-

Posts

2,457 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dvm27

-

I did cheat those joints on Pegasus Alan but did them correctly on Speedwell. David does discuss the lofting of these angles in Volume I of TFFM. It really is quite easy to mill them if you have an angle plate. I only had one breakthrough out of the whole bunch so I increased the chock angle for it's replacement.

-

Those are tricky little timbers! A bracing piece inside the hull between the cants and outer counter timber (at the toptimber line) is indeed the way to go. I left the fillers quite full and faired them in place.

- 889 replies

-

Swan class 3D model in progress

dvm27 replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

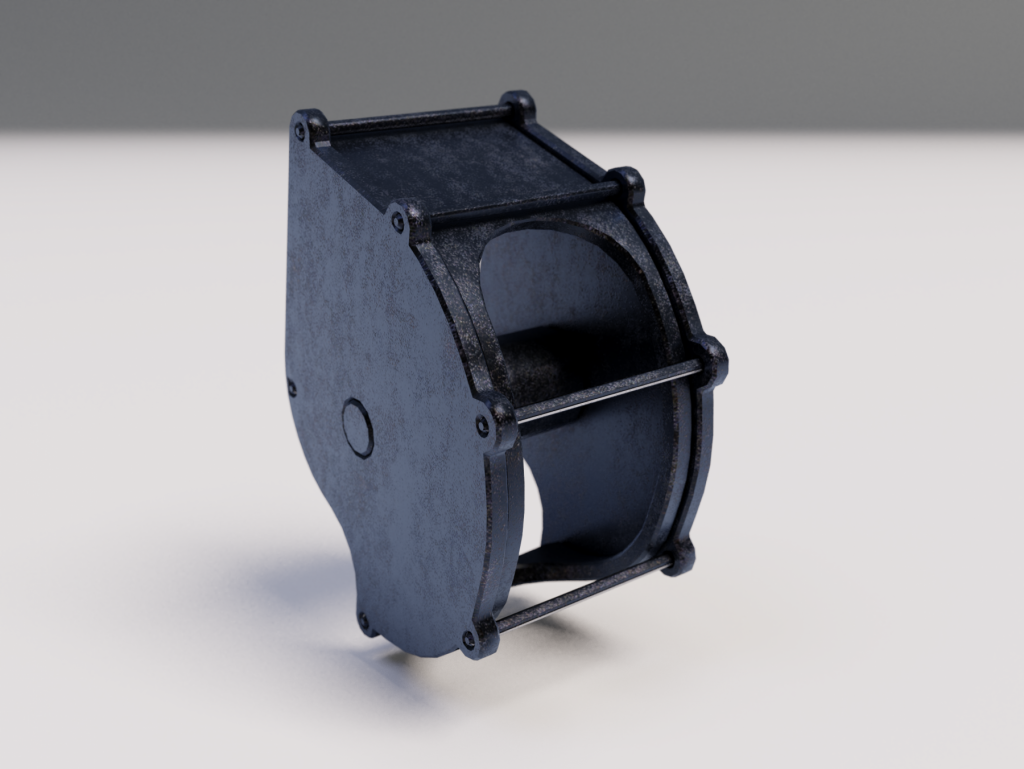

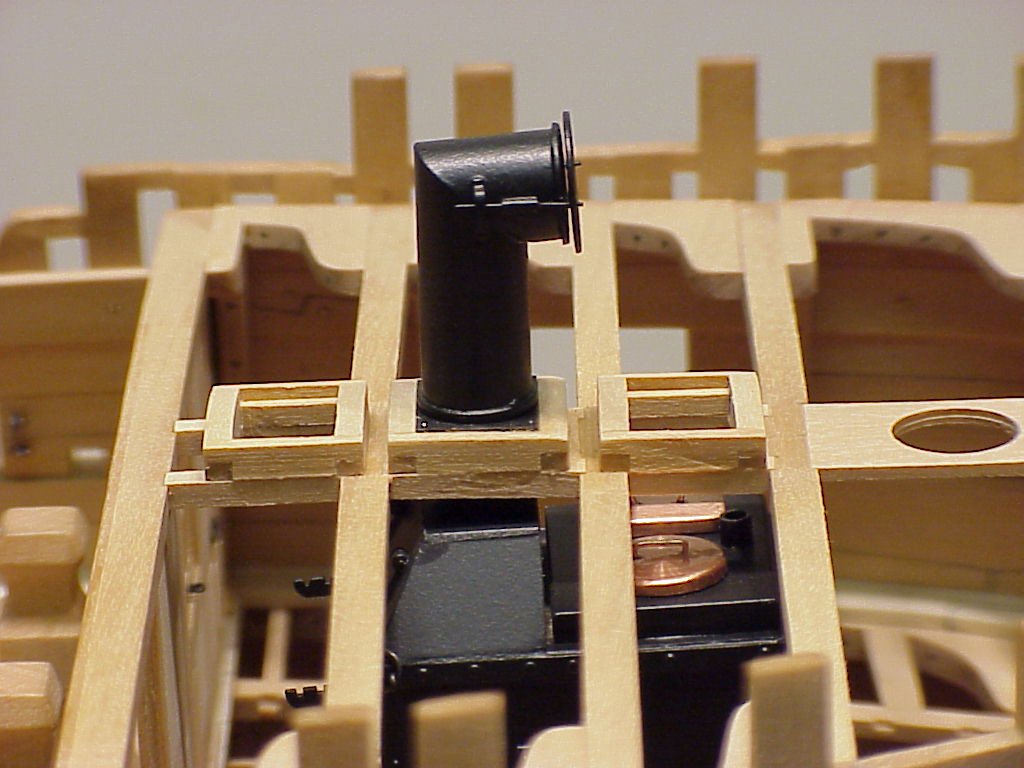

True that, Danny. Most of the features on the platforms and lower deck are not visible in our finished models. How cool would it be to show the photo below and say "this is what my magazine looks like"?- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Swan class 3D model in progress

dvm27 replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Yes, Denis's work is amazing. You should see the high resolution photos. I honestly can't tell his work from mine (well, actually I can...his work is flawless). David and I will absolutely be releasing these photos, which follow our books chapter by chapter, when Denis is finished. The photos will be viewable on a PC in high resolution. Printing costs would be enormous so that's not an option. We wish to provide them, at a very reasonable price, to those who have purchased our Swan class plans over the years, sort of a parting gift from Admiralty Models for all your support over the years.- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Swan class 3D model in progress

dvm27 replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

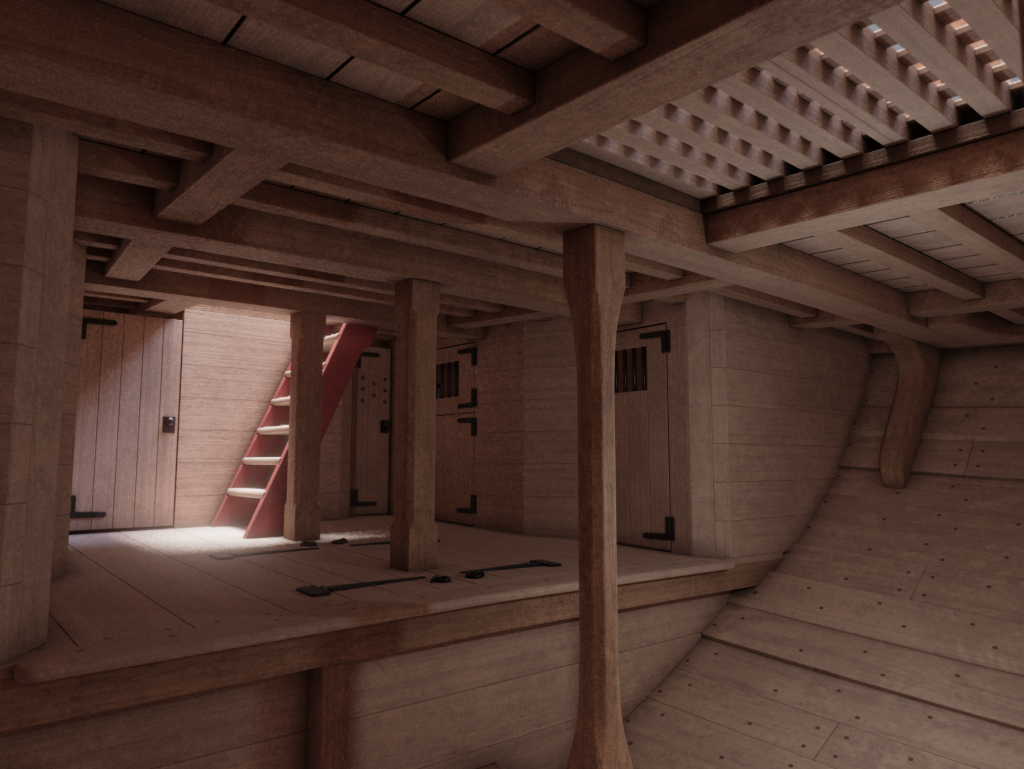

Denis has been busy building our 3D Swan class ship. It's very exciting when it all comes together, for example the aft platform view below from the main deck (photo below). When paired with The Fully Framed Model series of books I don't believe there will be another more thoroughly researched and illustrated ship model reference available.- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Looks wonderful, Ben. Now get those fillers in and brace them before you snap them off with an errant elbow strike like Toni and I did!

- 889 replies

-

As many sizes of rings are frequently required you can also make your own by winding 24 or 28 gage brass wire around the appropriate sized drill bit. After winding and making sure the ends are taut you can cut them straight down the middle with a very fine fret saw blades. Ends need to be sqared up before soldering using a file.

-

Dan, there is a guy on Overhaulin who does beautiful pinstriping by hand - no taping off or other guides. Just hire him.

- 287 replies

-

- michelangelo

- ocean liner

-

(and 1 more)

Tagged with:

-

What grit for disc sander?

dvm27 replied to clifforddward's topic in Modeling tools and Workshop Equipment

I use the 180 grit for everything. Your can remove as much (towards the end) or as little (towards the center) as you need with a smooth finish. If you need 80 grit you probably should be cutting your wood to closer tolerances before this point. Changing the paper is relatively easy but does take some time and a lot of mineral spirits. -

Le Soleil Royal by Nek0 - 1/72 - Marc Yeu

dvm27 replied to Nek0's topic in - Build logs for subjects built 1501 - 1750

Bienvenue, Mark. From browsing websites all over the world it is apparent there are many extraordinary ship model makers whose work we have never seen. Happily, several of them seem to have discovered Model Ship World recently and we are very pleased to view your work. I especially appreciate the meticulous lining out of your hull. It takes a very brave builder to take on a model with such exquisite carvings!- 208 replies

-

- le soleil royal

- 104 guns

-

(and 2 more)

Tagged with:

-

Those look very nice, Cliff. Does he include instructions for cleaning off the excess and polishing?

-

SOLEIL ROYAL 1669 by michel saunier

dvm27 replied to michel saunier's topic in - Build logs for subjects built 1501 - 1750

Lovely work, Michel. Even more impressive is the fact that the blank is just one piece. I seem to recall M. Frolich built his up of several pieces (perhaps to insure the best wood grain orientation). -

ancre Chebece 1750 by Jeronimo - FINISHED

dvm27 replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

I'm so sorry about your setback, Karl! Most people wouldn't have the heart to jump right back in with a replacement build but you have certainly done so. In the medical profession we usually say "bad things come in threes". I like the German proverb better. -

Personally, I think it's easier to temporarily mount the completed frames, perhaps with small spacers glued between the toptimbers to lock them in place and a tack or two where they sit on the keel, mark off the sill locations, remove them and then cut the mortises with a chisel. I believe it's much cleaner to make these joints using a chisel with the frame on a flat surface then filing them in place and keeping them the mortises parallel athwartship.

-

Your cannons and especially vent and touch holes are excellent! Do you have a CNC lathe? Perhaps a ground form tool?

-

So copper seems pretty amazing to work with, Ed. You just blacken everything in place with no prior prep like degreasing with alcohol or acetone? Does the liver of sulphur always work or do you have some failures as I do with brass from different manufacturers?

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.