-

Posts

1,468 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Snug Harbor Johnny

-

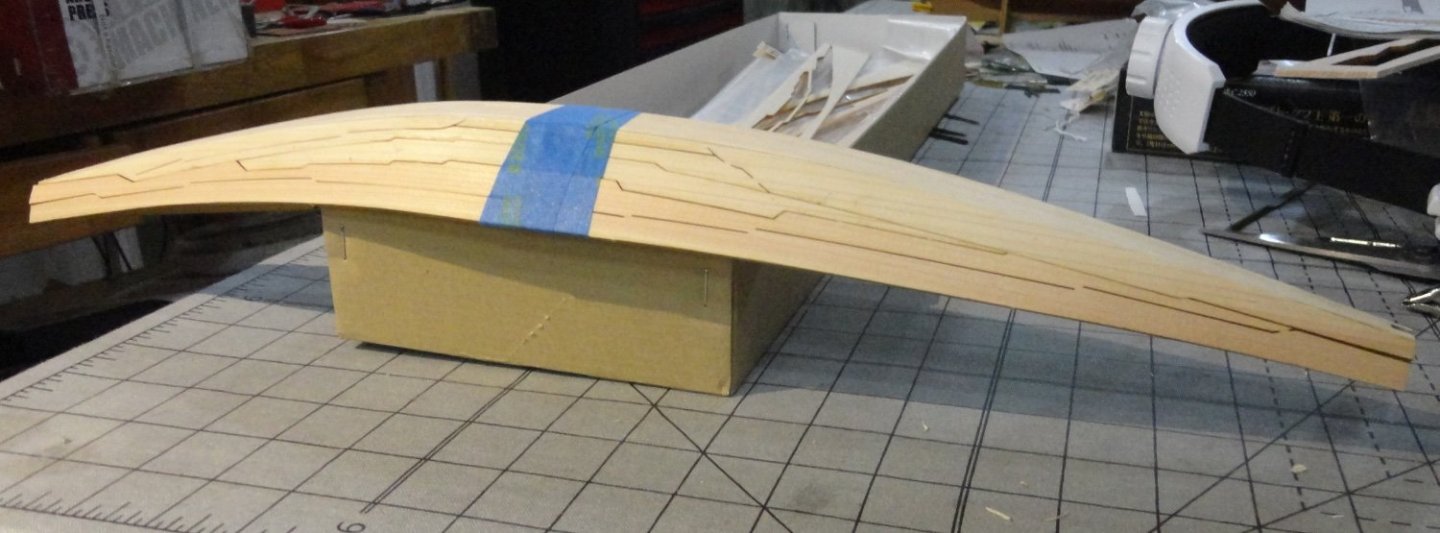

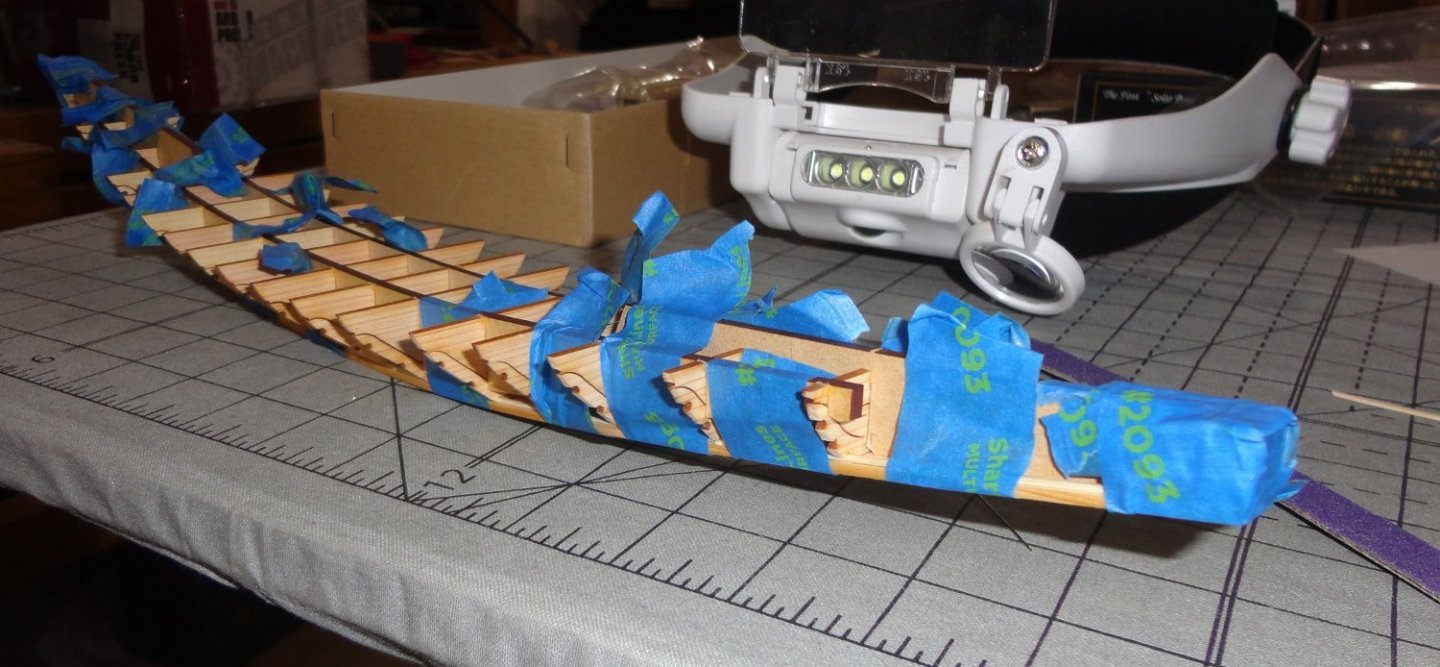

Ahoy mates ! I found that bending the middle strakes for each side was easy, and I modified the method as follows: Run hot tap water over the piece as before, then (once half-soaked) I moved the strake back and forth over the gas burner flame ... almost right on the flame (there is a danger of scorching if the wood goes dry on the surface) and it will become almost too hot to hold (but not quite) and the wood will give off steam. Then it bends easily, but I used both hands with the fingers positioned on the outside of the bend and the thumbs on the inside as a 'human mandrel'. One has to have the 'feel' of how far to push it, but the Japanese Cedar is generally compliant. Since wet wood doesn't sand very well (raises fibers like crazy), I let it dry a bit first. It fit into position like a glove and there was no adjustment needed on the angle where the edges going with the garboard strakes. Glue was applied and I kept using blue painter's tape, with clamps on one end where it needed a little more than tape. Left and right were glued and allowed to dry together. Some observations: Titebond glue (aliphatic resin) once past the 'grab' stage will go into a 'soft set' (something like 30 minutes). There is still pliability at this time, and some positional adjustments or re-clamping can be done then. A wood part can be pried off still without too much trouble to re-position after 'refreshing' with a little new glue. After 1 - 2 hours it has what I might call a medium cure, and the parts can be sanded/trimmed with care. If something slipped while setting, the isopropyl alcohol removal method (see earlier in this build) will work quickly and effectively. A 'hard cure' takes several hours. When removing blue tape, do so gradually (and at a 'low angle' to the plane of the surface) to avoid pulling up wood fibers. I use the tape for painting edges that has no more than a 'medium' stick ... other tapes with more 'stick' should be avoided. Gorilla tape is RIGHT OUT. I bent the final strakes as above and decided to tape them to the frame to set the bend. A view of the interior as the planks dry. Once dry I removed the tape (except in the middle so the planks would not fall off), and they had very little spring-back. This may be because I worked them good per the 'wet wood over flame' method described above. They were over bent a little so allow for spring-back. Obviously there is some, but noting to fret over. I have to get into scrubs for an evening shift at the hospital, so I'll post more on planking later. Johnny

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

Rob has offered some good advice, which is pasted from an earlier post in this log: "I just wanted to help those, thinking, or beginning rigging on their own models. 3 things I want to leave you....1: Use the appropriate size cable for your rigging (Smaller is better). 2: Use the appropriate color, Greyish tan is best, (deadeye lanyards are NOT running rigging...stop using tan cord) 3: Rig as much as you are comfortable with(but if you put that much effort into your hull build...why stop there, challenge yourself, you'll be a better modeler because of it)." In perusing a number of logs, the ones who make use of what can be considered 'miniature rope' for their rigging (made on a mini rope-walk such as Chuck's rope rocket, or purchased from a vendor using similar techniques) look the best. There is very little rigging 'fuzz' - which shows up on close shots, and must be visible on a close examination of the model. Some kit rope isn't too bad and can be treated to reduce 'fuzz', but given the effort (and cost) that goes into a build, why not make the most of rigging opportunities - as rigging is often 'half the model'.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Ahoy Chris! 'Had to do a double-take on certain metal ship models offered by the Piececool brand, since I have a couple by Metal Earth (Iconix) kits that are 'ringers' for the photos in the link. So I did some research and found that Piececool and Metal Earth are different brand names for the same products engineered by Tenyo, a noted Japanese manufacturer of an eclectic variety of 'thin metal' assembly models (ships are a small subset) ... there is no piracy involved. Metal Earth is intended for U.S. sales, whereas Piececool is marketed in China - same ship kits. You can get either legitimately on-line, and Amazon carries some of the both brand's product line. The quality level (according to a metal molders' review) sets the standard, whereas the ARE some 'other' brand names that are copy-cats with lower quality (e.g. thinner metal that breaks easier).

-

There is a brief build log of a small-scale metal USS Arizona I posted ... it was a 'break' from a much longer project of a wooden model. The the metal medium may be of interest to some (like me) who would never attempt metalwork if it were not in kit form - thus fully engineered.

-

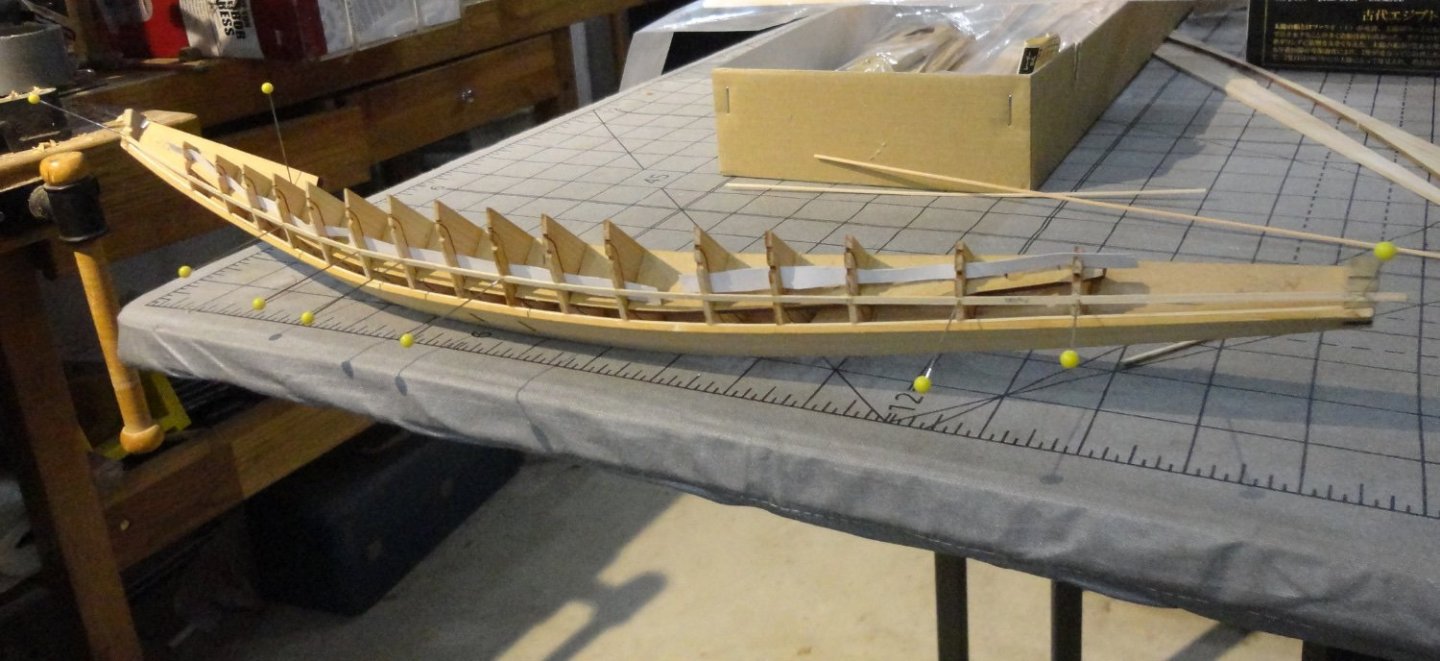

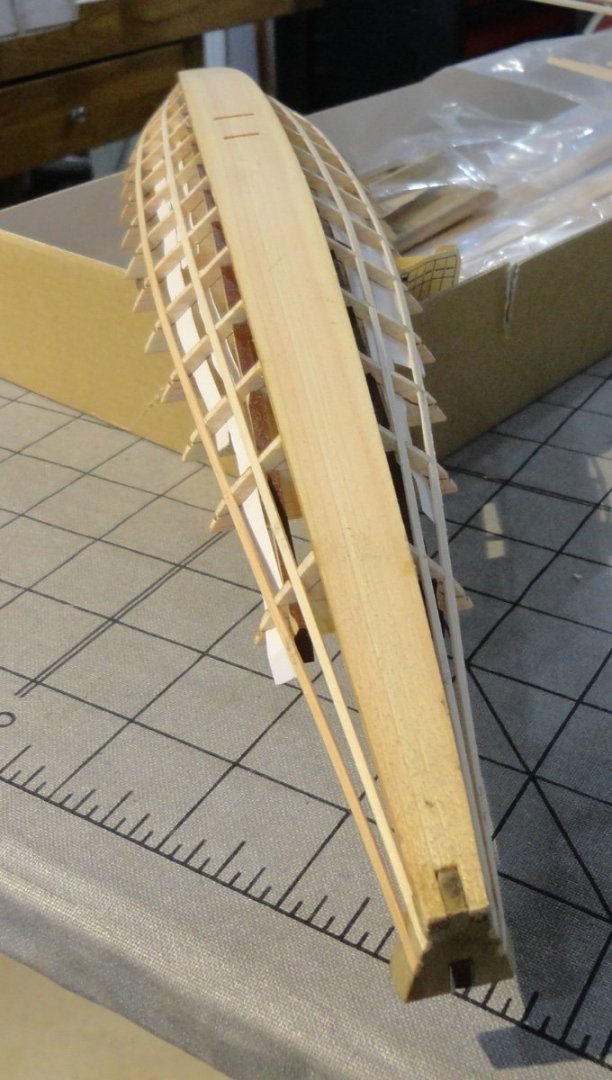

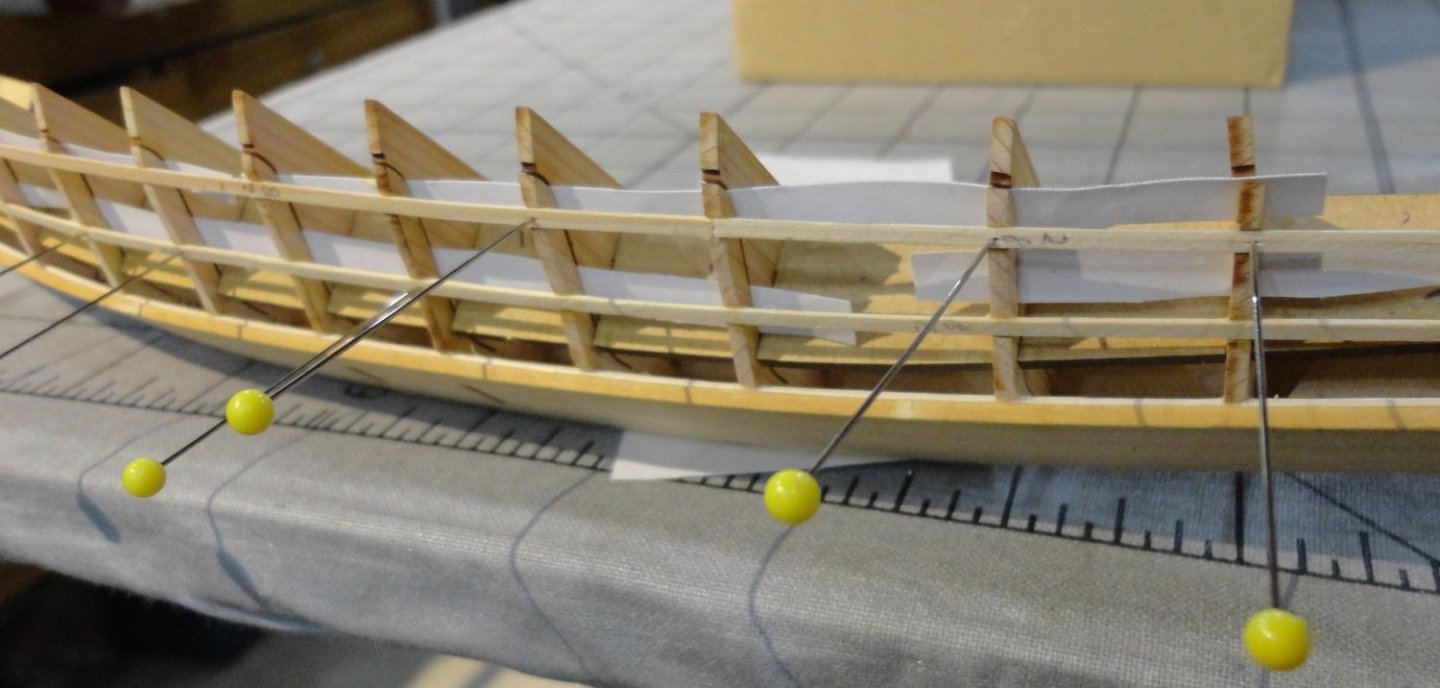

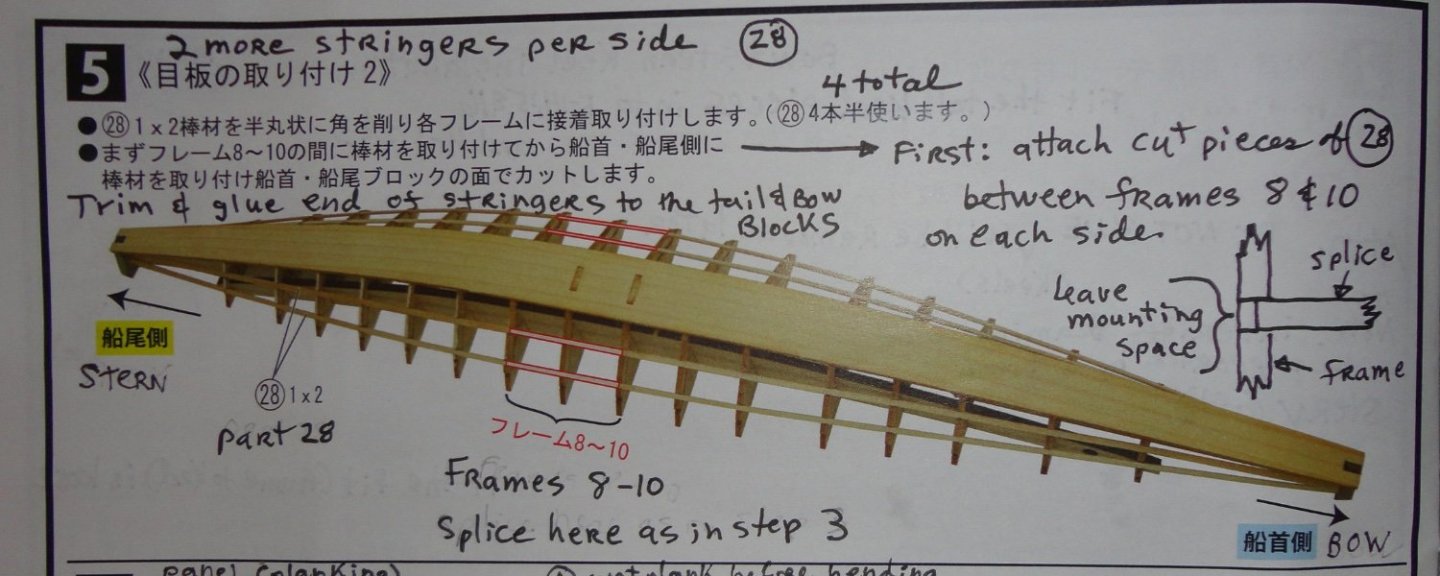

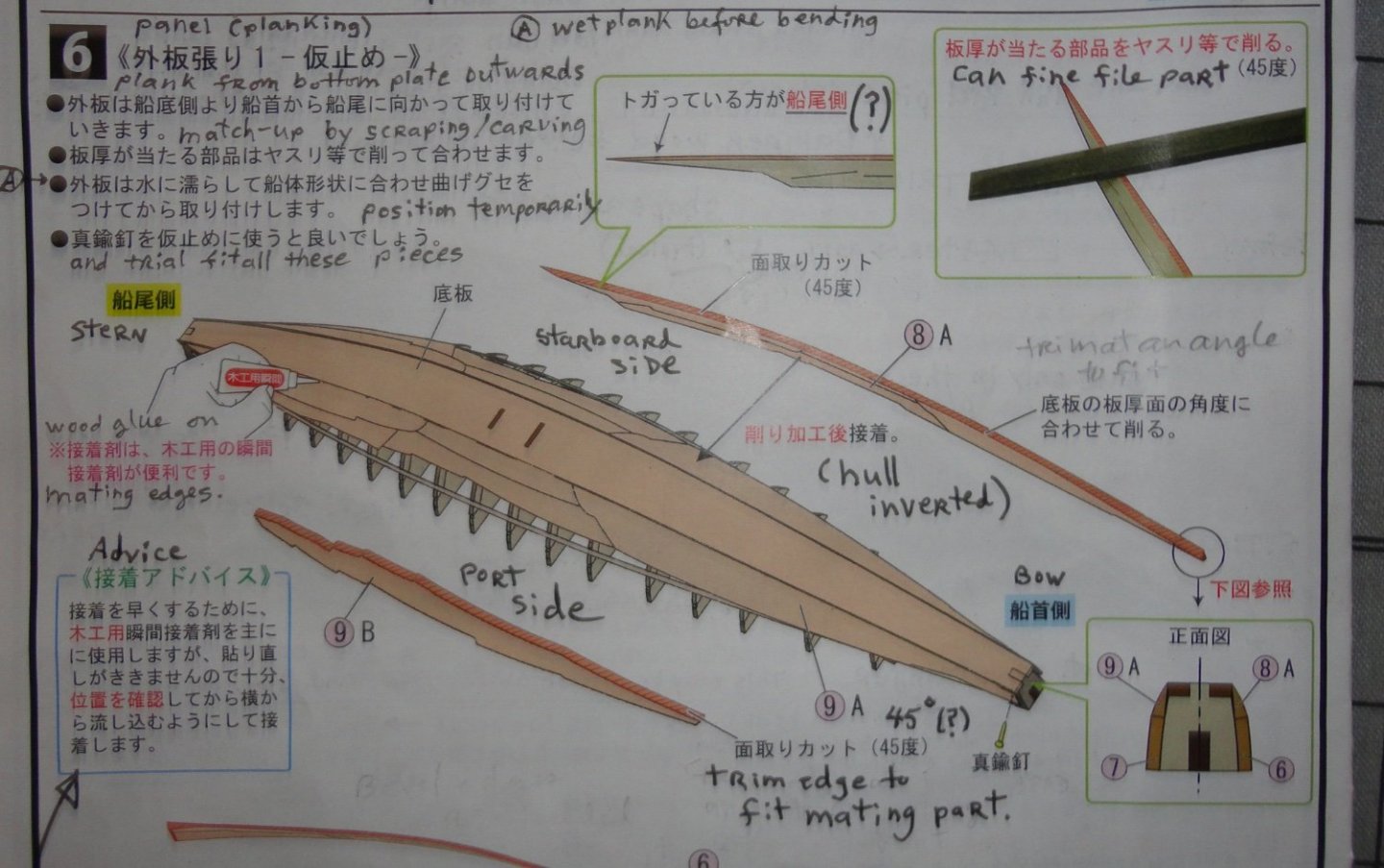

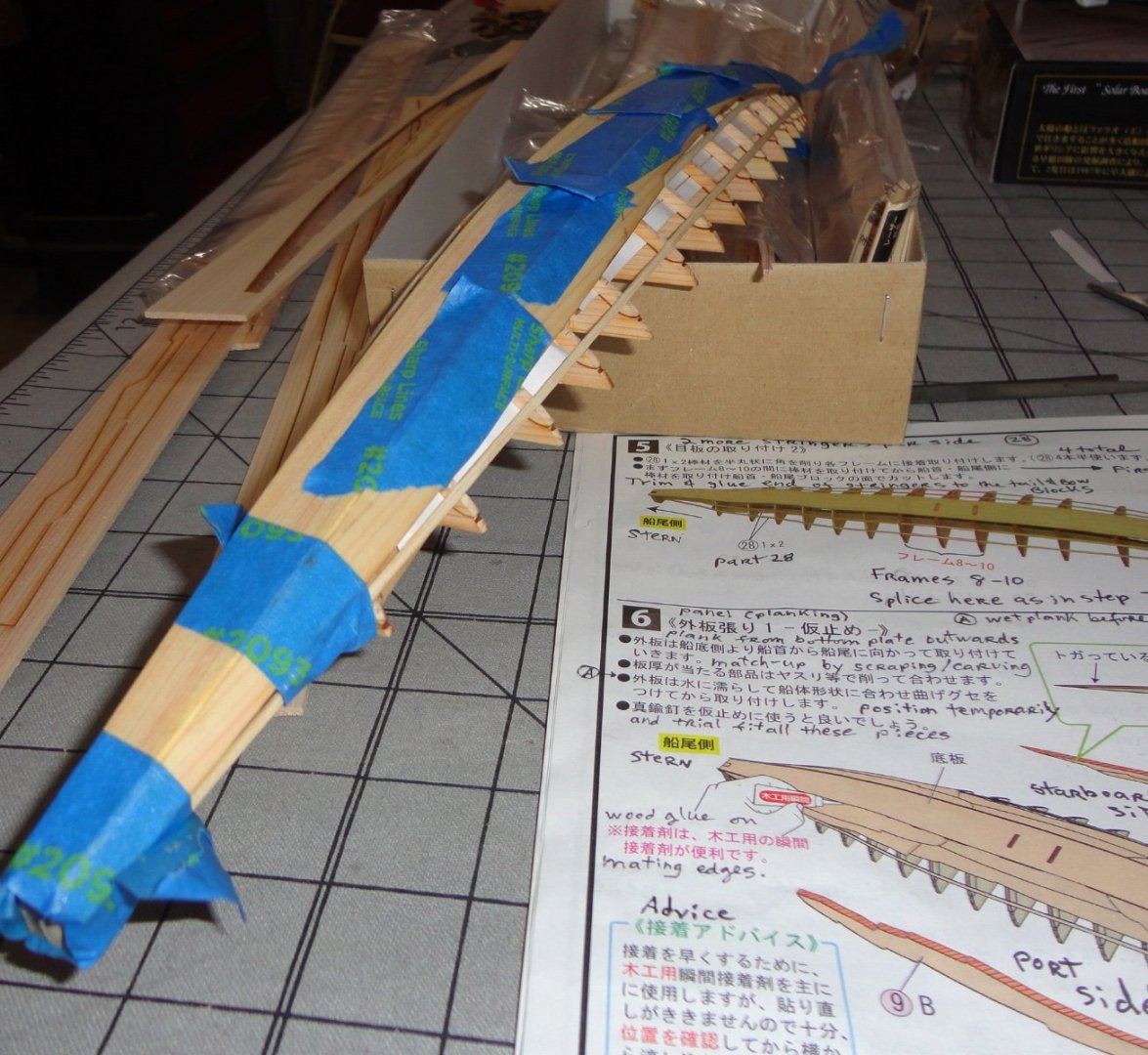

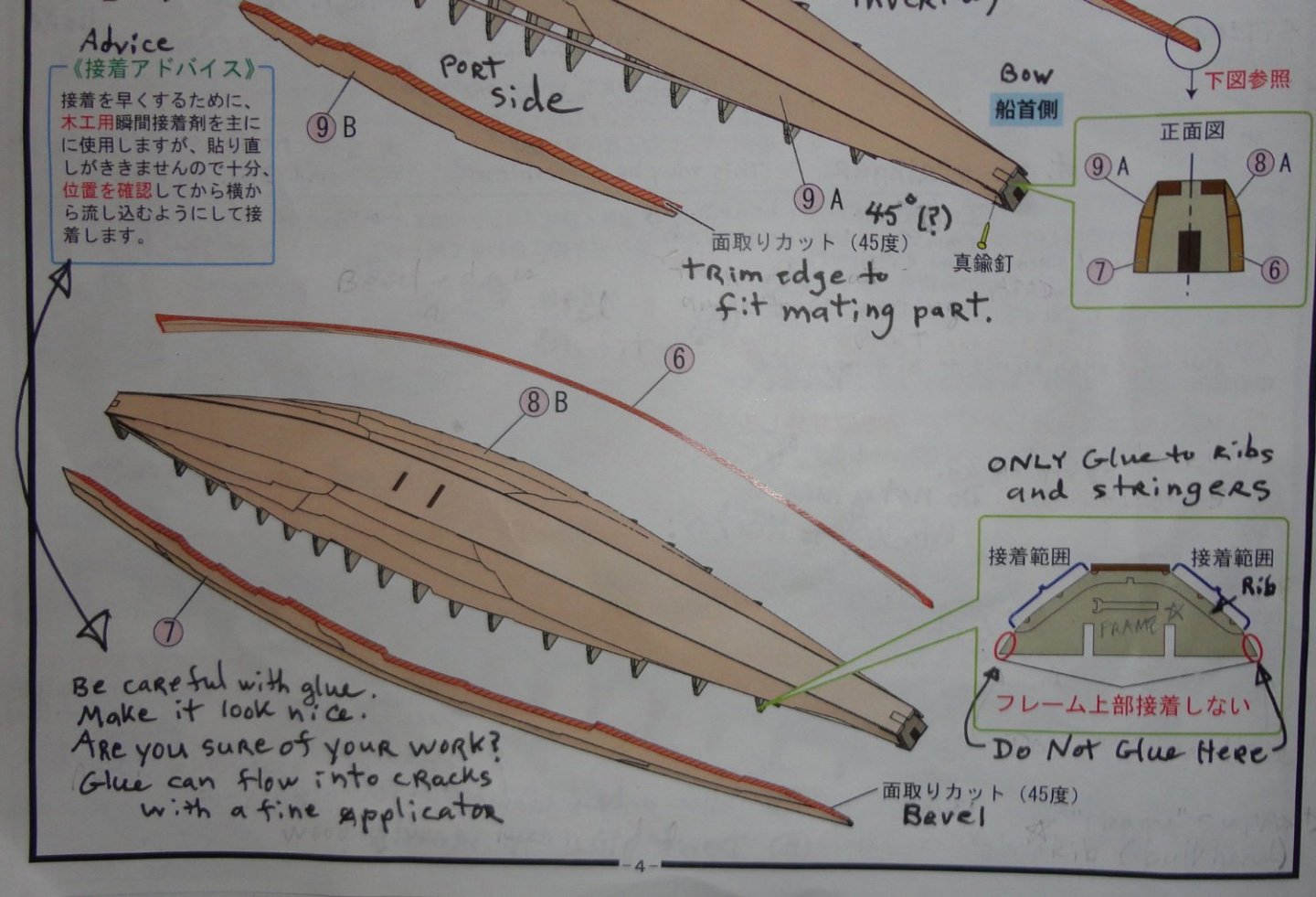

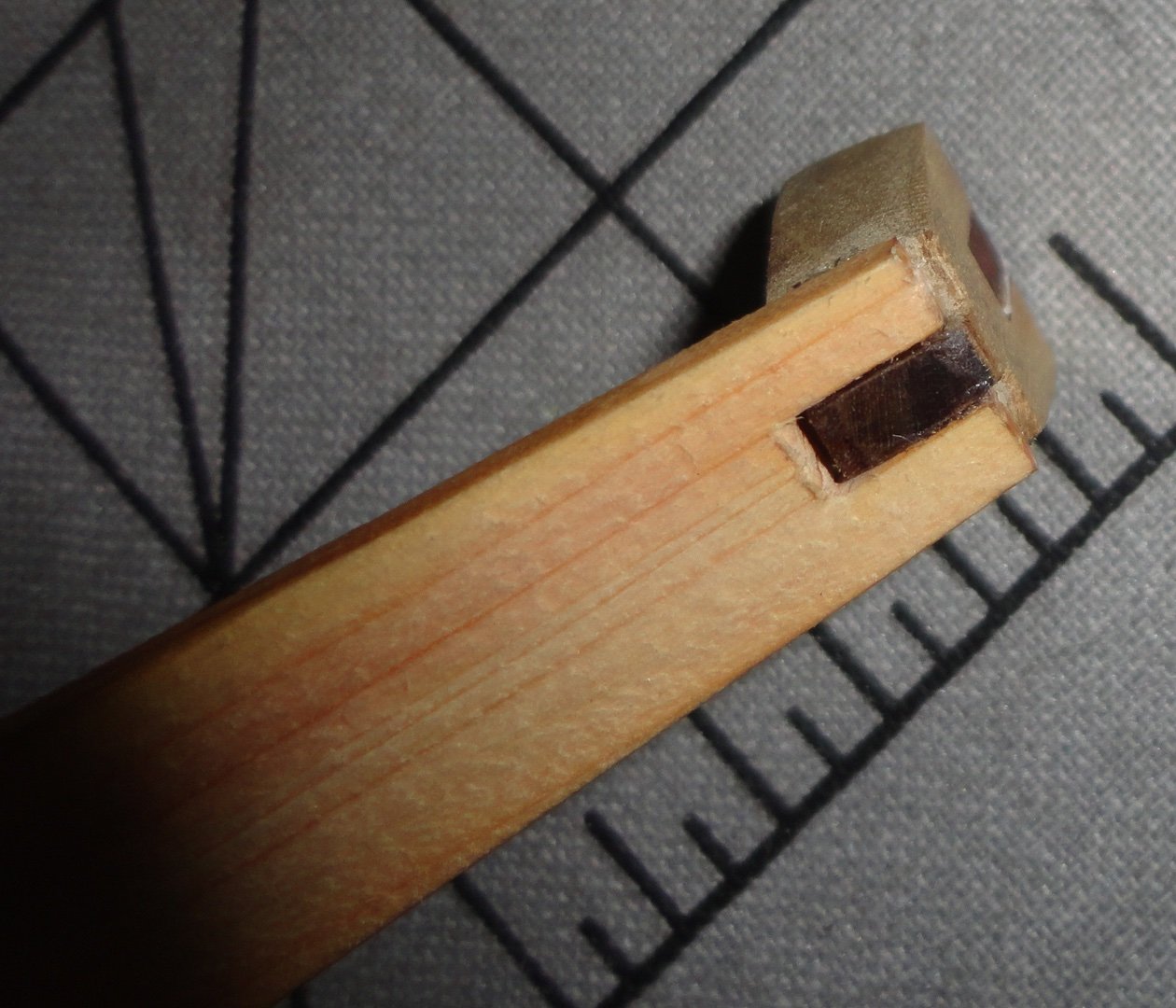

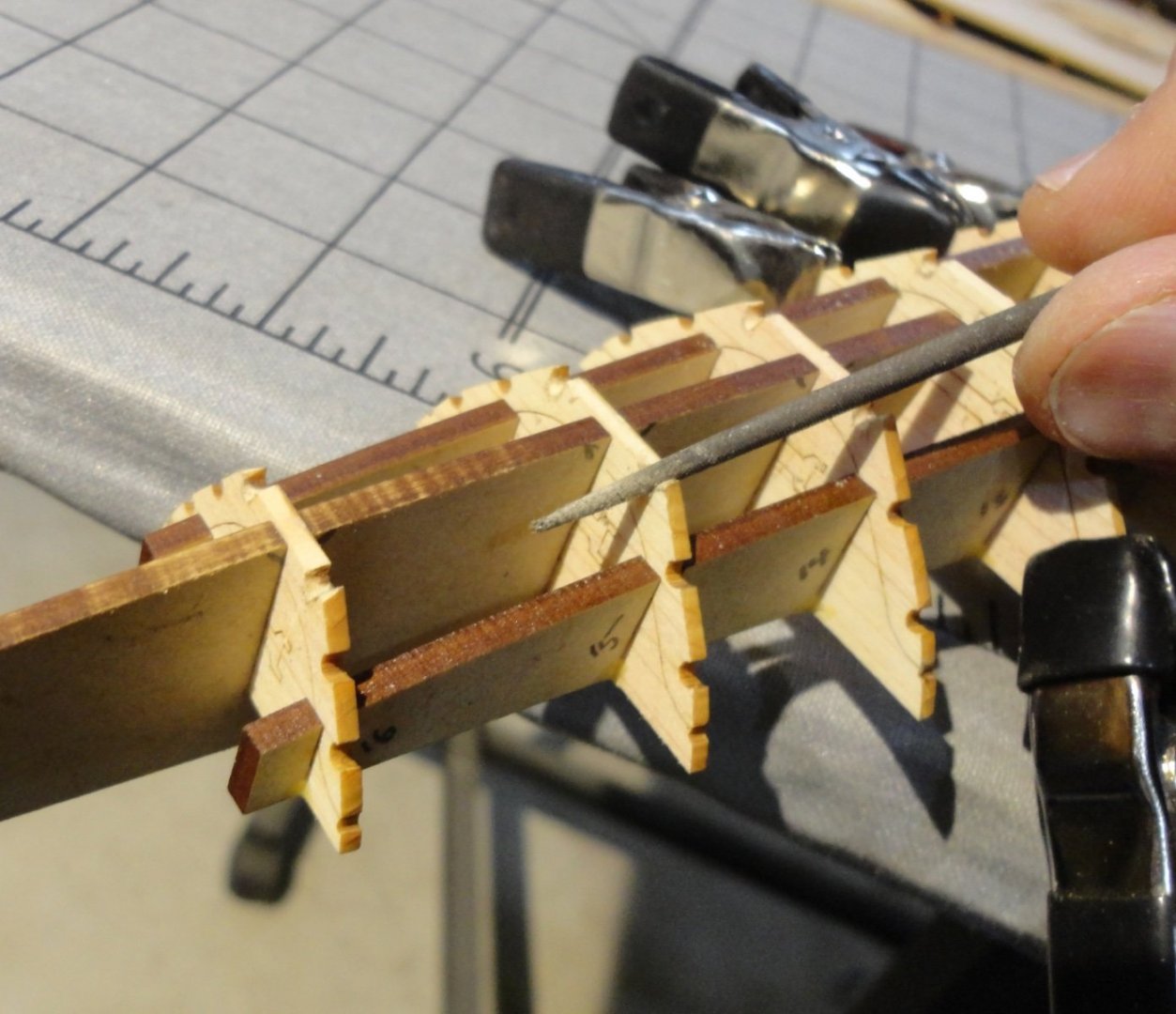

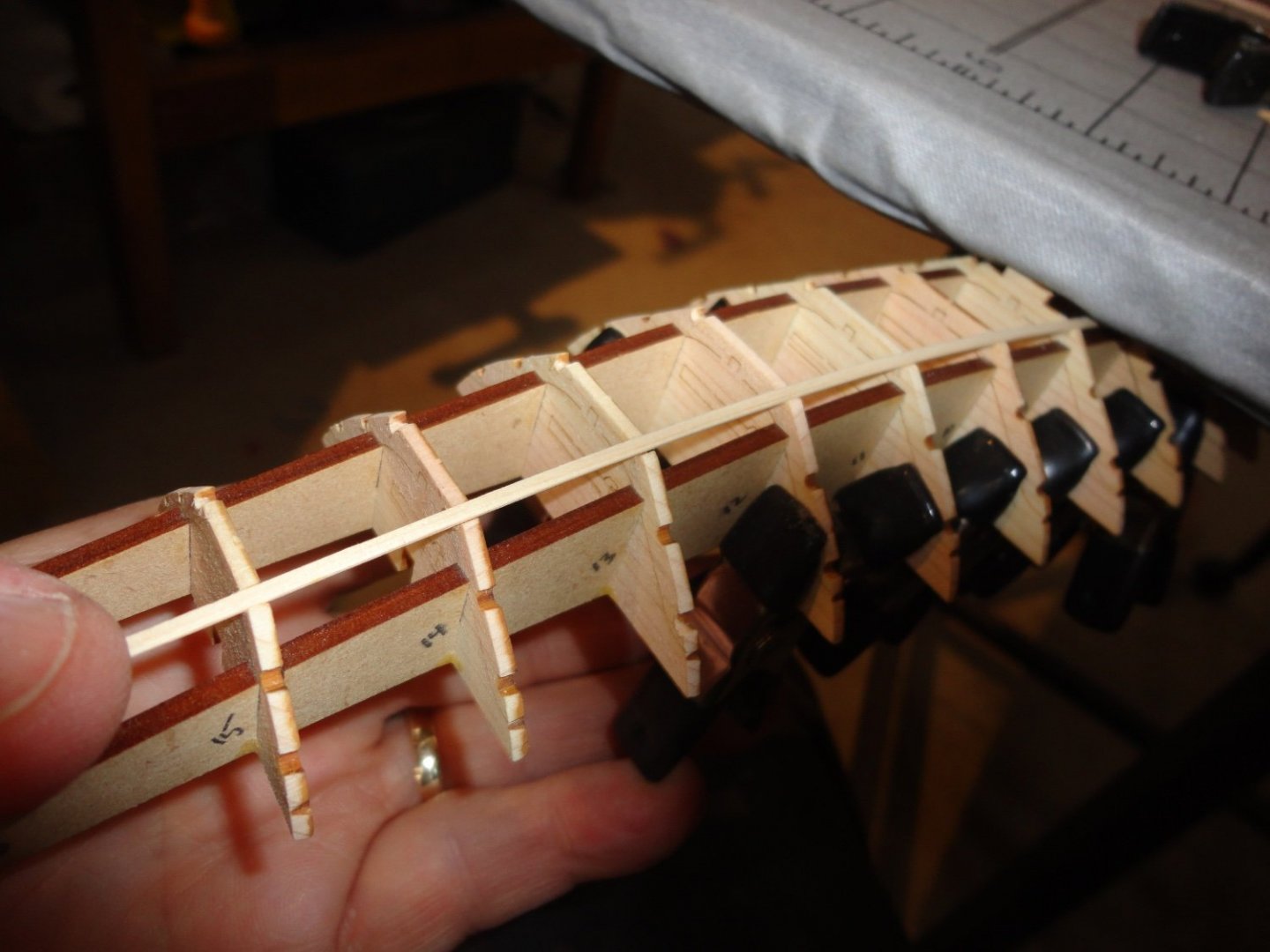

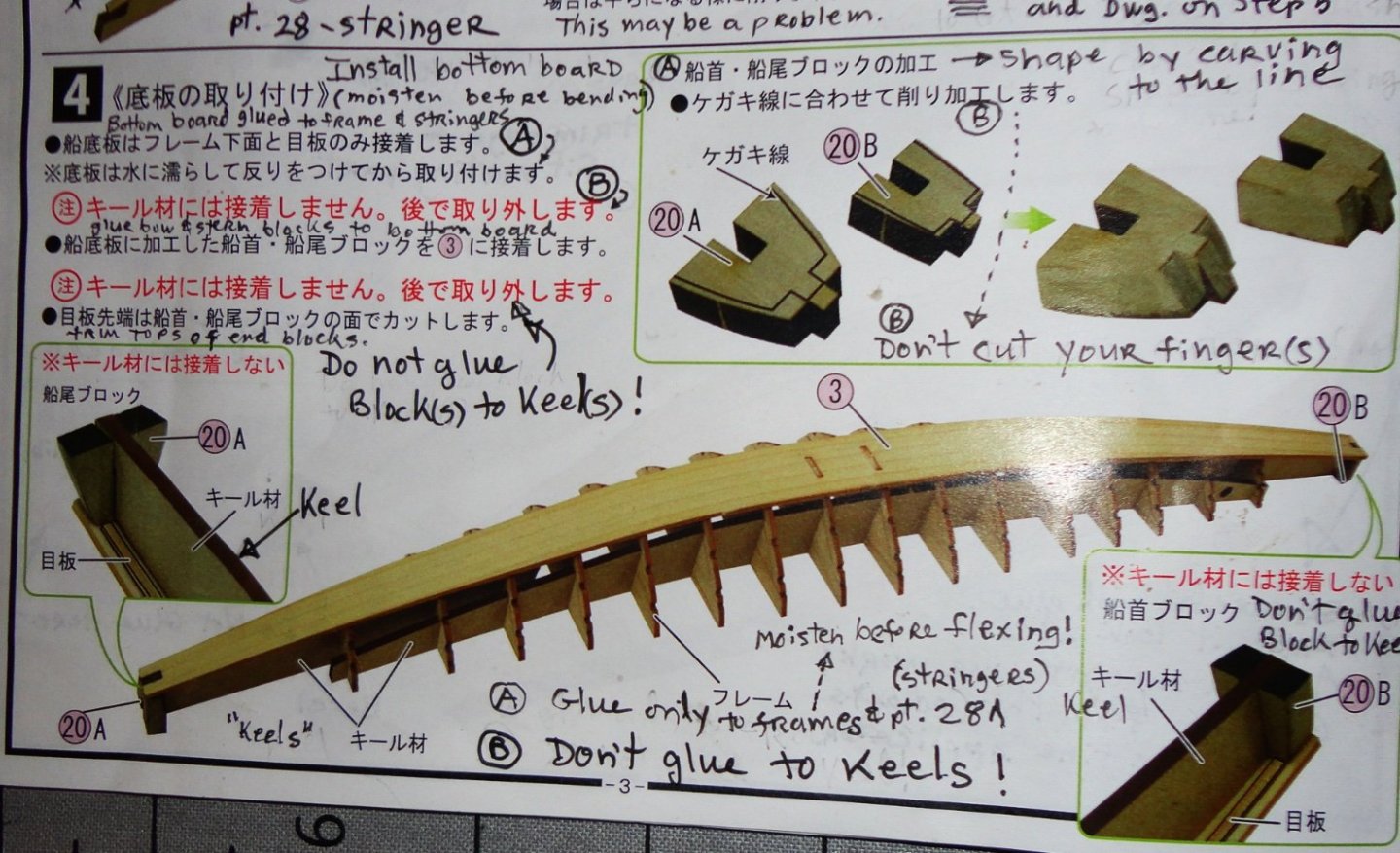

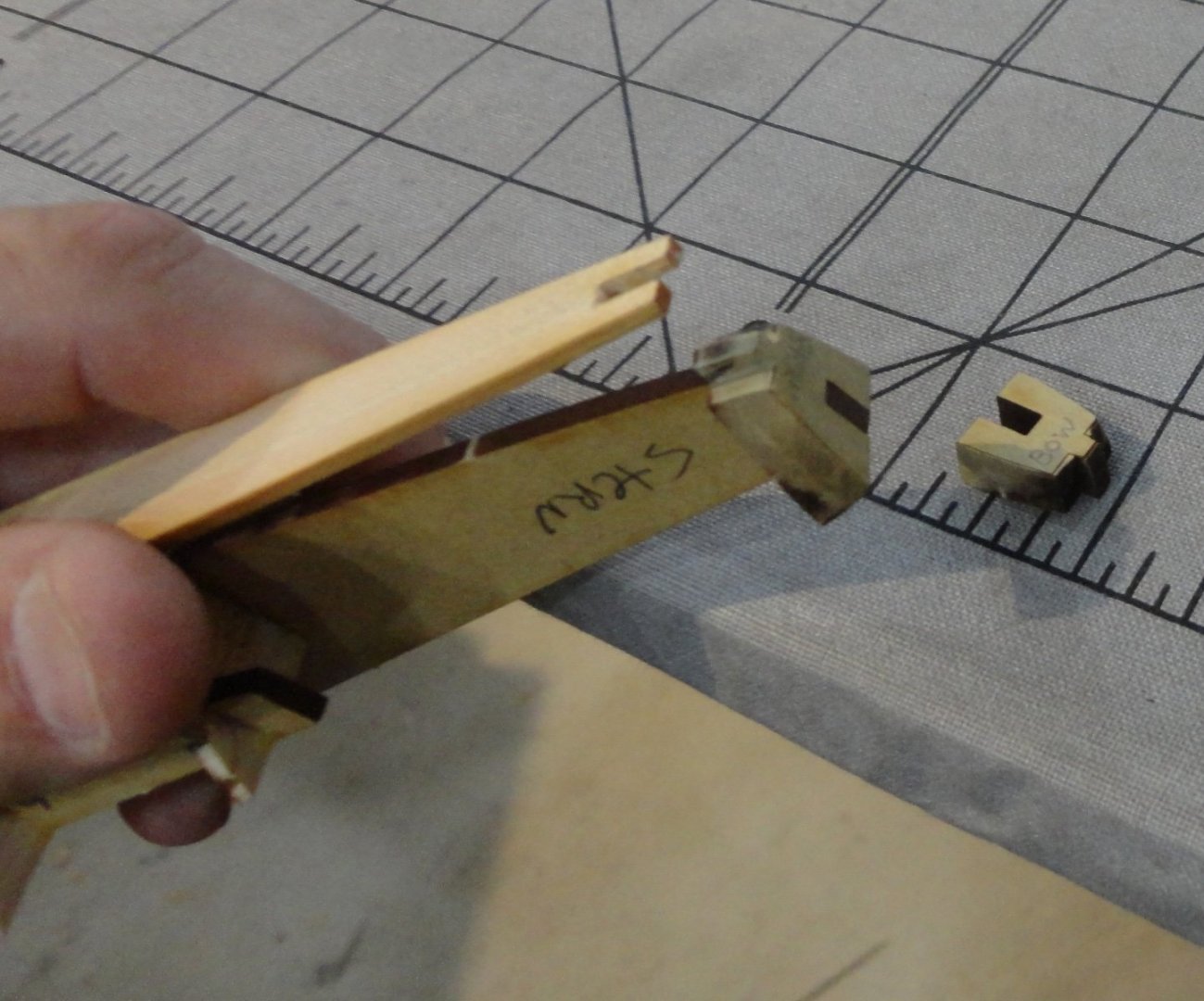

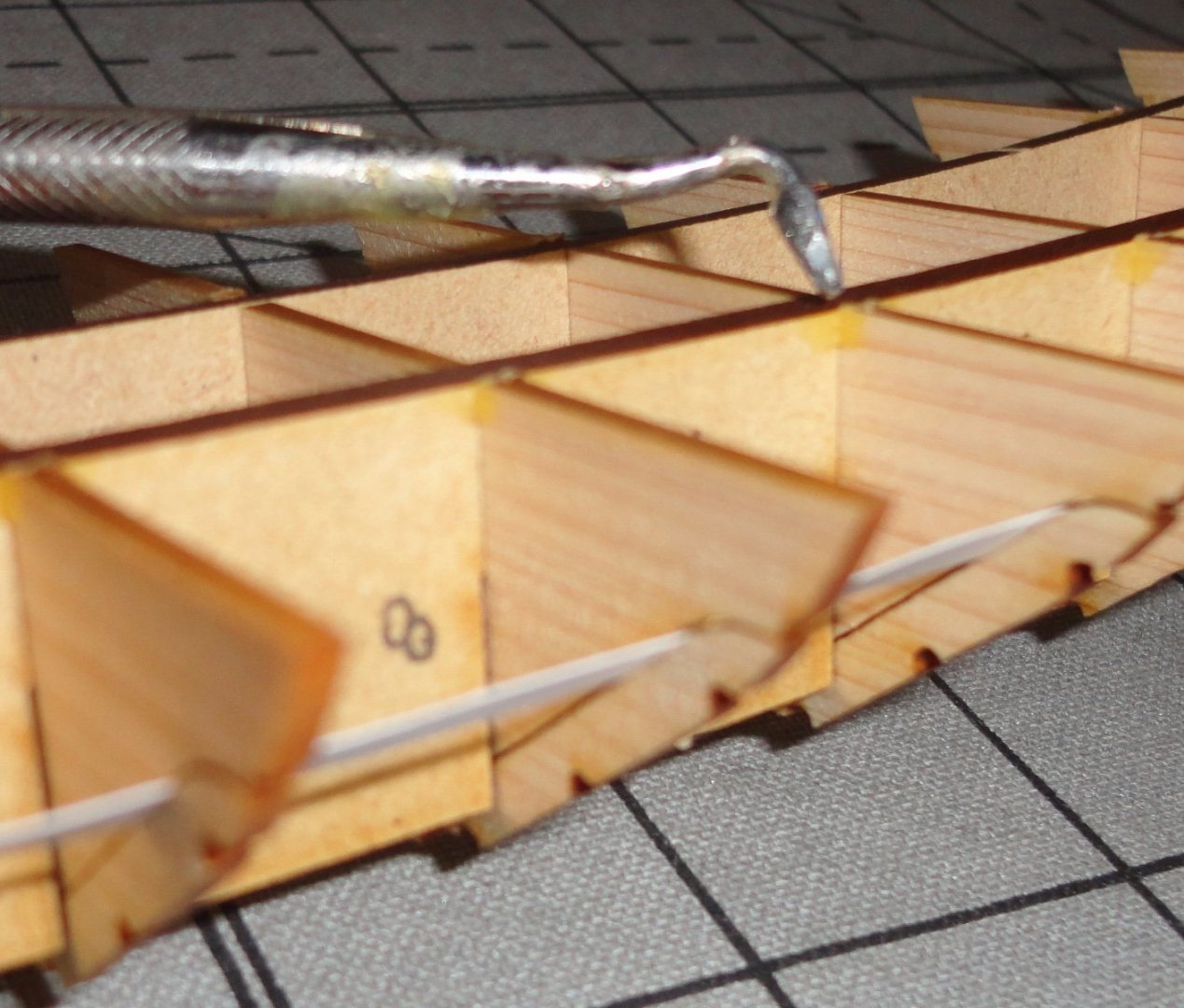

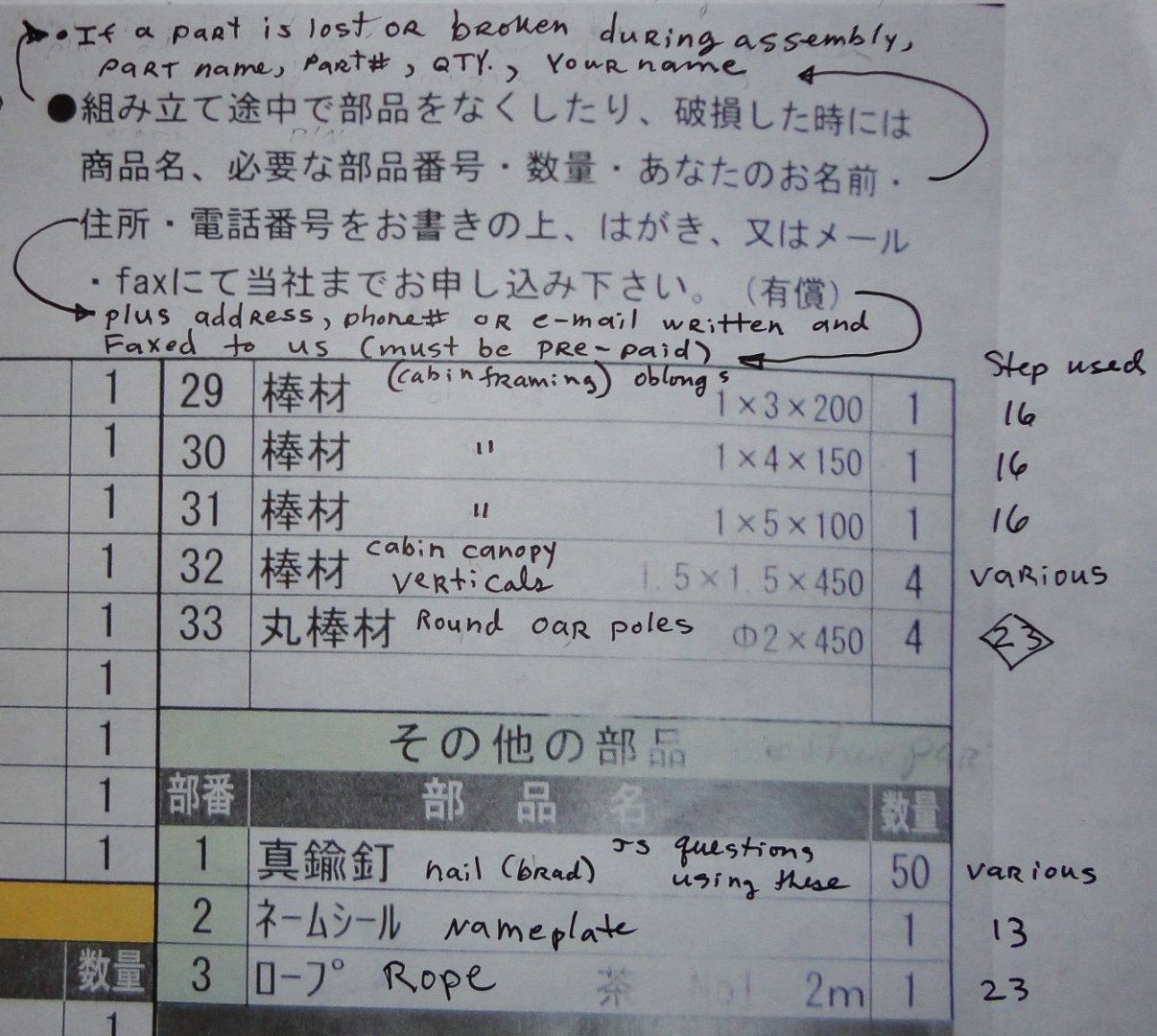

'Been a couple days since my last post, but I've had progress in between many other chores. FIRST, the isopropanol titebond softener WORKED like a charm! I used 90% iso (as opposed to the more common 70% found all over). It didn't take long to work and I was able to get the mis-glued end block off, clean off softened glue residue, let dry then re-glue (after a little filing and trimming) where it should be. I also used a 'dremel' (actually a foot control flex shaft Chicago Tool found at Harbor Freight) to cut two places for the side stringers to go ... seemed a good idea that actually worked out. Below is a picture of the first side stringer in place, and I used a few pins (with care) to retain. 'Reminds me of building balsa model planes as a kid. Note also that I put strips of filing card stock between the ribs and the frames to fill the void where the ribs were laser cut. A closer look at the rib gaps filled by paper strips. Below is a pic of the second stringer installed (with pins) ... and great care was taken not to push the pin in any more than needed due to the danger of cracking the ribs. I had to fair the stringers with the handy hacksaw blade equipped with sandpaper. Then everything was ready to consider installing what amounts to the garboard planks. I cut the aforementioned side rails to consider widening the bottom plank ... but then discovered some real disadvantages to that. A.) The side planks in the kit are designed to be mitered to the bottom plank. So if they are to be installed on TOP of a widened bottom plank, then the side planking would end up higher by the thickness of the bottom plank. I couldn't trim that off the garboard planks due to the configuration of laser cuts on that plank to conform to all the odd-shaped component of the original ship. Trimming the topmost plank later would also present problems. B.) The angle between the bottom plank and the garboard planks amidships are at a more acute angle than at bow and stern. This angle would have to be matched on the outboard edge of the garboard planks, so any over-cutting would result in gapping hard to fix. Building per kit layout is done by angling the garboard planks on the inboard side a little at a time, which CLOSES the gap between them and the bottom plank gradually. The original ship is profiled on the exterior, so I expect to use a scraper to round things up a bit. This can also expose some of the edge of the bottom plank as seen on the original - which should close and residual gap between the garboard planks and the bottom plank. The original had a flat bottom, and I expect that was to go into shallow water and be able to draw up to a bank on the Nile. Below is step 5 (now done), and again - I didn't just splice between frames 8 & 10, but used stock starting at one end (then the other on the next stringer) and splicing where convenient 3 frames from the other end in order to conserve stock. So I soaked the starboard garboard plank under a hot tap water, then discovered that our tea kettle had corroded in two spot in the bottom and leaked. Water was boiled in a frying pan and ladled over the plank until pliable. I even held the wet plank over the gas stove burner (by about 3 inches) and moved the piece back and forth until it was very pliable. Using both hands, I formed the piece ... a compound curve that has to twist near the ends. I held it up the the frame to judge the bending, then started to trim from the bow end as shown on the instructions for step 6. This turned out to be a sub-optimal way, as I was working down from one end trying make an acute cut at the very bow (per the picture in the instructions. Top half of step 6 instructions. They must presume a certain level of experience, confidence and creativity on the part of the modeler. Easier said than done. I had to trim some to get close to where I thought I should be, then trial fit. I was afraid of cutting too much with the X-acto, so resorted to the sandpaper covered hacksaw blade. I also had to let the wood dry out some - but not totally so I could still bend it. I worked on it for over an hour - trimming/sanding, fitting, bending, re-sanding ... then fudging some. I even resorted to bending the bow end some with my teeth - and also accomplishing some of the 'twist' near both ends with my mouth and teeth. It was a real bugger to do, and the most difficult plank I've ever had to fit ... so this plank is not at 'beginner' level. The 'pointy' end at the stern presented its own problems. I now realize that I should have started beveling the plank amidships, then worked out toward the ends. This I will do on the port garboard plank. I marked the extent of the areas that needed glue applied on the ribs, stringers and bottom plank. Then the garboard plank was located, taped amidships and then out to both ends. I let the glue dry a couple hours, then removed the tape to see some gapping. Wood glue was put into the gaps, then the excess wiped away. I applied saliva by licking the seam (I would do anything for love ... but I WON'T do that) and spitting out any residual glue. Since the angle at the edge of the garboard plank comes to a point (supposedly to make a mitre with the bottom plank), I used the smooth round handle of a round file to 'burnish' the softened edge of the garboard over towards the bottom plank. This drove out some of the glue, which was wiped up, then more burnishing. As the glue started to 'grab' the gap remained closed. Near the bow and stern, the plank ended up slightly shifted vertically from the bottom edge of under plank, but this will be modeled/scraped later as needed. As I said, this entire process was a pain, but in the two photos below, one can see that the join ended up pretty good ... but then I've done planking before, as well as a lot of other wood working and crafting. How a beginner would fair with the garboard planks on Khufu's ship is another matter. There is a little gapping going towards the stern, but there is also enough material to scrape away later that the gap will disappear. Note also the laser cut on the garboard plank that represents the odd-shaped original planking. Once all the planking is done and shaped to my satisfaction, I plan to engrave a 'connection' on the surface of the plank where there had to be disconnects in the laser cutting to prevent those pieces from falling apart. Below is the bottom half of the step 6 instructions. I note the translation of the "advice" ... 'Make it look nice.' 'Are you sure of your work?' I also note that they show a brad used, which I did not do. I used tape, which did pretty well - but the very end of the garboard at the bow wasn't quite in contact (probably why the show a brad) - so I used a pinch clamp to hold it fast until the glue set well.

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

Dremel rotary tool?

Snug Harbor Johnny replied to Mark m's topic in Modeling tools and Workshop Equipment

My brother claimed the old-fashioned belt driven dental drill with foot control from my Dad's estate. (For basement stuff it was first come, first dibs.) The big advantages to it was the head having a 90 degree angle, and the decent torque at low speeds. The trick to get used to is manipulating the mechanical 'arms' connected to the drive head. I have the low priced flex shaft unit sold by Harbor Freight, and it has been useful. I like the foot control and the torque is pretty good at low speeds. -

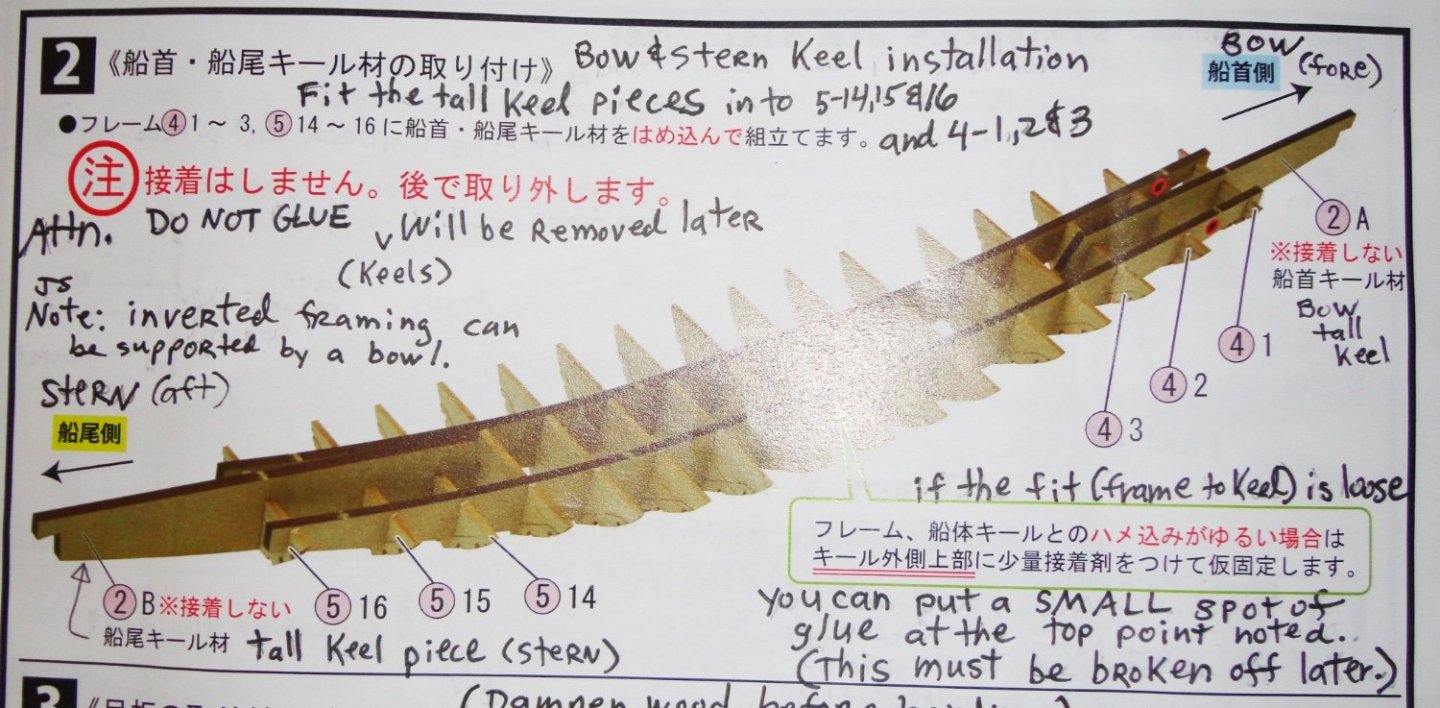

'Great idea, Ron ... Now that you've mentioned it, the iso glue softener tip appears now and then in posts - but I'd forgotten all about it. Aha, this is advantage of wood glue over epoxy or CA. I'm taking time to fair the other stringer attachment points by laying the end of the round file (actually, an oval file would be better) OVER the rib with a stringer in place to see if there is a gap. Then a couple more file strokes are made before the next test. When the fit is right and there is no gapping, I can mark a small pencil 'x' at that point. Where I put pencil marks on the build is at points that will not show. Another idea that came to me was to use a file to make cut-outs for the stringers (two per side) on the sides of the end blocks. That seems better for pre-planking prep. Speaking of planking, I was looking ahead to how the first side plank goes in according to the instructions ... and I see a certain difficulty not consistent with a 'beginner' level kit. They show the bottom plank trimmed flush with the end block, and the first plank beginning with a HUGE angle pared on the inboard side. But that angle must then be reduced gradually to about a 45 degree angle - but that requires that the bottom plank go from being flush with the end block to having about a 45 degree angle. Both planks have to have a 'spiral' bevel that matches well - a hard feat to do. Yet this is NOT the condition of the planks on the original. Museum photos show the bottom plank with an exposed side thickness down the entire length ! These were thick boards (what, something like 4" ?) with internal tenons, and the first planks were fitted to the top inside edge of the bottom planking from bow to stern. The kit would have been better designed with a WIDER bottom board that one could just fit the edge of the first plank to the bottom board - angling the edge of the first plank only. Once done, any overhang could be trimmed off the outer edge of the bottom board. This would have made more sense AND be closer to the original. What to do? I could glue a strip of material to the edge of the bottom plank to widen the entire plank, then install the first side plank as above. A straight strip will have to bend in two axis ... but since I have the board used to laser cut the bottom plank, a french curve can guide a knife to cut around the original perimeter where the bottom plank came out of it's mother board. That will have the exact curve along the width of the bottom board, so it will only need bending in one direction fore and aft. The wood provided seems quite pliant in thin strips, so I'm going to try this approach ... a minor 'kit bust', and something future builders may do to lessen the headache of doing it according to the kit instruction, such as they are. As noted in my review of the unbuilt kit (reviews section of the forum), I used Google Translate and held a cellphone over the Japanese text to see what the app would display on the camera screen. The 'translation' kept changing, and some really odd things would come up in succession ('wish I'd written some of them down), but some of the translation was consistent. Something that made sense as 'Do not glue. Will be removed later.' might morph into, 'No I won't do it. Come to my house later.' or 'She can't assimilate. Only take her later.' Go figure.

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

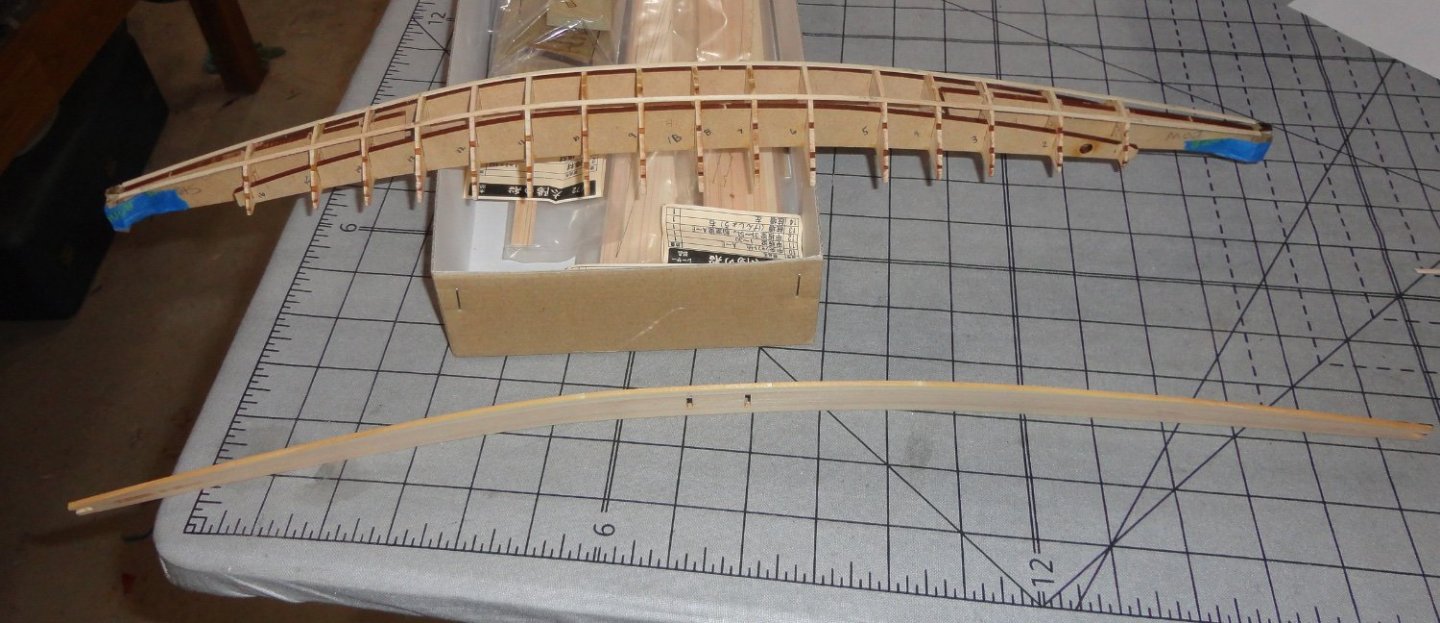

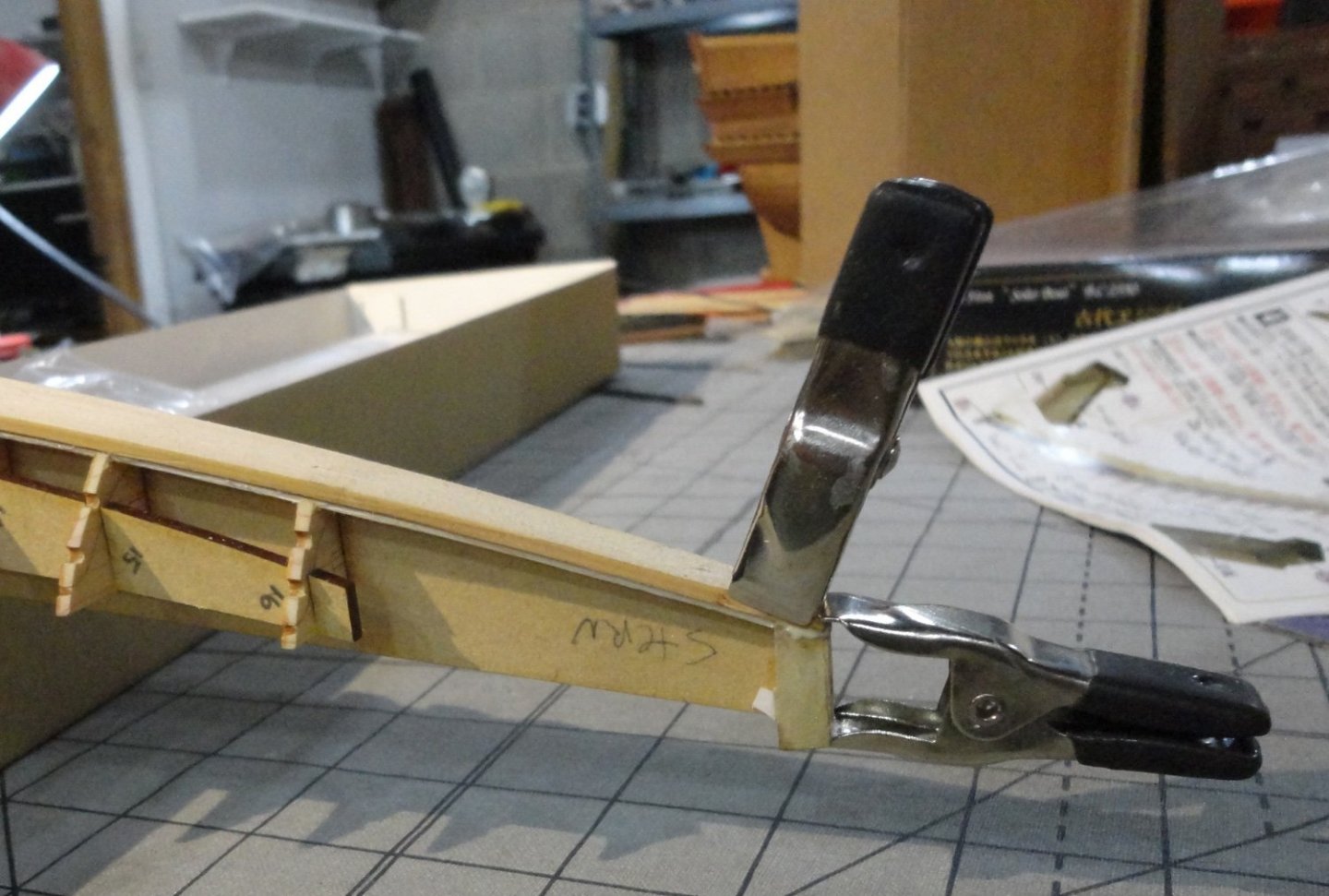

So I've progressed a little further on the Kufu ship ... I forgot to put the scale in the title, which the kit claims is 1:72. The original Royal Yacht was 145 feet in length, so the model should be marginally over 2' long (haven't bothered to measure the full size drawing yet). BTW, the drawing came in TWO pieces, which I'll have to join with tape to make a single page ... a minor inconvenience. I decided to pre-bend the bottom plank but running some hot tap water over both sides, then moving the parts of the plank I wanted to bend over a steaming tea kettle. Sorry, but since I had to use both hands to do this I couldn't take a picture. I try not to annoy the Admiral with my hobbies, and since I did this at about 11PM so the piece could dry by morning - I did not want to disturb her slumber ... duh. Anyway, the kettle did the trick and I found the heated plank easy to flex (with care) and it 'took' a pretty good approximate bend. Then I used the frame assembly as a 'caul', and secured the moist plank to the frame with strips of blue painter's tape (folding the ends over on themselves before using so it would be easier to un-tape later). This blue tape has enough 'grab' top clamp pretty good, but the sticky side is not aggressive enough to pull fibers from the wood when un-taping. In the morning before running off for per-diem work, I un-taped the plank and there was only a little spring-back. In theory, a bending caul with a slightly greater curve than needed will produce a dried piece that will spring back to about the right shape - but this would have been too much trouble and the bent plank coming off the frame was plenty close enough. I'd recommend pre-bending BEFORE doing the trial fitting shown in the previous post, since this will stress the part less and prevent that 'white finger' effect when one has to squeeze hard on something. There are other ways of bending planks (like a hot mandrel, or a heated piece rubbed against a curved mandrel) - whatever is preferred. Then I glued on the first two stringers - noting that the kit instructions to only put in a splice between frames 8 & 10 is superfluous. It seemed wasteful of stock, and I have no idea how far that stock will have to go in other places in the build - nor do I know (at this point) whether the mfg. is 'stingy' with provided stock (as some are reported to be) and only giving barely enough to accomplish the build (which presumes that one does not make mistakes or break a couple pieces). So the part #28 (1 x2 mm cedar) that was scraped to an approximate 'oval' on one side only (I marked with pencil '28' on the flat side so not to get it wrong later) was glued (starting at the stern block) most of the way along the ribs, and only stopped three ribs short of the bow - where I cut it carefully to take up half of the cut-out in the rib. Then I measured and glued a piece to finish going out to the bow block. I used 'thickened' titebond applied with a dab in each cutout (dental tool used for neatness). This stock did not require moistening, since it bent readily and offered little resistance to the gradual bend required. Surprisingly, it stuck right to the congealing glue and did not require clamping ... sweet. But look closely in the photo below. Some of the cut outs were not filed perfectly, and the stringer 'stands proud' just a bit from the ribs. This will affect the gluing of the bottom plank as will be seen shortly. Better trial fitting of the stringers, a little better fairing after the stringers were glued and trial fitting the bottom plank AFTER gluing/fairing the stringers is advised. Everything is related on this build, and there are things I didn't 'think ahead' on. When the glue was cured, there was some additional faring of the stringers, but I did not want to thin them too much because they are thin enough to begin with. The attachment to each rib does help reinforce the stringers, but they are still delicate and subject to breakage if pushed. Below is a photo of the pre-bent bottom plank next to the frame assembly with ether first two stringers. Note that the end blocks are retained by blue tape at this stage. It is another 'catch-22' situation. If they are not in place when the bottom plank is glued, any mis-alignment (yaw) due to a slight looseness of the location tabs amidships will result in lateral displacement of the ends of the plank - a situation that will be hard to fix once the glue dries. The taped end blocks locate the plank properly fore-and-aft ... but there is a risk that they will 'shift' outward slightly (tape flexure), so if glued (as I ended up doing) to the bottom plank - corrective sanding would later have to be done. My solution (in hindsight) would be to use the blocks here as a guide but glue the plank to all the ribs and stringer EXCEPT the final fore and aft stringer pieces and the blocks. Once the glue is dry, everything can be untaped and the blocks (and ends of the stringers) can be adjusted/trimmed as needed THEN glued. BTW, note that I'm using the kit box to support the frame ... the quickest and easiest thing to do. Yeah, I know a few of the capitalized acronyms like; LOL, ROFL, BTW, FWIW, PITA, etc. ... but I asked several people what IDK meant - and nobody seemed to know. OK, so below is everything glued and taped-up to dry. So the bad news was that the blocks had shifted, but the good news was that the plank lifted slightly from the stern block (tape 'give' - a clamp would have held more firmly) so I could remove it, scrape and adjust for perfect fit and regale with clamps as seen below. I include another view of this, with my beloved Wasa in the background. Yeah, I will resume work on it over thew Winter, and even then, maybe having two project underway will permit work done on one while glue is curing on the other. A side benefit of this hobby is that I like to think about different ways I might do something, look for other ways used in other builds - then weight the advantages/disadvantages of the various approaches, all while doing something else like gardening, chores, or while pushing drugs as a per-diem pharmacy tech at our local hospital. There are many miles to go every shift with a cart full of medications, thus I'm a legal 'drug-pusher'. Other techs tend to use hand baskets, but I tell them that I use the cart even for light loads because it looks better than using a walker. The last photo in this post shows a close-up of the mis-match between the bottom plank and the bow block. That was the OTHER bad news that the bow block had shifted AND the glue bonded the parts. Here is where the stringers that 'stood above' the ribs (and not fully faired since I did not want to thin them excessively) came back to haunt me. They cause the bottom plank to bend over a slightly longer curve, and therefore did NOT fully engage the bow block. OK, I can correct this later once planking is complete by sanding the face of the bow block as needed. Hopefully, Forum members who'd like to build this kit can benefit from all the observations I'm making in this build log. Certainly, as a presumed 'beginner kit', actual beginners will benefit from the expansion of what translates from the kit instructions. Another story about a good news - bad news situation. It was on an old US navy whale boat friends of mine converted (back in the 70s) into an ersatz 'Viking ship' (more like a small Knarr). There were five oars to a side, and I was one of the rowers on a weekend excursion ... yes, we all were wearing our best attempts at Viking garb, with wooden shield hung on the gunwales and a variety of weapons available on board. The wind was not with us, so we were rowing hard. The leader manning the steer board (mounted, obviously, on the starboard side) said, "I have some good news and some bad news." I shouted, "What's the good news?" He answered, "A round of mead for all the crew!" (Cheers from all.) Then someone else yelled, "What's the bad news?" The answer? "the Captain want's to go water skiing !" ... a true story ... Johnny

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

The advantages to gluing sandpaper to a hacksaw blade are: a.) It is a longer tool than the fingernail file, and can be bent into whatever curve (unless extreme) is needed to fair over a longer distance. b.) the blade is much harder to 'kink' than a foam core fingernail file. Of course, the files can be handy in many circumstances and come relatively cheaply in packs. The other 'tip' in my build is the use of 'thickened' carpenter's glue (by leaving the top off the bottle for a few days - my absent mindedness produced something useful in this instance). It 'grabs' quicker and dries faster.

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

'Seems the thin plastic of the cathead whiskers and the martingale are easily subject to breakage. Maybe thats why they've been replaced by metal in other builds. Obviously, ship models are delicate by their nature and are easy to damage. But some parts are more easy to break than others. When done, a protective case makes sense - as dust accumulation is the long-term enemy of any model.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

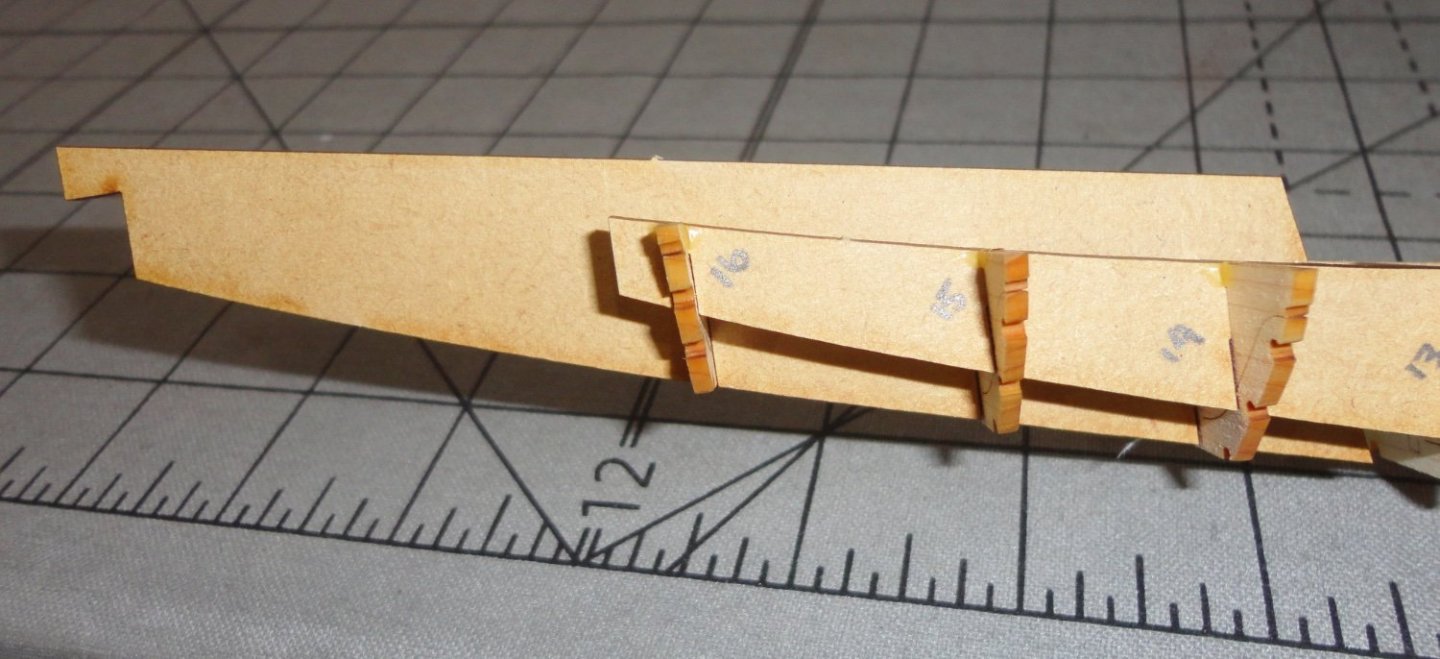

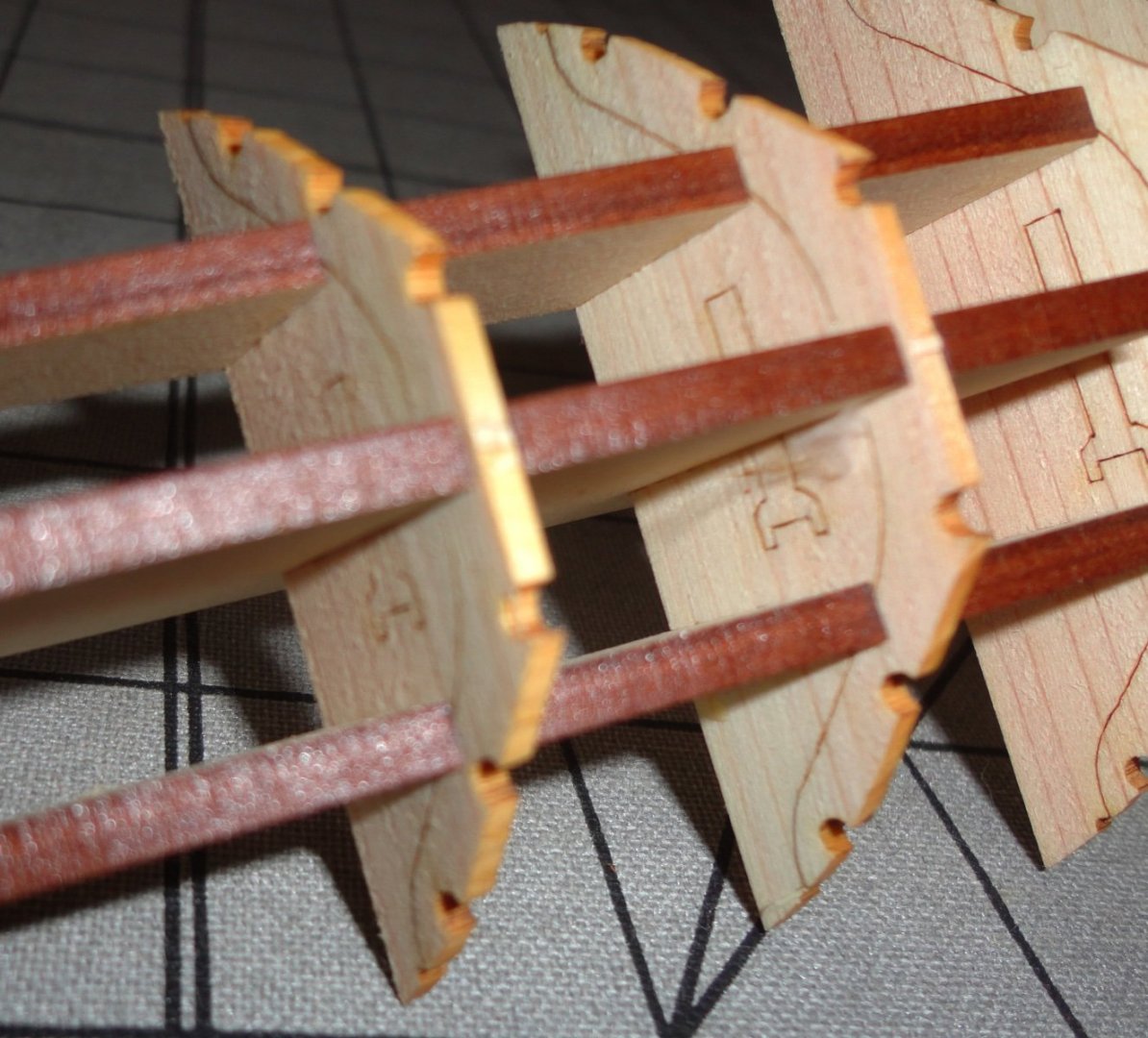

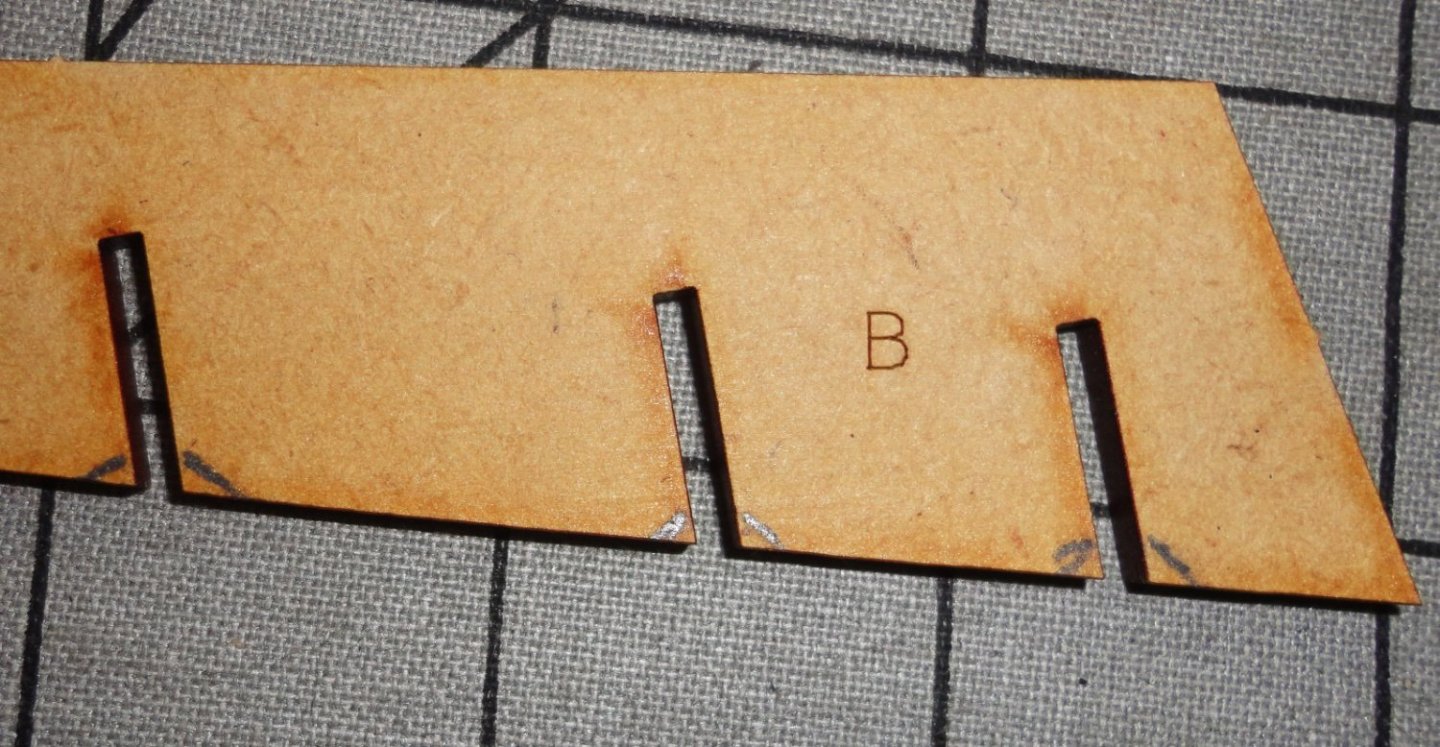

I mentioned that the ribs needed fairing, and thought how to proceed. Knife cutting is risky, as is Dremel sanding. A flat (wood) backer for sandpaper doesn't produce a curve (true for fairing any hull), so a flexible backer is desired. Then I thought to glue sandpaper onto a hacksaw blade. Out of a hacksaw, they are bendable to a fair degree and will 'hold' a curve - yet still have 'flex'. OK, one should grind the kerf off the cutting edge, but I was in a hurry to try the idea and figured the thickness of sandpaper on both sides of the blade would be thicker than the wavy teeth on the blade. I chose 100 grit 3M no-slip paper and spray construction adhesive that provides a good grip quickly and is fast setting. I traced the edge of the blade and cut strips of sand paper with scissors (a good way to dull them, so a utility knife over a cutting surface (cutting the back side of the sand paper) is better. Yeah, I know - do as I say, not as I do. The 100 grit paper turned out to be a little too aggressive - 120 grit would have been better, but too fine will take longer. Since there ribs are almost laser cut free of the frame (bulkhead), I almost broke one off - so the fix was to put temporary clamps to stabilize the ribs while working. You can see the nice curve the sandpapered hacksaw blade was bent to. And EASY pressure (very light) did the job for the bottom of the ribs. Of course, the semicircular cut outs for the stringers will need some fairing. Below, a tapered round file was used to work in the cut outs. Later, the clamps were repositioned and the sides of the ribs were faired (adjusting the bend of the hacksaw blade as needed). Note that the central 'keel' has been placed (no glue!) and it helps support the delicate ribs. The stock for the stringer (part #28) is listed as 1x2 (mm), and is very flexible dry ... no need to wet before bending on the gradual curves of the hull. Rounding it per the instructions made me think it would be hard to get it done evenly - and I considered looking for 3/32 round wood doweling to use instead, then trim down somewhat with a miniature plane before sanding flush. But I found that using a scraper (hook edge - and a piece of strip stock that was sheared had a natural burr that was suitable) and holding the stock worked well enough, as not much material had to be taken off ... just enough to test-fit. 2x2 stock may have been more suitable, but what is in the kit will serve - although delicate. I took a lot of time test-fitting formed stringer stock along the various routes it will take, adjusting the cut outs in the ribs a little at a time as needed. The whole affair could be slapped together without all this pre-fitting, but as mentioned before - doing these adjustments will build a beginner's skills without jumping into an HMS Victory right away. Shown is a step ahead of where I'm at - one that instructs the bow and stern end pieces (at this stage) to be shaped. I decided that it would be better to form them NOW, and test the fit with the bow and stern central keels - as well as check that their fairing works with a trial fit of bottom plank. Parts 20A and 20B are tricky rascals, as the exterior shaping is dynamically curved and not flat. 'Looked like carving was NOT the way to go ... too risky for both part and fingers, so I 'roughed' the perimeter against a fine grinding wheel (still having a sharp corner) taking care not to over grind or scorch the material. Then I used flat files to work them down and refine during trial fitting. 'Spent over an hour on each one! BTW while these parts are wood, the 'keels mentioned earlier as 'composite' are really a pressed paper product - perhaps something that might be for structural members in a large card stock model. No matter, they are used as temporary framing for the hull construction. A picture of the blocks getting ready to test fit. The hull is significantly curved, and the stern is more highly curved than the bow. When done, its all rather sexy - and there is a certain mystique about Egyptian artifacts. OK, I'm pressing things together (note the 'white thumb') then adjusting with a file between trials. Doing this right the first time will pay off with a better model as I go along. I'm considering making something to support the hull framing when upside down ... as opposed to putting it over a bowl as was suggested elsewhere. Also note: you really have to keep the bow and stern parts straight, as well as which surface of the bottom plank will be inboard. You can see some of my pencil markings here and there. The bottom plank will come up on a curve on both ends, so the slot where the end blocks will be glued at the ends of the bottom plank has to get a relief angle filed into it since the end blocks are vertical. As mentioned, there are all different angles to deal with. The block need to have a good fit (just snug but not tight) to the central keel of either end. The good fit is to assist in the assembly of the bottom plank ... but the keels have to be able to slide away later after all the planking is done. So I glued paper shims as needed (very little glue needed, and tension clamping between stock until the glue dries will keep the paper from wrinkling or expanding) to where the blocks fit the keels and made sure to test fit until the 'feel' was right. The picture below show the blocks on the keels and also the 'relief' cutout (nicks) along the keel bottoms to prevent any glue from bonding the removable keels to the hull planking. This configuration could have been programmed in the laser cutting, but that is a detail that got past the designers. So it seems also that even WITH a translation of the Japanese instructions, the information is relatively sparse - and may presume a certain amount of modeling sense and skill on the part of the builder. It is definitely NOT a 'snap together' project.

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

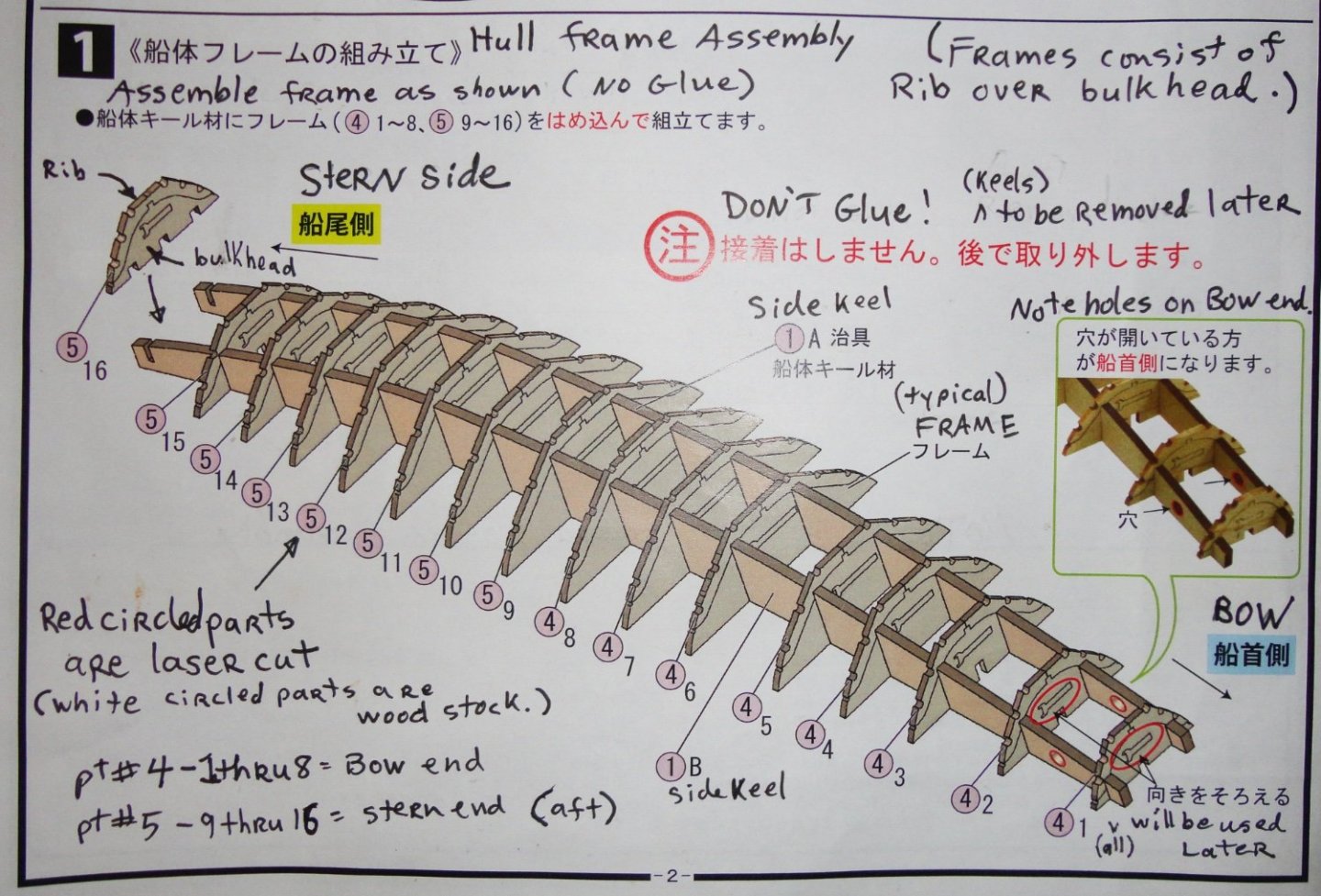

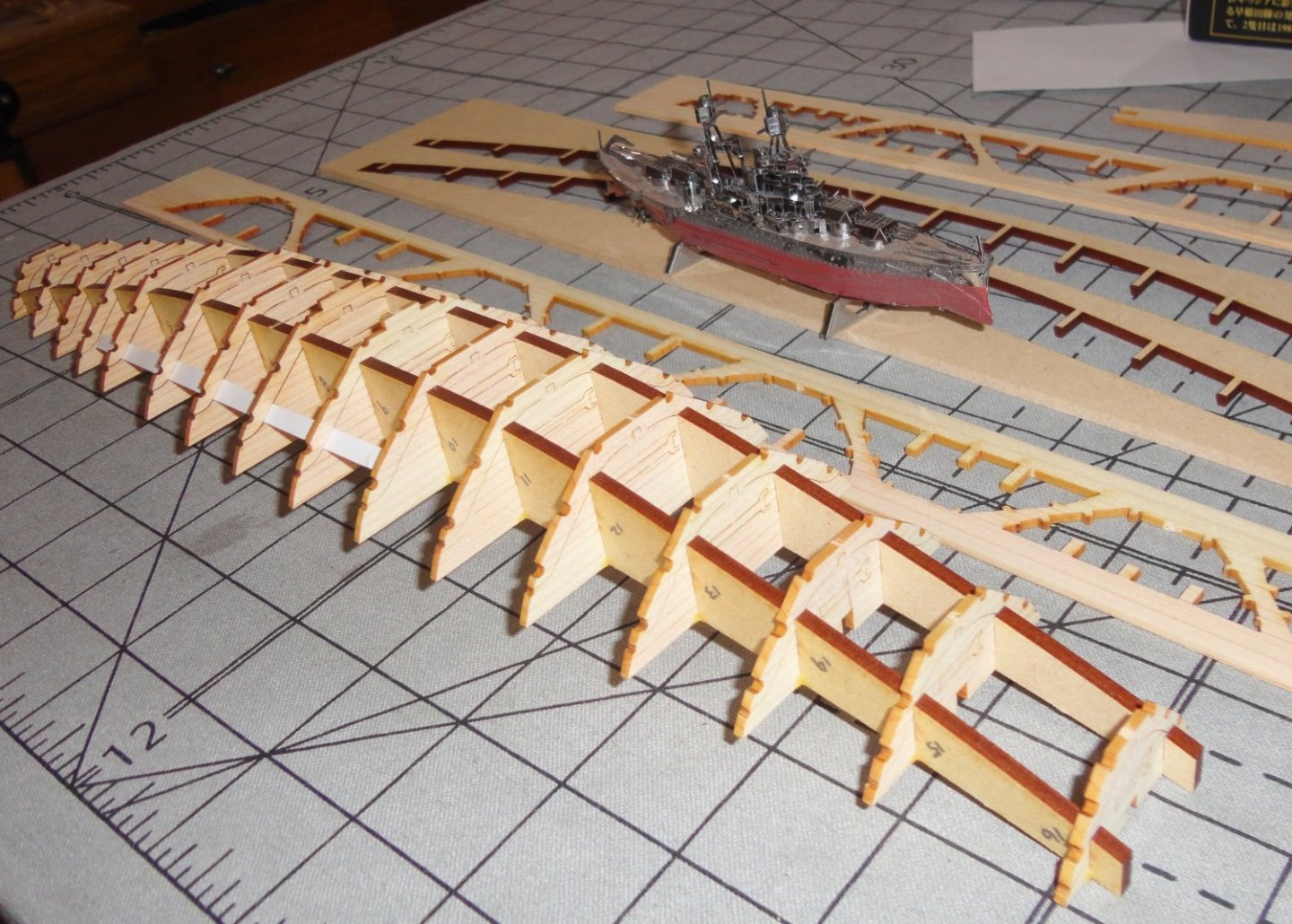

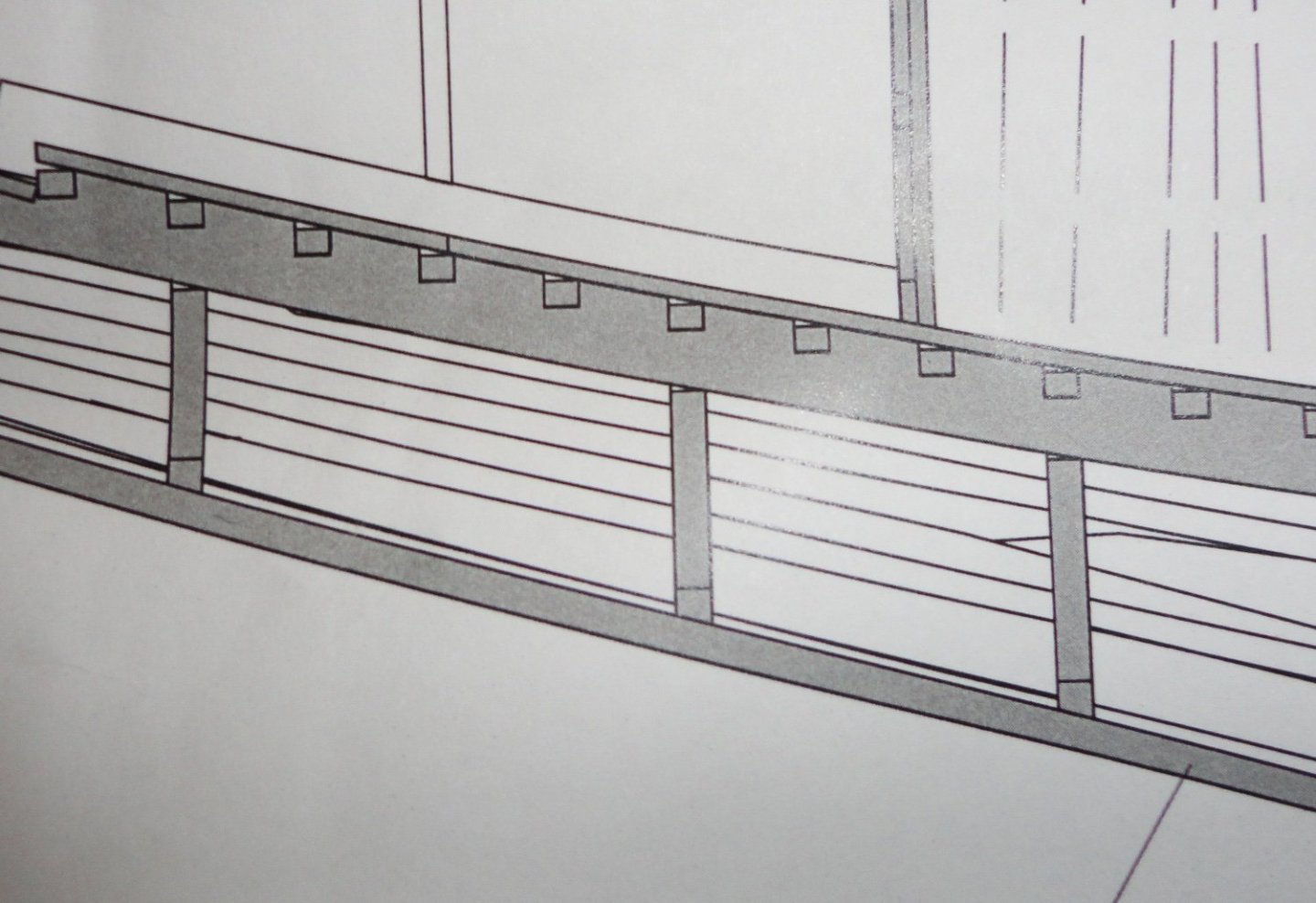

Ahoy mates ! Well, I've started this 'palate cleanser' kit based on some nudging from fellow modelers. I do not rush anything, yet the absence of masting, sails and rigging make this interesting kit one that can be done in far less time that many others. I reviewed the Woody Joe kit (unbuilt) in the Review section, and suggest that the log there be seen - since I don't want to repeat information contained there (with a few exceptions). I knew I'd be 'into' this model, since I like 'early stuff' - and will get around eventually to build the Billings Roar Ege (as a further prelude to doing the Billings Oseberg - and I want to do the best job on that one). I can't say enough about the quality of the laser cut parts on cedar stock in the Woody Joe kit. There are just a few breaks as 'attachment points', and an X-Acto knife breaks these easily. The parts then come out easily, cut to precise shapes with very little 'burning' on the edges. The frame (bulkhead) in the image below (detail from a pic in the review) shows how the rib (the only part to be left behind once the hull is planked) is almost completely free of the matrix to allow for ease of removal of the rest of the frame later. The width of the laser cut is about .006" - the thickness of a filing card (more on that soon). Care must be taken when handling these parts so they won't break. Now to step one, with my 'translations' written in. This step is meant for assembly with no glue, but there will be an exception. Once fitted, the framework is pretty good with little flexing, but the frames can be dislodged from full engagement - so the 'exception' to gluing (which even the kit instructions later mention) solves any slippage problem and renders the assemble pretty solid when dry (titebond glue). First, lets see the initial assembly. As you can see, I've inserted a strip of filing card stock in the tiny gap left by laser cutting the ribs from the frame. I will be putting a lit more of these spacers in before planking to prevent inward movement in these areas. The kit instructions expand on the clear pictures, but do not address the gap issue (easily solved). Oh yes, the little metal model (6" for and aft) of the USS Arizona was another 'palate cleanser' I did a build log on. It was a tricky thing to make, and I wanted to show that I DID complete a build earlier (last year) on the forum (check it out for yourself) as I was stuck on the problems with 'fixing' the old 1:100 Billings Wasa - now on hold but substantial progress was made last Winter. A closer look at the framing. Really, the design and execution of this nifty kit is ingenious - I love it already ! Now we come to the issue of fairing. Looking at a small portion of the full-size drawing of the model (needed for the build, as one must get a number of dimensions off it), you can see that the bottom board (the original has flat bottom planking) is faired to the ribs. No doubt about it. But to make the temporary building framework removable after planking to the ribs and 'stringers', the frames have to go in vertically. The laser cutting is in x and y dimensions, so the bottoms go in 'stair step ' fashion. This is typical of many model kit boat hulls and requires fairing (discussed in detail in other builds and as a separate issue elsewhere in the forum). BTW, I use the term 'stringers' from my old stick-built model airplane days, where 1/2 fuselage members are built right on the plan and joined by a series of thin balsa square stock running fore and aft ... known as stringers. Khufu's boat has a few, (representing internal battens on the original). The kit can be built by a 'beginner' without addressing the fairing issue with an acceptable result - so the kit says nothing about it. But I'll take a little care to do some fairing without breaking any of the ribs - it may be a tricky business. Once decked, one can hardly see the interior - but I'm picky on doing some things (loose as a goose on others) - and I'd like the rear access deck (hatch) pieces to be removable, as they were on the original so men could get under for maintenance. Khufu's boat shows signs of prior use, and must have been his personal yacht - the final trip was to bear his body to the great pyramid. Below shows the exact places to put a dab of pre-thickened wood glue with a dental tool. I have an old bottle of time bond kept on its side, and the glue has lost about half the water content - so is slow as the molasses in January. But this 'thickened' glue has its uses ... it is sticker than 'as bought' glue, 'grabs' quicker and dries faster. Glue dab are ONLY placed on the outside corners of the joins in the frame - as this will be easier to cut for later removal. Step 2 in the instructions appear next that even mention this option. Sorry for the 'bright spot' in the picture just where the instruction note shows the place to put glue dabs - but I have pictured this above clearly enough. Now I trial fitted one central 'keel' to see the 'steps' that need fairing. Note that the bow is not symmetrical to the stern, ergo there are holes in the side 'keel ' pieces to keep the ends oriented correctly. There is 'stepping', but is hard to see in the first picture. The second picture shows the stepping better, and (as in typical fairing done with kits) it is the edge toward either the bow (forward of amidships) or the stern (rearward of amidships) that get sanding/trimming. Right now, I'm not sure how I'll approach this. Note the tiny 'relief notch' at the end of the rib to prevent gluing planking to the frame BEYOND the rib. This is essential to permit easy removal of the framework later. The central 'keels' (bow and stern) to not have any relief cut, and as I want to glue planking to the ribs there might be a danger of 'squeeze out' glue sticking to the 'keel'. This is easy to sone by removing small amounts of material shown by pencil lines in the next picture. The kit directions mention nothing about this, but I can see ahead based on prior experience. First timers often learn by doing, and re-doing what went awry reinforces the experience gaining process. Just a few small cuts will do. I trial bent (partially, without wetting) the bottom plank to see how the amount of fairing will change going outward - and this is different between the bow and stern since they have different amounts of bending. I may wet, heat and pre-bend planking as I go to lessen the clamping force (done in many places on this build with rubber bands - not included in the kit). 'Sorry, but the focus is off, or I moved a little (holding the camera with one hand). That's all for now, mates. And further progress will require a little more thought before 'jumping in'. If you hand a chimp a banana, don't expect him to think about how he's going to peel it (much less read instructions).

- 63 replies

-

- Finished

- Khufus Solar Boat

-

(and 1 more)

Tagged with:

-

Ahoy to any who might review this fine build from 2015-2016 . This Mamoli kit came to me from my Dad's estate intact, and the overall quality is decent ... the minor 'busts' in this build do it justice. I've pondered the GH for a long while, postponing any attempt to build it based on the Mamoli kit until I could find contemporary info on the original. Queen Elizabeth knighted Drake on the deck of the Hind, such that it was after limping home again with enough value in the hold to make an astounding profit. The ship had been towed a little ways up the Deptford while a mooring was prepared on the Thames (logical to do) - thus validating those who said it was moored on the Deptford. But the long-term home was on the Thames - eventually filled-in around the ship before it sank from rotting hull planking. Masting and ordinance were removed and a wood shed built over it ... eventually deteriorating, as did the ship. It appeared on two early 17th century maps in the same place on the Thames, and by 1630 it was described as having some ribs sticking up like a whale skeleton. Sometime about 1650 the remains were knocked down (some wood salvaged to make a few pieces of furniture (one chair is on exhibit in England), and the hold filled in for good. Later work in that area may have seriously disturbed more of the hull, but there may well be enough of it left so that future archeology may determine the hull length and beam at the waterline, and the lines there and below. There are no known paintings, BUT there is the famous Drake Cup (also on display). Drake gave Elizabeth a coconut, and she had it crafted with silver mountings to make a splendid ceremonial cup with a lid that she gave back to Drake some time later. There is an inconclusive line image engraved on part of the coconut, but the silver lid is adorned at the top by a silver miniature of the ship! THIS qualifies as a contemporary image of the GH, and the Queen was familiar enough with the actual ship that it most likely represents an approximation of the real thing ... realizing that there are some scaling/slight clumsiness involved with casting/soldering the silver miniature on the cup - given the techniques of the time. The miniature does not have a 'Captains walk' - like most French 'race galleons' (from razee - or razored - since the heights of the stern and forecastles were reduced). They differ substantially from period Spanish gallions. There are a gunport openings visible (on the miniature) on the weather deck (no guns) and the Mamoli kit guns are on the weather deck (opposed to the Thames reproduction - thus other kits - having guns below the weather deck - orlop?) There is a stern spar to rig a large lateen (no sails on the miniature) as seen in contemporary engravings. The main and fore masts have a sail and topsail each, and a yard on the bowsprit. There is a contemporary engraving (with ship distortions of its own) depicting the capture of the Cagafuego by the GH off the west coast of South America ... no captains walk on the GH, which has many similarities to the silver miniature. The detailed engraving of Drakes 'Caribbean Fleet' also agrees with the miniature. So what about the size of the original? An experienced Portuguese navigator surnamed DeSilva was captured in the Carribean, and accompanied Drake on the GH around the horn and up the coast until being let off in Mexico (presumably Drake did not want a navigator to witness any possible discovery of the Northwest passage, which Drake was to attempt). DeSilva was fluent in Portuguese, Spanish and English - with some French, and was the personal guest of Drake on the GH and had the run of the ship. Later DeSilva was questioned by Spanish authorities and the dreaded Spanish inquisition - transcripts of both depositions were recorded and exist to this day (English translations can be found). DeSilva was likely suspected of collaboration, thus was closely questioned to get any scrap of information about Drake and the ship he sailed. DeSilva's life and his immortal soul depended upon the accuracy of his testimony - so I' be willing to 'go to the bank' on it. DeSilva said the GH was French built and not new - ergo purchased by Drake with funds raised for the venture. There were 7 guns on each side for a broadside (5 each side of the deck, and presumably 2 on each side of a quarterdeck as was typical of French race galleons depicted in surviving illustrations) plus 2 stern guns (typical) and 2 at the bow. It is unclear is they were light guns on the forecastle deck (a possibility), but I think it more likely that they were on the gun deck covered by the forecastle deck angled about 45 degrees toward the front. He declared the tonnage (in Old Portuguese Tons) to be 220 - which computes to 180 of today's Tons. This represented the cargo capacity and DeSilva was expert enough to assess this properly. The Thames reproduction was that of 150 tons (yet having the length on deck of a 180 ton vessel), and proved unseaworthy until side pieces were added at the waterline - then it went all over the world by sea ! The reproduction - as does the Mamoli kit - has a mere 19 feet beam on the weather deck and 23 feet at the waterline (as originally built). Ergo there indeed is not enough room for cannon carriage recoil, so the repo (and some kits) have the guns on the next lower deck of 23' beam. A 180 ton vessel will have 100 feet 'on deck' (fore and aft - much like the Thame replica) BUT will have about a 23' beam on the weather deck and will be 28' at the waterline. The GH of these dimensions would have had enough room for guns on the weather deck to recoil, and enough room below deck to house the large crew Drake had at the start of the venture. There also would have been room (as the crew size shrunk from losses of various causes) to eventually store tons of loot and a very large cargo of far-eastern spices. The side 'bulges' added to the Thames replica give it the needed breadth at the waterline that, if the ribs were revised to match this beam, would give 23' on the weather deck. BTW it has the 100' on deck mentioned earlier - and that does not include bowsprit. So by altering the framing Mamoli provides (widening the model), and taking into account some of the other features mentioned - a closer approximation of the Golden Hind can be had. Fair sailing ! Johnny

-

I've attached a photo of the aftermath of the aftermath of the collision of HMS Surprise (formerly Rose) with a seawall while being nudged by a small tug to a repair facility about 3/4 mile from her museum berth (presumably for hull planking repair). The photo speaks for itself, but I found a Youtube video showing the collision in real time with sound ... like a train wreck in slow motion (crunch). I'm not a tech, and the file may not work on the forum, but anyone can search under 'HMS Surprise crashes into a wall'. 'Not sure what they were trying to do, but the tug was on the 'blind side' of the Surprise ... and had no line of sight with the seawall. The backing speed was much too fast, and the lookout had communication difficulties with the tug. HMS Surprise crashes into a WALL at Marine Group!! - YouTubehttps-::www.youtube.com › watch.weblocHMS Surprise crashes into a WALL at Marine Group!! - YouTubehttps-::www.youtube.com › watch.weblocHMS Surprise crashes into a WALL at Marine Group!! - YouTubehttps-::www.youtube.com › watch.webloc

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Khufu's Solar Boat from Woody Joe

Snug Harbor Johnny replied to Snug Harbor Johnny's topic in Wood ship model kits

No way around building Kufu's boat now. It will also serve as an 'extension' to my review, e.g., the kit calls for rounding the provided square stock to support the canopy framework over the cabin. This seems a lot of work - so they could have provided round stock, since MANY of these verticals are needed and individually rounding them can result in irregularities unless one uses a draw-plate (presuming the square stock is straight grained). As mentioned, the original posts have lotus heads that I'd like to include - ergo the idea of turning bamboo skewers. Obviously the kit can be simply built 'as is' and get a nice looking result, but I'd like to do better. Per forum rules for the Review Section, the kit reviewed must be unbuilt - so the build will have to cover additional oddities or work-arounds that can only be discovered by doing a build. On the topic of having too many unbuilt kits stashed away, that is how old kits find their way onto Ebay when these things end up in estates or are otherwise passed down. My Dad left me two Steingraeber kits - the Agilis and the Fair American. I quite forgot that he had the hull of the Agilis (Baltimore clipper) planked and decked - so I neglected to search for it in the jumble left in his house (the executor allowed a limited time for basement scrounging, and most things upstairs had already been pre-labeled for various recipients). Later I harvested what was left in the box as raw materials. The other kit was unbuilt but was missing components, and like the Agilis there were things I didn't care for in those 1970's kits: screw eyes were to be twisted into the hull to tie 'chainplate' made of rigging rope; plastic deadeyes and blocks, both out of scale; masting appearing too tall for the hulls; simplified rigging; dubious fittings and rigging rope ... yet there was decent planking wood and mast/yard stock of various diameters. More recent kits do a better job of the lines and everything else on the Fair American, so the materials are being used on other projects as convenient, e.g. I'm using the gun carriages for the 1:100 Wasa (fitted with the optional Billing gun barrels). Old kits can have die-cut or pre-cut bulkheads (versus the laser-cut pieces common today), or they may be simply printed onto whatever stock was included ... meaning that many parts will have to be individually cut out (preferably with a scroll saw), then cleaned and hand fit into place. 'Guess its all a matter of how much fiddling one will do on any given project, and what short cuts or simplifications are acceptable to the builder. Every project is its own voyage of discovery, and the journey along the way is what makes it worthwhile. -

Khufu's Solar Boat from Woody Joe

Snug Harbor Johnny replied to Snug Harbor Johnny's topic in Wood ship model kits

Thanks, Clare. I have 5 kits in stock aside from the build (summer suspended) of the Billings old Wasa kit. Rather than accumulate any more, I need to start a 'buy one - build one' policy. Your 'nudge' prompt me to squeeze-in a build of the Khufu boat, as I've been thinking about ways to do it justice as I roam the hospital halls in my per-diem job as a pharmacy Tech ... lots of picking and delivery and endless running around with meds. It's what I call a 'working retirement' ... well, with inflation and meager savings wee still need the income. Johnny -

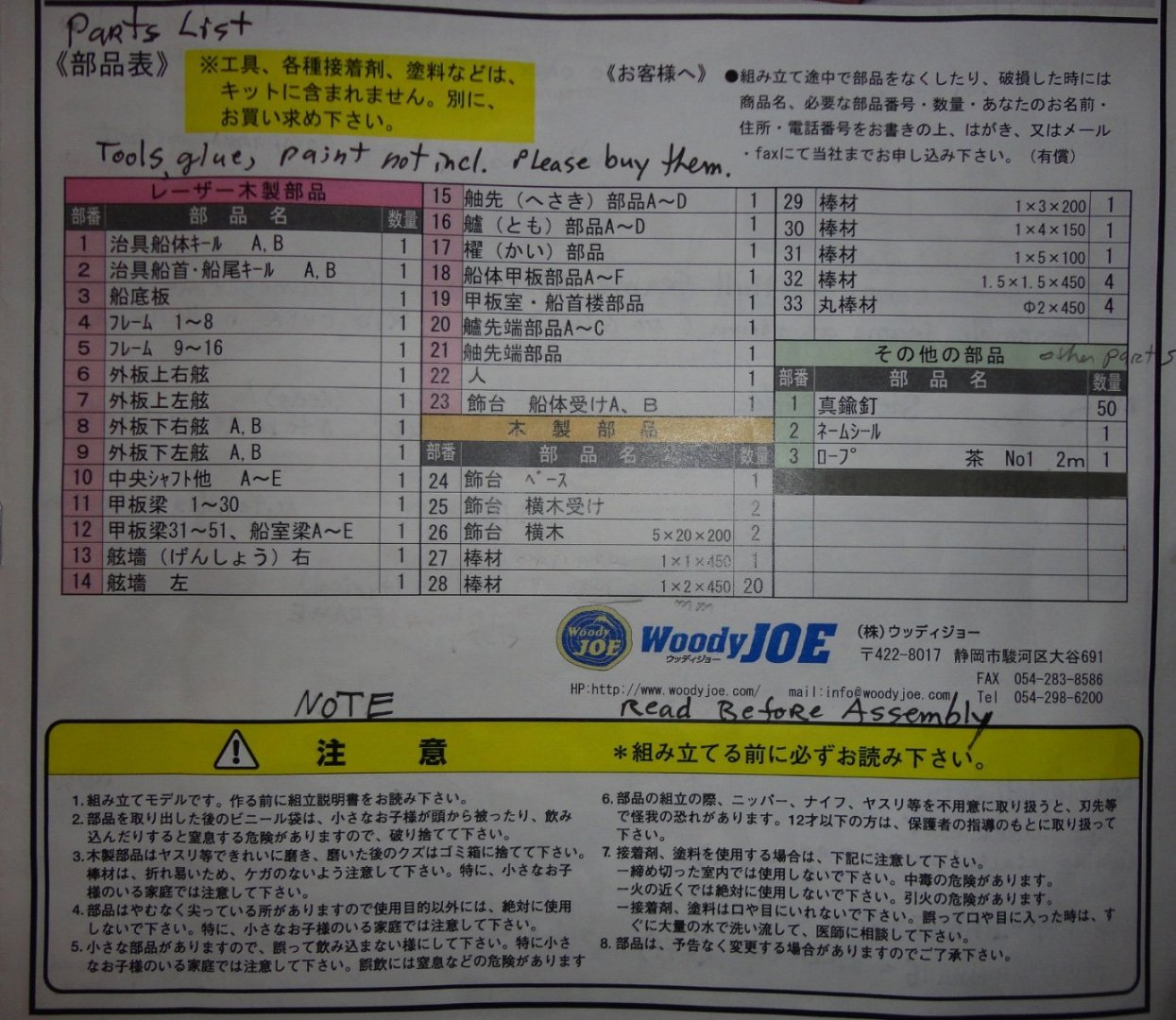

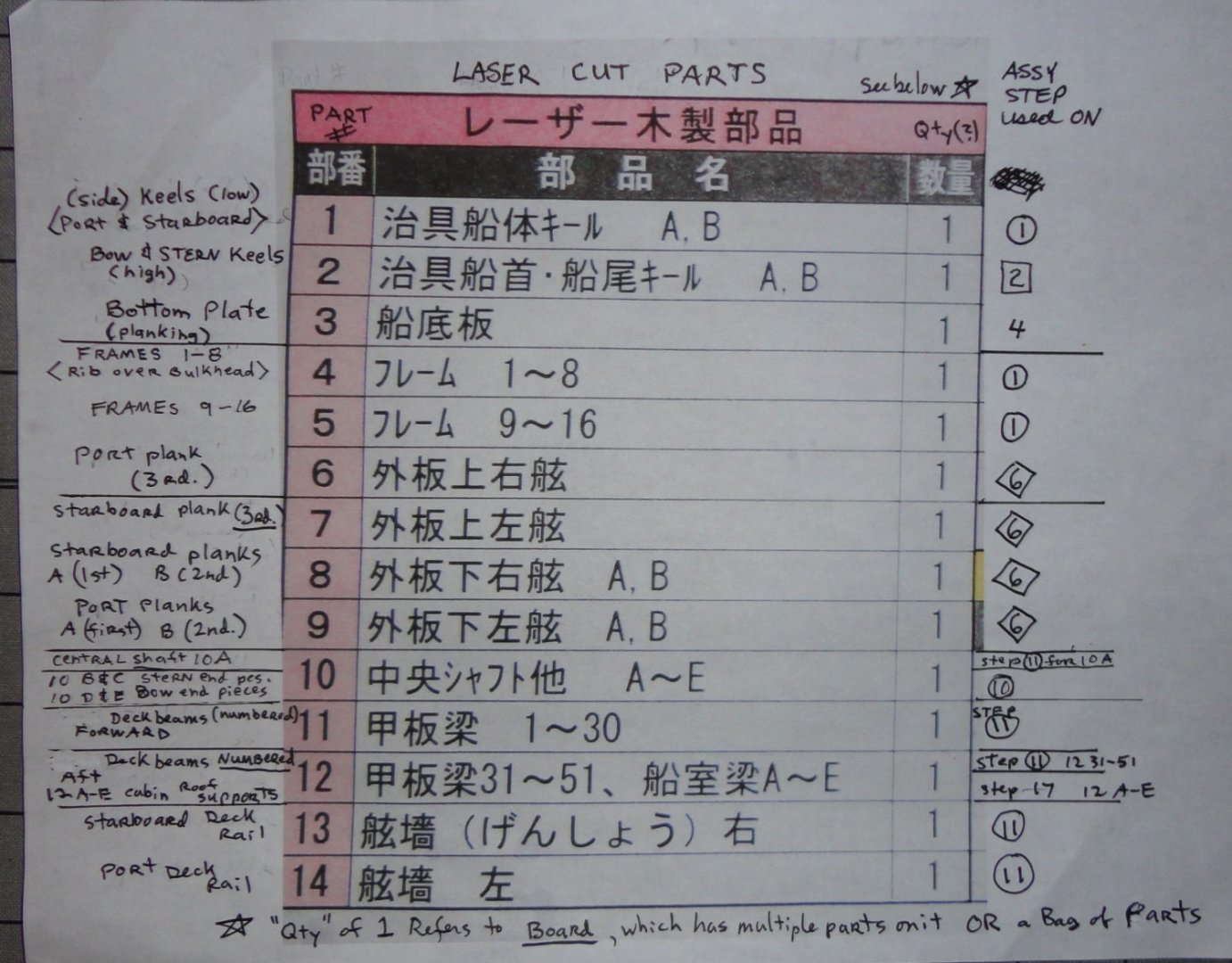

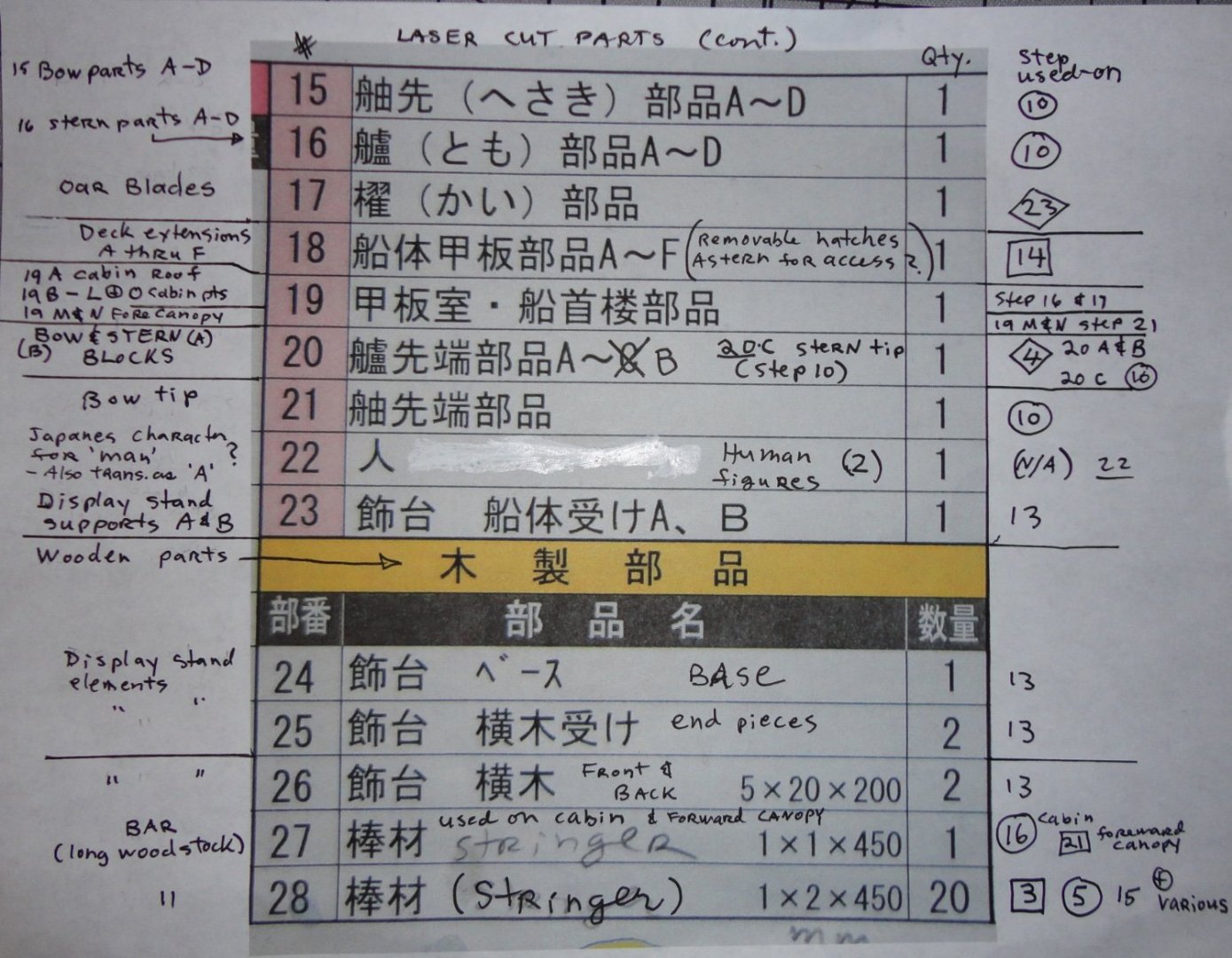

Ahoy from Sung Harbor Johnny ! After seeing a summarized build of the funerary yacht of Pharo Kufu (also known as Cheops, builder of the Great Pyramid of Egypt) offered by the Woody Joe company of Japan, I was intrigued enough to order one to examine for myself. The subject is the oldest complete ship in existence (about 145' overall length), and was discovered in 1954 in a sealed chamber next to the Great Pyramid. It was apparently entombed intact, but in 4,500 years the internal reed fastenings deteriorated enough that the tenoned planked hull 'disassembled' itself. The experts took their time to take everything out of the chamber and eventually reconstructed the craft for display in its own museum. You can find out all the details on line, as I'm focusing on the kit. Per info found in the forum, one can order from a dealer in Japan (Zootoys ?) and pay through PayPal. I didn't want to setup an account for a single purchase, so ordered through an Ebay vendor - with Ebay securely handling my credit card info. as a 'guest' (no need to join Ebay). The price in yen listed by Woody Joe works out to around $176 - not including tax (Japan has a 10% value added tax) or shipping, so my guess if ordered through the dealer in Japan might come to $220 altogether. I paid $248 (plus $11 to 'expedite') through Ebay, but wasn't pinching pennies (the middleman has to make something) and preferred the security offered by Ebay. I was pleasantly surprised that the well-packed box arrived in 12 days via FedEx - and the carrier water for someone to answer the door and receive the package (the Admiral, who knew that I place the order). The first photo shows most of the contents, all well organized and in plastic sleeve sub-units (not in the photo is the instruction pamphlet - more on that later) and the two-piece drawings of the model (needed to produce parts of the kit) have been left folded, since I did not want to depict an image of it. Note: what looks like a singe sheet of laser cut wood in some of the packages is really a stack of SEVERAL sheets contains multiple parts. You are just seeing the top sheet in those stacks. The design of this kit is rather sophisticated as the model to be constructed has many curves - including the deck. So the cabin on the deck has curved bottoms, vertical end pieces (so they are not 90 degrees at the base) and a horizontal roof. It would be difficult to work out all the odd angles, or even the method of assembly in a scratch-build. This may be a great project for someone new to wooden ship modeling to begin with, since the focus is on learning to handle, bend, do some trimming/shaping and gluing of wood (and some fairing) - and later tint as desired. There is no mast or sail, since the original was towed and the oars were mainly for steering and positioning, although in a pinch rowing was possible. Thus there is no rigging (other than to secure the oars) ... no guns, gun ports complicated carving either. The vessel has interesting lines, and there is a clever way the planking is done upside-down on an internal framework that is ultimately removed. The only 'catch' (which I knew about in advance) is that all the instructions are in Japanese. This might be a real disadvantage for a beginner, were it not for the Google translate app. I happen to have the most basic Trafone Blu phone (Android) that I use for emergencies only, or to keep the Admiral posted as to my whereabouts should I have to be away. If an old, non-tech guy can figure out how to download an app I suppose just about anyone can do it. I used the phone's camera (after selecting Japanese to English) held above the Japanese text (just a bunch of characters to my eyes). What appeared in the picture was then an 'overlay' of English text ... but the verbiage kept changing into alternate 'translations' ... ways of saying things, I guess. Part of the challenge was the small size of some of the text in Japanese - so I took pictures of those areas with my digital camera (not the low-res cell phone), pulled the images onto the desktop of my computer, then printed the photos to hold the translator over. That solved many problems, but the smallest text required me to crop the photos of that text in photoshop in order to print an further enlarged version that the translator app could reliable make sense of. In short, translating the instructions into English is an absolute MUST for this to be a beginner's kit. The process of doing this familiarized me with the well-illustrated instruction pamphlet, and queued me into some of the finesse needed in a few places of the future build - as well as a few places for improvements. The wood is all of Japanese Cedar (the original ship was made of Middle Eastern Cedar) and there is no plywood. In an ideal situation, all the wood stock should be heartwood, yet there is a transition form heartwood to sapwood in some of the kit stocks. (Note: the 'keels' used temporarily during construction are composite material - but are not part of the model as these parts are removed.) The wood looks great, with no warpage - and the quality of the laser cutting is the finest I've see ... they must have a micro-fine beam that is perfectly tuned so not to have excessive burning seen on some other kits. The pre-cut display stand is some other wood comparable to heartwood poplar. Some really fine brass brads are packaged for use in some places - but I'd rather find an alternative construction technique and use the brads for something else. There are two laser cut scale Egyptians (flat), which is a neat idea (so why not supply a few of them to put on disc bases for placement on the model?) Just to contrast to a couple other beginner (or slightly above) kits at a comparable price... Billing's Roar Edge (a re-design of the challenging Vikingsskibbe) might be considered a beginners kit, but all the laser cut parts are a type of plywood, and many note that the instructions could be better - it does make an attractive coastal trader at 1:25, the same as their Oseberg. Occre's Endurance (perhaps an intermediate kit) has a lot packed into the box - and good instructions as well (augmented by an excellent on-line video), yet some note that simplifications of the original ship were made to ease the build - so adding aftermarket upgrades (e.g. 3-D brass railings) will raise the cost. Back to Khufu's Ship: Below is a closer shot of the laser cutting. Cabin pieces have roughly parallel lines, as planks were used to make the original cabin. What looks like 'gaps' in these lines is by design, as surface battens (also on the original) go in these places - so once assembled one does not see any gaps from the outside - as if the cabin were laboriously planked from the inside. The left board is seen from the bottom of the laser cut - showing a minimum of 'burn'. The right board is seen from the top of the laser cut - and it is clean and precise. What looks like (and is) a rib on the left is still attached to a 'bulkhead' - the slots of which key into aforementioned 'keels' used to make a building form that is later taken away in a specific way. As I said, a lot of engineering went into this deceptively simple kit - it is surprisingly sophisticated once one envisions the actual build process and the competed results. The components of the hull planking sections have a lot of irregular lines, which is because the original boat was made of irregularly shaped planks that were expertly joined together, stabilized by internal tenons and fastened on the inside with reed twine and papyrus caulk ... no need for nails, rivets or tree nails. The photo below is interesting. I've hand written my translations (gleaned from the app, but not always clear or identical) for what seems to be optional items to 'pimp' the model somewhat. 'Don't know why someone would paint the hull green - or apply gold to the bow and stern. It likely had a shade cover, but the museum ship doesn't have the extended framework going past the cabin astern. The next pic is the parts list, that took a little figuring out. The translation of the cautionary text is below the picture: 1. Assembled model is shown. Please read all instructions before assembly. 2. The plastic bags in the kit must not be handled by children, place over head or swallowed. There is a danger of suffocation. Please safely discard plastic bags. 3. Smooth all parts and discard waster or scraps in the trash. The material is easily broken especially by children. Take car around other people. 4. Parts are still sharp - use only for intended purpose. Be careful if small children are present. 5. There are small parts. Do not let children ingest or swallow, especially small children. Swallowing presents a suffocation risk. 6. A need for nippers, knives or files when assembling. Those under 12 need parent or guardian supervision. 7. When using adhesives please note the following: - Don't use in a closed room. Don't overuse. Danger of addiction. - Don't use near fire - danger of ignition. - Don't get paint or glue in eyes. In case of accident, rinse with plenty of water and see a doctor. 8. Parts subject to change without notice. The last 3 images are enlargements of areas of the parts list above. 'Turns out that a part number often refers to a laser cut board containing a number of parts - some numbered and some lettered (e.g. 15 -A, 15 -B versus 5 -9, 5 -10). Again, the cross referencing of parts and the steps they are used in gave me a much better understanding of how the boat will go together when I get to building it (future build log). 'Looks like a fun build. 'Guess whenever a build gets underway, I'll have to include the images of steps with translation (plus other tips). Fair sailing! Snug Harbor Johnny

-

Very nice work. I'm still absorbing everything from the several fine builds on MSW - as well as figuring out a few 'sleight of hand' tricks to try before tackling a clipper project ... and there is a lot to digest from Hackney's book that is applicable to the 1:150 Academy Cutty. The difficulties involved at the reduced scale may be compensated by details tiny enough to be omitted on smaller versions. My 'guess' for the smallest size to fiddle with on a model (for my fingers at least) is around .010. At 1:96 (about 1:100 for easier math) that would represent about 1" on the actual ship - so the 'dots' on deck planking are shown in 1:96 (at my skill level). At 1:150 the dots may be omitted, as .010 represents 1.5" at that scale. On a model at about 1:50, one needs to think about showing stuff that measure 1/2" on the ship - and at 1:25 one might show things as small as 1/4" ... per my arbitrary limit of working with .010 sized materials. Yet a 6"block at 1:150 is .040 (1mm) ... I can't imagine me trying to strop something so tiny, so I'd have to just tie a thread to a seed bead instead. 'Guess everyone has to work within their own limits ... and some of the tiny work seen on some MSW posting astounds me.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I wouldn't bother untwisting the cords, but just make rope of the opposite twist (running the drill in reverse on the Syren's Rope Rocket). It will still look OK on a model.

-

The Surprise (guess that name will be permanent, with the popularity of the film ... too bad they did not make the sequel) was originally the HMS Rose - famous in Colonial Rhode Island history. It was independently build (by contract) by a good friend of mine, John Fitzhugh Millar (now of Williamsburg, Virginia) back in the early 70's. This was around the time the repro. of the sloop Providence was built in preparation for the Bicentennial. John explained how expensive maintaining and sailing a ship the size of the Rose (now Surprise) can be, and although leased for a couple films (one of which was Man Without a Country), sold and repossessed twice - he was lucky to about break even when a sale finally went through. John did come away with a real treasure - for he met his future wife Cathy while conducting sea shanty sessions aboard the Rose, and the couple run a B&B in Williamsburg to this day, where the inestimable JF Millar has written a number of books on colonial history, architecture and art (13 Colonies Press).

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

'Looks sharp with Syren rope ... true 'miniature' rope spun much like full-size rope (although full-sized ropewalks produce rope from the far end to the spinning head, the result from the Syren 'Rope Rocket' where the rope comes together from the middle outwards is essentially the same thing). I've seen numerous builds on MSW, and perhaps the single best upgrade one can do on a ship with rigging is to use properly made miniature rope. It look better, feels better, behaves better and has very little (if any) of the 'fuzz' you see on close-ups of builds using average commercial rigging (I wouldn't call it rope) ... cord. Whether bought or self-made (with a little practice - and it's not that difficult) miniature rope won't detract from all the hours spent on the hull and other fittings - proper rope will ADD to the effect. BTW - I love your Drakkar model. Do you plan to add sea chests that the rowers would have sat on?

-

Questions Before I Buy My First Ship

Snug Harbor Johnny replied to Magarkus's topic in New member Introductions

'There is a build log on the Woody Joe 'Khufu's Solar Boat' - a model described by the builder as 'easy, but not too easy'. It is a copy of the actual funeral boat recovered from the base of the Great Pyramid, and the original was re-built and now on display in a museum. A few simple tools , sandpaper and glue are all that appear to be needed. There is no mast (or sail), thus no rigging. But the laser cut parts appear to make a remarkable model of the oldest compete ship in existence. The planking is done in an innovative fashion, where the ribs are part of the forms and the hull is planked from laser cut sections upside down. Then the ribs are detached from the forms and the hull comes away. You have to see the build to appreciate this. I plan on getting this kit for my stash ... NOTE: the instructions are in Japanese, so a translator app for your phone will be very helpful. The kit comes from Japan, and the selling company accepts PayPal and is legit. -

Poly rope - Which adhesive product?

Snug Harbor Johnny replied to LyleK1's topic in Masting, rigging and sails

I'd recommend thinned model airplane 'dope' ... a familiar name was Aerogloss, which sold thinner separately as straight dope is too thick for this application. Old-fashioned hobby shops used to sell this, but there are far fewer such shops around - so one may have to go on-line. Otherwise, clear nail polish (preferably thinned) can work. BTW use with plenty of ventilation in small amounts because of the odor/outgassing. Another product one used to find was Duco cement, which also sold a thinner. Once again, kids got into the habit of 'sniffing' any of these so they are far less available to prevent abuse. Try buying more than one can of spray paint at most hardware stores ... there is some kind of program to prevent 'youths' from getting spray paint for graffiti. Best to experiment on test pieces first to assure suitability for the effect you want with rigging elements. -

There's scale, and then there is practicality. From what I've seen thus far, very many models have at least a 'tad' of leeway when it comes to the deadeye sizes. One must pick which things to 'battle' and how much to fret over any detail. I seen postings of models large enough not to be able to get out of the space in which they were built. Larger size may mean deadeyes and belaying pins will be easier to be 'in scale', but then smaller stuff has to be represented that does not have to be included in smaller scale versions. There is a 'rule' or 'formula' I somewhere in this forum to calculate the minimum real-life size of anything one the original ship that should be represented at any particular scale. If anyone recalls that, they might just post in this thread.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.