-

Posts

2,457 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dvm27

-

Appreciate your using the palm of your hand to provide scale Keith. Makes those small blocks even more impressive!

-

Those resin painted castings looks terrific Chuck. May I ask who makes those powders?

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well done Chris. Your model came out beautifully. Any thoughts on your next project? The twins must be no work at all at this age, allowing unlimited shop time : -)

- 290 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Wow, Toni, phenomenal work on this very difficult area!

- 1,449 replies

-

Pandora by marsalv - FINISHED - 1:52

dvm27 replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Your quarterdeck detailng is spectacular, Marsalv. Keep those photos coming! -

Swan class 3D model in progress

dvm27 replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

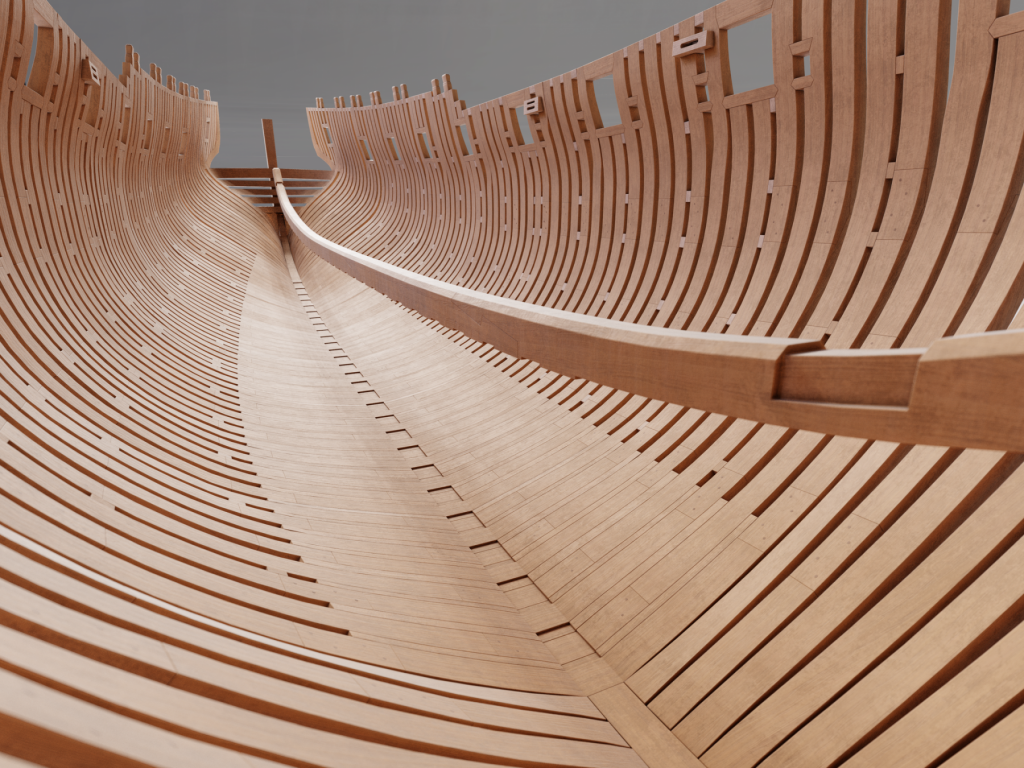

I could tell you Wayne...but then I'd have to kill you! Seriously, our renderings are being done by a very talented individual in Europe. I have no idea what software or computer he uses and wouldn't understand even if he told me. But I honestly can't tell whether the photo below is his rendering or my model.- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Swan class 3D model in progress

dvm27 replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

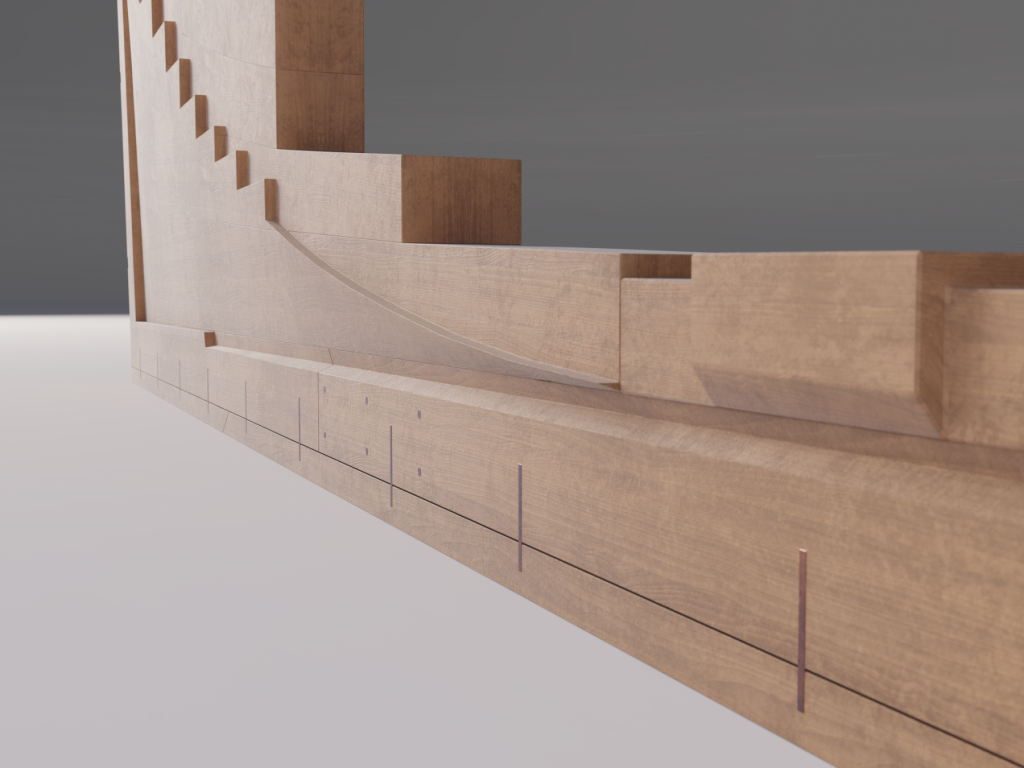

I know what you mean, Danny. Remember that wicked sternpost and aft rabbet transition? David's illustrations were awesome but how helpful would these photos have been!- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

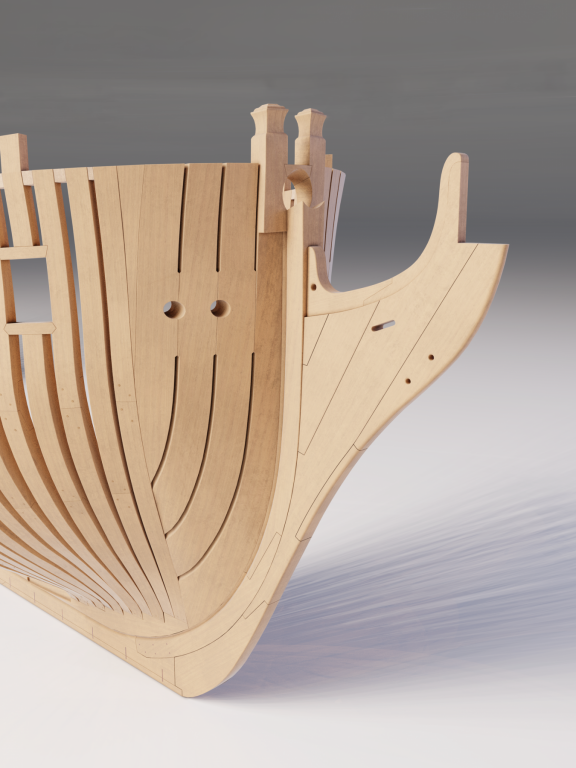

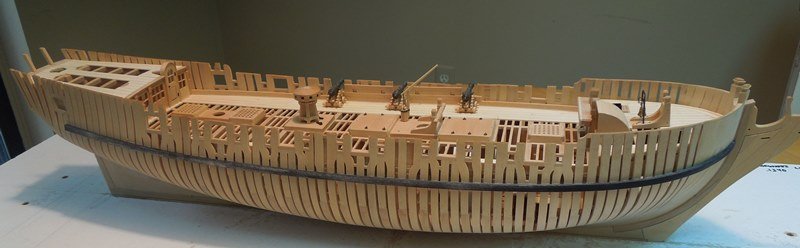

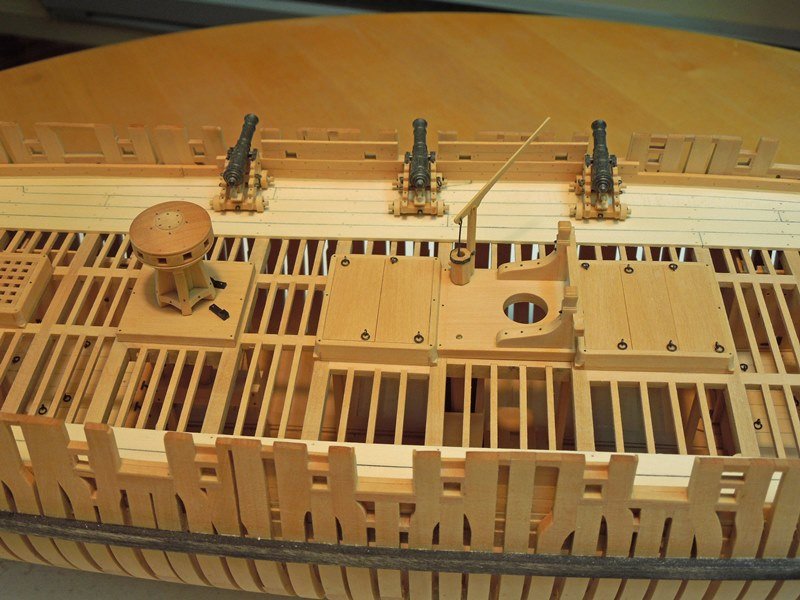

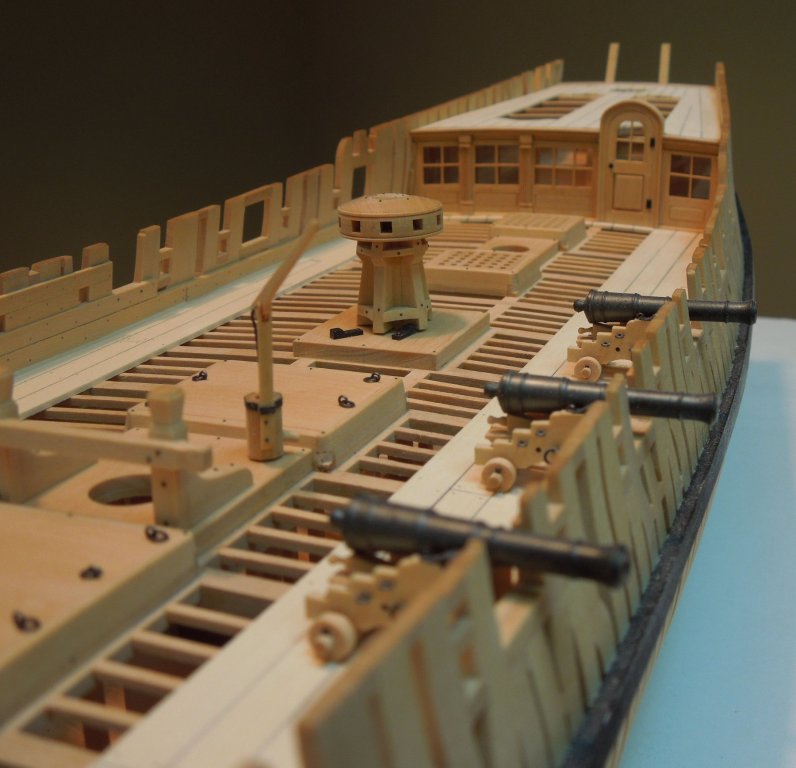

Admiralty Models has been working with a very talented 3D computer modeler who is building us a Swan class ship model (Pegasus). Besides the exceptional quality of his work, I can see the enormous benefit of a 3D model in showing how all the various pieces fit together. As the model's construction closely follows the actual vessel, it's build may be viewed in sequential layers. Our builder is precisely following the four volume Fully Framed Ship Model series of books, bringing David Antscherl's seminal work to life. In the near future, we will be offering the fully framed and fitted out computer model to those in the process of building a Swan class model or are contemplating building one. Between the Swan books and computer images I believe we will have the most comprehensive instructions and photos available for building a fully framed ship model. Stay tuned!

- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

Gary's suggestion above The Wooden World is a very good one for your needs. For example, Chapter VII, Officers contains the following topics: A career at sea, Patronage and Promotion, Authority and Duty.

-

As many of my favorite modelers are posting updates this weekend I thought I'd share some recent progress on Speedwell. She is now sporting her copper cupola (say that three times quickly!) which arches over the steps to the "Great Cabin". I use that term in quotes because, after the lockers are installed, there is little room for the commanding Lieutenant. But this little vessel was designed for shore duty and was seldom used for sleeping. The cupola was shaped from a square of holly, hollowed out then spray painted with a hammered copper finish followed by matte varnish. The rudderhead cover was also shaped from a holly plug which was then hollowed out. The panels were added to each side. Each one was a different dimension and all are hand fitted. A little more work on the inside and outside of the hull and Speedwell, Volume I, will be off to the press!

-

Pandora by marsalv - FINISHED - 1:52

dvm27 replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Fantastic Marsalv! The difficult planksheer with those seemless moldings is First Rate. -

Honey Bear by albergman - FINISHED

dvm27 replied to albergman's topic in - Build logs for subjects built 1901 - Present Day

Let me get this straight. You made this beautiful model from scrap synthetic wood offcuts , bondo, cardboard and leftover scraps of various materials? I am truly humbled!- 18 replies

-

- honey bear

- fishing

-

(and 1 more)

Tagged with:

-

Looks great, Chuck, and certainly reflects other contemporary models. The blue looks a bit vivid to me but perhaps I'm used to a deeper blue on the Navy Board models I've seen.

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Headrails are the icing on the cake and yours look very nice, Toni. I've found that any small imperfections I'm stressing over tend to disappear as work on the next section gets underway. For those about to start work on those tricky headrails, please check out our next Admiralty Models workshop in October http://Www.admiraltymodels.com. We will be covering the expansion drawings and construction of this challenging area using laser cut pieces by Chuck to compare to your efforts.

- 1,449 replies

-

Let me know how that works out for you, Keith. Then I'll do the same. Of course playing pool will be a bit more difficult but it's a small price to pay when all those little bastard escapees end up in the bucket!

-

Been awhile since my last Speedwell update. David and I were hoping to have volume one of her construction in book form by the end of the year but I suspect it might be a tad later. I do envy you retirees!

-

Miniature Russian carving tools

dvm27 replied to druxey's topic in Modeling tools and Workshop Equipment

I have had my set for a couple of months and I can honestly say they are the best set of chisels I have ever purchased. They are honed to perfection and come in just about every shape or size one might need. I have made great use of them and my model looks all the better because of them. Well worth the investment!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.