-

Posts

1,621 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by SJSoane

-

-

Beautiful detail and construction, Gaetan!

Mark

- J11, CaptainSteve, mtaylor and 1 other

-

4

4

-

Finally, the cannon are finished except for the blackening. That was five months, off and on, making these cannon.

When they are all laid out in one spot, that is a lot of firepower!

Tomorrow, I will try the blackening with Jax's Pewter Black. It is a few years old, but I don't see an expiration date. So I will try and see.

I will also try cleaning them with Frei Otto's Pickle, which I got as part of a package of jewelry supplies. It is supposed to clean up and brighten for soldering, so perhaps this will help with the adherence of the blackening. Jax also recommends cleaning with dish soap right before blackening.

Does anyone have experience or advice using this pickle, or any other advice on getting good outcomes with the blackening?

Mark

-

I fully confess to OCD on this, I am trying to get help for it...

A small reason for this is that I got involved a number of years ago in studying the classical language of architecture, which also used a proportional system for defining the proportions of everything in a building, from the largest shape down to the smallest moulding profiles. I found it to be a fascinating exercise, compared to today's "I feel like it looks good".

So, I have been interested in the parallels between buildings and ships designed according to proportional systems, and wondered if the same reasoning held true in both. I think I have discovered that the ships were a lot more flexible in this regard.

Fun exercise; now I will follow Steel's table wherever it might lead me!

And druxey, surely there never would have been a conversation as you described, in the entire history of ships...😀

Mark

-

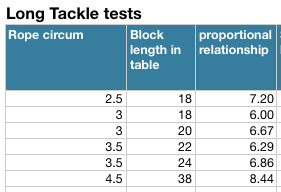

OK, I admit I am getting obsessive about this, but I looked at Steel's table more carefully, and discovered that there is no consistent proportion of rope to long tackle block size.

See below the 6 different long tackle blocks in Steel's table. The 18" block reeves both 2 ½" and 3" circumference ropes, while a 3" rope reeves through both an 18" and a 20" block, and a 3 ½" rope reeves through both a 22" and a 24" block.

And while there is a rough proportion of 6 to 6.86 times the circumference of the rope to the block length, the outliers at the small and large end are both a larger proportion than the middle range.

In other words, there is no rational and consistent proportion between rope and block length, according to anyone's proportional systems!

Now it could be that the ship did not want to stock too many sizes, and some served equally well for slightly different ropes. Although why the same sized rope could use two different block sizes is anyone's guess.

Assuming these were not typos in the tables, and these were the real reality of the ship's blocks, then I am inclined to follow the tables rather than calculate to an unrealistic and inaccurate precision that did not really exist. There had to be a reason for this irrationality that I can no longer fathom, and now my head hurts from trying!

Best wishes,

Mark

-

-

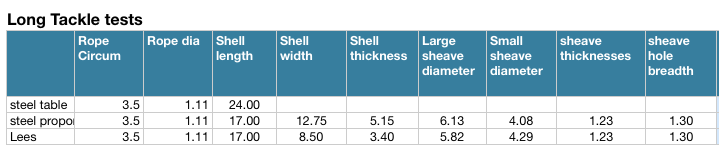

Switching back to the block sizes for a minute, I used a spreadsheet to calculate the block sizes according to Steel's directions, and compared the results to the blocks in his table. I did modify this somewhat, when I realized that a calculation based on the circumference of the rope would usually create a block with an inch and fraction length; but the lengths were always even integers. So I rounded up to the next full inch size. This brought the calculated blocks closer to the ones listed in the tables, usually within an inch or two although still smaller.

The biggest discrepancy concerned the long-tackle or fiddle blocks.

As seen below, I looked at the spritsail halyard, which according to the table is a 3 ½" circumference rope, with a 24" long tackle block.

But using Steel's own formulas, the block would be only 17" long. He describes this block following all of the rules for a single block, only ⅔ times longer, and with the lower part of the block including the second sheave as ⅔ less than the upper part of the block.

Lees' Masting and Rigging used different formulas that still arrived at a 17" long block. His formulas give a somewhat thinner and narrower block given the same length. And he give no sources for this formula. (p. 166)

17" is a long way from 24", we don't need Alan and druxey's calipers to see this difference. But I have found no other sources that could resolve this discrepancy.

I suppose I could work backwards from 24" to determine what the proportions would be for all of the other parts relative to a 3 ½" circumference rope. Presumably, this would create a top sheave larger in diameter than would be required for a single block running the same circumference rope. Maybe the lower sheave should be the size for the single, and the upper 5/3 bigger?

Who to trust?

Mark

- paulsutcliffe and mtaylor

-

2

2

-

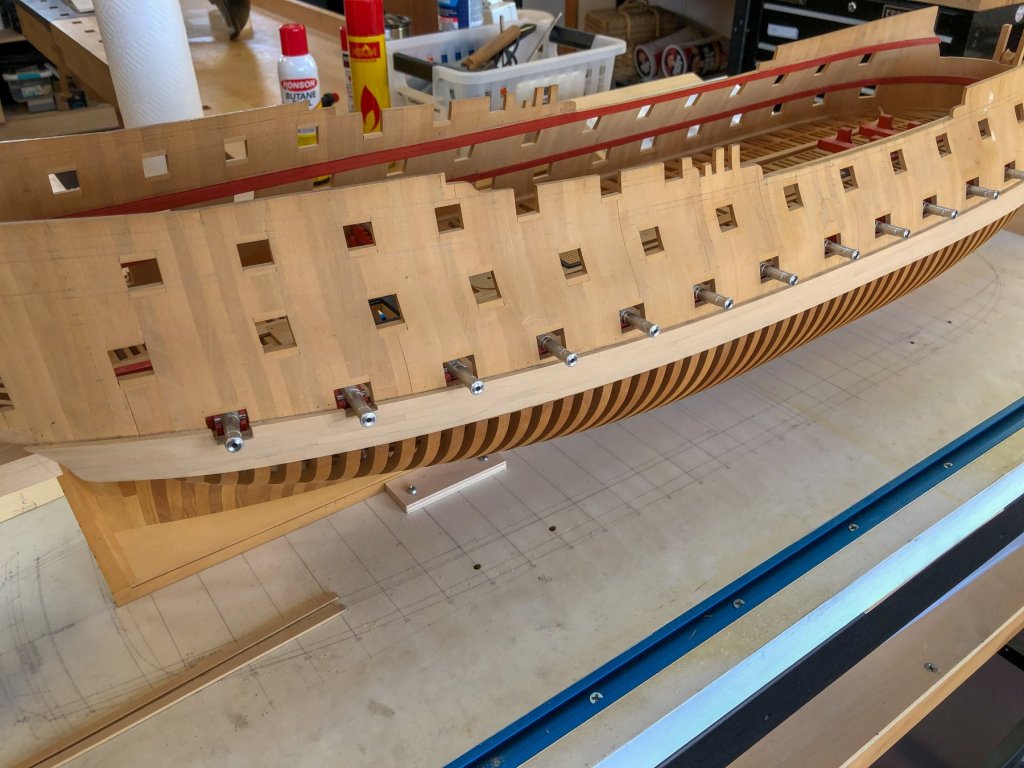

After a long few days, I have only the 9# guns left to drill. Just 18 to go!

Just for fun, I put the 32# into their carriages and into the starboard ports. They are a little low because the deck is not yet in, but it gives a good sense of what the gundeck must have been like. And how awful it would have been to see that ship approaching you with guns run out and a hostile intent!

Mark

-

Alan, you are right, we seem to have an irresistible desire to get it "exactly right", even though the difference is imperceptible--until druxey gets his calipers out, of course. It is like wanting to solve a math or engineering problem, where there is a great feeling that one has found the right answer, not an almost answer. But what a crazy attitude to bring to this hobby, where everything is approximate. Oh, well!

It still amazes me to see how much full size boat construction is done by eye, not by precise measurements. There is a lesson here!

Mark

-

Thanks, druxey, I am glad I didn't overlook something. You and Alan are probably on the right line of thinking that this has to do with the dates.

The Bellona was built in 1760, 30 years before Steel's tables or formulas. Since everything grew as the century wore on, I would think the Bellona's sizes would be at the smaller end of possibilities, likely smaller than in the tables at the end of the century.

So I will likely stick with the formulas, assuming this was an earlier tradition passed down to Steel even as the blocks were being made larger in practice, as reflected in his tables.

Oh, boy, more fun with a spreadsheet...

Mark

- paulsutcliffe, AON, mtaylor and 1 other

-

4

4

-

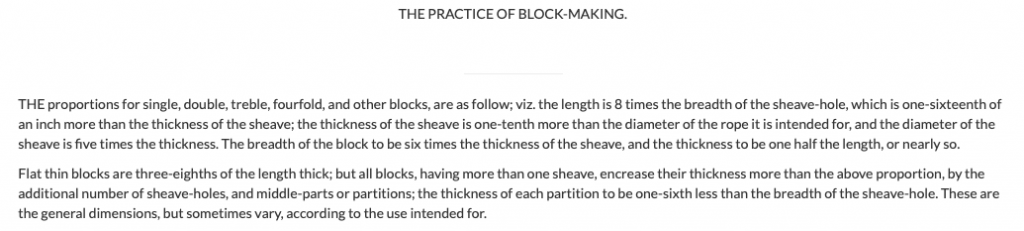

Hi druxey,

I got them from:

and these are repeated in David Antscherl's Fully Framed Model Vol. IV p. 63. They also can be found in Lees' Masting and Rigging, p. 164, but there are some discrepancies in this source relative to the other two. Lees, for example, has the sheave diameter as 4 times the width of the sheave, but the other two are five times. Also, Lees has the width of the sheave hole as a sixteenth more than the sheave, but the other two have it as 1/16" larger.

Mark

- paulsutcliffe and mtaylor

-

2

2

-

On 4/11/2019 at 2:04 AM, KORTES said:

Jack-pins.

I found the technology of making jack-pins in the report of Uriy Kimborovich (bim), that he used for his schooner “Izmail”, for what I’m very grateful to him. I made a simple device out of the materials I had.

Material - pear tree. Firstly I prepared the bars of the desired diameter, and so as not to waste too much material (for the support fixture in the collet) I was carving from a long rod, as the length of the coordinate table would allow me.This is a very interesting way of turning small, thin pieces. I have not seen this before. Very clever!

Mark

- vossiewulf, mtaylor, Keith Black and 10 others

-

13

13

-

Thanks, druxey and Marc, for your thoughts on boring cannon. I do remember the advice I got from Gaetan years ago about how one's skills and speed increase through repetition. This is proving to be very true.

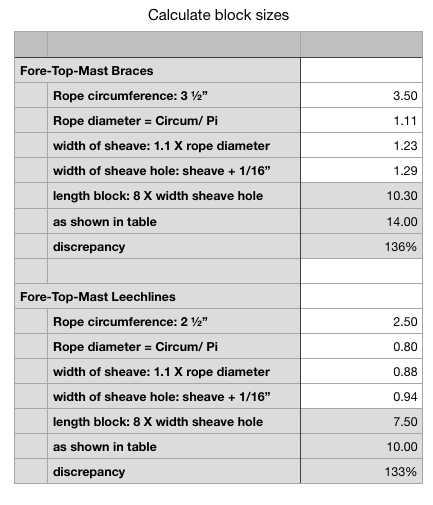

However, taking a break from drilling cannon, I started looking again at the rigging for the cannon. I dug out my old spreadsheets, and noticed for the first time a big discrepancy in Steel's tables for sizing rigging and blocks.

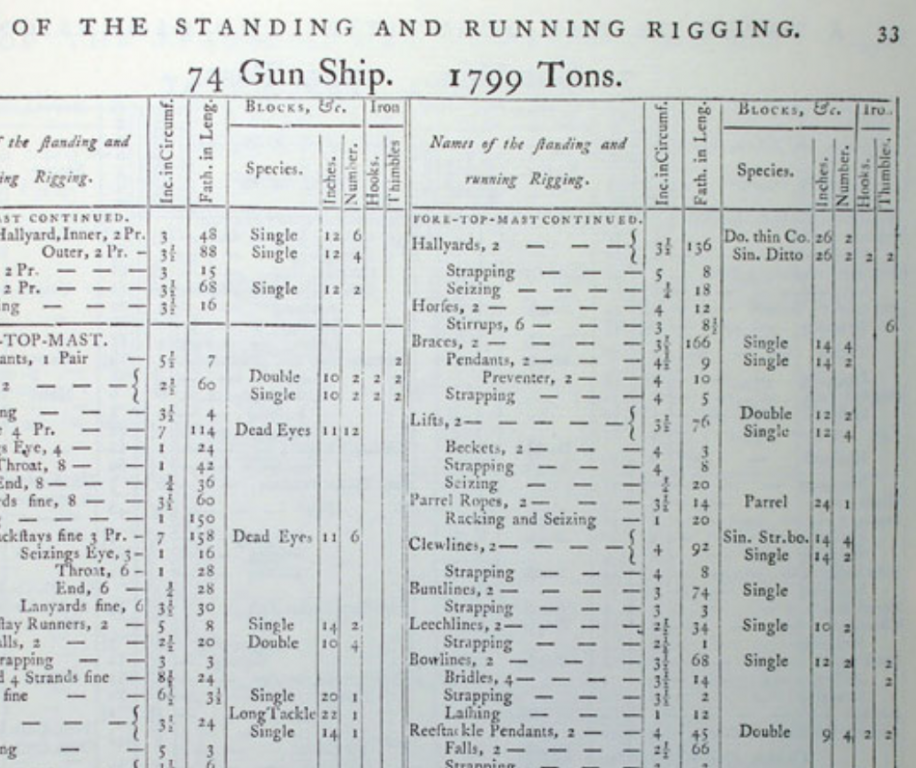

What he says about the sizes of blocks does not correspond to the blocks listed in his master table, a reproduction of which can be seen here:

https://maritime.org/doc/steel/tables/pages/032-ShipOf74Guns.htm

So here is what I found. Look at the table:

Look at these examples to explore:

Fore-Top-Mast Braces

rope circumference: 3 ½"

Single Block length: 14"

Fore-Top-Mast Leechlines

rope circumference: 2 ½"

Single Block length: 10"

But when we follow his instruction on sizing blocks (see spreadsheet below), this is what we find:

The Fore-Top-Mast Braces single block should be 10.3" long

The Fore-Top-Mast Leechlines single block should be 7 1/2" long

This isn't just a little off, it is off by over 30%. Every block in the table appears to be larger than what his proportional rules would specify.

Am I misunderstanding something here? And if not, should I be following his table, or following his calculations?

Best wishes,

Mark

- mtaylor and paulsutcliffe

-

2

2

-

On 4/9/2019 at 5:05 PM, AON said:

I have no idea why my photos get turned or become out of sequence when loaded.

I've tried to correct this but possibly I need a sprinkle of holy water to correct the problem.

Alan,

I just discovered the other day--after suffering from the same problem--that you can drag photos directly into the text box where you want them, rather than dragging them into the attachment box at the bottom. They still show up in the attachment box, but they stay in the right order in the text box. I am not sure of the effect of holy water as well....

Mark

-

Beautiful, crisp, craftsmanship!

Mark

- Stuntflyer, Canute, Martin W and 3 others

-

6

6

-

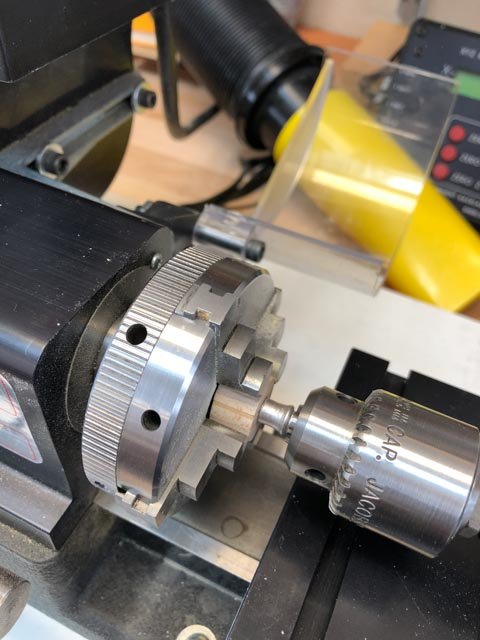

Here is the sequence I am going through for facing and boring the muzzles.

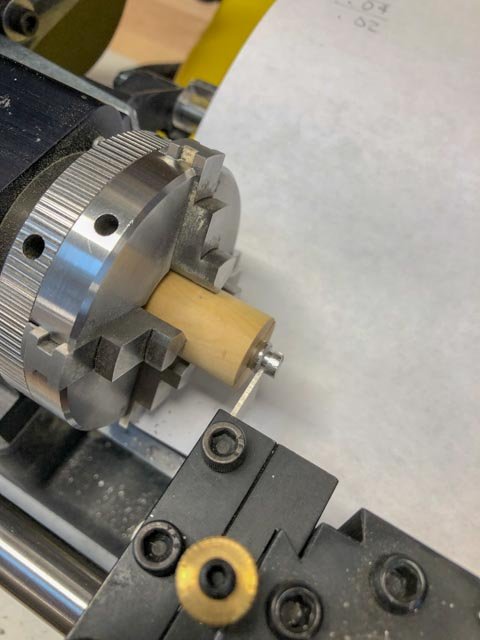

First, the barrel is put in the centering jig:

Then the jig is mounted in the 4 jaw chuck, using the drill chuck in the tailstock to grip the cylinder at the front of the barrel, to ensure it is centered before tightening up the 4-jaw chuck:

Then the cut-off tool is run up against the long cylinder cast at the front of the cannon, to true it up. I do this turning the chuck by hand. I also true up the outermost edge of the swell of the barrel, also turning the chuck by hand. The pewter is really easy to trim:

I cut off the excess, using a hand saw:

Then, I center drill and drill the bore:

Next, to keep the foremost moulding the same thickness, I run the cutter up against a .10" feeler gauge, and set the digital readout to 0".

Back up the cutter, face the barrel down until I hit 0" on the digital readout. This trims up the face so the moulding is exactly .10" wide. Done. Next. Only 60 to go....

-

Hi Greg,

I thought about upgrading my Sherline lathe and mill to CNC a while ago, but somehow it seems like a steep learning curve and price. Have you considered this?

Mark

-

Hi Mark, I knew you were kidding, but your comment did make me curious about how this process could scaled up beyond the needs of one ship. I know now that I would get too bored doing this regularly, even if I could figure out ways to speed it up with multiple moulds.

I had jewelry friends who did lost wax, and I did look into the idea a number of years ago. But the cost of the equipment quickly killed that idea for me. Now if I made my cannon out of gold, it might be worth it, because I could sell them as jewelry for pirates!😀

Mark

- paulsutcliffe and mtaylor

-

2

2

-

- Canute, paulsutcliffe and mtaylor

-

3

3

-

Thanks, Marc, Greg, Rob, Gaetan and Mark. After working all winter on these cannon, it is very gratifying to get to this milestone.

Mark, I have endless admiration for those who make these commercially. I would never have guessed how long this would take. Admittedly, I had a large learning curve, and a few setbacks; and now I know more of what I am doing, it started to go faster.

One would have to make multiple masters of each size, so it would be possible to pour in gangs rather than singly. Even so, the most laborious part is dusting with the talcum powder so there is just enough even coverage without blocking up details, and this would still have to be done for every pour. I would have to charge $100 a cannon just to make it worth my sanity!

When I started this quest for cannon, I explored the different ways this might be done: a duplicator on the lathe, 3-D printing, and casting. From my perspective now, even if I had been able to make the duplicator work, it would never have achieved the detail and consistency of the casting, and it would have been even more tedious. 3-D printing is still an interesting option, although it turned out to be beyond my budget to have them printed commercially, or to gear up with a 3-D printer of my own. So I defaulted to casting, which in the end gave a very satisfactory outcome. Maybe that is why it has been used for centuries. Now if only I had the equipment to do lost-wax casting....😀

Best wishes,

Mark

- Hubac's Historian, mtaylor and druxey

-

3

3

-

Thanks, Ed, it is fascinating to see the logic to the grouping and arrangement. It seems to be a very rational way of managing so many intersecting lines, according to function and geometry, and location.

It would be interesting to look at a typical maneuver in John Harlands' Seamanship in the Age of Sail, like tacking or shortening sail, to see how the lines needed for that task are distributed around the ship. Would they have been grouped into specific location so a small crew could efficiently manage without running around the entire ship? Or did a crew always have to be large enough to man every necessary line at the same time? I am sure members of Model Ship World who are sailors and have sailed on a tall ship would know this.

I still cannot fathom how a sailor in the middle of the night in a storm would reliably grab just the right line off a crowded pin rail. I wonder if they glanced aloft just to confirm, or if they always knew for sure.

Ed, your model makes clearer than anything I have seen so far just how many lines were involved in managing these majestic ships--and I remember reading you left some off!

Thanks again, this was very interesting to read.

Mark

-

- KARAVOKIRIS, Siggi52, GrandpaPhil and 6 others

-

9

9

-

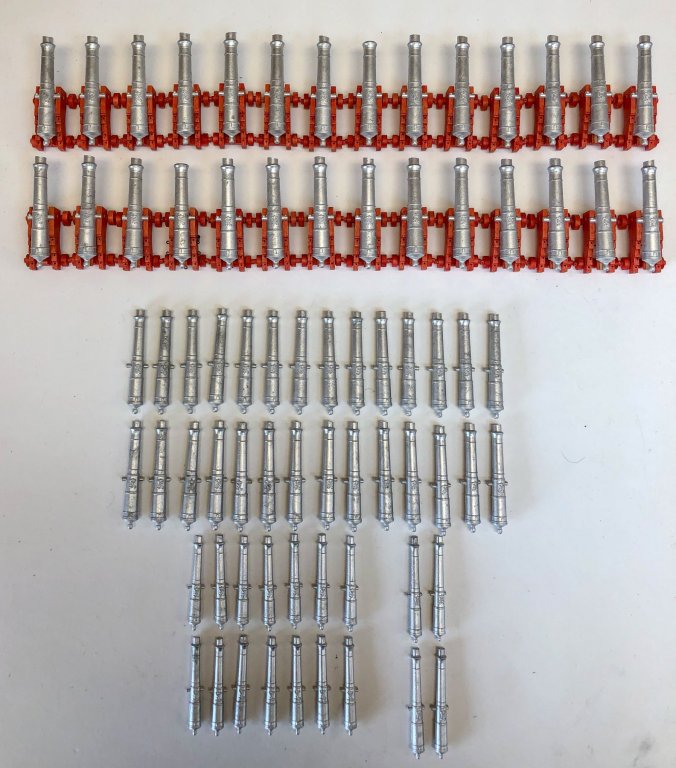

The cannon are all cast!

It is fascinating to see all of the cannon together. 74 guns provides a lot of firepower, when you see them all in one place. And I am glad at this point that I did not build a first rate ship with 100+ guns. This got very weary after a while.

Next, cleaning up with files, facing and boring the muzzles.

And then messing with blacking.

A big step completed!

Mark

-

Hi everyone,

More casting, I have only 11 of the 32# and 9 of the 18# to go. The 9# in long and short are done. I couldn't be patient enough to wait until all were cast, to see how they look lined up in the 32# carriages:

However, I got up this morning to cast the final cannon, and my MicroMark butane burner died. It won't start. The sparker still works, and trying to fill it quickly has the butane coming out at the nozzle, so I assume it is full. There are no instructions for cleaning, so I appear to be dead in the water. I will have to buy another one, or figure out how to melt the pewter another way. I have a stand-up micro butane torch for soldering, but the heat point is too fine to heat up the entire ladle of pewter.

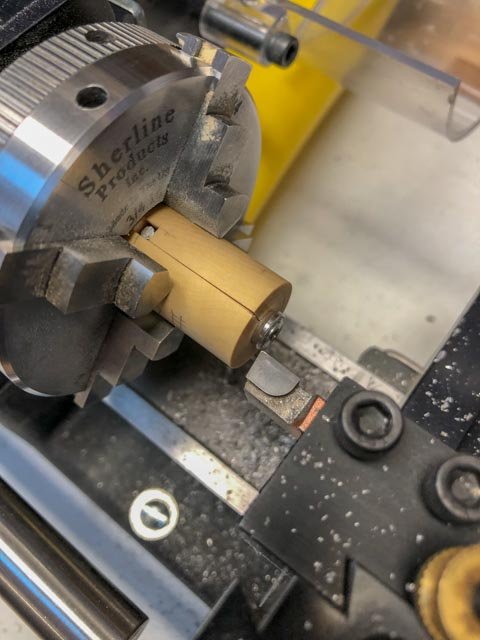

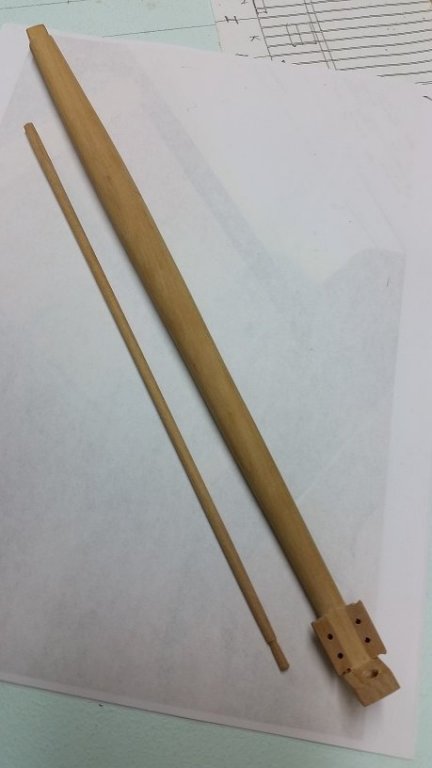

So, moving on for a moment, I made the fixture for the 18# cannon, for facing and boring the muzzle. Much cleaner this time, now you helped me with the boring tool. Worked perfectly. This time, I glued thickish paper between two halves of the blanks, so I could easily split these apart when finished turning.

- yvesvidal, GrandpaPhil, JOUFF and 9 others

-

12

12

-

Thanks, Gaetan, it worked perfectly!

So here is the fixture for drilling and facing the 32# cannon. This one is a little ragged inside because of my boring challenges. Now I have that figured out, the 18# and 9# fixtures ought to come out a little more elegantly. This one needed a little adjustment internally with a flexible shaft cutter.

Mark

- druxey, paulsutcliffe, dvm27 and 8 others

-

11

11

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

in - Build logs for subjects built 1751 - 1800

Posted

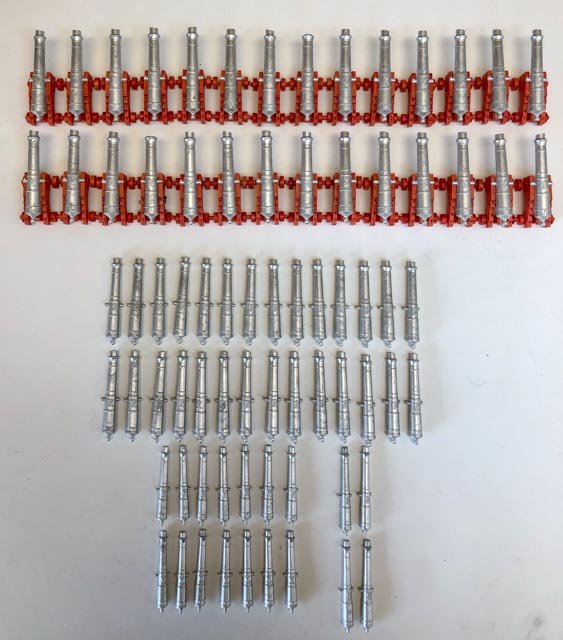

Thanks, Mark, I followed your process, substituting only the pickle solution that I got from Otto Frei. It was quite an elaborate setup on the workbench, with the dawn soap, then rinse, then pickle and its rinse. I used a toothbrush to scrub with the dawn soap:

The Jax Pewter Black worked perfectly, even though it was a few years old. I tried a few ways of applying it. First, I put the cannon in a 50/50 solution of Jax chemicals and water, and let soak. It was a terrible outcome, turning a rusty brown. Then I tried applying 100% Jax with a rag, which got a good color, but was a mess after a while. So then I settled on a small paint brush applying the Jax directly. This worked really well, because I could work on a few places taking the color less than others. And it kept the mess to a minimum, with only a small amount of Jax in a little plastic cup.

After the Jax dried, it was a little rough and dull. So I tried steel wool afterwards, as suggested by Jax. This really buffed it up, but took too much color out. So then I just buffed the cannon with a small cloth. It gave a very nice luster, and left the color.

And the entire set is DONE. All they need is a ship now....

Mark