-

Posts

1,310 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Elijah

-

Looking good! Using glass is a good idea.

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Looking good E.J! What is that thing that you are using for wood storage?

- 961 replies

-

De Eendracht by kay - 1:50 - a dutch flagship

Elijah replied to kay's topic in - Build logs for subjects built 1501 - 1750

That's some very neat work! I like how the stern is turning out. It looks like a tower! -

Hello. I know it's been a while since I last updated, but I promise to update again soon. Either I will update once I finish the outside planking or within a week, whichever comes first. Basically, I'm just letting you know I'm still here . Thanks for sticking around!

- 228 replies

-

- gunboat

- model shipways

-

(and 1 more)

Tagged with:

-

Your metal work is fantastic! Nice job!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Looks like a fun build, Hennie! If all of those green boards are decorations, you must have a lot of painting ahead of you !

- 192 replies

-

- sovereign of the seas

- sergal

-

(and 1 more)

Tagged with:

-

Nice progress Patrick! Did you get any pictures at the exhibit in Japan? What have you been using to finish your decks? They look very nice.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Welcome, Jesse! It's great to have you along!

- 228 replies

-

- gunboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you very much, Gerty! Welcome aboard!

- 228 replies

-

- gunboat

- model shipways

-

(and 1 more)

Tagged with:

-

Nice work Jesse! Those carronades look ready for action!

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

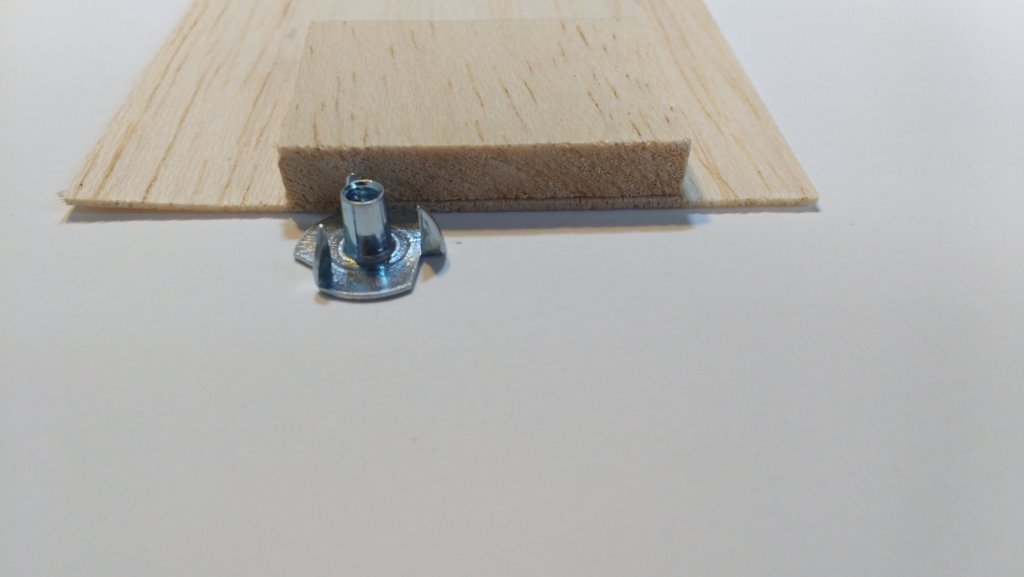

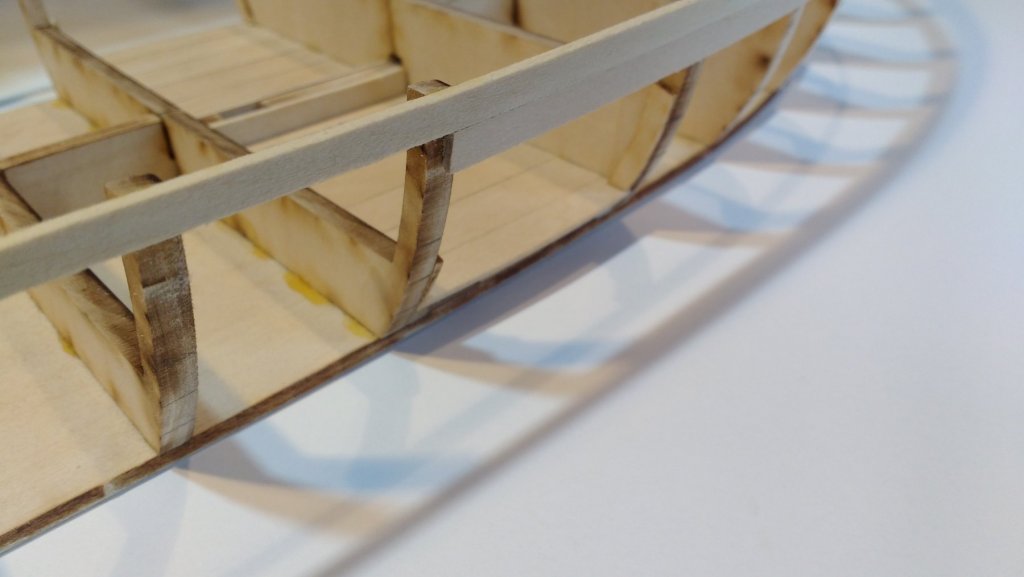

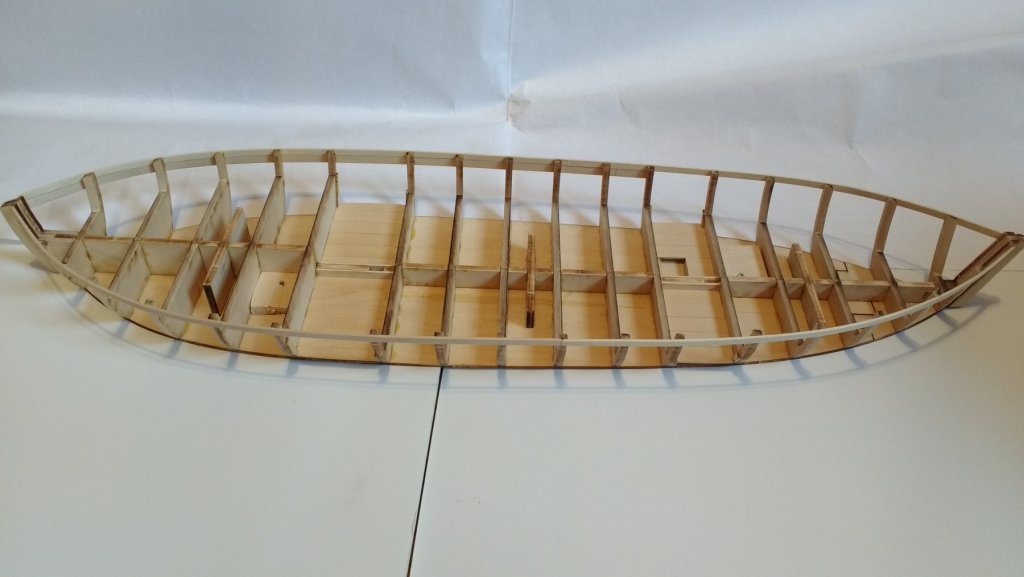

Hello again! It's been a few weeks since I've updated my log and thought it time to do so again. First, I added the cockpit flooring. That was just glueing the supports and short planks in place. Then was figuring out and adding the mounting system. Kurt recommended using t-nuts for that. I then located and drilled a hole on either side of the keel, one below the fore deck and one below the aft. I then aligned that hole and drilled it in to the filler block. Taking into account the thickness of the base of the t-nuts, I layered the wood so that when the t-nuts were installed they would sit flush with the base. I then glued them on to their respective places and used a screw to keep them aligned. After that, I lined off the hull and started planking. I have thinned the ends of the planks that for into the rabbet and beveled the underside of the planks for a tight fit. I also used a number 2 pencil to add 'caulk' to the underside of each plank. I first soaked the planks and clamped them to the hull to dry. I noticed that the field made small debts in the planks that way. A lake water and a bit of sanding makes it not noticeable, but since then I've used little balsa tabs as spacers to take the dent. So far I have finished the sheerstrake on both sides. I have noticed that although the planks above the Wales aren't spiled, they do vary in width. Thanks for looking in!

- 228 replies

-

- gunboat

- model shipways

-

(and 1 more)

Tagged with:

-

The masts look very nice! All of your work is very tidy!

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Wow, it's been a while since I've stopped by. She is looking fantastic! Your machinery is superb! You are doing some great work!

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Wow! That interior looks great! Looking very good, EJ.

- 961 replies

-

The framing is looking great, Bob! It doesn't even show signs of being laser cut!

- 682 replies

-

- halifax

- lumberyard

-

(and 1 more)

Tagged with:

-

Those plants are a great addition! Are they made with tapered wooden dowels with a little moss on top?

-

Brig Eagle by robnbill - 1:48

Elijah replied to robnbill's topic in - Build logs for subjects built 1801 - 1850

Those masts look wonderful! My guess is that those sheaves will make the rigging process more easy, especially when positioning spars?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.