-

Posts

5,946 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

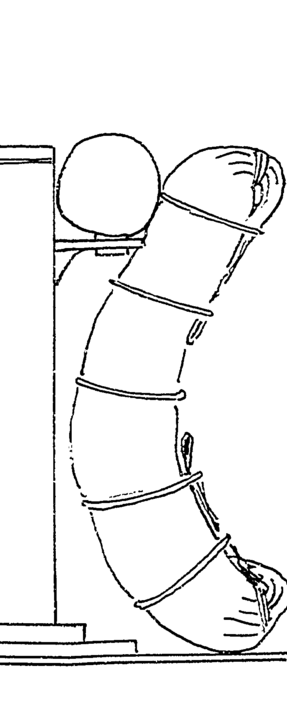

Hi all, another small update, I am being slowed with research at the moment but finding a little time to do a few small things such as making the hammocks for stowing around the funnel as shown in the photo. I posted a photo of the railings earlier; these are only 11mm high with the hammocks 22mm. I did these by rolling some washed drafting linen around a styrene rod (.8mm) then cutting them into lengths before attaching the marline hitch lashings. The rolled linen was soaked with a diluted fabric glue (water) solution and I originally had intentions of removing the rod. However, even with the stiffening from the solution it proved to keep these straight enough as shown in the photo so I left the rods in-situ. I have just noted i need to tidy up some of the rod end (to hide them a bit better). I also did try to add the clews and ring that would have been folded inwards (as shown below) but simply could not achieve it with my clclumsy fingers at this scale 🙂 As these faced in towards the funnel they would not have been seen anyway (well that is my poor excuse. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

-

Very nice work Greg; you have really mastered the pre-shading etc which looks absolutely fabulous. cheers Pat

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

That detail looks great Greg, you've done a excellent job on those guns. There is no harm in covering the boats with canvas, that is how they would have been at sea unless being used anyway cheers Pat

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

An interesting and enjoyable build to follow Dan; you can be justifiably proud of your efforts - she looks great! cheers Pat

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

Agree with Michael, this will be an interesting subject and build. Very fortunate you were able to get a thoroughly researched set of plans and info. cheers Pat

- 219 replies

-

- smack

- cross-section

-

(and 2 more)

Tagged with:

-

Another example of your fine craftsmanship Ed. cheers Pat

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Nice work OC; you are making some very good progress with this very nice model cheers Pat

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for the head's up Steven. I can't say it is readily available these days but I have a little bit tucked away. look forward to seeing the restoration of your Royal Harry. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Great to see you back at it Mark. You seem to have that 'death star' sorted now, that sheet looks very nicely cut. cheers Pat

-

Hi Tim, nice job on the build. Look forward to seeing it and yourself at the SMSV meeting. cheers Pat

- 115 replies

-

- Scottish Maid

- artesania latina

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Thanks for looking in Denis; slow progress at the moment while I concentrate on further research and get the 3D printed parts underway. cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

An hour or two per day has served you well Ed (no pun intended); the rigging looks great cheers Pat

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Glad you enjoyed your trip Rod; and thanks for posting pics. Mate your call on the masting and rigging - whatever 'floats your boat' so to speak. The main thing is do you like it displayed like that - if yes then go for it. it certainly is a different adaption of the 'stub mast' display. cheers Pat

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

You have to be happy with that result Danny; great work and a very polished high quality job. cheers Pat

-

Nice work Eberhard; I know how difficult (for me at least ) turning acrylic can be - turned up very cleanly. cheers Pat

-

Your rope walk makes up some nice rope UV and those tops will look great when complete. cheers Pat

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.