donrobinson

Members-

Posts

1,909 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by donrobinson

-

That made me smile Skip, and you are certainly right. I really think it is a lot of overkill on my part as the plans only called for blocks on the bow and stern but when it is all said and done she should be real nice to plank

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Hi Mike, To answer your question.. No, the Amati version is a entry version kit and this one is by no means that. I built that one for my grandson as a present and it was a lot of fun to build, however, this one is even more fun to build and I am pretty sure it will be on my shelf when it is done

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

HaHaHa, told you it was just a little crazy, Thanks for all your comments and likes. Just a little different to say the least but it worked and will be covered up. Whether I needed blocks between all bulkheads I'm not sure, probably not, but now I am certain I will have a good base. Thanks Again

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

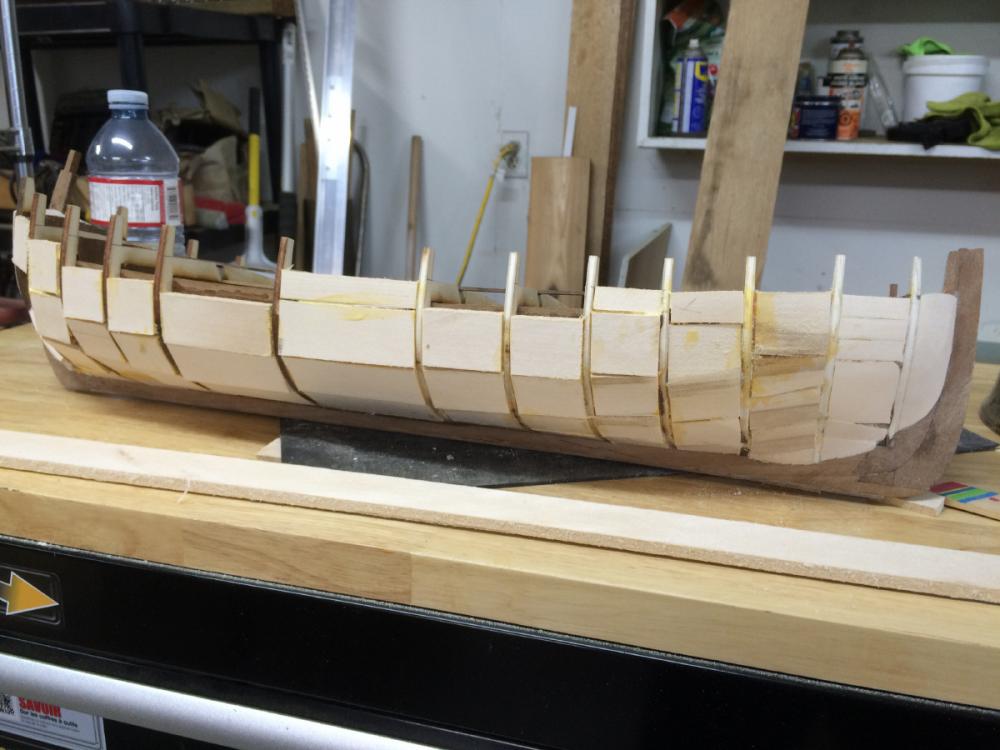

Good Morning All, Well I finally sucked it up and got the filler blocks finished on the port side. This was a evil job but one that I decided had to be done as the hull is only single planked. I know by following the plans and installing only bow and stern blocks it would have been just fine as the planks are 1.5mm thick. So, yes, I am a whole bunch nuts It was a total of 30 hours finishing this side, starboard side should go faster I hope. I used basswood(and wood filler and spackle ) which I think is going to give a real good base for the planking and proved to be fairly easy to work with. Warning: the following pictures are not pretty and caution should be taken before viewing. This unorthodox method should not be tried in a normal home!!! There was no alcohol consumed during any of this procedure, what happened after will remain private . Yah I know, crazy looking stuff. After a lot of sanding it is actually real smooth and test planks lay nicely on it, hopefully all this helps with the planking. It is now on to the starboard side as now she has a terrible list to the port . The lumber in the pictures is for some flower/garden boxes that I have been hired to build so I won't have any updates for a few days. Take Care and Enjoy your builds

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Excellent work Igor, congratulations on her completion

- 71 replies

-

- Santa Maria

- Tehnodiktata

-

(and 1 more)

Tagged with:

-

Paint Over Varnish?

donrobinson replied to mikiek's topic in Painting, finishing and weathering products and techniques

That is the nature of the beast with any flat paint, a flat black being the worst. Flat paint does attract dust and dirt and does not hide smudges or finger prints, and is almost impossible to wipe any of this off without further damage to the paint. I would without a doubt put a few coats of poly on to protect it. Any further minor damage is easily repaired with paint and a little more poly. This one of the few advantages of using flat paint is that it hides repairs and touch ups very well. Using a flat or satin poly will keep the sheen pretty much the same as you have now. I have used this with real good results, it leaves a low lustre finish and gives good protection. It is also available in non-spray containers -

Opinions on Sherline DRO for Lathe

donrobinson replied to rtropp's topic in Modeling tools and Workshop Equipment

I think it would be a real good addition especially when doing repetitive jobs. I find the job of counting revs. and writing them down just another way of making mistakes, with my memory by the time I reach over to write down what I have done it is invariably forgotten . I'm not sure if you have the mill also, if you do, it would be a good idea to buy the extra kit for it also. It can then the DRO can be interchanged with both machines quite readily. Lastly it is really not a matter of it is required it is a matter of it is available and you deserve it(upon Admiral's permission of course) -

Looks like this will be a very interesting build and kit, will be waiting for more updates

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You are doing great, you and your grandson should be very happy when done

- 206 replies

-

- battle station

- panart

-

(and 1 more)

Tagged with:

-

Man! That looks sweet Mark. Real nice job on the painting

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Your work is always amazing, a real treat to watch this wonderful ship be reborn

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Very nice work, the rigging is looking great

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Looks awesome Dave, she must be getting close to completion

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Hi Ian, I just read your last post and I truly hope your enthusiasm does not falter too far. I am really looking forward to seeing this little beauty completed and also the Victory. You are only about 7 hours away, so if things don't shape up I'll be down to shake things up

- 86 replies

-

Looks as though you are getting lots of good advice Elijah, I'll stay in the back and watch you carry on

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

I'm not sure where you live but Modeller's Workshop(one of our sponsors) makes them, just contact Rick.

- 249 replies

-

- billing boats

- vasa

-

(and 1 more)

Tagged with:

-

I'm about the same as Thistle17, I use various shapes and sizes of wood with sandpaper glued to it(or double sided tape). For fairing a hull I typically use a paint stir stick with sandpaper attached to it, with a different grit on either side. As for sand paper I use sandpaper that is meant for belt sanders as it lasts much longer and is better quality. Poor sandpaper is much like using a dull chisel, requiring more pressure and causing more breakage.

-

Two thumbs up on the fix, she looks good. What was the final procedure?

- 60 replies

-

- king of the mississippi

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks to all for stopping by and for all the likes. Ian: Thanks, the curve was a little bit of a challenge but I think it will be a lot easier using square stock. I proclaimed yesterday a "day off" so I did not get the second one done. Energy level is much higher today and the weather is still too cool and wet for yard work so hopefully I 'll make some progress today and have some updates. The lathe is a Sherline which I bought last year along with a mill, really good tools.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

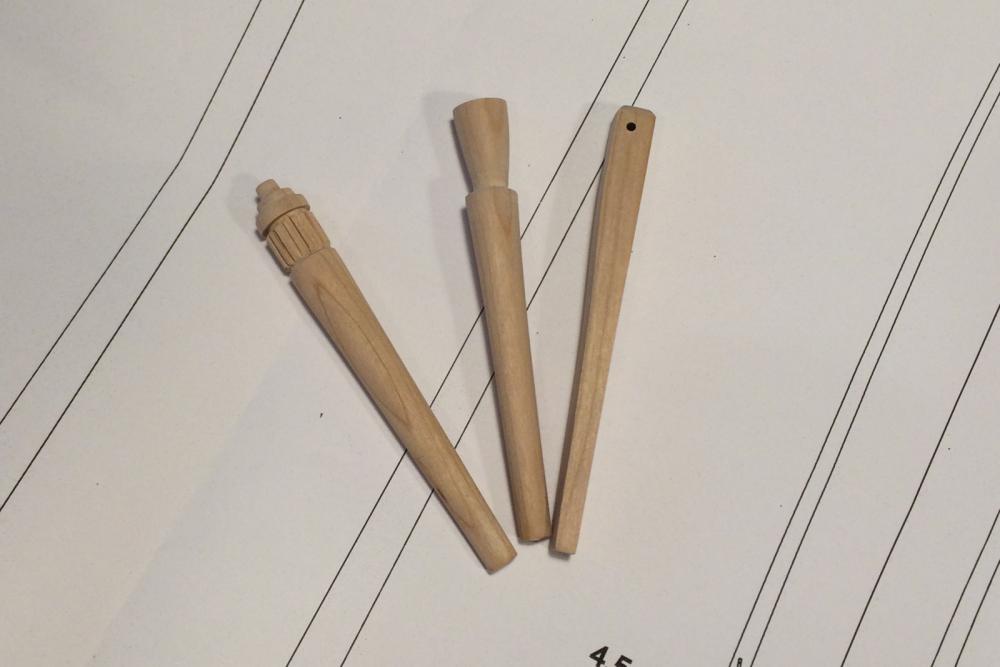

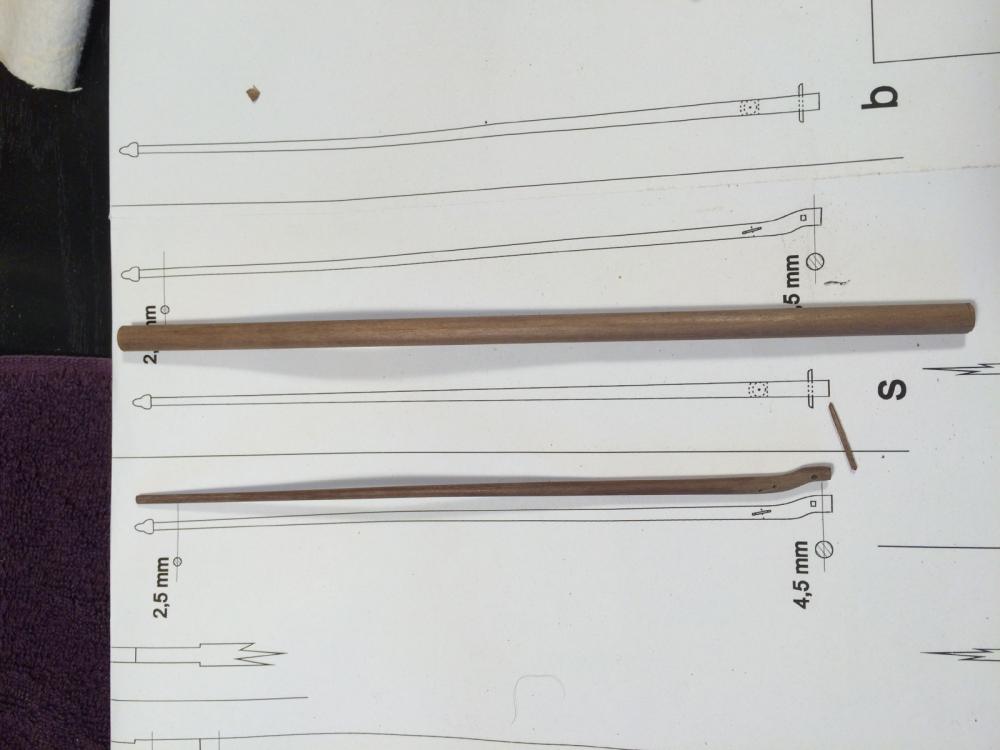

Hi all, well it is kind of embarrassing what I have to show as it is not much. I have been busy with just about everything except ship building lately. The spring yard work on the acreage is almost done and it is finally raining so I hope to get more time in the workshop. I took a little diversion from filler blocks and made the bits and started the mast tops. Using the lathe with sanding blocks and files I shaped the bits Here are the three finished bits, they still need poly Mast tops are carved from 8mm dowel Sanded taper using a shooting board Then the finished product, well not finished but I'm done with it ...... as it is cut 1.5" too short . Not a total waste as it works great as a swizzle stick . Anyway I have since milled a piece of 8mm square walnut and will attempt to re-build to proper length today and possibly do some filler blocks. Thanks for stopping in and have a good one.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.