-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

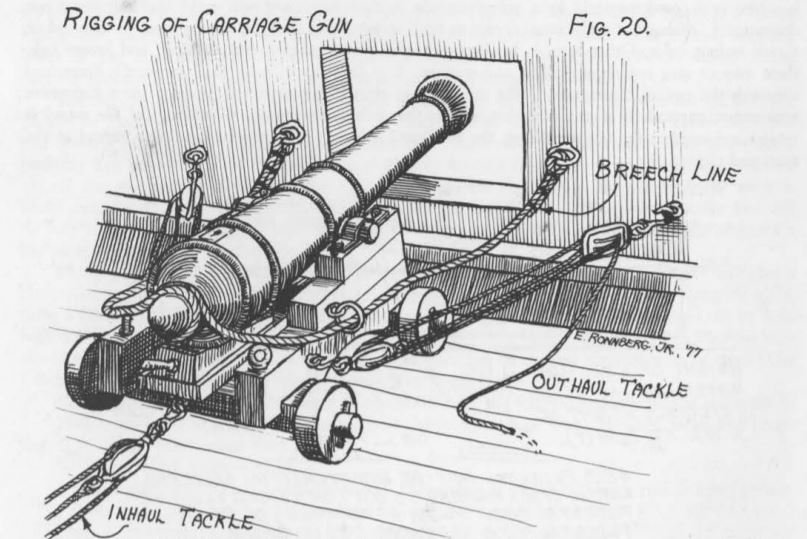

To "rotate" the cannons there was a set of "training/outhaul tackle" on each gun. Most models only show the basic one for recoil. The training tackle had pulleys and they also used a handspike to move the rear of the gun for training. The outhaul could be used for training. On some ships, there was an extra eyebolt on each side further from cannon to make training easier.

-

Looks factory fresh to me. I remember in the showrooms many times you couldn't get with 5 feet of one unless you showed them your bank account. Though I do recall sitting in the driver's seat of a Ford GT (whatever the commercial name of the GT-40 was) for about 10 minutes once. I knew the sales droid.

-

Stealers

mtaylor replied to Sheerline's topic in Building, Framing, Planking and plating a ships hull and deck

I was going to post what Druxey said. It looks like at your bow end, the planks are too wide. A tutorial will help you.- 23 replies

-

- hms victory

- corel

-

(and 1 more)

Tagged with:

-

Welcome to MSW, Tom. I hope you can find the info you need to finish and it looks like you've recieved a lot of help so far. Sorry, but I removed your phone number. Please us a PM to the other person when giving out personal info.

-

Looking at the detail at this scale boggles my mind. Stunning work, Marc.

- 2,696 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Wonderful work, Gary. And the figures give it a sense of perspective as to the size of the ship.

-

Beautiful and interesting work, Anthony. How are you going to display her? I just can't see hanging her on a wall like other half-hull models.

-

Super nice work, Hellmuht. This is something totally eye catching.

- 158 replies

-

- byblos ship

- Egyptian

-

(and 1 more)

Tagged with:

-

Not a twit, Steven. We've all done that kind of thing. "Oops" followed by a few choice words. I do love the way this is looking.

-

You might give some thought to something like a Hahn jig. Cut out the center around the upper part of the hull, notch it for the beams. When making your frames, add an extension to the top of the beams so the hull is above the board. Here's two photos of one of my builds using this method. By cutting out the center around the inside of the hull when doing the board, you have access to the inside.

-

I can't add to what's been said, but Welcome to MSW.

-

Welcome to MSW, Doug.

-

Ripping Planks - what I've learned from others

mtaylor replied to glbarlow's topic in Modeling tools and Workshop Equipment

Glenn, Don't regret this. Excellent topic and presentation. BTW, here's another way similar but different from Kurt's and some others. I use a short tall fence over my long short fence. I then set the tall one such that it is about halfway (usually less) down the blade. Kickback is basically a thing that never happens with this. Usually push sticks on sort pieces and fingers on big ones. -

A DIY thickness sander

mtaylor replied to Kris Avonts's topic in Modeling tools and Workshop Equipment

Now that's a different way to put the sandpaper on the roller. Looks like a great way. -

Dornier Do-217K-1 by Papa - FINISHED - Revell - 1/72 - PLASTIC

mtaylor replied to Papa's topic in Non-ship/categorised builds

Two bristles? I vaguely remember seeing brushes with only one. Maybe they don't make those anymore as it's been along time since I was really into plastic.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.