-

Posts

4,894 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

I have the Excalibur 21", purchased through Carbatec and have been delighted with it. If you pick your timing right, you can get it for about $200 or so less than their regular retail - they go on sale periodically. The only issue I had with mine was a breakage in the upper drive link assembly. It seems that since I bought mine, they changed the design and "designed out" the part that failed - which is a long way of saying, you won't have the same problem! Carbatec were excellent in their support service and helped me to identify the new parts I needed and then sent them to me very quickly. In short, it is an excellent machine and well worth the money. Best of luck with your shopping!

-

Very nice work so far Gary. Love the extra detail on the gun deck.

- 85 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

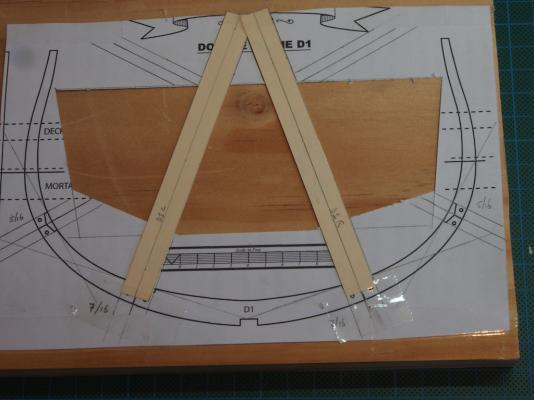

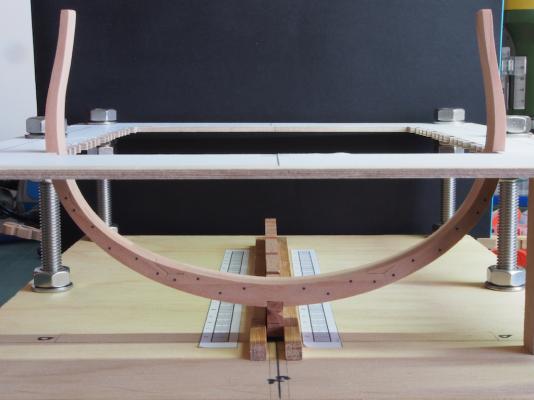

Revised Chock Making Method I wasn’t entirely happy with the chocks in my test frame and decided to try a couple of different methods. In the end, this is what I did. I first marked up some “construction lines” on the frame template, and then cut a cardboard template strip (from a manila folder) to suit the width of each of the chock sizes: Then I held the frame sections in place over the template and traced around the inside of the scarf joint to mark the chock shape onto the template. The shape was then transferred to the chock “stock” and finessed to shape on the Byrnes Disc Sander: This worked reasonably successfully, so will continue with this method for the remaining frames. Here’s a shot of the finally finished frame D1/D2, complete with blackened bolts, in position in the jig. Now to make a few more……..

- 456 replies

-

- finished

- bomb ketch

-

(and 2 more)

Tagged with:

-

Hi Sean, The smaller blocks are definitely an improvement and they look okay with the frapping. The only other thing I could suggest would be to have a look at Dafi's photo etch material that he supplies for a 1:100 scale Victory. I would think that the scale difference would work in your favour here. Might be worth investigating/considering.

-

Looking terrific there Bob. As Augie said, enjoy the holiday/family time, but as this is to be an "extended" visit, I'm sure "time off for good behaviour" will allow you the occasional visit to the shipyard!

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Congratulations on reaching a major milestone Mark. She looks great and I can't wait to see the planking started. You must be feeling very pleased with yourself - and rightly so too, especially after the brave decision to start over when Ver 1.0 wasn't going to plan.

-

Lovely little touches of detail to complement your fine build there Gil.

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

I'm with Toni here Remco!!! And for Remco's next miniature challenge....................

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Hi Sean, I just went and counted what's on my model and I have 30 plus 10, so it looks like Mamoli has stiffed you two guns/carriages. If you can't get replacements (which might be difficult after the fire they had), then two options might be to leave one port closed on each side (say, under the poop deck), or leave two ports closed on the "wall" side.

-

Pen Duick 1898 by Mfelinger - 1:20

gjdale replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

Just found your log Matija. Beautiful work so far - I just love your decking. I'll pull up a chair and follow along from here too. -

A very nice collection there Ray. Diana is looking superb.

- 536 replies

-

- diana

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Dave, that's a good thought and worth consideration. I'll probably stick with the copper wire though as it gives me what appears to be a pretty satisfactory outcome.

- 456 replies

-

- finished

- bomb ketch

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.