-

Posts

4,897 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

I love the Chris Craft boats. Are you going to make this a working RC model?

- 49 replies

-

- dumas

- Chris-Craft

-

(and 2 more)

Tagged with:

-

Outstanding, as always, Rusty. I look forward to following your next project.

- 152 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks pretty good to me B.E. and knowing your attention to detail, I suspect you will be dissatisfied if you decide NOT to do the other 11 guns. So best you get back to it!!!😉😄😄😄

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

While you’re waiting for the Winnie, Bob, maybe a Medway Longboat or a Royal Barge from Chuck would help to fill the time?

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

Congratulations on yet another fine build Bob, despite the best efforts of the kit manufacturer! Here’s wishing you improved health and greater enjoyment of your modelling in 2019.

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

Now that is some beautiful work Ben - congratulations!

- 889 replies

-

Closing in on the finish line Kevin! Great work so far.

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

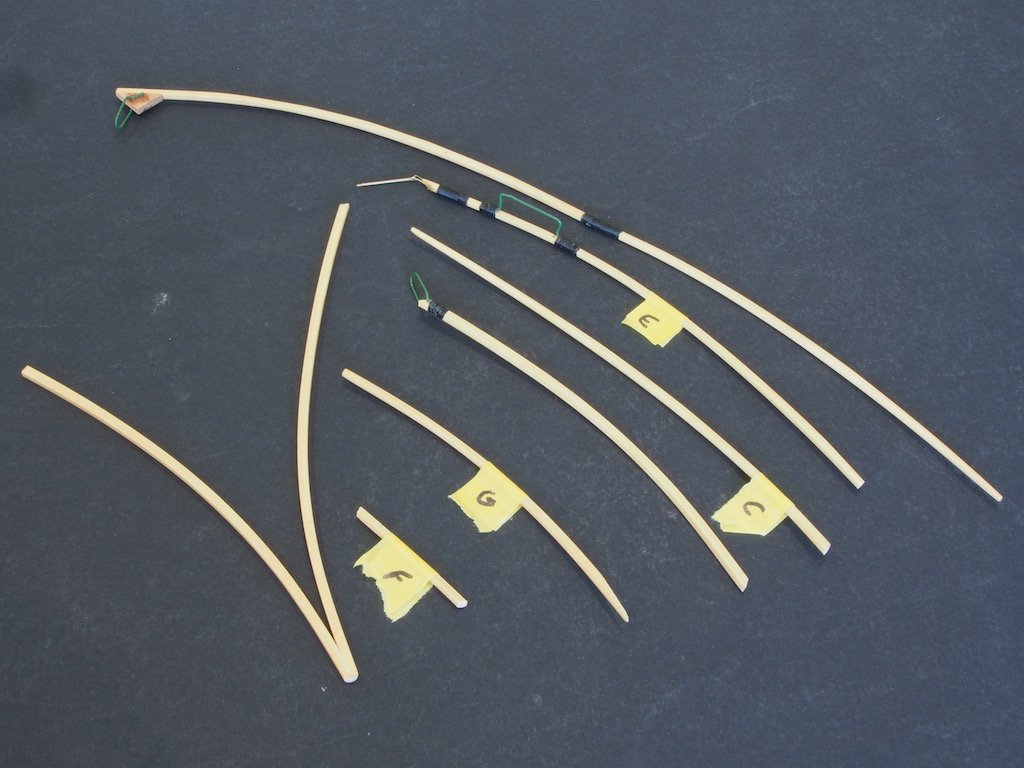

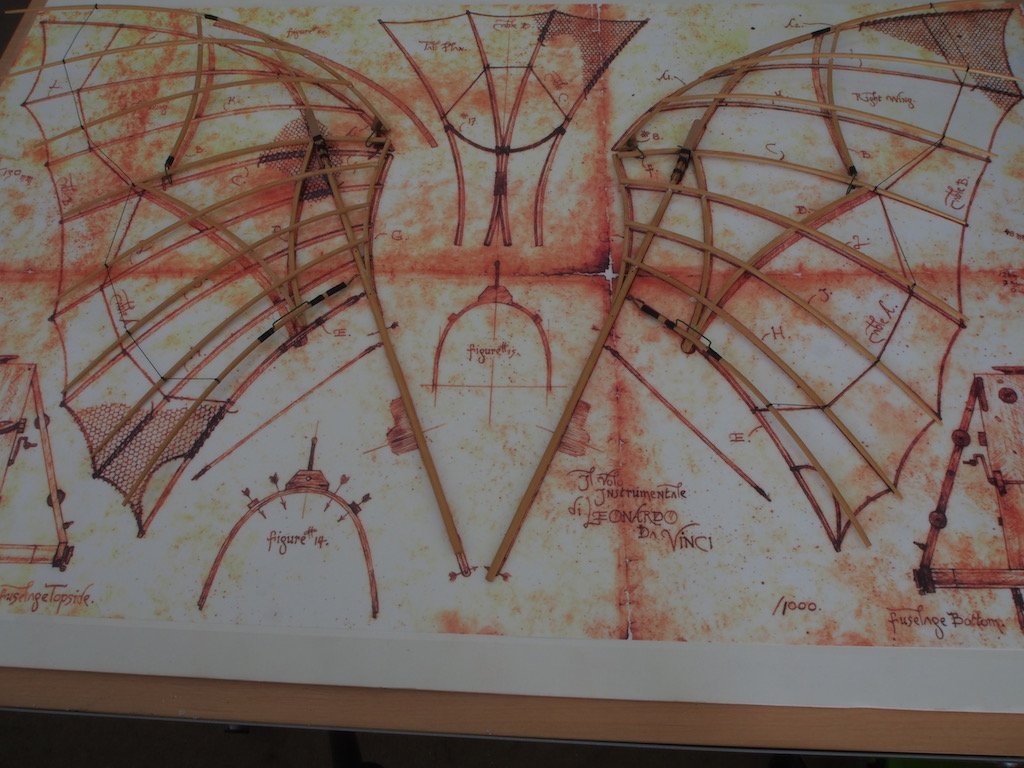

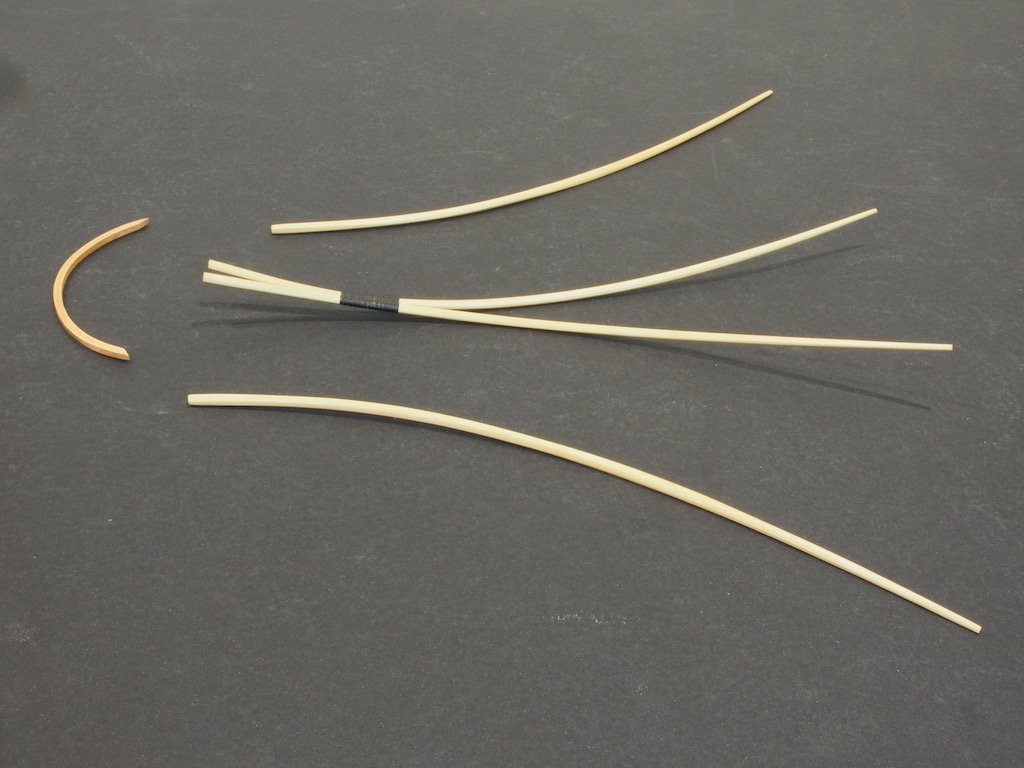

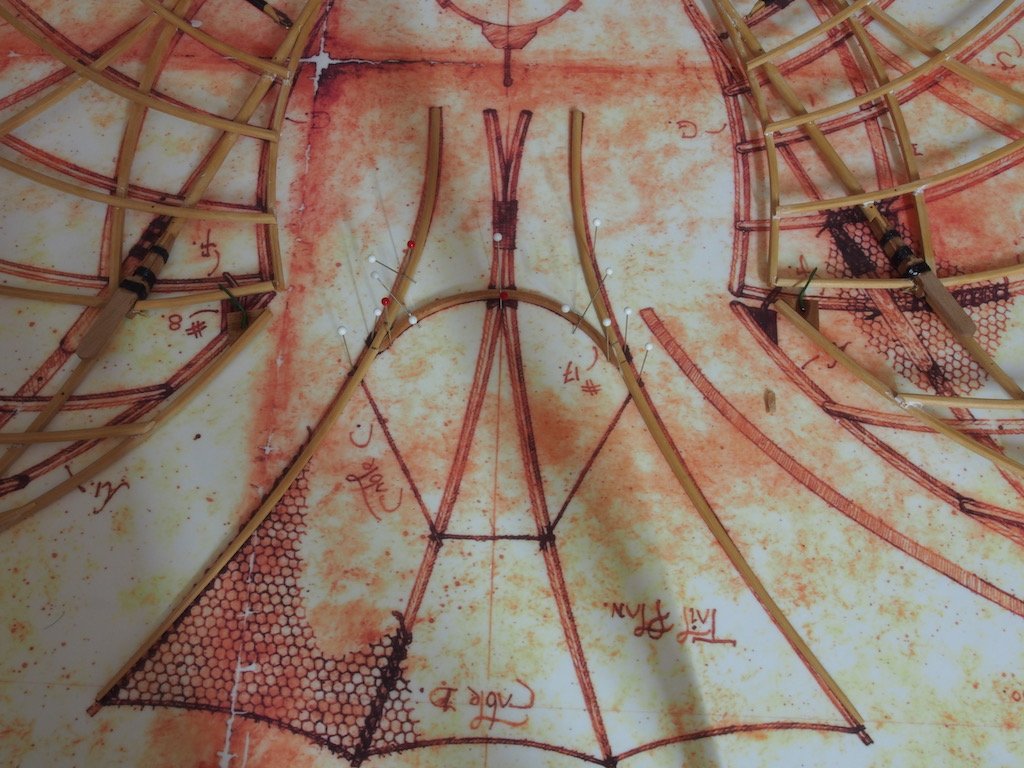

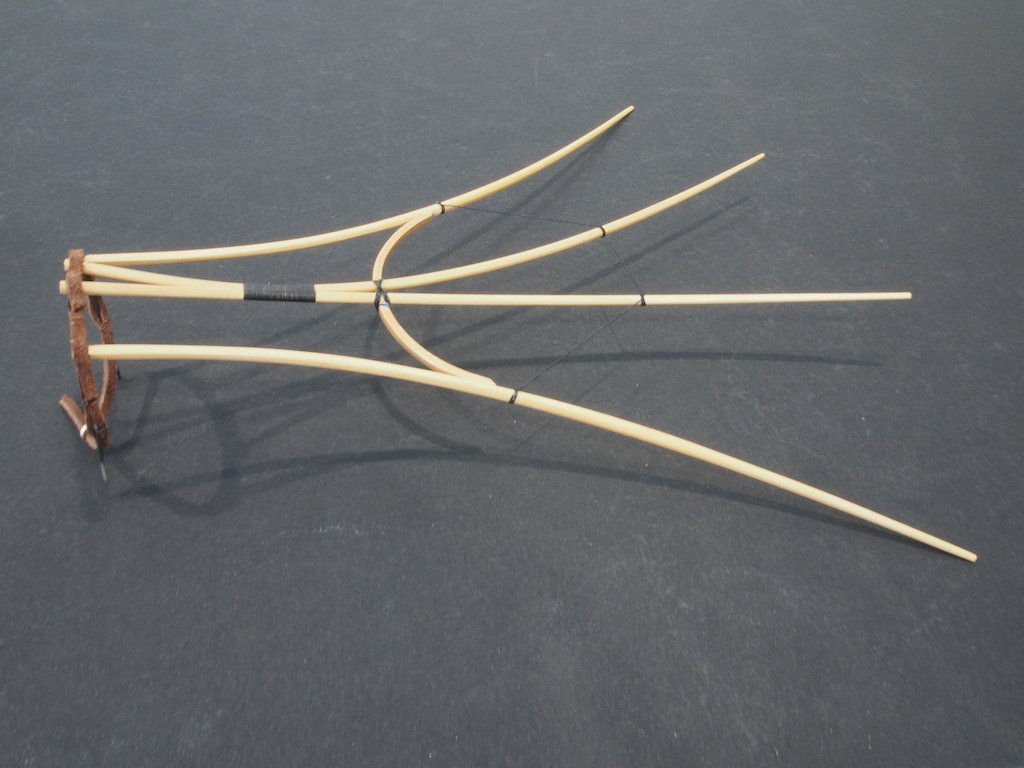

Thanks Carl, and to all of the "likes". Construction of the wings begins by placing the shaped ribs individually over the wing plan and cutting a variety of lengths and shapes. The photo below shows some of these ready for use: Once all ribs are cut to size/shape, the wings are built up over the wing plan, in alphabetical order. Here is what this phase looks like: Here is a photo of the wings at this stage, removed from the wing plan: Two wing struts were then made, fitted with hardware and seized with thread – the plans call for them to be slightly different lengths: Construction of the tail section begins with creating a curved “shaper” made up by laminating three pieces of 1/8” x 1/32” Cherry around a plywood former created from the supplied template. The “shaper” is then placed over the wing plan and trimmed to final size/shape: Two of the remaining wing ribs are then glued and seized together such that they curve in three dimensions. Here are all of the tail pieces prior to final assembly: Tail construction then proceeds with the shaper and two outer ribs glued together over the wing plan: The two inner ribs are then notched on the underside and placed over the shaper. The blob of “yellow tack” is to provide some weight/balance so that the inner ribs set in the correct position: The Tail Mounting Bracket is then made by first bending a piece of (very) stiff wire to shape and then adding a leather strap, which was first cut to shape and fitted with a “buckle” as well as two slits for the wire: The Tail Mounting Bracket is then attached to the Tail Assembly: Finally, some cable (thick thread) was added in accordance with the Wing Plan. Here is the final Tail Assembly: The next step will be to cover both wings and tail assembly with mesh, followed by final assembly of all parts to the fuselage. The finish line approaches…

-

Hey Slog, Nice to see an update on your lovely model. I understand fully the inconvenience of work getting in the way of the important stuff! Let’s face it, modelling isn’t a matter of life and death - it’s far more important than that!!!

- 244 replies

-

- borodino

- dom bumagi

-

(and 1 more)

Tagged with:

-

For blackening copper, you need to use Liver of Sulfur. Readily available online. I use the gel form. A little goes a long way. The best thing about it is that you can use it ‘in situ’ and just rinse off the surrounding wood with water if there is any overspill. Much easier to use than brass blackening solutions too! Ed Tosti uses it extensively on his builds (Naiad, and Young America) - he actually uses copper where he can instead of brass.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

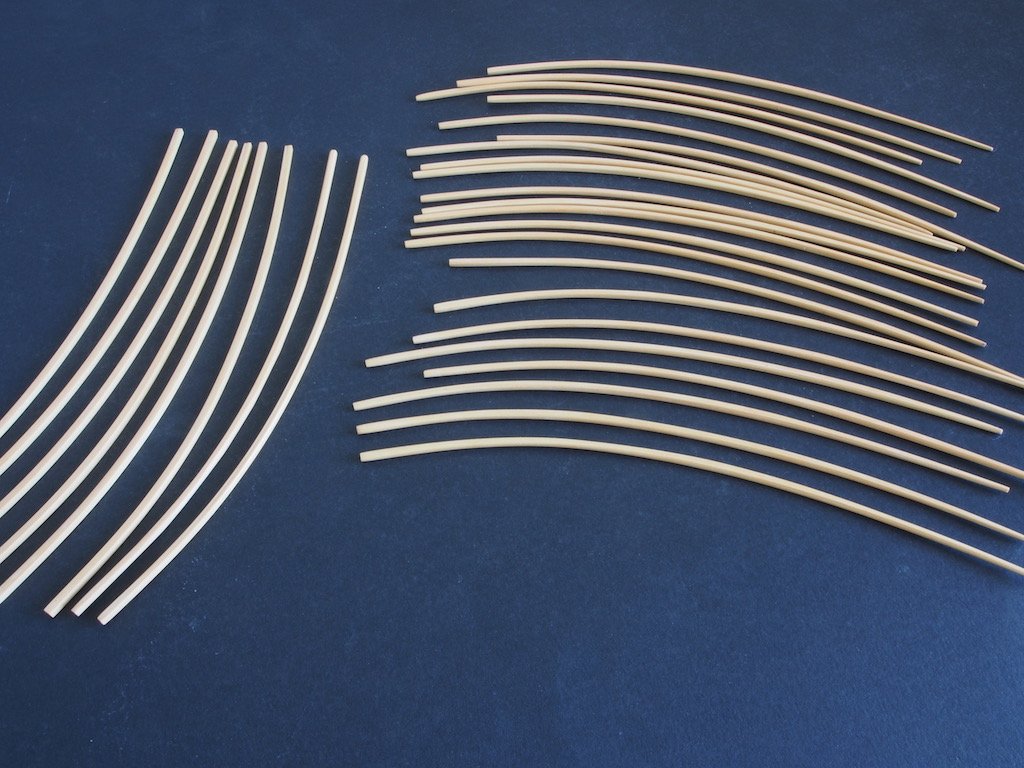

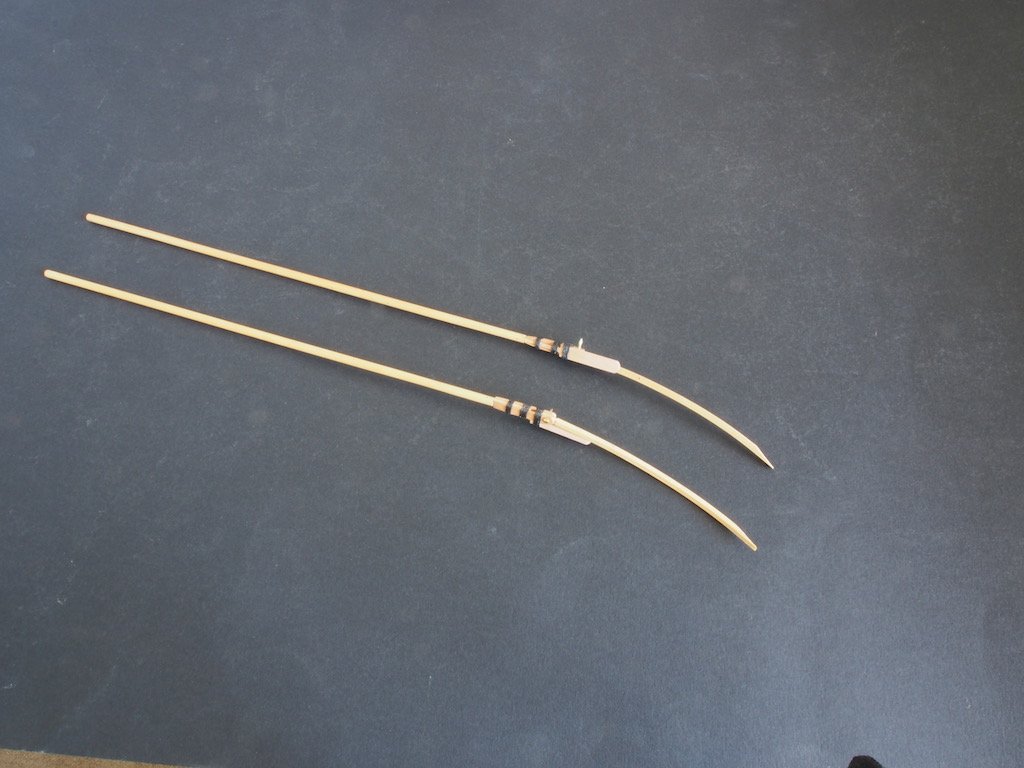

It's been a long time between drinks for this log! The usual "life got in the way" excuse applies - mainly work-related - but I have managed to re-commence work on this project in the last couple of weeks - spurred on by receipt of my Medway Longboat kit from Chuck!😉 The somewhat tedious process of shaping all of the spars was the next step. The two spars of shape ‘B’ were sanded square and set aside. Of the 30 spars of shape ‘A’, eight were sanded square and set aside. The remaining 22 were tapered square from two thirds of the way back to the end of each rib. After tapering square, these 22 along with two that were not tapered, were all shaped octagonal. I found the easiest way to do this was using a very small hand plane. All the spars were then given a finish coating of Shellac followed by furniture wax. Here are the resulting spars, although the photo does not really show the shaping terribly well. It was then on to the main wing spar shafts. Although the kit provided some 3/16” dowel for these, I used some 1/4" square boxwood stock to make these. After cutting to length, I started by drilling the holes as indicated in the plans while the stock was still square. I then used an approximation of the 7/10/7 rule to draw some layout lines for shaping to octagonal, for which I again used a small hand plane. The spars were then chucked in a hand drill and sanded round to the final thickness of 3/16”. It sounds like a lot of work, but this progressed quite quickly in the end. One end of each main spar was then shaped with a ‘step’ to receive two parts similar to a gaff neck (the part is unnamed in the instructions). These parts, together with the shaped end of the spar shaft, form a housing for the next part called a ‘spring clamp’, into which a wing-tip spar (cut from the spar shape 'B') was inserted. Once all the shaping was complete, the spar shafts received the usual treatment of shellac/furniture wax. I forgot to take any progress photos of this stage. The spring clamps were shaped from 1/4” x 3/32” Cherry stock and fitted to the spar shaft housings using a dab of glue and three ‘seizings’. Here is a photo of the completed main spar shafts, with wing-tip spars inserted. and a close-up of the spring-clamp arrangement... All of the shaped spars, together with the main spar shafts, will now be used to construct the wings.

-

Very nicely done Ryland - great idea with the jig!

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Outstanding Michael - I can’t think of anything further to say - simply, outstanding!

- 2,215 replies

-

Nice work, as always, Rusty. Your build log will certainly be a key reference for me in due course.

- 152 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Received my kit on Friday - just two days after my Birthday, so my wife was happy that I’d been away from home with work during the week and she could present it to me when I got home! I still have a couple more weeks travelling to do before having a few weeks off over Christmas, so will delay starting until then. In the meantime, it has given me some impetus to get back to the modelling table and get cracking again with the current project, which has been in limbo for the past several months.

- 109 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.