-

Posts

2,020 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by tlevine

-

-

-

I have finished the base. I am not totally satisfied with it but it will do for the time being. The base is marble and the edges were roughened up. The pedestals are turned from pear and drilled to accept a threaded rod which screws into a captive nut in the keelson. Thanks everyone for following this five year epic journey.

- herask, Chuck Seiler, Maury S and 43 others

-

46

46

-

For a wood model such as Bluenose, get a small bottle of yellow carpenter's glue. That small bottle will last for several kits. One of it's advantages is that it is dissolved with isopropyl alcohol. There are a lot of builders who swear by CA but I rarely use it. For those times that you need to bond dissimilar materials, two part epoxy is your best option.

-

My best advise is to buy the best tools you can. Don't waste money on cheap equipment. For this build I would suggest using sanding blocks and sticks instead of a plane. Glue the sandpaper to various shapes and lengths of wood to give yourself a variety of configurations. I have never used the fine tooth saw blade. Pop for a few good jeweler's files. Start with a medium flat, triangular and round. At this stage you probably don't need chisels. #11 Xacto blades will substitute for them. Add a Dremel to your list. I prefer a battery tool but it is heavier than electric. Consider getting a self-healing mat to prevent marring your workbench. And don't forget good lighting!

-

I would never consider using a scalpel for heavy duty work. The blades are designed to incise flesh, not wood or plastic. They also cannot be resharpened the way an Xacto can. For myself, I find the #7 handle superior to the more typical #3 handle. I have a small hand and this handle allows me to grip the handle with my fingers almost completely extended, allowing me to look over my fingers to the workpiece more easily.

-

-

-

For those of you trying to decide whether to become a full member of the NRG but did not want the hassle of a print Journal, the Board has an exciting announcement. The Journal is now available in a digital version in addition to the print version. Check it out by going to the NRG Home Page and follow the link.

-

Maury, I have a couple of things to keep me busy. Atalanta still needs some final cleaning and touch-ups. I also plan on doing a little more on the Echo x-section. Finally, it is time to learn a little CAD so that I can loft my own plans. Who knows what else I will come up with.

- mtaylor, billocrates and Martin W

-

3

3

-

-

Dowmer, I tried stub masts a while back and decided that I did not like how they looked. But thanks for your suggestion.

- hollowneck and mtaylor

-

2

2

-

Gentlemen, I appreciate all of your observations. Although she still looks a little clunky compared with the masters on this site like Doris, it is the best I can do. I promise you that I am a much better surgeon than a sculptress. I have lowered the figurehead, making sure the bowsprit clears the top of her head. I have also re-positioned her so that she looks to the horizon. I started painting with a coat of acrylic gray primer. The clay soaks up the paint and this helped seal it. The rest of the painting was done with various acrylic paints. The apple and the buttons on her skirt are gold leaf.

At this point all that remains is cleaning the ship, touching up the black paint on the wale and installing a base. I do not plan on masting and rigging her.

-

-

I have started work on the dreaded figurehead. I decided to make her out of clay rather than attempt carving. I felt sorry for the wood that I would butcher. Thank you to Chuck for his clay sculpting lesson and thank you to David Antscherl for carving a figurehead of Atalanta for Chuck. The photos he took and posted on MSW were a godsend. Here is the link to those photos.

This is a copy of one of Chuck's photos of Atalanta. She is holding a golden apple in her right hand. The first thing I did was make a wire armature. This provided more strength to the arms and legs. I mounted the armature over a mock-up of the stem.

The first layer of clay was applied. I was not too careful with this as it was simply a base to build upon. I used white Sculpey clay with a few drops of softener added. After every significant addition I baked the clay per the instructions to harden that section. I think the biggest piece of advise that I can give is be careful with your proportions. Stand in front of a mirror. Your wrists hit the femoral head. Measure a female hand for the correct length (mine is 6"). How long is your torso in relation to your legs, etc. The breasts are not cones, as you can see in the picture above.

I decided to add the clothing and hair after I had the proportions correct, leaving the details of the hands, feet and face for last.

After the other details were completed I test-fit the figurehead to the actual stem. I discovered that I had forgotten to incorporate the taper of the stem on my mock-up and had to add extra clay to the medial thighs. Obviously there is still some finesse work remaining. I have a question for the members. Should I paint it white to minimize losing detail or in natural colors (white robe, dark brown hair, tanned skin). The apple will be gold, either way.

-

Greg had drawn it to my attention that when I rebuilt the rudder head cover I had forgotten to add the sill. Greg, this one's for you! You can also see the gunport tackle and tubes. The tubes are made of leather which I simulated with rolled paper dyed with brown Rit.

The rudder chain has been installed. It attaches onto the spectacle plate with a U-shaped tackle. The last things on my punch list are the figurehead, cleaning and paint touch-up. After my experience with the upper quarter carving the figurehead has me terrified.

- Vivian Galad, JOUFF, coxswain and 26 others

-

29

29

-

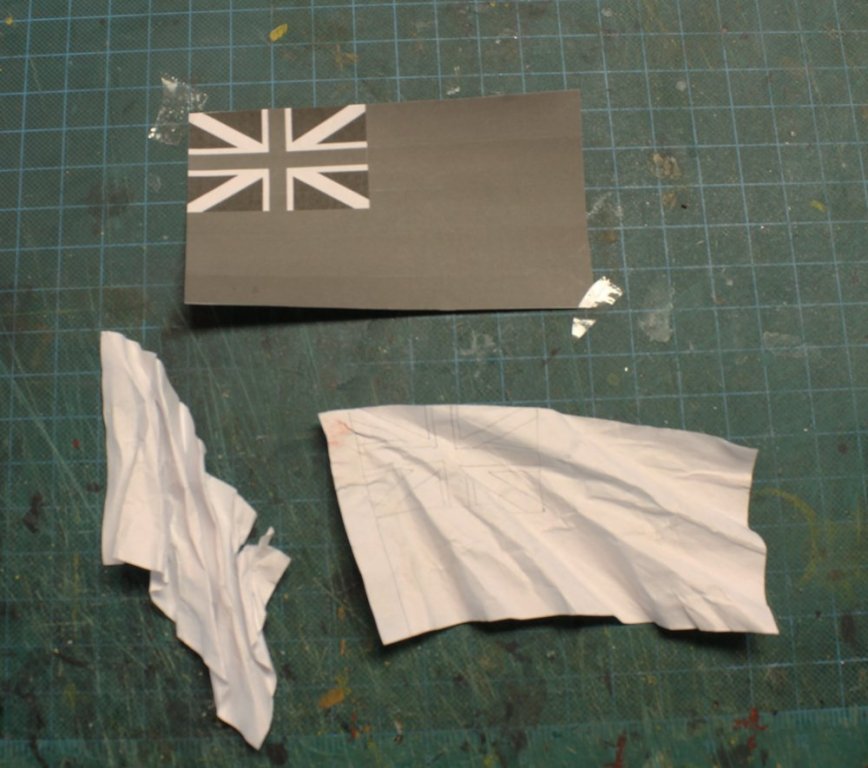

I debated back and forth whether I should put a flag on the ensign staff. Although few models of this style are shown with flags, I decided to make one. My reasons were that the model needed a pop of color and I had never made a flag before and wanted to see if I could do a good job.

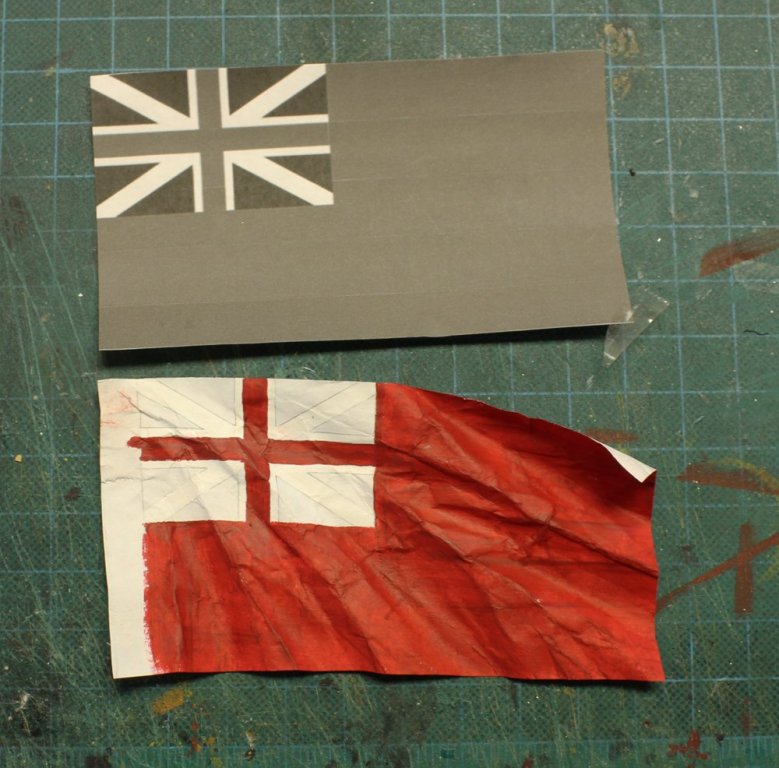

The technique that follows is exactly what was demonstrated by Gus Augustin at an NRG Conference a few years ago. I determined that the correct flag for 1775 was the red ensign. I drew the outline onto both sides of a piece of plain copy paper with pencil. Next, I cut the flag out, leaving extra paper inboards to make straps to secure the flag to the staff. The flag was shaped by crushing it in my hand, being careful to leave the inboard edge flat.

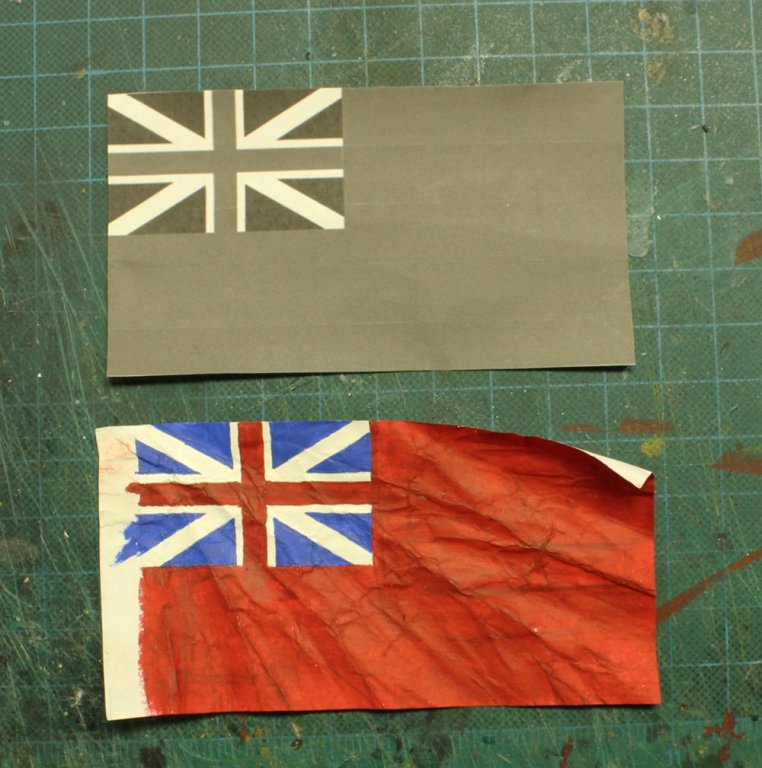

The flag was gently wet in a bowl of water and the crinkled shape was formed after laying the wet flag on a piece of glass. I did not touch it again for a few days but Gus states that one should wait at least 24 hours. The flag is then (sort-of) flattened and painted. Start with the light colors and gradually go darker. I used Poly-S and Model Master acrylic paints full strength.

Once the flag was dry I air-brushed it very lightly with gray to soften the colors. Finally, I reformed the flag and secured it to the staff. Overall, I am pleased with the appearance.

-

Karl, thanks for the tip. Some beautiful carving on those models. As my punch list has gotten smaller, I could not put off the upper quarter carving any longer. On both the plan and the contemporary model I could not tell for certain what the creature was. Because of the tail, I had to choose between a dragon and a lioness. I decided upon a lioness because that is what Atalanta was turned into after she had sex in a temple. The first thing I did was make an oversized mock-up of the carving out of Sculptey. Then, I made a second mock-up that fit into the space. Once I was satisfied with that I drew the outline on to a block of English boxwood. The color was a good match for the costello boxwood and I wanted the extra strength because of the tail.

After a few failed attempts, the lioness slowly came out of the wood. The hardest part was the head, both the direction and appearance. Although in the pictures the face looks more like a bear than a lioness, it was the best I could do.

-

-

I have spent the last few weeks constructing the lantern. I used the brass photoetch from Admiralty Models for the carcass. Rather than post a step-by-step construction, take a look on their website. http://www.admiraltymodels.com/Tips.html The document is at the bottom of the page. The exterior was painted to match the wood and the interior was painted red. The candle is a roll of paper and the glazing is mica. The crank is brass which was cut and filed to shape. All metal was blackened.

-

The larger the number, the larger the diameter on DMC thread. When I started making my own line I purchased all of the sizes 20-100 and made test line do determine the diameter of the completed line. (All you need is a few feet.) The diameter will be different for right-hand vs left-hand line so if you plan on having the correct lay for the different lines you will need to lay up both left and right-hand test line. Remember, the line diameter will vary a little based on your individual technique.

-

One of the other reasons beginning modelers become discouraged is the length of time required to finish even a simple model. Most of us have built a number of plastic kits, either as a kid or an adult. Unfortunately, that leads to an expectation of accomplishment in a short period of time. To us, a quick model means completion in less than a year!

- Nirvana, JJolley, Frank Burroughs and 4 others

-

7

7

-

-

-

- dvm27, GrandpaPhil, VTHokiEE and 13 others

-

16

16

HMS Atalanta 1775 by tlevine - FINISHED - 1:48 scale - from TFFM plans

in - Build logs for subjects built 1751 - 1800

Posted

I am bringing her to Las Vegas, Chuck, although the thought of having her on the back seat all the way from Chicago and back is giving me chest pain. There will be no sudden stops!