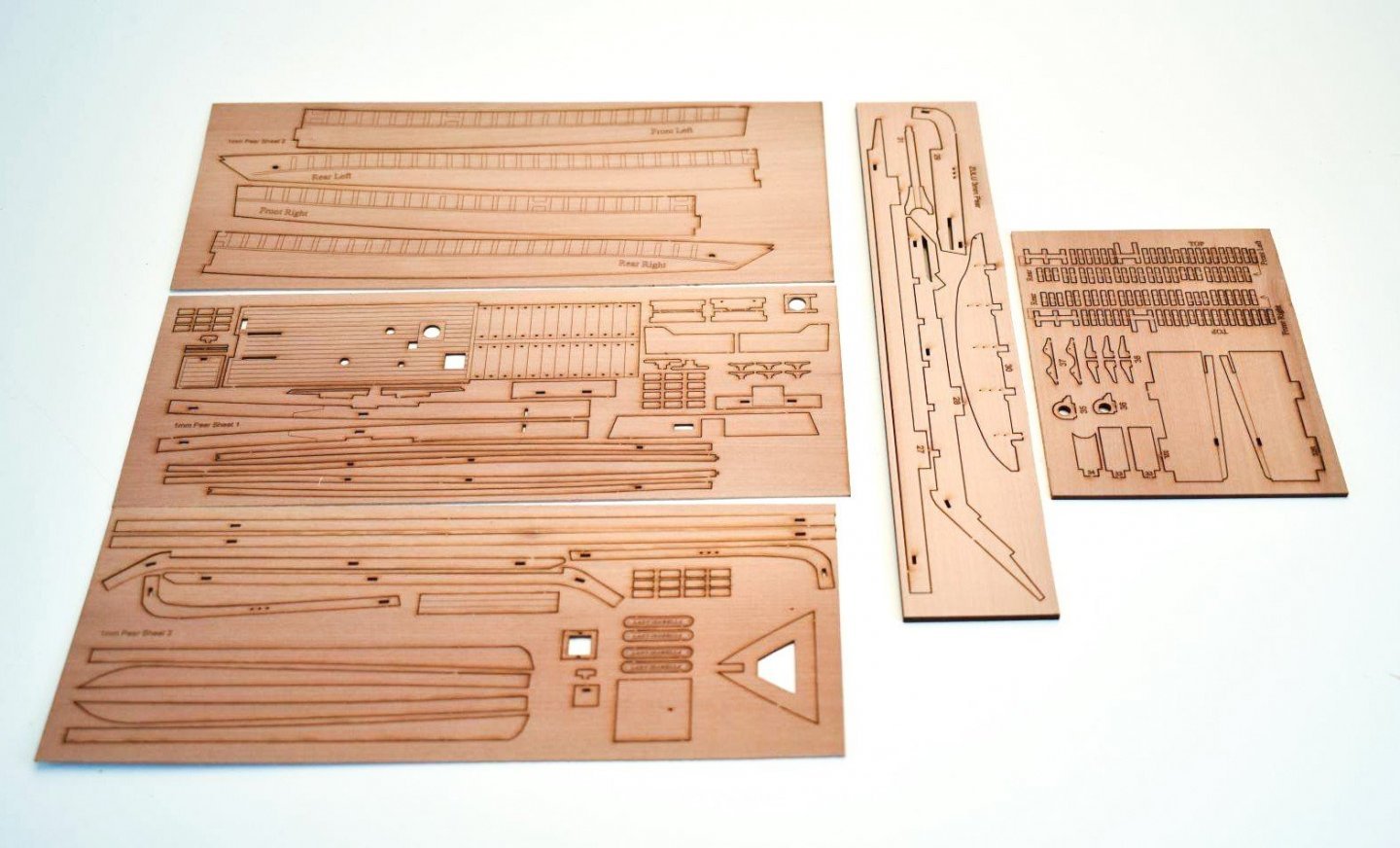

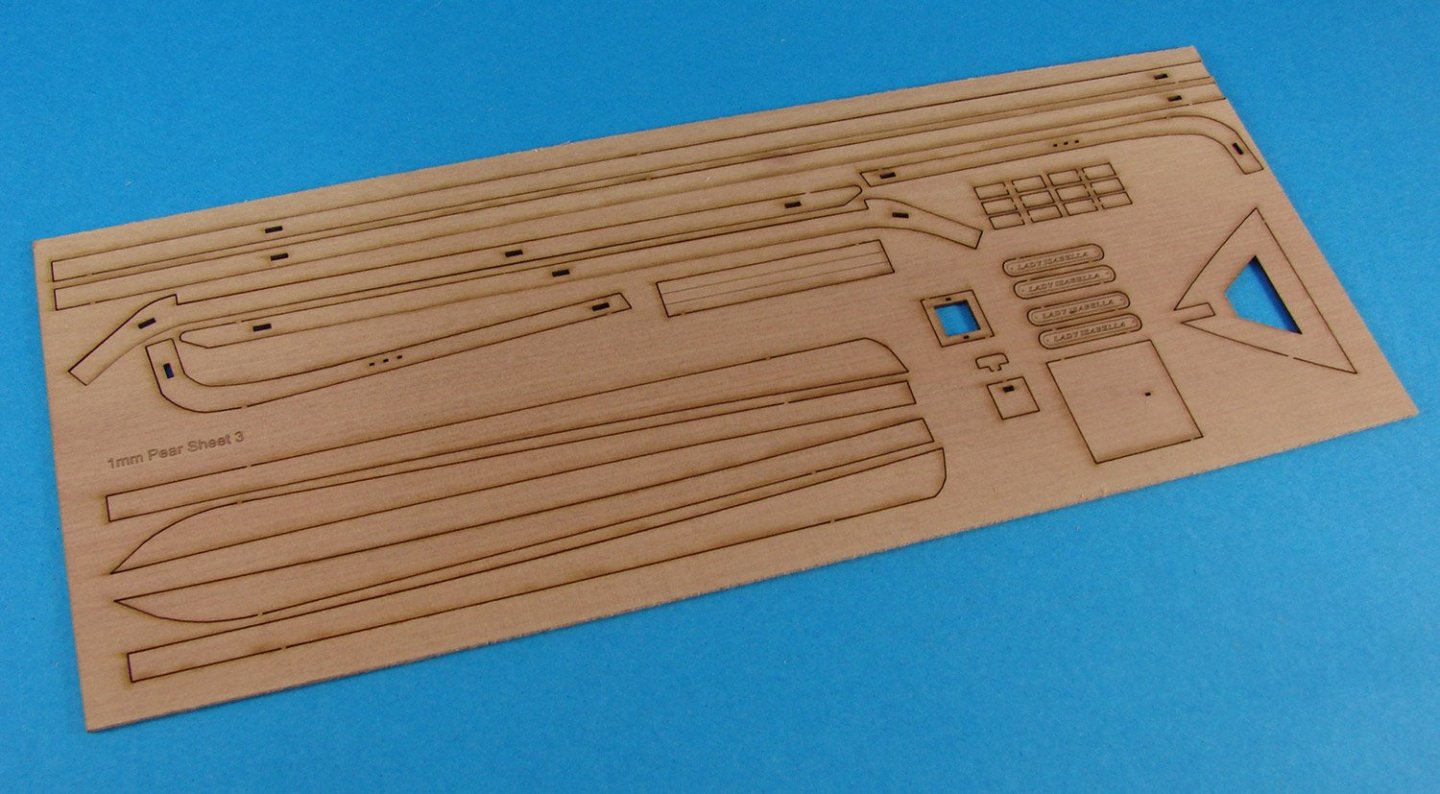

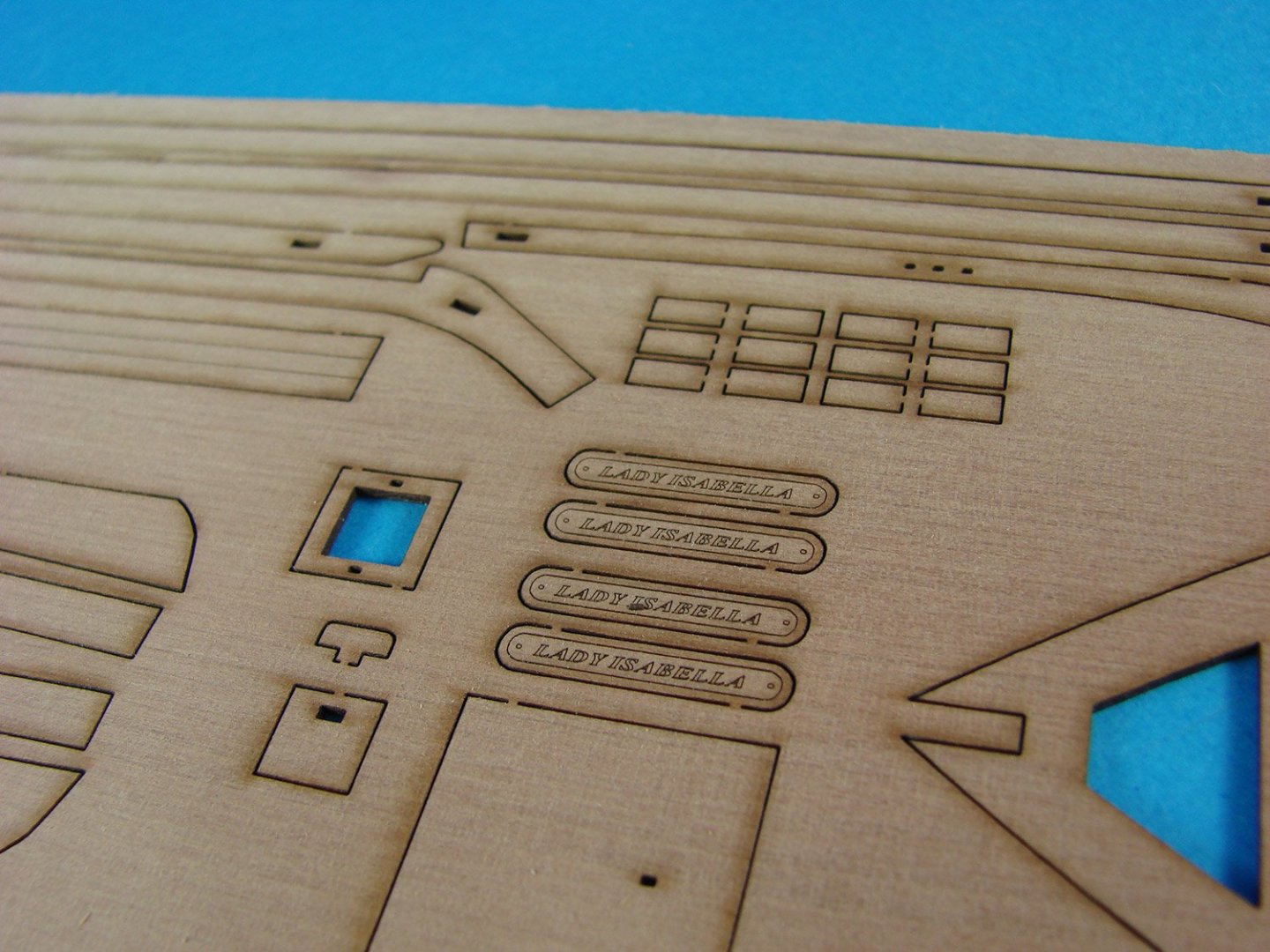

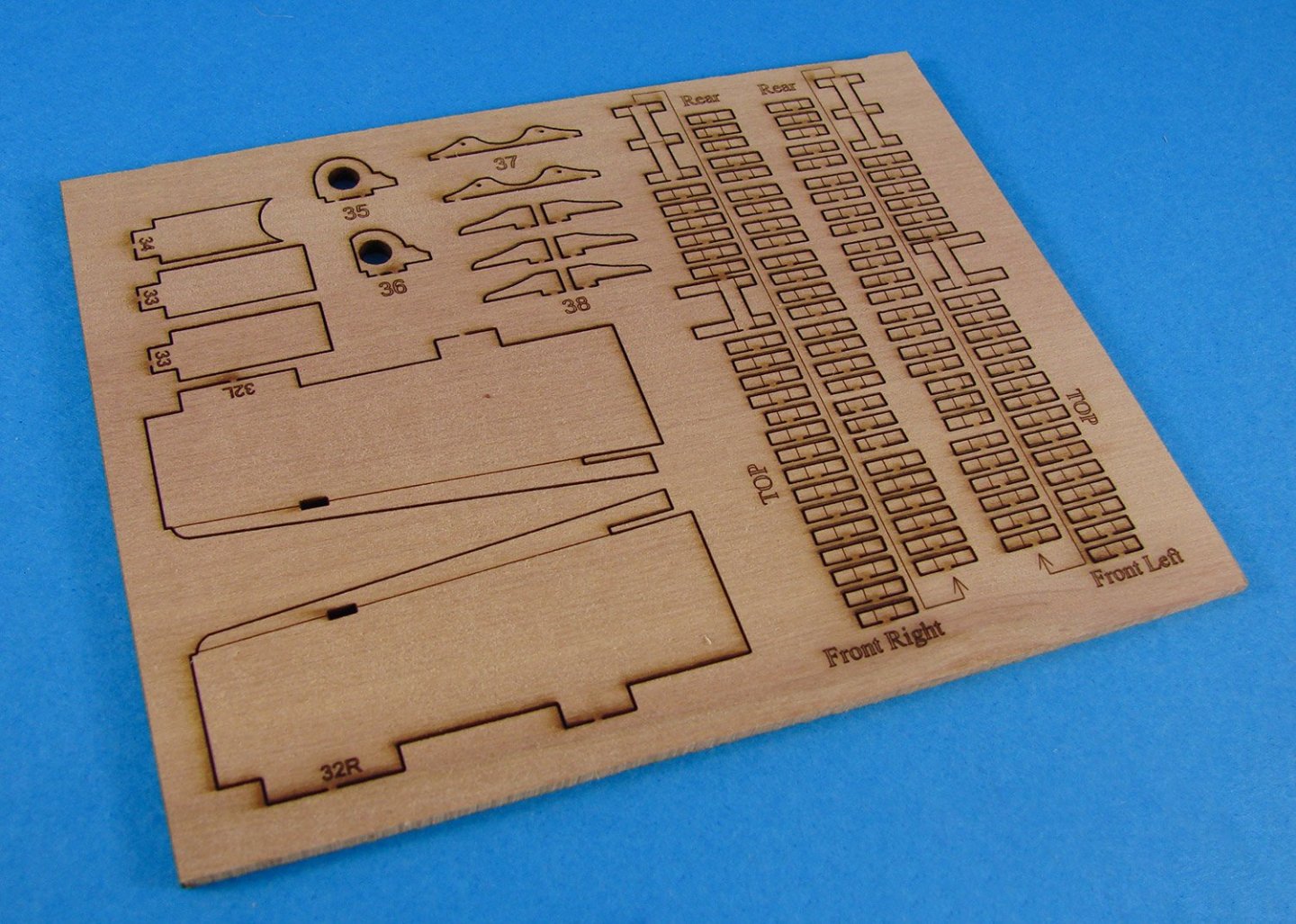

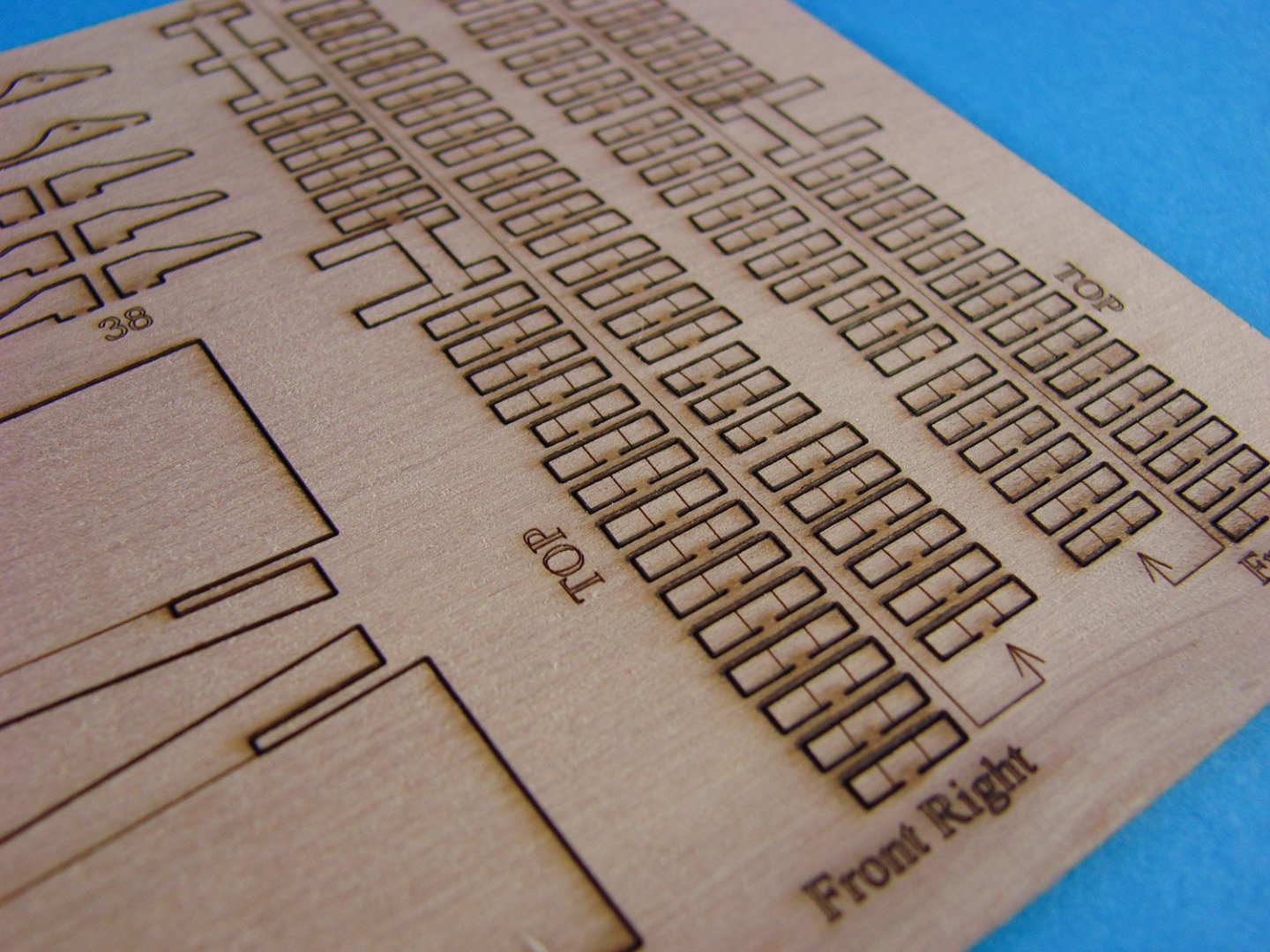

One thing you'll note here is that Vanguard Models are now using laser engraving on their parts, so everything is pre-numbered and there are also bevelling lines so you can roughly shape bulkheads before assembly to the false keel. Final shaping can be done later.1mm pear sheets

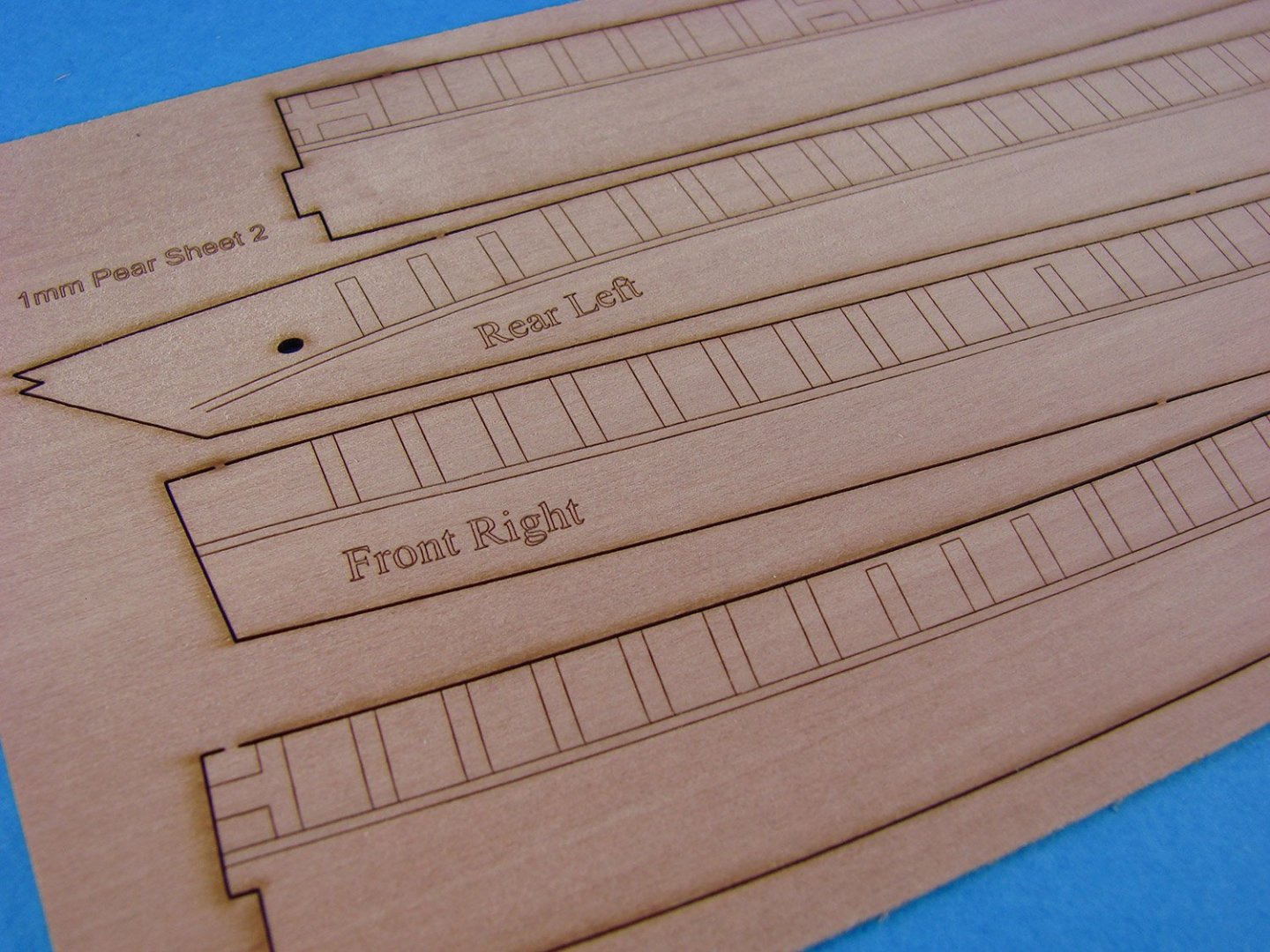

These are very nice indeed. Timber quality is excellent, and I love the pink hues of this stuff. Note that the bulwarks (supplied in halves) have the positions engraved on them for the timberheads. The first two lower planks are also included to take the guesswork out of those shapes near the keel. A rabbet has also been cleverly engineered into the design, and you won't need to cut or chisel a single thing to create it! The rabbet will help those second planks sit snugly into position.

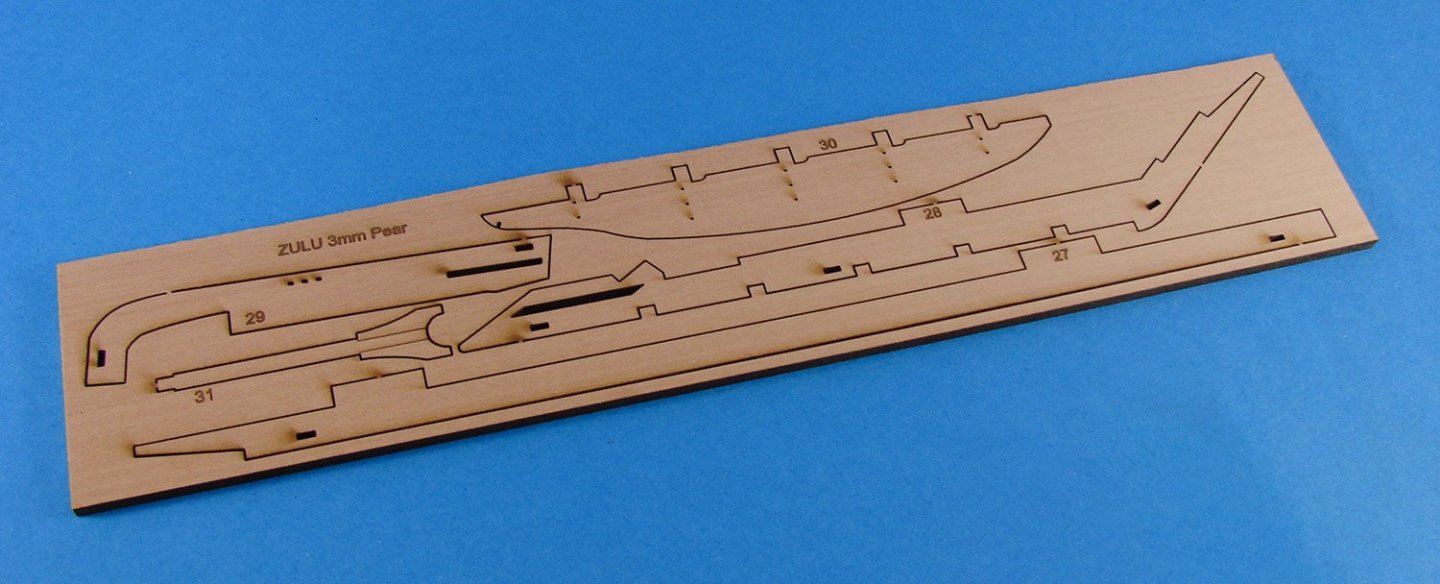

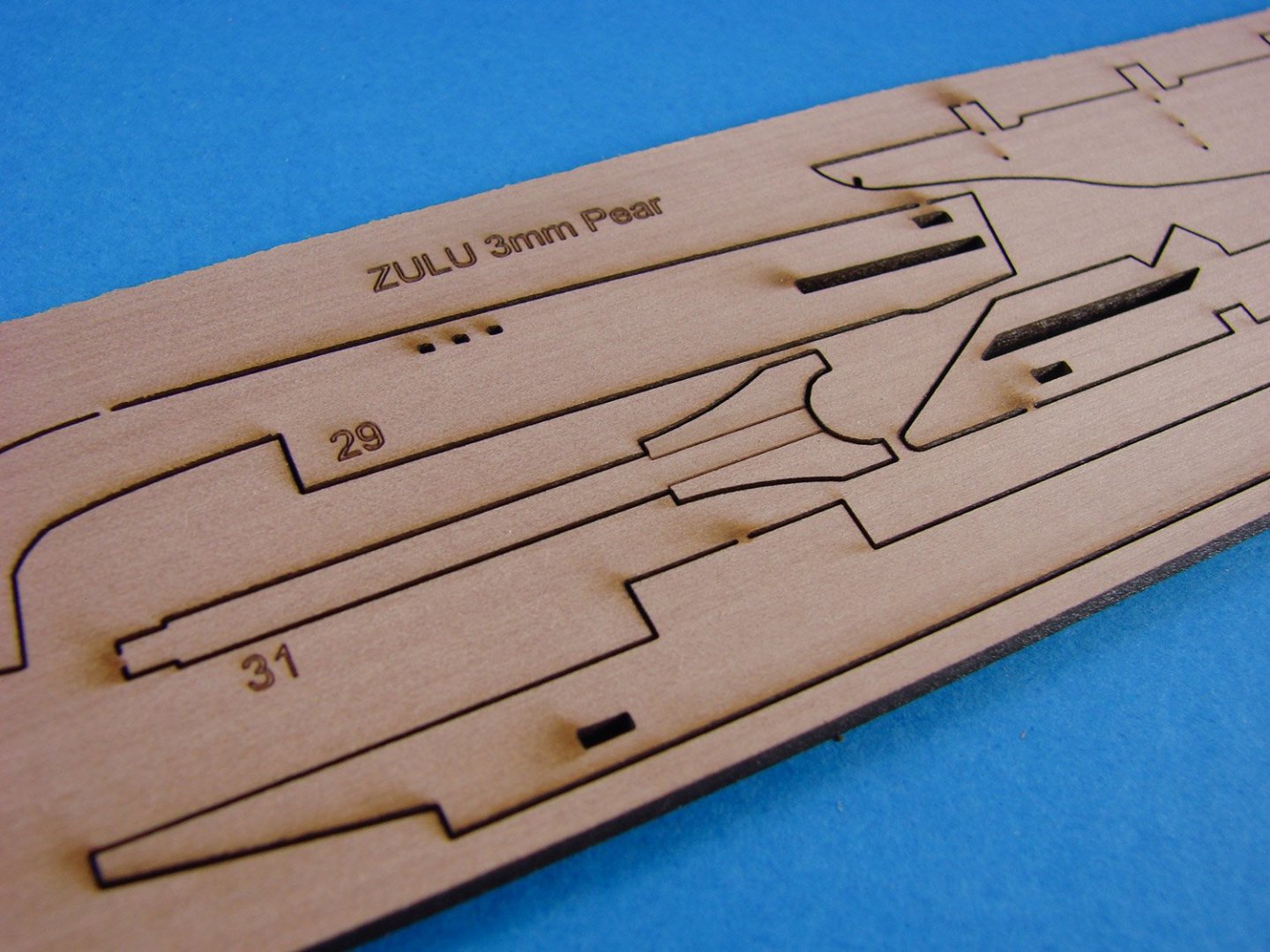

2mm pear sheet

3mm pear sheet

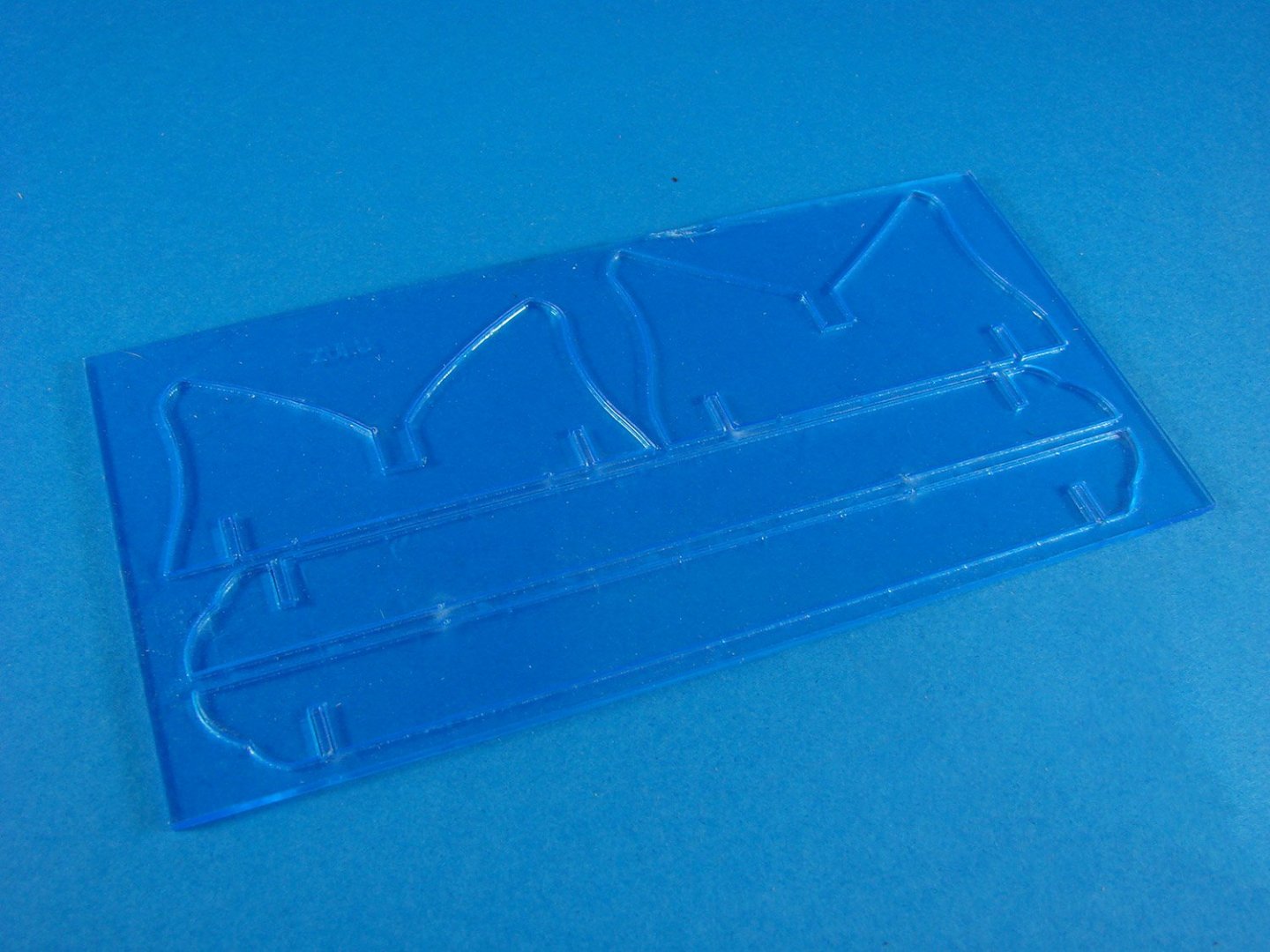

2mm acetate sheet

All models from this company have clear acetate stands supplied with them, and this includes these two fishing boats. These just push together with no need for adhesive, although you could, if you wanted to, drop a little PVA into the slot as it will dry clear. The acetate is covered in a blue plastic film which you first peel off, as seen here. A benefit of a clear stand is that it won't hinder the view of the completed hull!

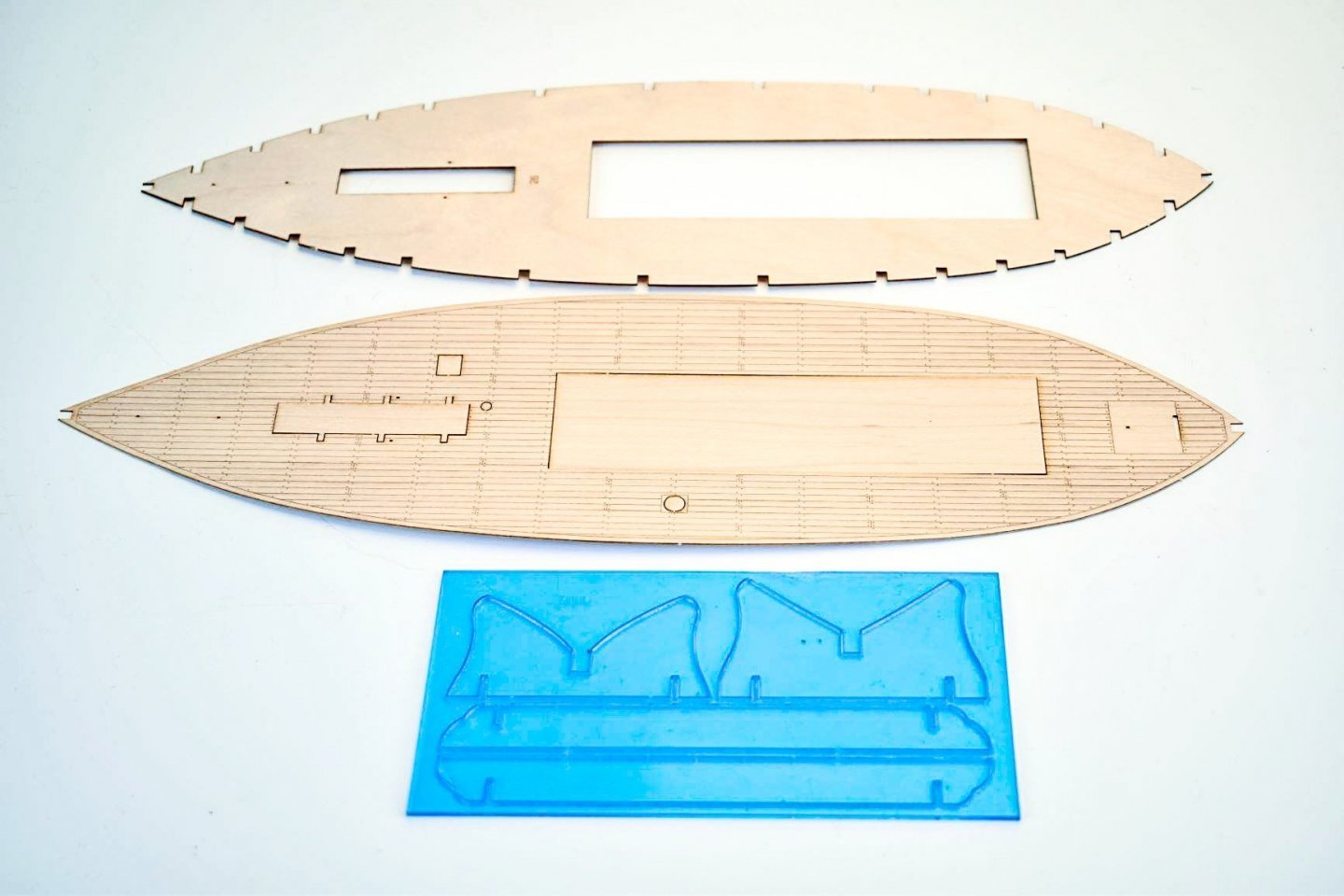

0.8mm ply (single part) and 0.7mm maple deck

All kits, as standard, will be supplied with an engraved lime wood deck. The kit which I've been sent has the maple option. As you can see, it does look really neat, and the engraving is excellent, including proper trunnels instead of just dots. This deck will sit atop the ply one seen here, but only when the hull is built (and painted).

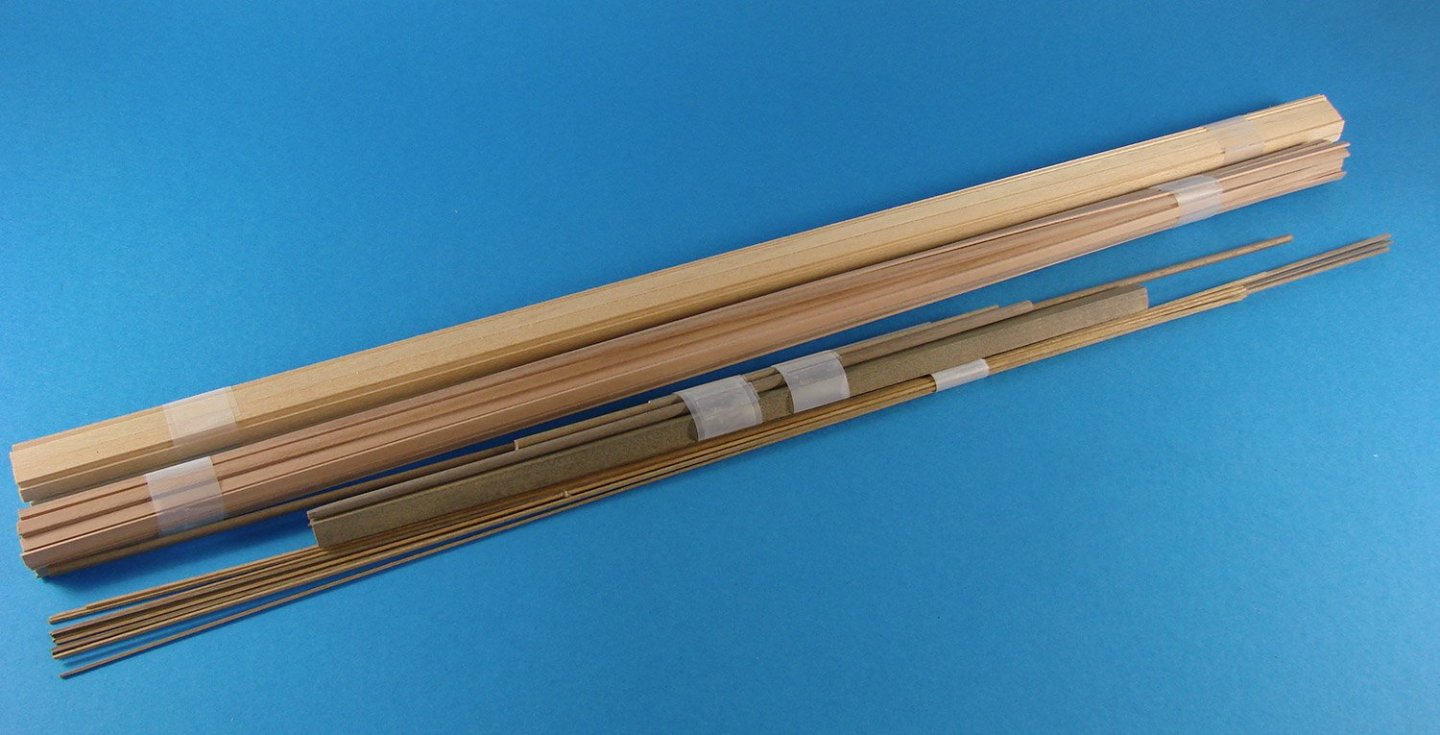

Strip wood and tube

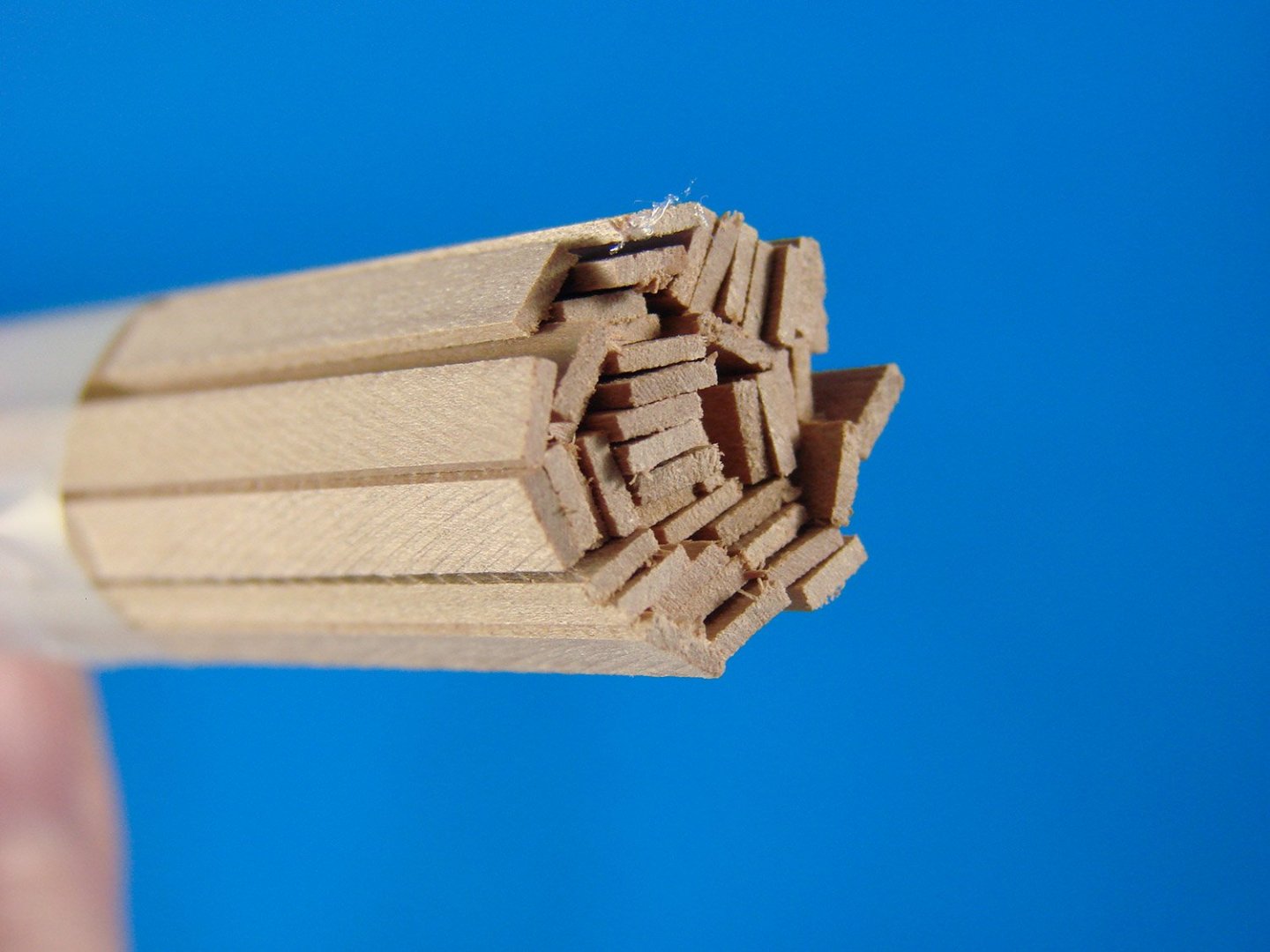

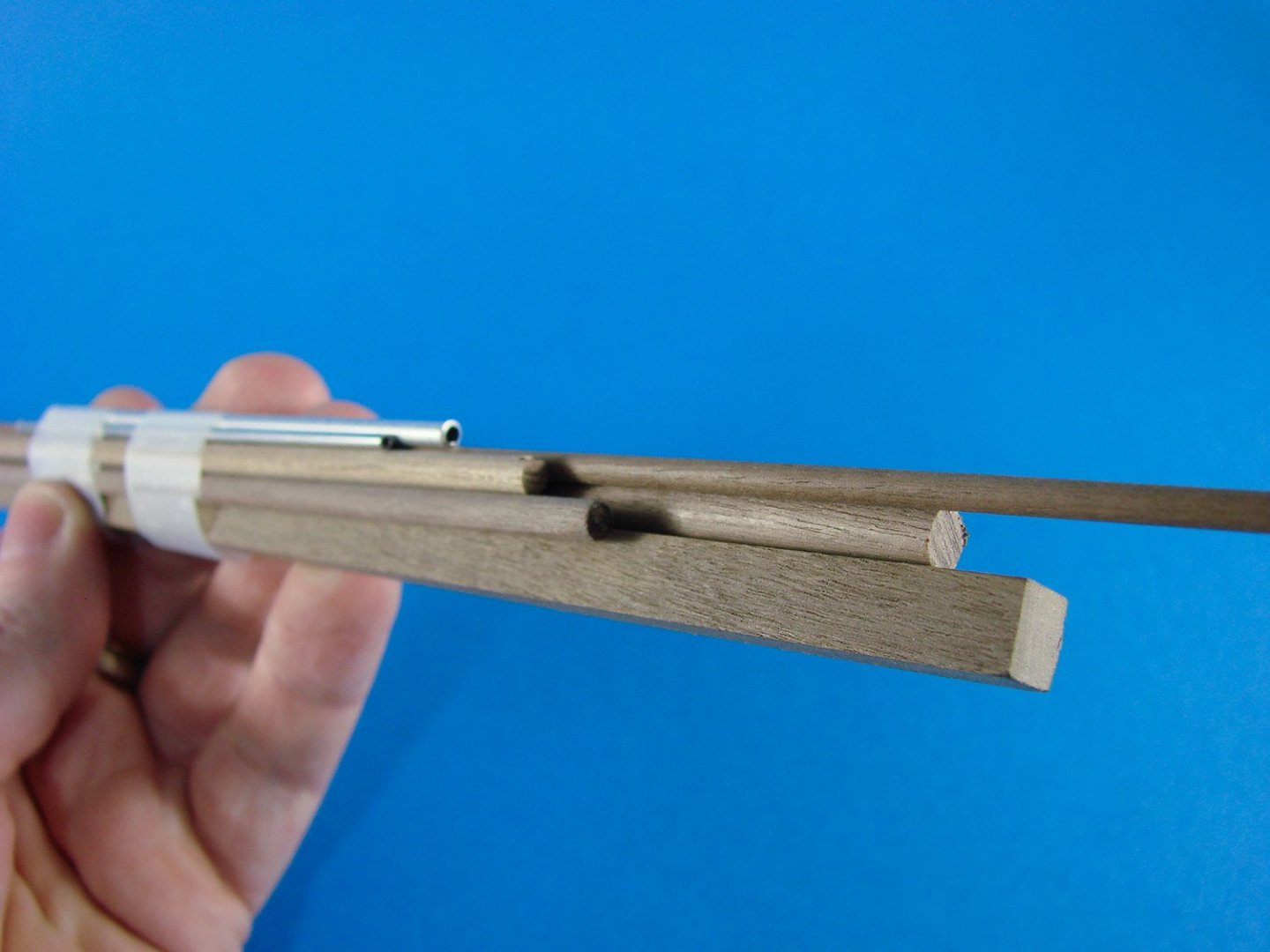

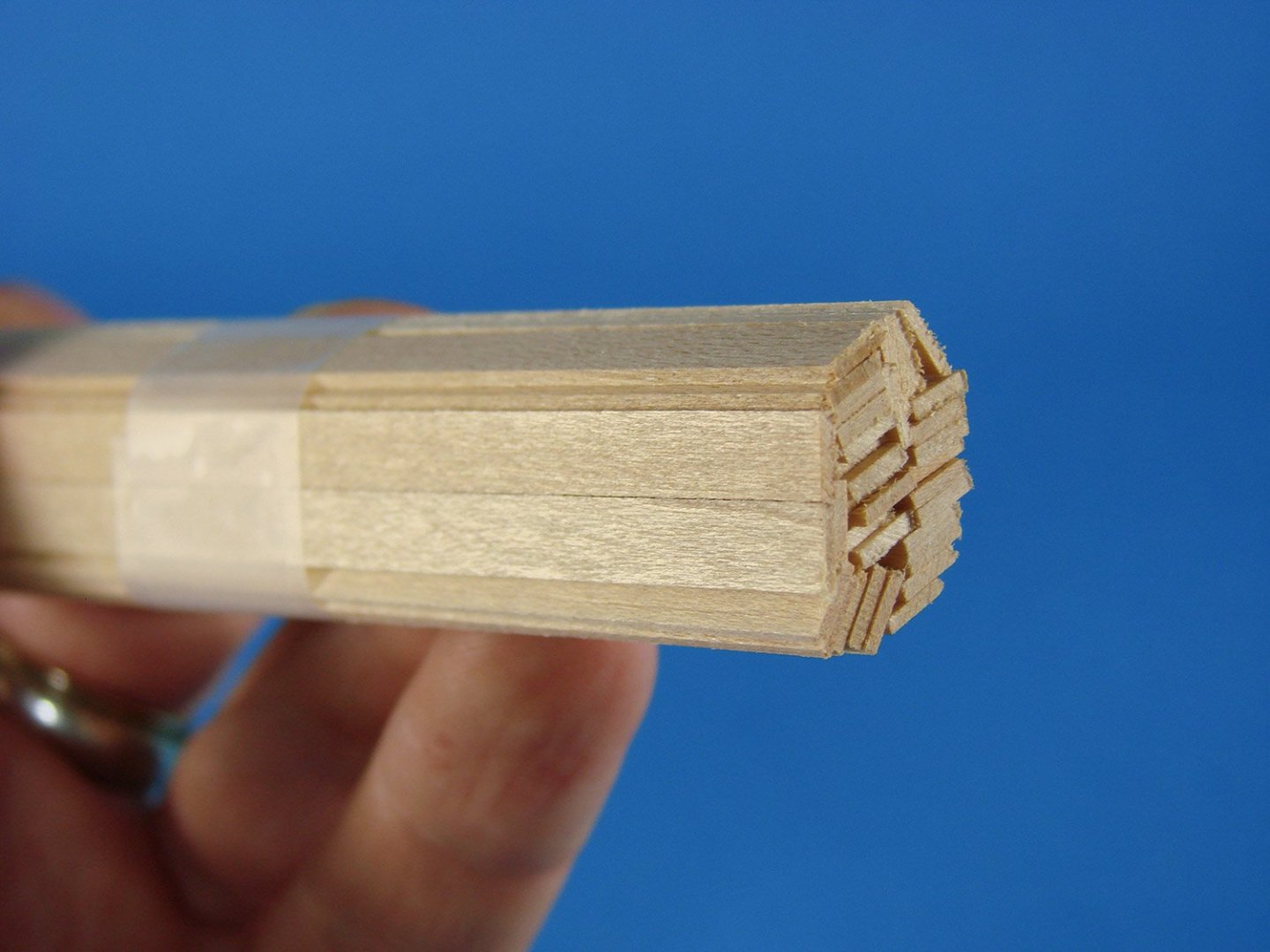

Three bundles of materials are supplied with this kit, all of high quality. The alloy tubes are for the flues. Materials are 1x5mm limewood for first planking, 1x4mm pear for second planking, and walnut for the rest (dowels, half round strip and 1x1mm strip)

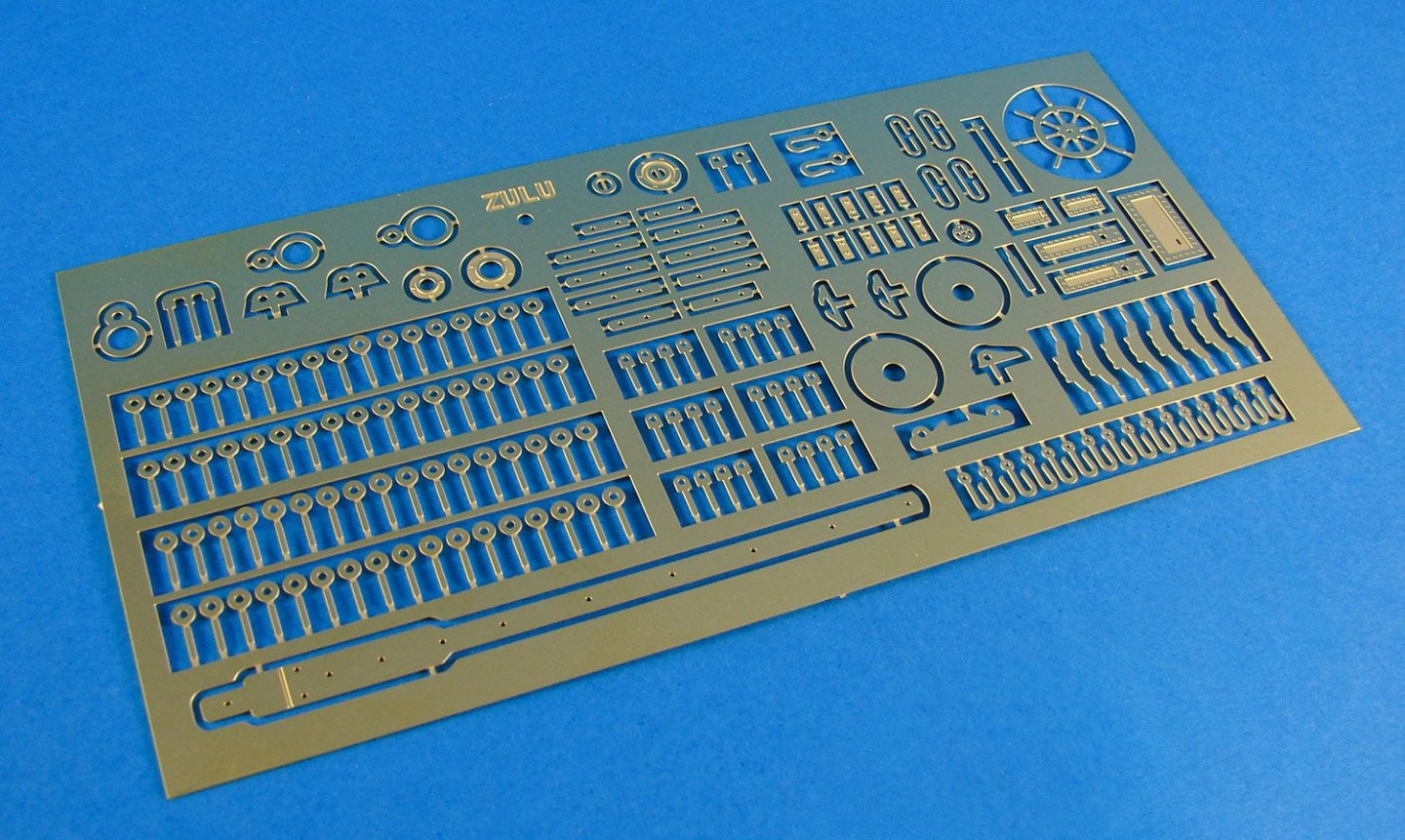

Photo Etch & errata

A reasonable size PE sheet is included, manufactured from 0.4mm brass. Brass nails are the excellent Amati ones with no malformed heads or points etc. Probably the best I've ever used.

As I say, this isn't a complete kit. It needs the rig, blocks, optional sails, instructions, plans and a box, but it should give you a good idea about how the finished product will look.

Here's a photo of the prototype, so far.

- kurtvd19, Morgan, Edwardkenway and 13 others

-

16

16

-

-

18 hours ago, ASAT said:

Just got mine - 10 days transit! But it was intact with no damage (UPS) Assembling it now.... I would add that a sanding block of some sort should be added to the list of tools required- the knife cleans the parts ok but the nubs need to be sanded flush..... in fact after doing a few nubs I am just using a sanding block with 100 grit on it.... and I am using 3M contact adhesive for the adhering the white laminated piece’s. just preference for laminating stuff...

Old habits die hard with me as I carved away those nubs with a scalpel. I sometimes think I'm still working on plastic models 🤪

- Scottish Guy, Keith Black, thibaultron and 2 others

-

4

4

-

1

1

-

On 1/31/2020 at 4:05 PM, Cazpert said:

Thanks to your presentation

I have perfectly mounted the support

It is a very good job

thanks again

Hope to see you using it on a build soon.

- Scottish Guy, Canute, mtaylor and 2 others

-

5

5

-

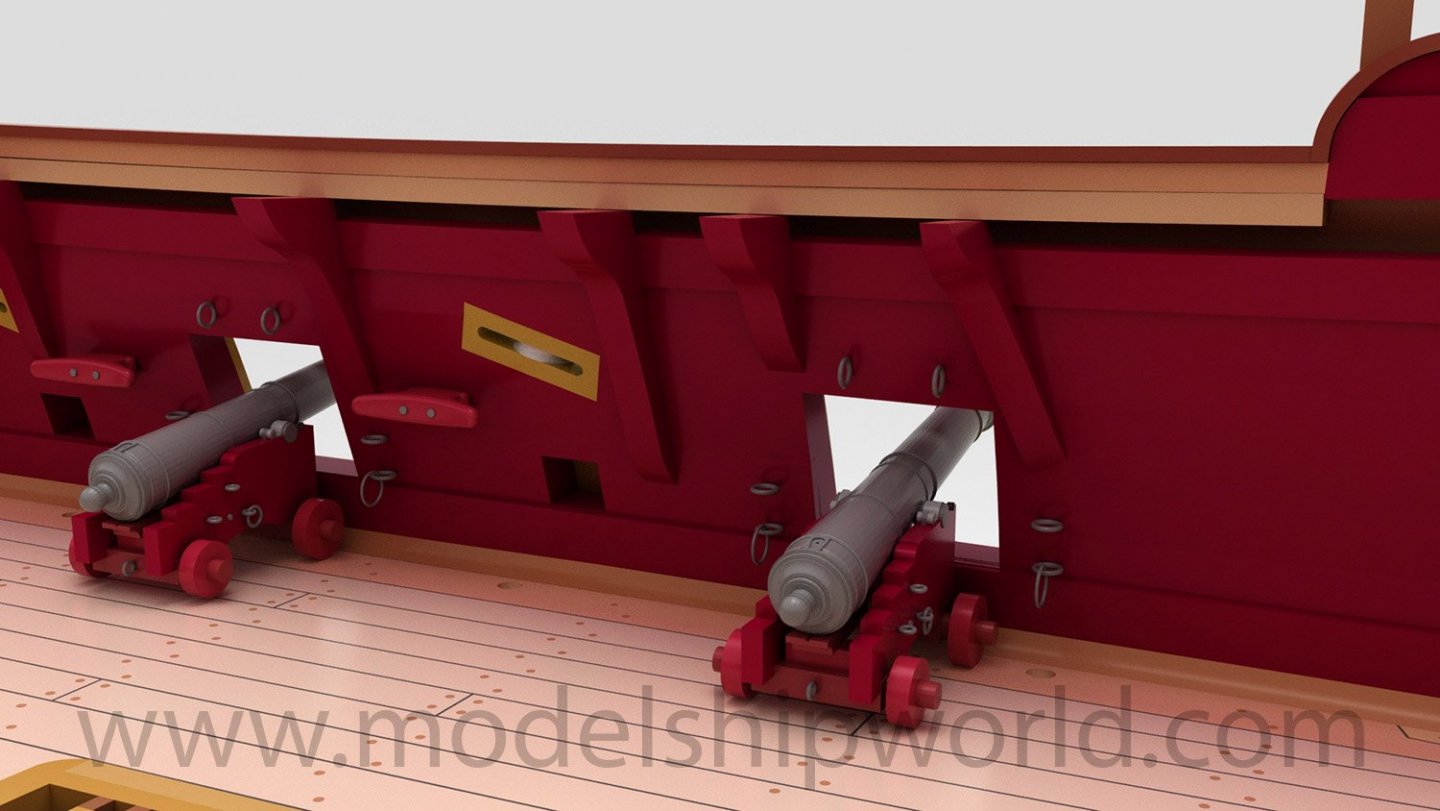

3 minutes ago, Dilbert55 said:

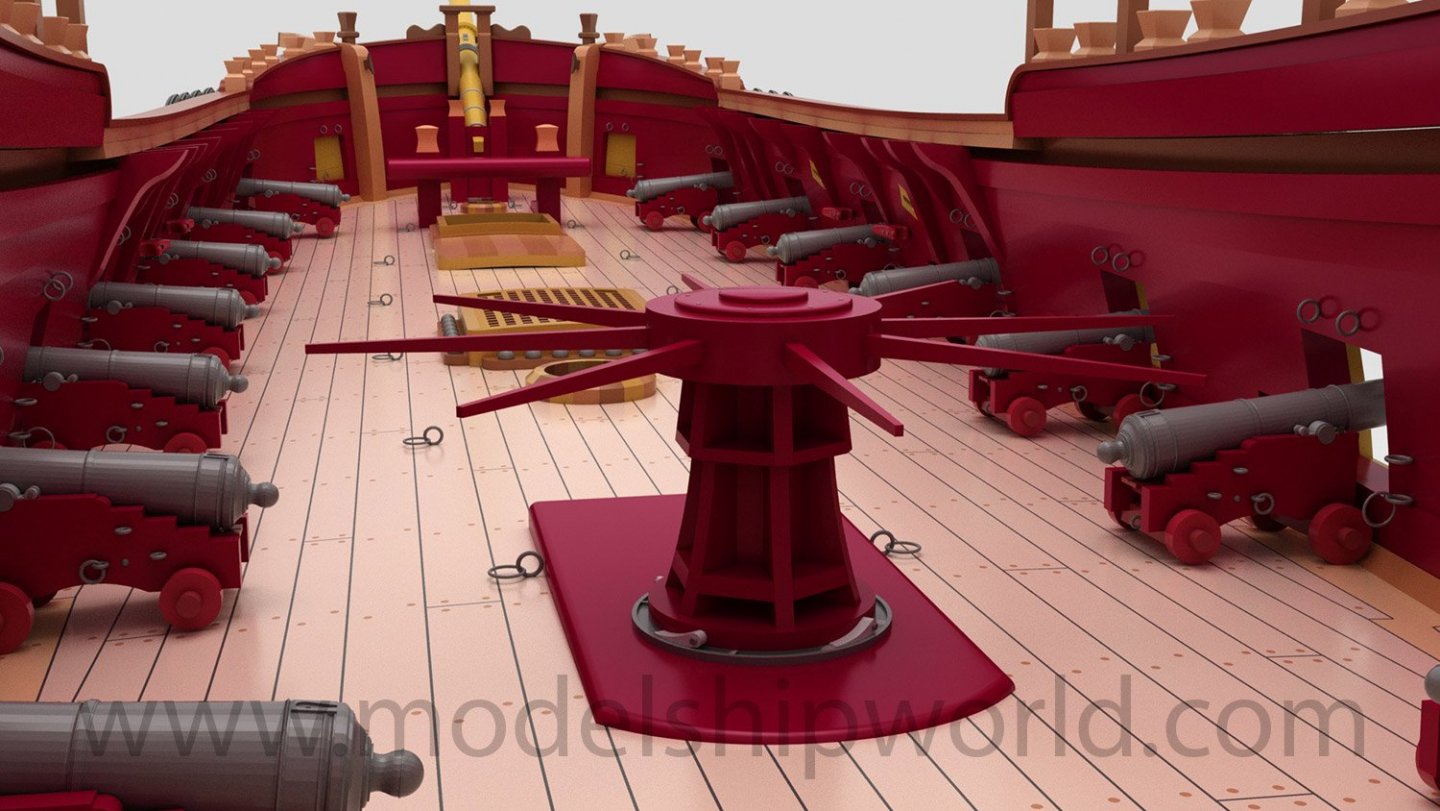

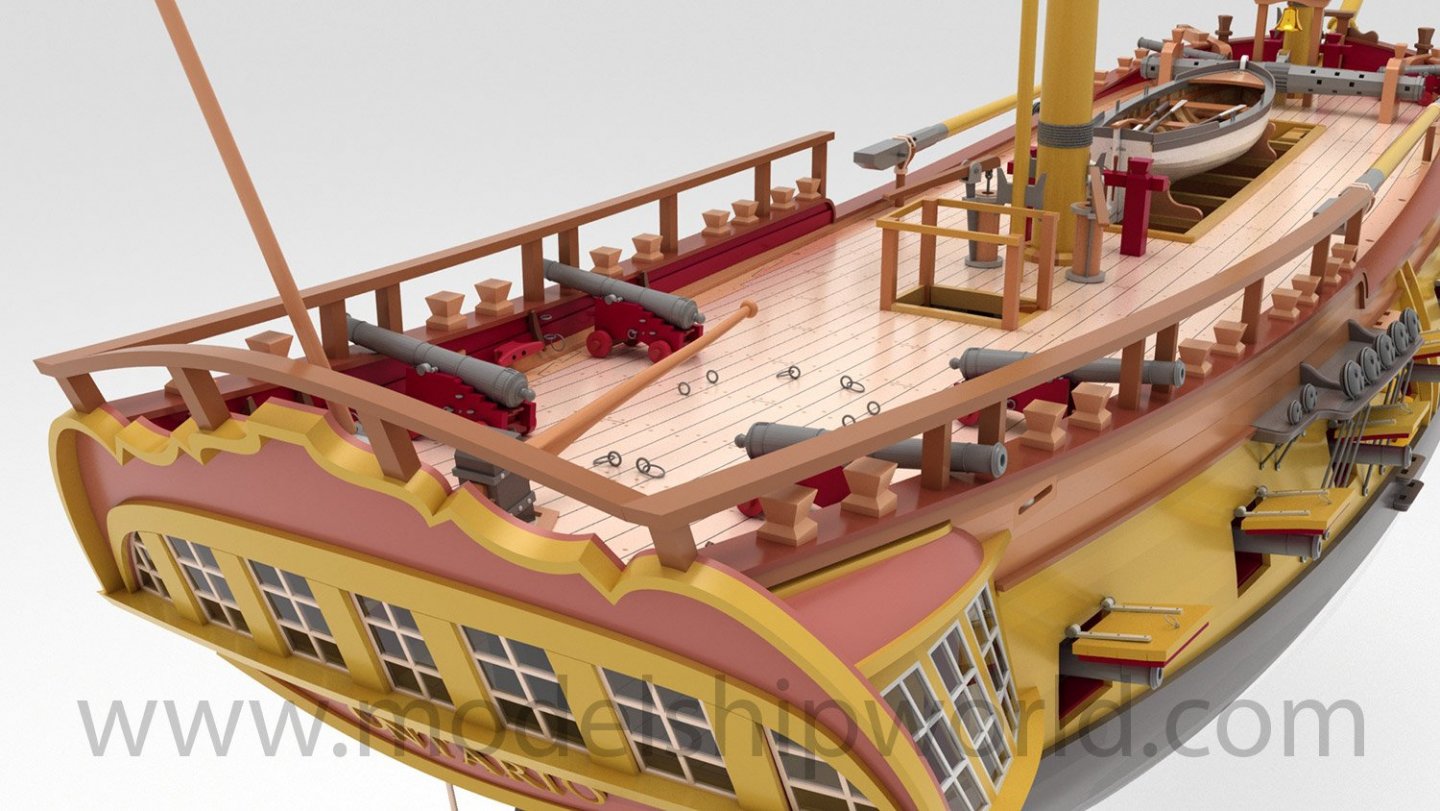

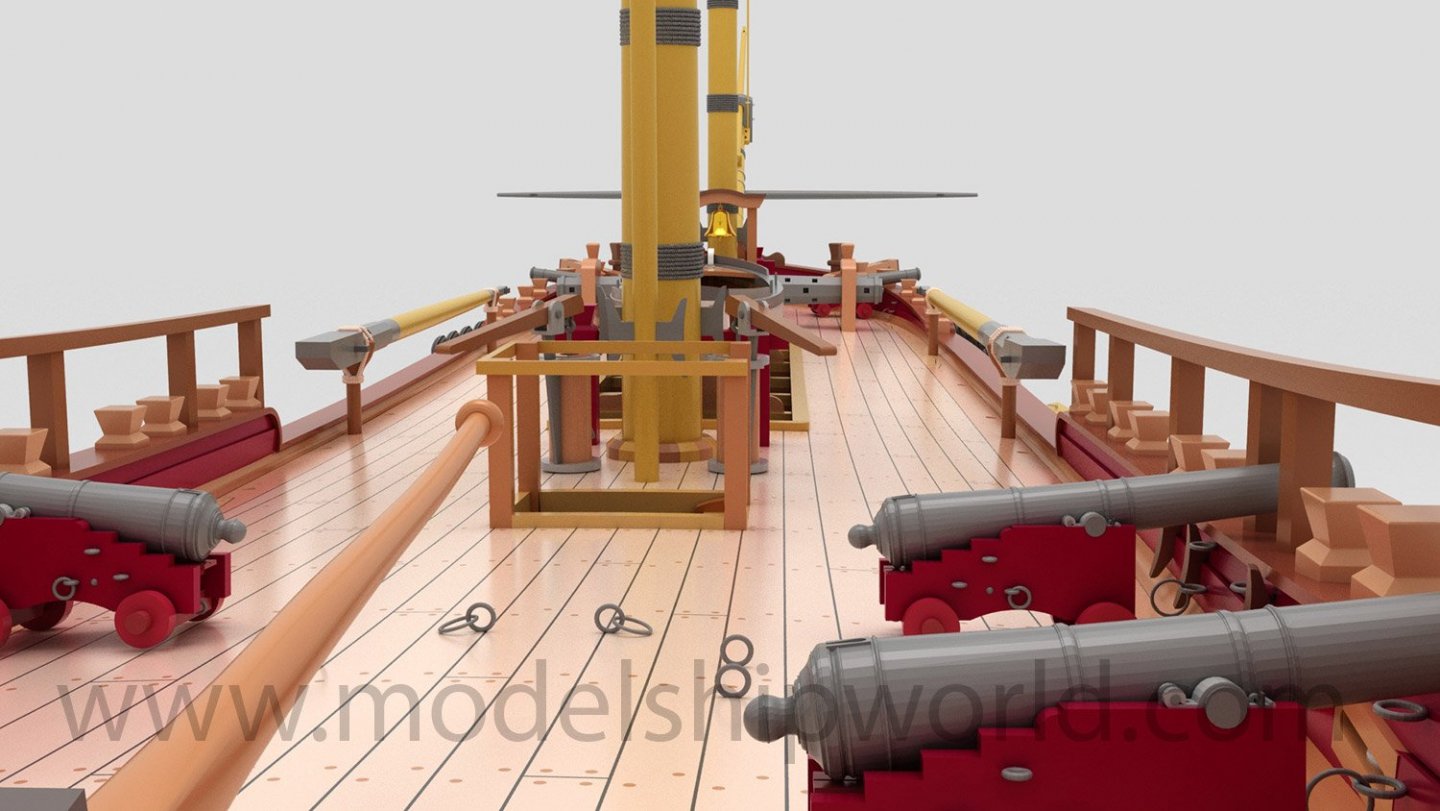

Maybe it's due to 3D rendering, it looks a bit plastic.

They are renderings.

The kit is mainly wooden.

- Yarr McNarr, thibaultron and mtaylor

-

2

2

-

1

1

-

Hi all,

MarisStella, in cooperation with The Art of Age of Sail, have just released their new kit, the 1:48 HMS Ontario. This is a multimedia kit, including many traditional elements, but also some 3D-printed , resin, and photo-etched parts. Finished model will be 81cm long.

We promise to being you an in-box review of this as soon as we can.

http://www.marisstella.hr/gotovi_modeli_galery.php?id=1111&tip=2&hms-ontario-81cm-1-48

- petervisser, ccoyle, BobG and 17 others

-

20

20

HMS TERROR by Wahka_est - OcCre - 1:75 - first wooden ship build

in - Kit build logs for subjects built from 1801 - 1850

Posted

Haha! I'm certainly not a professional! But thanks anyway.