-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

What Mobbsie said, Kevin. Lacing looks excellent.

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

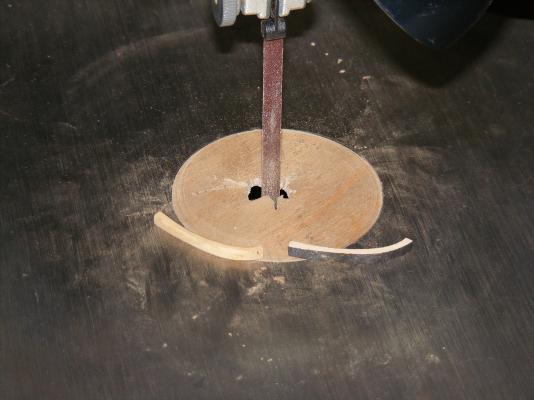

A minor update, model wise. A biggie for me. The stern is more or less complete. It still needs the carvings and the taffrail needs the finials but those are in-work and may be that way for some time as I move on to other things. I carve while waiting for glue to dry, etc. I was playing with the camera and some settings... here's the inboard side of the stern unplanked and then planked in silver maple. I'm using the maple where things would have been white-washed. The planked version also shows part of the taffrail installed. From the outboard side with part taffrail installed. This is the two other pieces of the taffrail on the scroll saw using the ScrollSander to clean off the laser char and finesse the fit. The final finessing was using a file and sanding sticks. And with the full taffrail installed. It needs a bit of cleanup and some wipe-on poly, but I'll that when get the carvings ready. The quarter galleries need to be built also before finishing. It's a bit off (about 1mm on the port side) but I'll live with it. All in all, I'm pretty chuffed about this as it was a big learning curve. I wanted the joinery perfect.. not quite there yet but to my eye, it looks good. Next up is the rudder while I sort out the quarter galleries. These have a bit of unusual shape in that they curve out past the stern and then back to the hull, like a half circle only not... Hard to explain but I'm researching and sorting it out.

-

Keep selling the Sculpy, Dave. With results like that, no argument here, only a "wow"....

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Like many things in life, Nenad, there's a compromise. A bit overscale won't hurt the final appearance and it's better to have the strength you need than to get way beyond this and suddenly the part breaks.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Wonderful work to see, Gerhard. Production work like this is never that much fun but when you figure out how do it, the rewards are well worth it.

-

Frégate d'18 par Sané , la Cornélie

mtaylor replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

Research is a fun thing just by itself, isn't it? -

ancre La Salamandre by tadheus - 1:24

mtaylor replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Joe, See Danny's log: http://modelshipworld.com/index.php/topic/11747-hms-vulture-1776-cross-section-by-dan-vadas-148-scale-from-tffm-books/?p=391772 -

I think that's a very astute observation, Greg.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Your efforts paid off well, Nenad. The pinrail is perfect.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

ancre La Salamandre by tadheus - 1:24

mtaylor replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Lovely, just lovely, Paul. I find the mast wedges interesting as they are different from what the English used. -

Pandora by marsalv - FINISHED - 1:52

mtaylor replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Just beautiful, Marsalv. -

Lady Nelson by Leo-zd - 1:119 - SMALL

mtaylor replied to Leo-zd's topic in - Build logs for subjects built 1751 - 1800

Leo, Thanks for the explanation. It's such a great looking bell. -

Uh, Robbyn.. I like the idea but don't copy what's on the plans with the copper. The plans are flat and your hull is curved. Line off the hull per the plans (much like spiling) and work the copper that way. If you'll go to the Victory and Contitution sites and look at the copper, you'll see they are really "even" and straight. The copper has to be fitted due to the curve of the hull.

-

The word "spectacular" comes to mind seeing this....

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Lady Nelson by Leo-zd - 1:119 - SMALL

mtaylor replied to Leo-zd's topic in - Build logs for subjects built 1751 - 1800

Nice looking ship's bell... is it wood or metal? Either way, it's great.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.