-

Posts

826 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by giampieroricci

-

-

-

very fine work!!! I really like the base of the model!

- Tobias and Keith Black

-

2

2

-

-

-

-

-

-

-

-

-

-

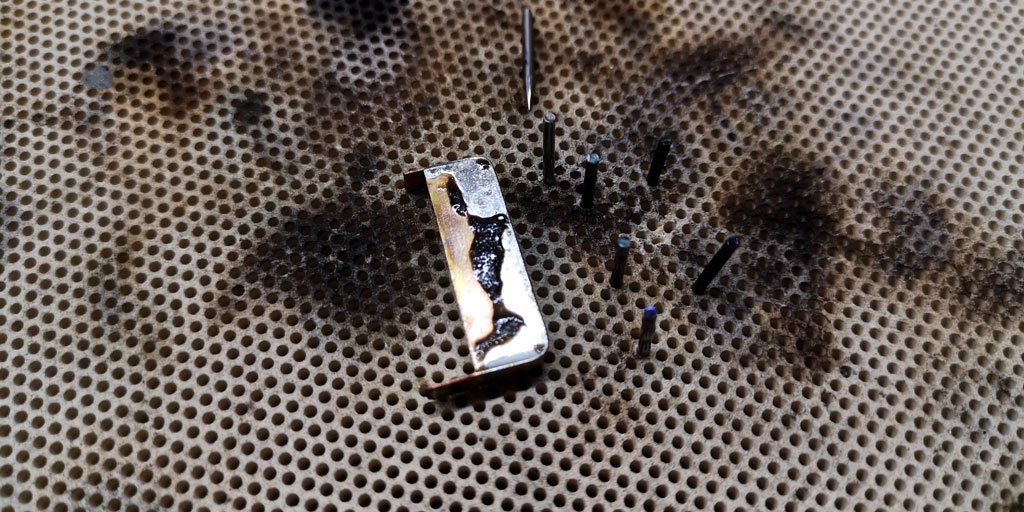

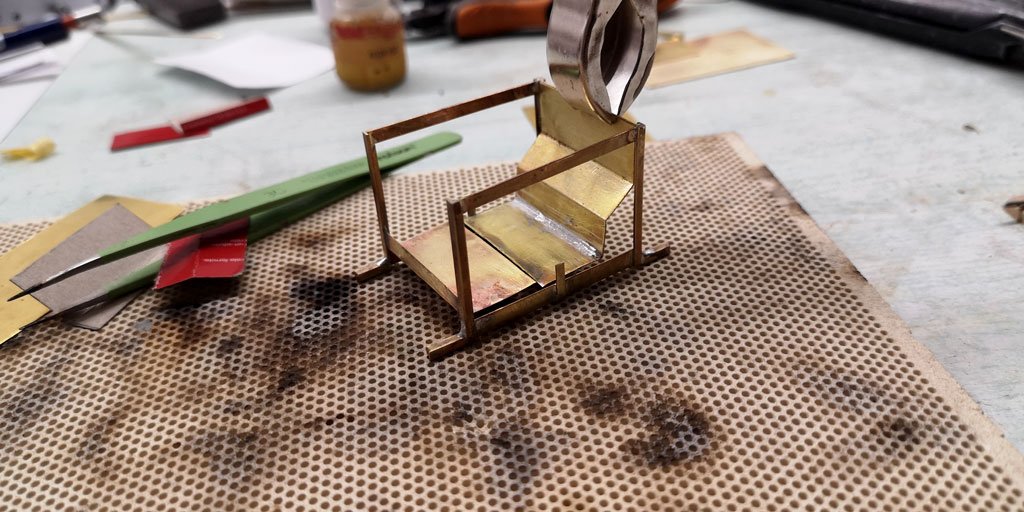

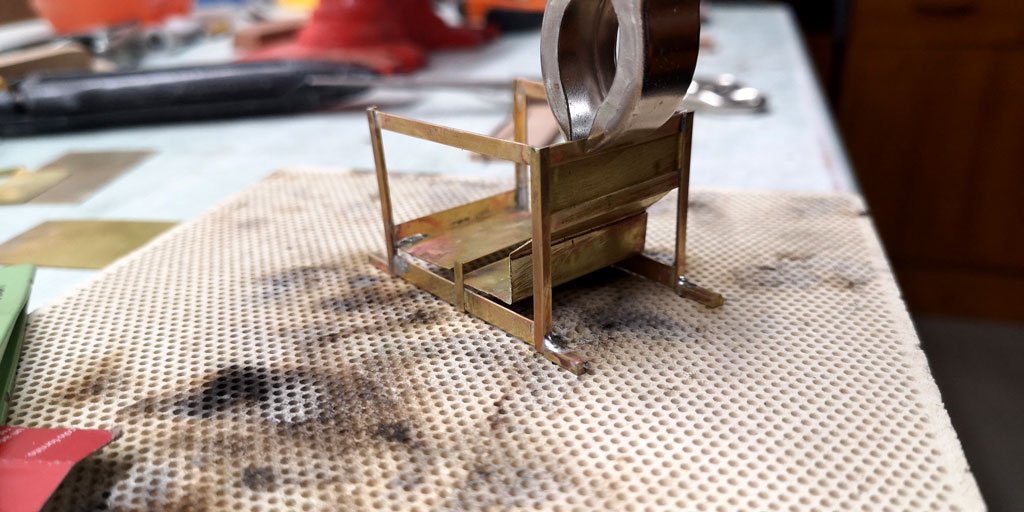

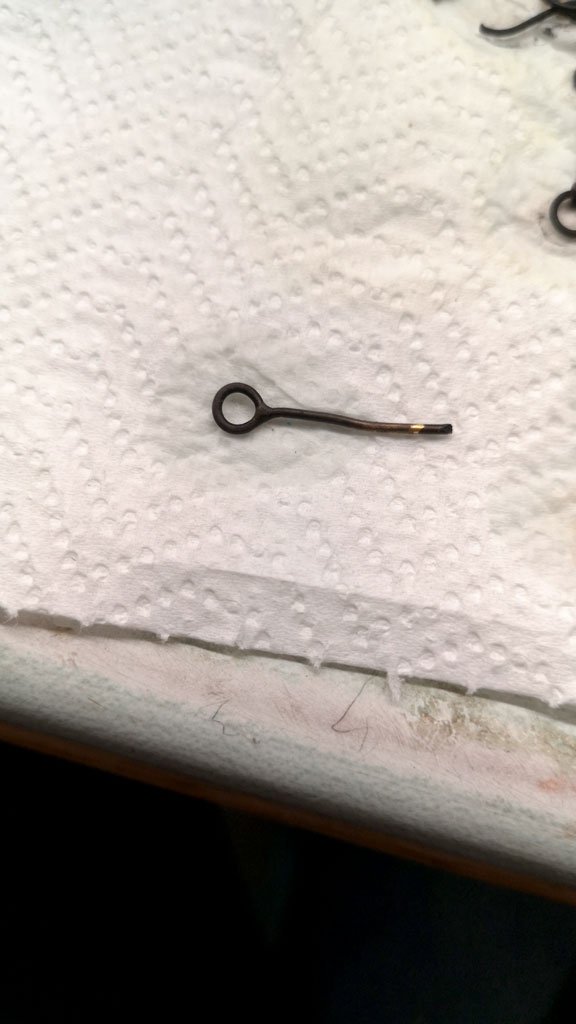

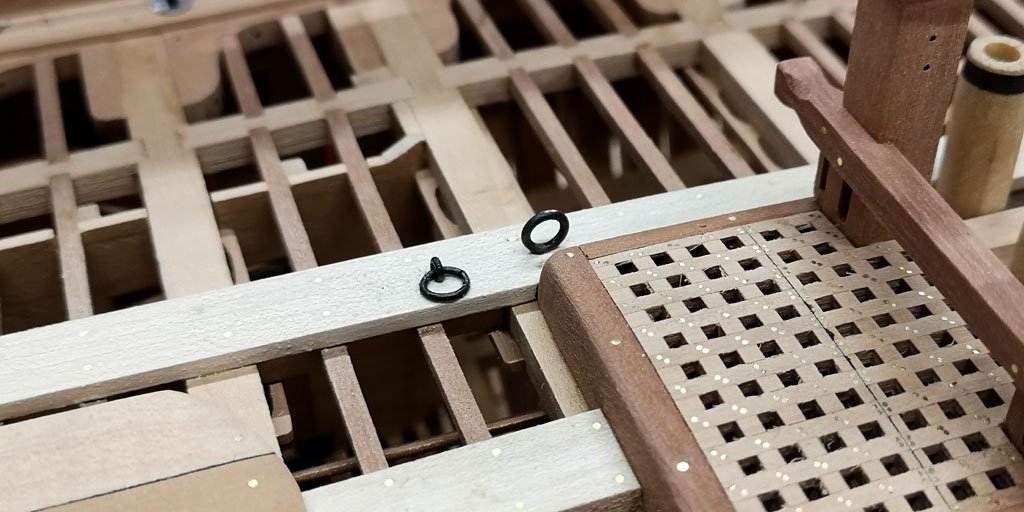

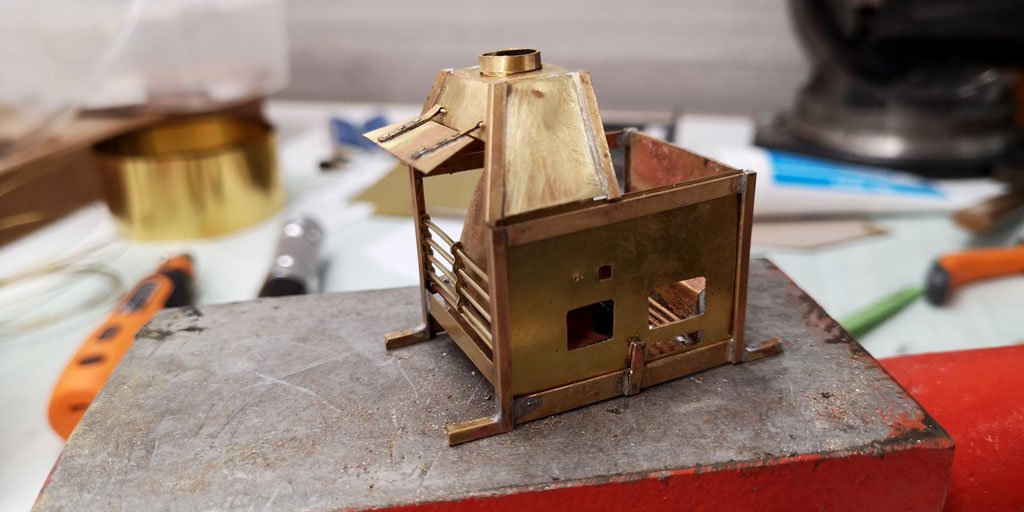

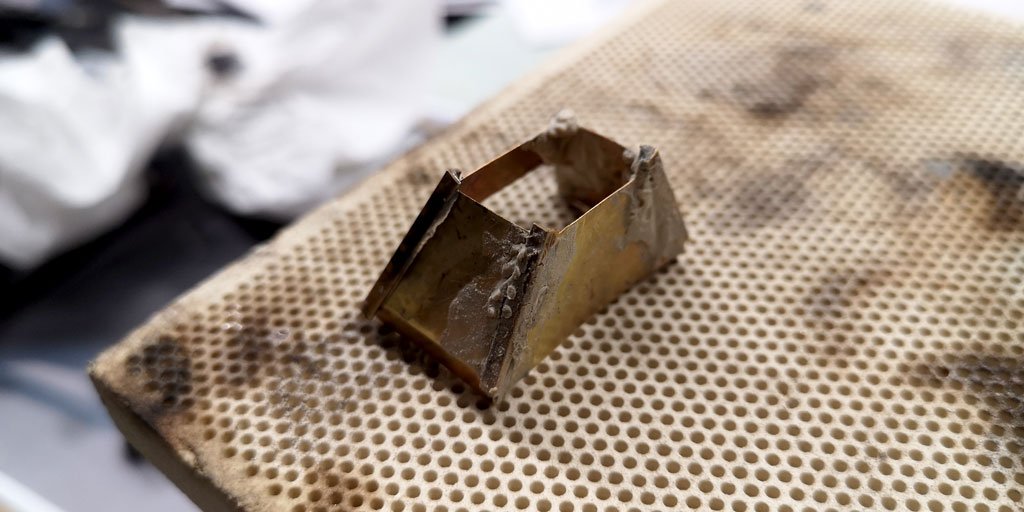

With these few pictures I try to explain how I do my welding. The parts must be well cleaned and kept in contact. With a brush I spread the flux all over the part to be soldered. With a flame soldering iron I heat everything around until the flux starts to boil. Now it is time to apply some of the solder, which is a silver-based rod.

Care must be taken to protect soldering joints already made with a heat-insulating paste

-

how beautiful is this model!!!??

- mtaylor, druxey, Keith Black and 1 other

-

4

4

-

-

-

-

-

what precision and what cleanliness!!!

you are one of the best modellers I know! Unmatched!

One question: will you leave the rudder hinges in brass or use burnisher?

(How I love those planes of yours!!!)

- Razer, Keith Black, Obormotov and 1 other

-

4

4

-

12 hours ago, Kevin Kenny said:

Also are you cutting the bronze plate on your table saw? They seem so exact.

12 hours ago, Kevin Kenny said:I am very envious of your soldering skills. I am not seeing any heat sinks? How are you keeping the previous joints from melting?.

hello Kevin and thank you for your appreciation.

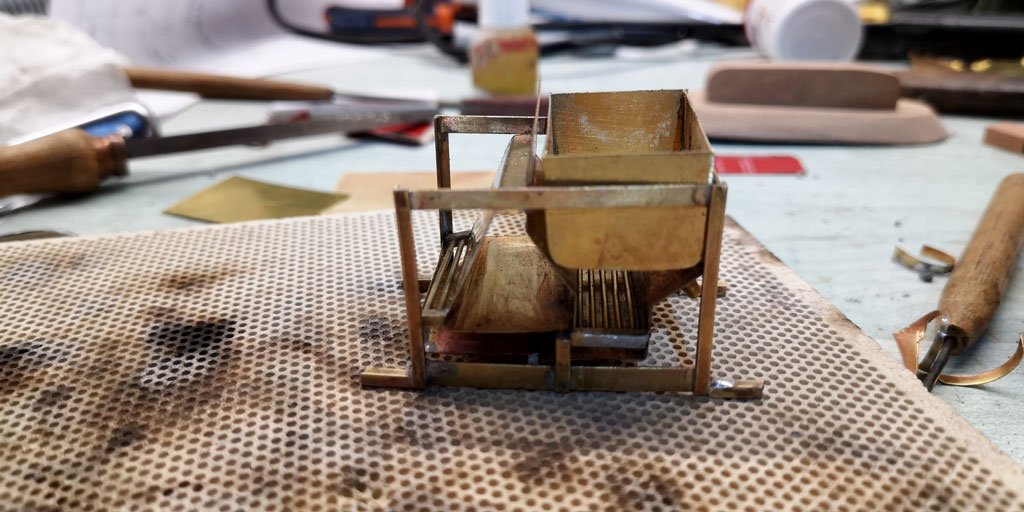

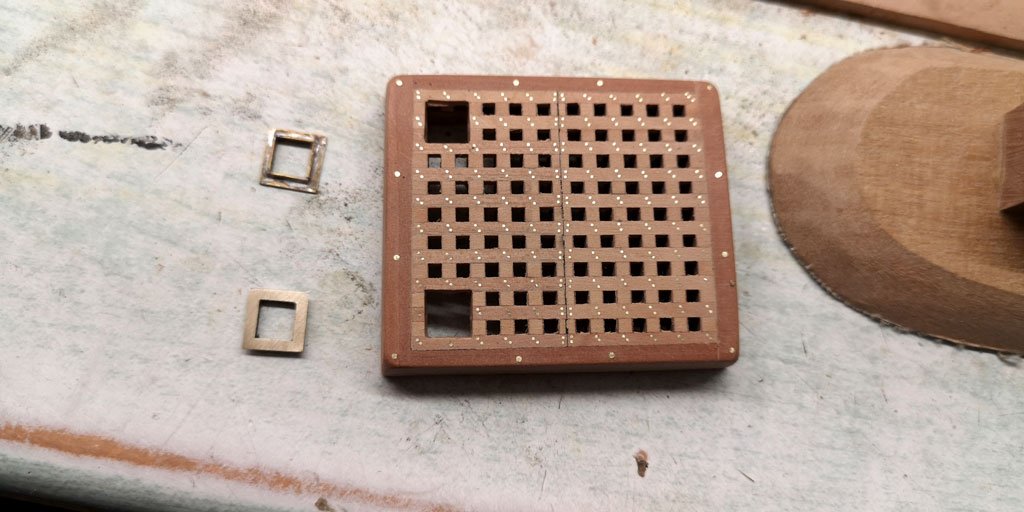

As you can also see from the last photo, I am using a heat-absorbing paste to protect the soldering done previously and I must say that it works very well!

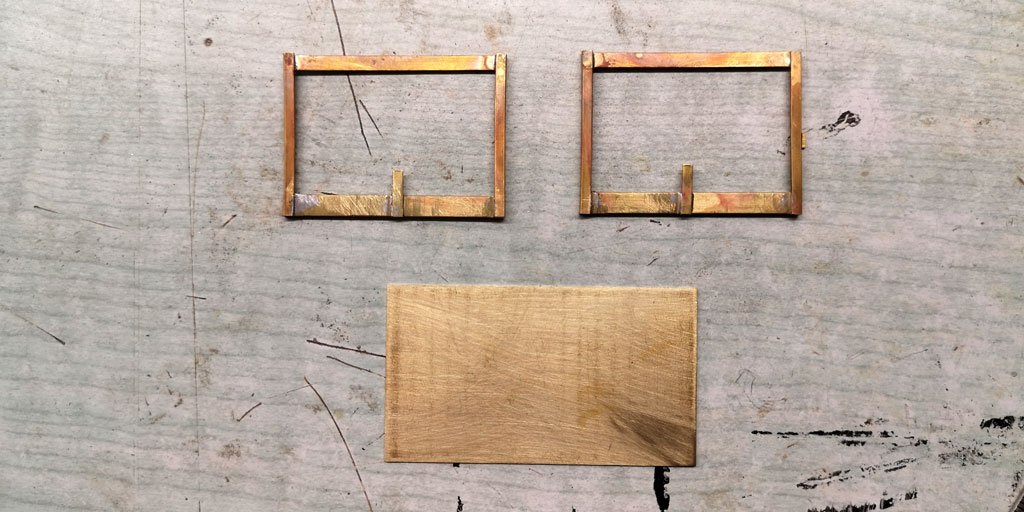

I simply cut the sheet metal with a pair of scissors as the thickness is very thin (0.25 mm). You can't see it in the photo but I use a wooden counterform for assembly.- billocrates, tkay11, Peanut6 and 1 other

-

4

4

-

-

-

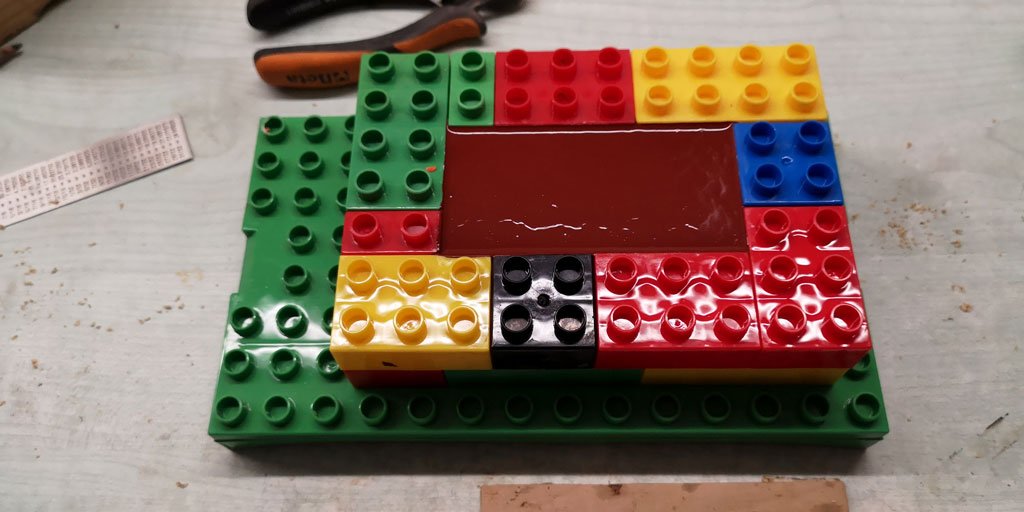

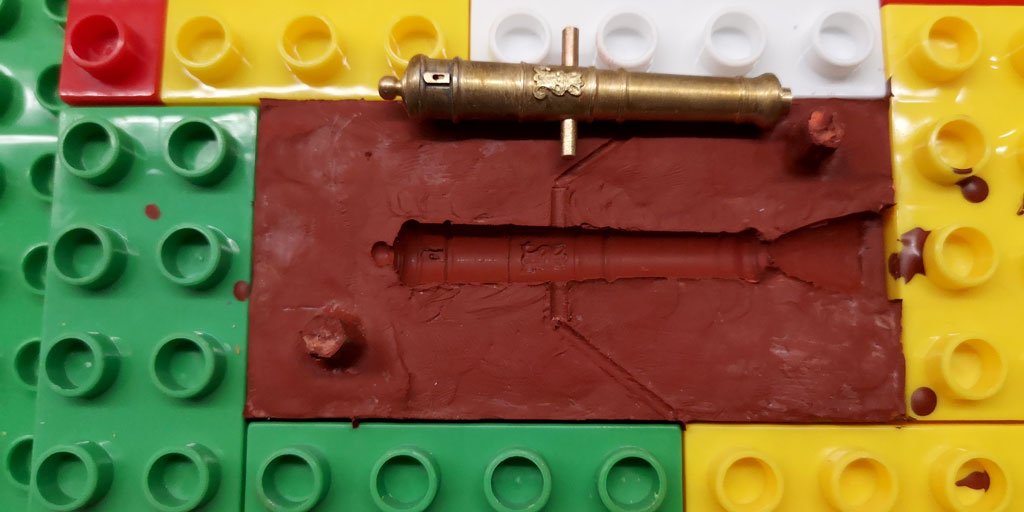

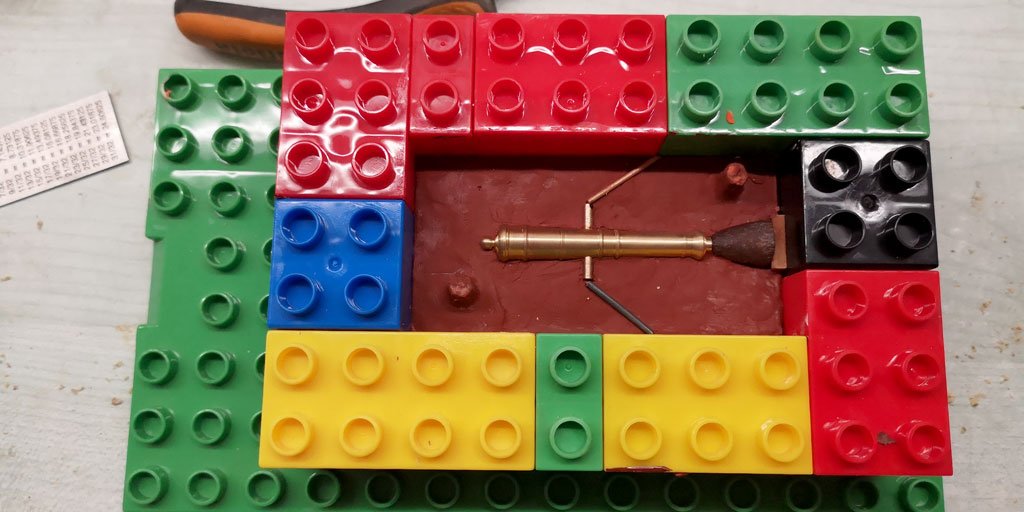

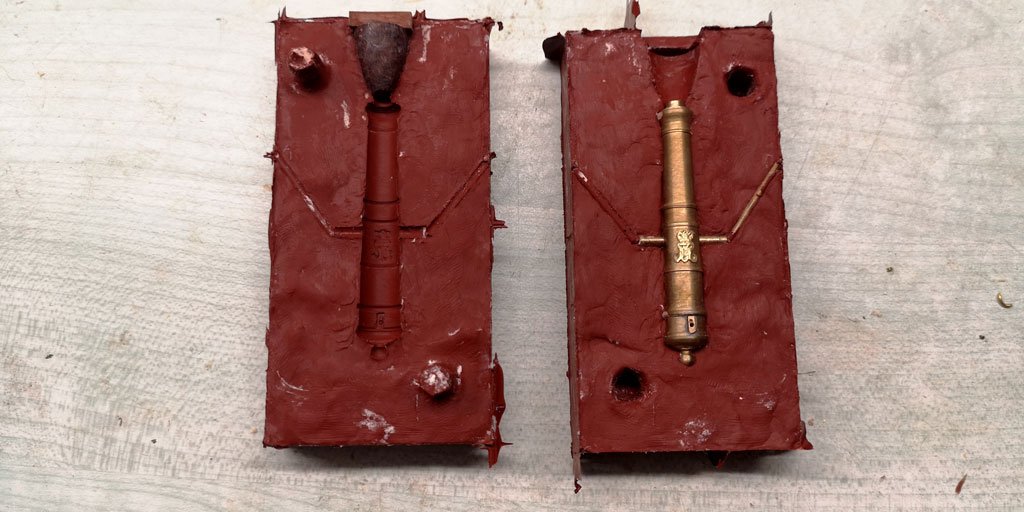

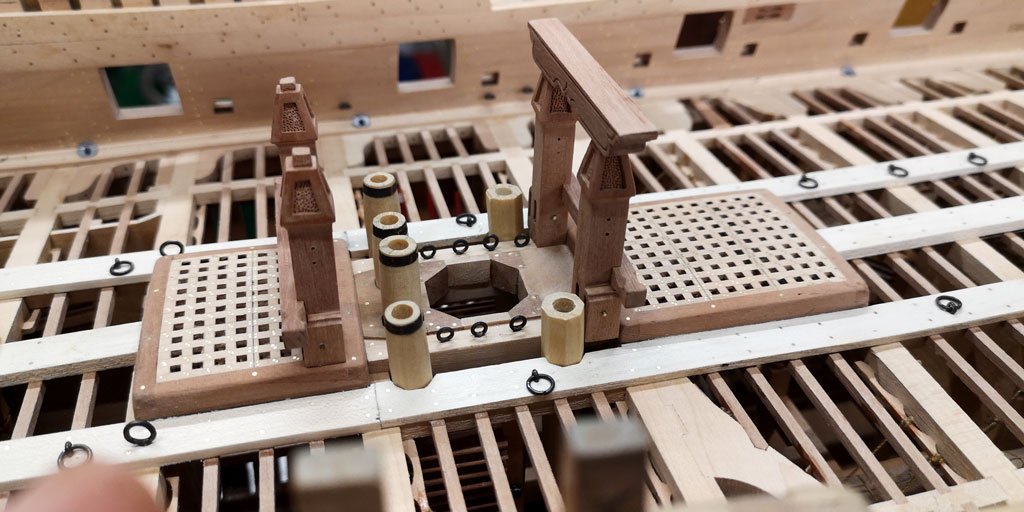

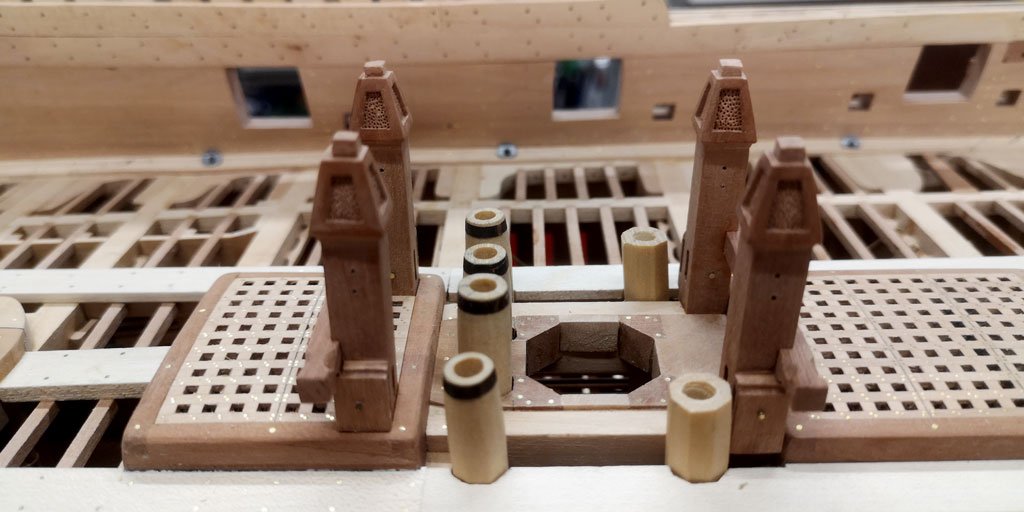

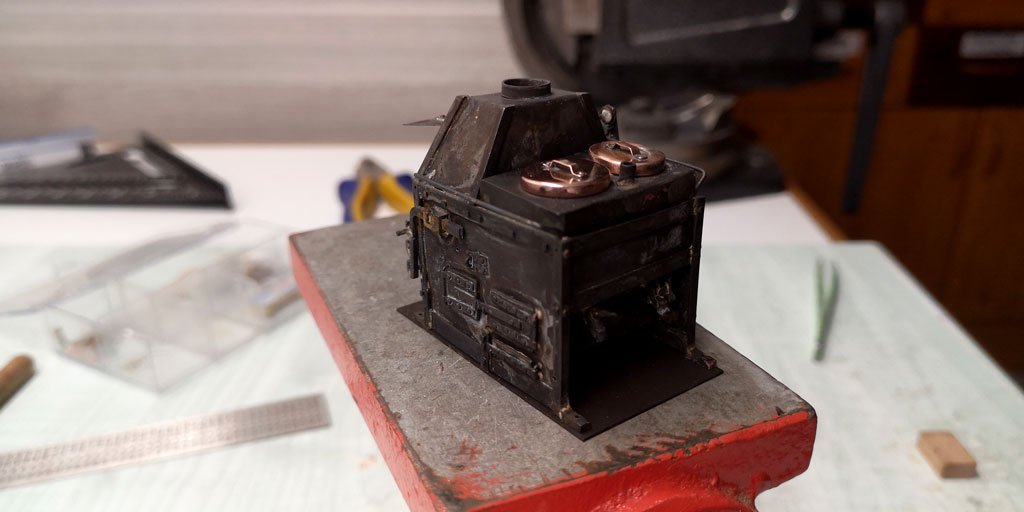

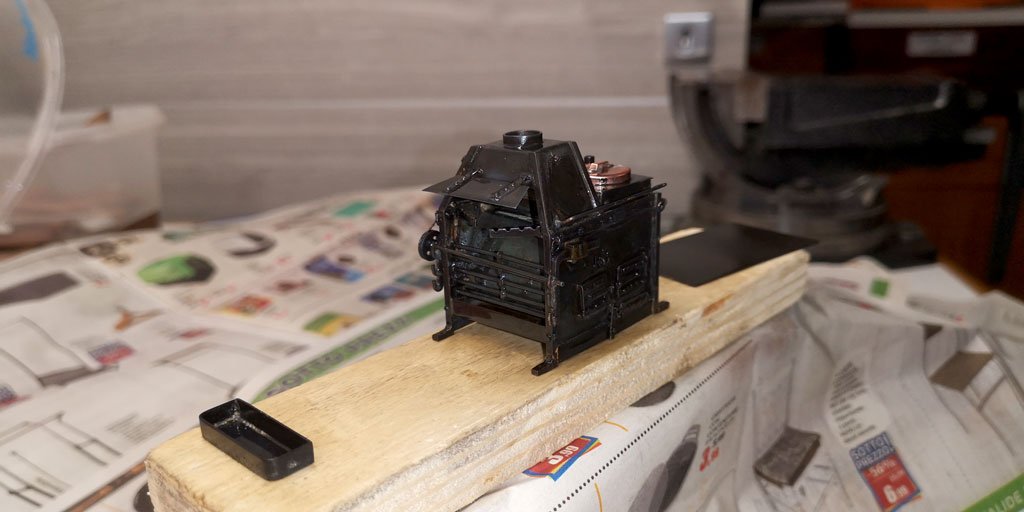

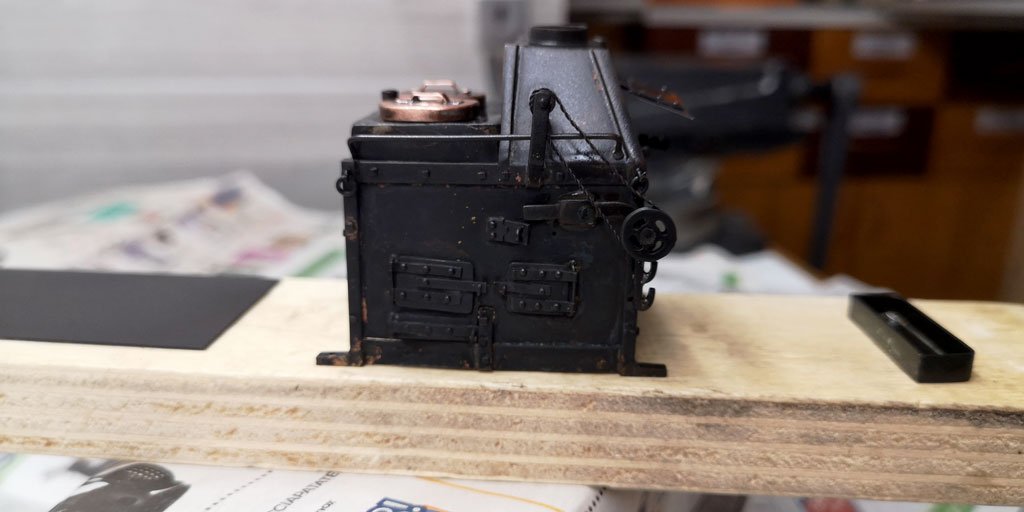

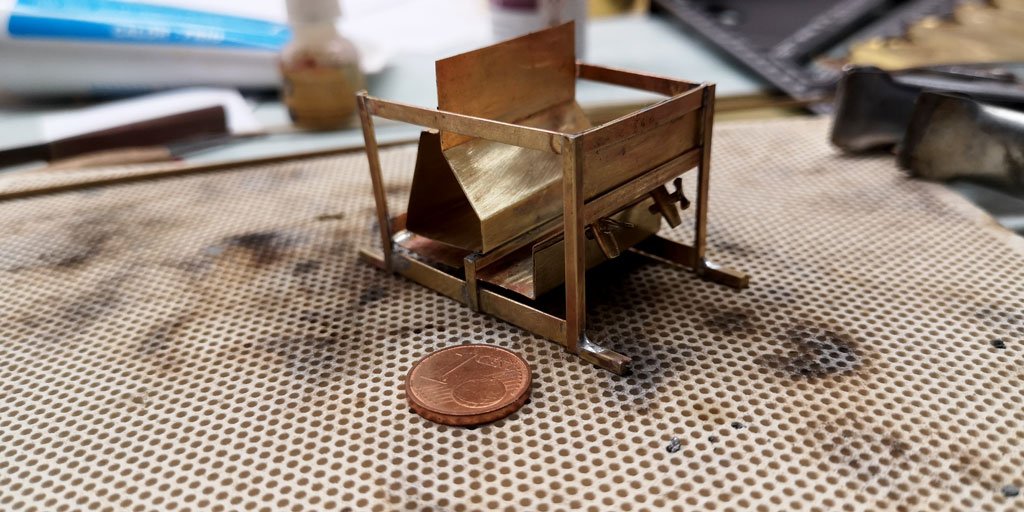

start of the galley stove construction:

- Seventynet, muratx, bdgiantman2 and 17 others

-

19

19

-

1

1

-

-

Speedwell 1752 by dvm27 (Greg Herbert) - FINISHED - Ketch Rigged Sloop

in - Build logs for subjects built 1751 - 1800

Posted

Congratulations to you, Greg, and to David for this wonderful model! So beautiful that I have already ordered the two volumes and hope they arrive soon, maybe one day I can emulate you!