-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Amazing work, Daniel. Even more amazing when one thinks about the scale. Yikes..that's tiny.

-

Gerald, I'm enthralled with this build. As for the picture problem.. I think you're missing a step or two. Have a look here: http://modelshipworld.com/index.php/topic/540-how-to-add-pictures-in-your-posts-and-pms/

- 281 replies

-

- falls of clyde

- tanker

-

(and 2 more)

Tagged with:

-

Thanks for the comments and the "likes". She'll be coming off the jig as soon as the last coaming is set into place and before the rest of the deck planking. I found some nice 1/4" mahogany and i"ll make a cradle that will hopefully do her justice and not hide her lines. I gave serious thought to pedestals but they just seem flimsy. i have one ship on pedestals and I get nervous anytime I have to move it. The longer I wait, the more problems I'll have once I begin removing the jig so time to bite the bullet and get her done. Bear with me on this....

-

I just remembered... this: http://www.arsenal-modelist.com/index.php?page=accessories∂=37

-

Now that's a great tool, Micheal. I'm thinking it could also be made out of brass. Gotta' go dig out my brass rod and see if I have enough. Thanks for designing and building this and sharing the plans.

-

Dos Amigos by bigcreekdad

mtaylor replied to bigcreekdad's topic in - Kit build logs for subjects built from 1801 - 1850

I'd go with the Early American putty. Something that hints at the treenailling rather than jumping out at you. I've only treenailed one ship (my first one) and after that, came to the conclusion that anything 1:64 scale or smaller, treenails overpower things as even the tiniest are too big. But that's me. -

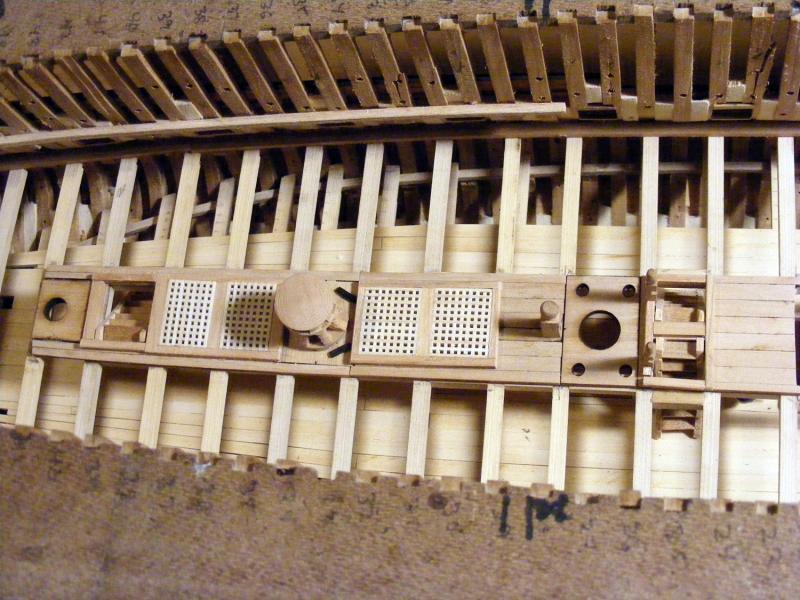

Thanks for the "likes", the comments, and the discussion. Things have been running, shall we say, dead dog slow here lately in the shipyard. I'm putting the hours in but seems like nothing gets finished. Probably normal then at this stage. The center line furniture aft of the main mast is done except for the pantry which is on hold. No point in blocking access at this point. Also the two crew ladderways forward of the main mast are done. The pic shows the capstan but it's only set into place at this point so it doesn't get misplaced or damaged. The crossbeam for the pinrail forward of the main mast has been safely tucked away so it doesn't get damaged. I'm moving forward on the deck to the remaining hatchways. After the planking the rest of the deck and doing the ceiling, I'll install what I have ready and make the pumps (do over!!!) and the fireplaces. Part of the bog that's slowing things down is taking measurements for the planking and transferring them to the drawings I'm making for the laser. I do find myself being happier with my output as I think I'm getting better at joinery and even more patient with fitting things than I was before. After a couple of "by your leave, sir" hassles, I found I need to measure 3 times before transferring any measurement to the wood. A bit of confidence here and there goes a long ways. Here's the pic and as always, comments, critiques, and discussion are welcome.

-

Chris, That will be a great shop when you're done. My shop is roughly 10X14 which is a spare bedroom next to the master bedroom. Keeping dust to a minumum in the rest of the house is a priority . Having said that... I use a heavy duty (somewhat) shop vac and it seems to work very well. When I use a machine, I move the vac to that machine. As space is a premium here, I can't put in a dedicated system with associated plumbing. I also run air purifier pretty much everyday and it also traps a lot of dus Here's the shop vac I use: https://www.lowes.com/pd/Shop-Vac-5-Gallon-5-5-Peak-HP-Shop-Vacuum/50159057 Here's the air filtration box I use: http://www.holmesproducts.com/deals/15-off-sale/holmes-allergen-remover-air-purifier-tower-with-true-hepa-filter/HAP716-NU.html#start=5 I hope this helps.

-

Gerhard, It's wonderful that you're back. I had to go Google the V8 solenoid engine. One impressive bit of hardware. I take it that these are all basically scratch-built? I noticed that they're producing some of the parts using a 3D printer.

- 72 replies

-

- bootlegger

- speedboat

-

(and 1 more)

Tagged with:

-

That's a tough one. I don't have an answer. See if this is any help as it's the only topic I could find where Apple isn't to blame. http://modelshipworld.com/index.php/topic/9689-photos-in-build-log-sideways If that one isn't a help, pop a post in the Site Suggestions and Problems forum. Or add on to the topic I found. Maybe the last post in this topic: http://modelshipworld.com/index.php/topic/12173-photos-upload-and-are-upside-down-how-to-fix

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Per, Are you using an Apple product to take the pictures? If so, that seems to be common. Open the pictures first in Windows Photo Viewer (if using Windows to access MSW). You can rotate them within that.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

If it's what I think it is, it was not uncommon back then, Dave. Another triple block would be below that hole. The lanyards went up to the triple which was seized to the lift harness of the main yard. Wasa has one for the main mast. But given the size of this beast, it may have had more.

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Computer routers

mtaylor replied to Greg the peg leg sailor's topic in Modeling tools and Workshop Equipment

That's really a laser cutter and not a router as such. I'd be very cautious using it as it's not enclosed. If it can cut wood, it can damage you. Also use it in a very well ventilated area as cutting some things, like mdf, releases toxic fumes. -

I had to look twice, Patrick. She looks right at home in the water and to the unknowing, they might think the real thing.

-

ARGHH! Plans needed for Mortar Vessel Convulsion UPDATED

mtaylor replied to bigcreekdad's topic in Wood ship model kits

Do a search from the main page and see who is or has built it and contact them. It's possible they haven't seen this post. -

Food for thought, Charlie. Would they have been painted to look like privateers? A form of camouflage? Given the choices, I'd pick the one's that please you.

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

Les, There's been a few topics on that that some searching should get you to. Basically, they used the main yards and the fore yards as booms with block and tackles. Pretty labor intensive work. Minor edit: Found one: http://modelshipworld.com/index.php/topic/2313-how-were-boats-launched-from-the-deck/?hl=%2Bship+%2Bboats+%2Blaunching#entry58384

-

That's great to hear, Buck. I'm looking forward to the double build.

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.