-

Posts

2,870 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by md1400cs

-

JIm, Saved an image of your sump pump - may try and scratch build one as well - Like your made mast also on my list - nicely done indeed. Regards,

- 66 replies

-

OC. As always big thanks Frank: No, I don’t have a thickness sander nor the room for one 🙁 --- Thanks for your offer – nice of you. The pear wood happens to be .5mm, and I am one of those stubborn builders –who never put any sealers on his projects – I prefer the look of unsealed wood. This current build is only my fourth in 40 years haha. First one still looks just right. (Santa Maria) I do understand why most builders add sealers – it does make a lot of sense. Peter: Welcome aboard, thanks for your overly kind words, much appreciated. I have followed your work and learned much from your logs, again thanks and welcome aboard – Yes the dummy carriages do help. Thanks mates for your likes, comments or just taking a look.

-

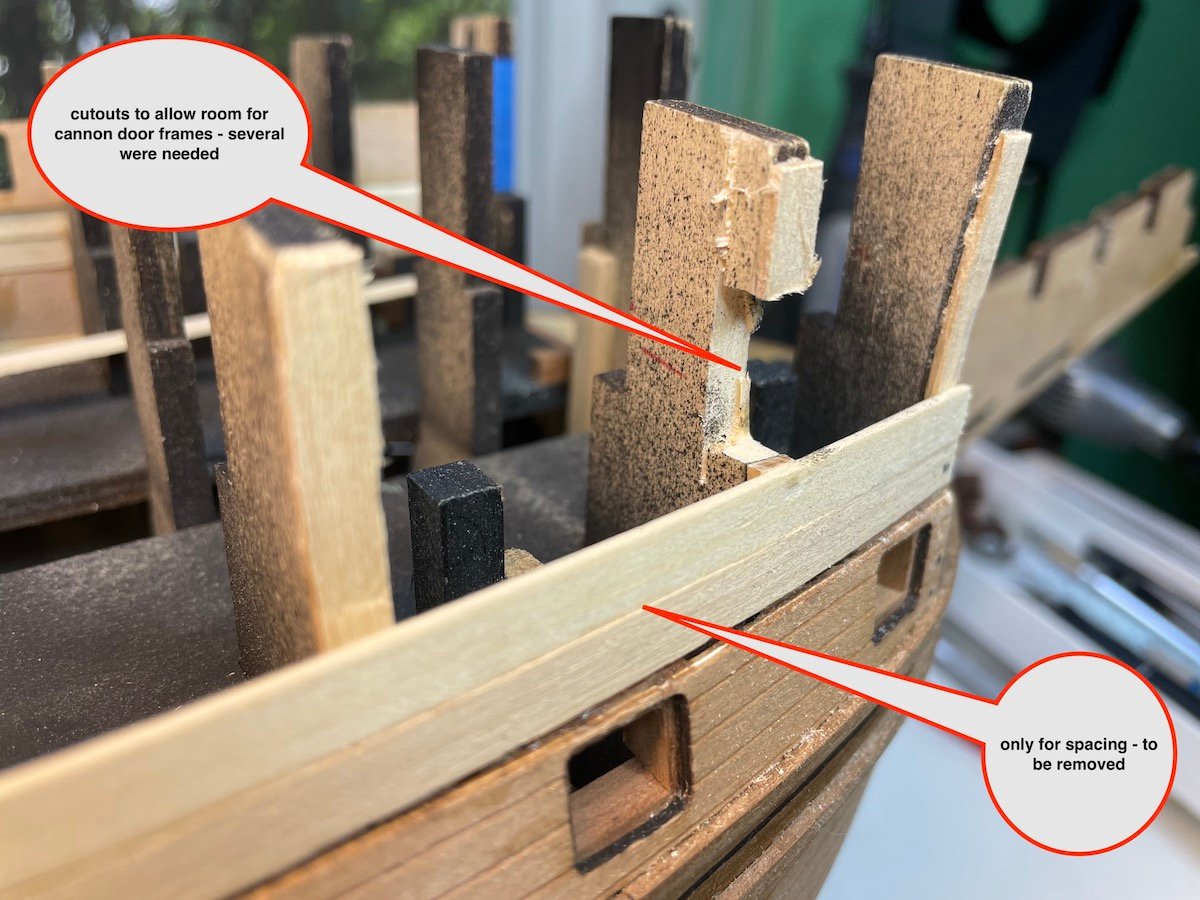

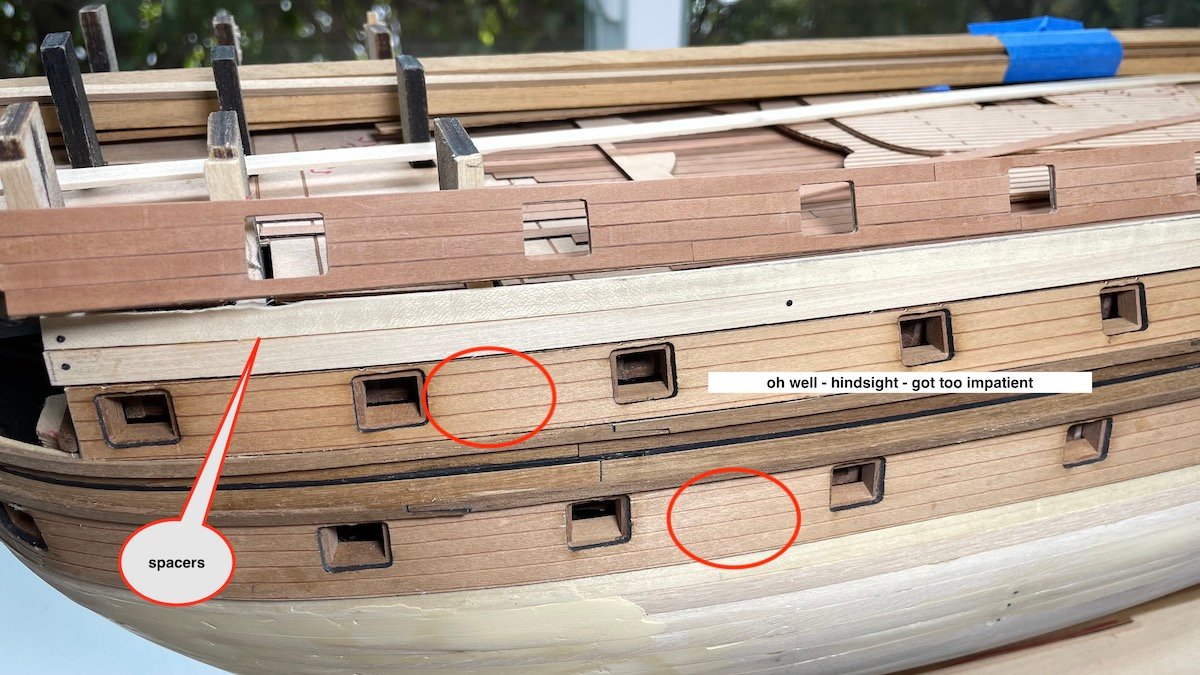

Hi All, Minor update but wanted to share a first big visual mistake – images are self explanatory – so will leave it at that. Should have taken the time to do the extra work. As always thanks for your kind likes, comments or just dropping by. Also big welcome aboard to new members who have chosen to start following this log. Thanks mates.

-

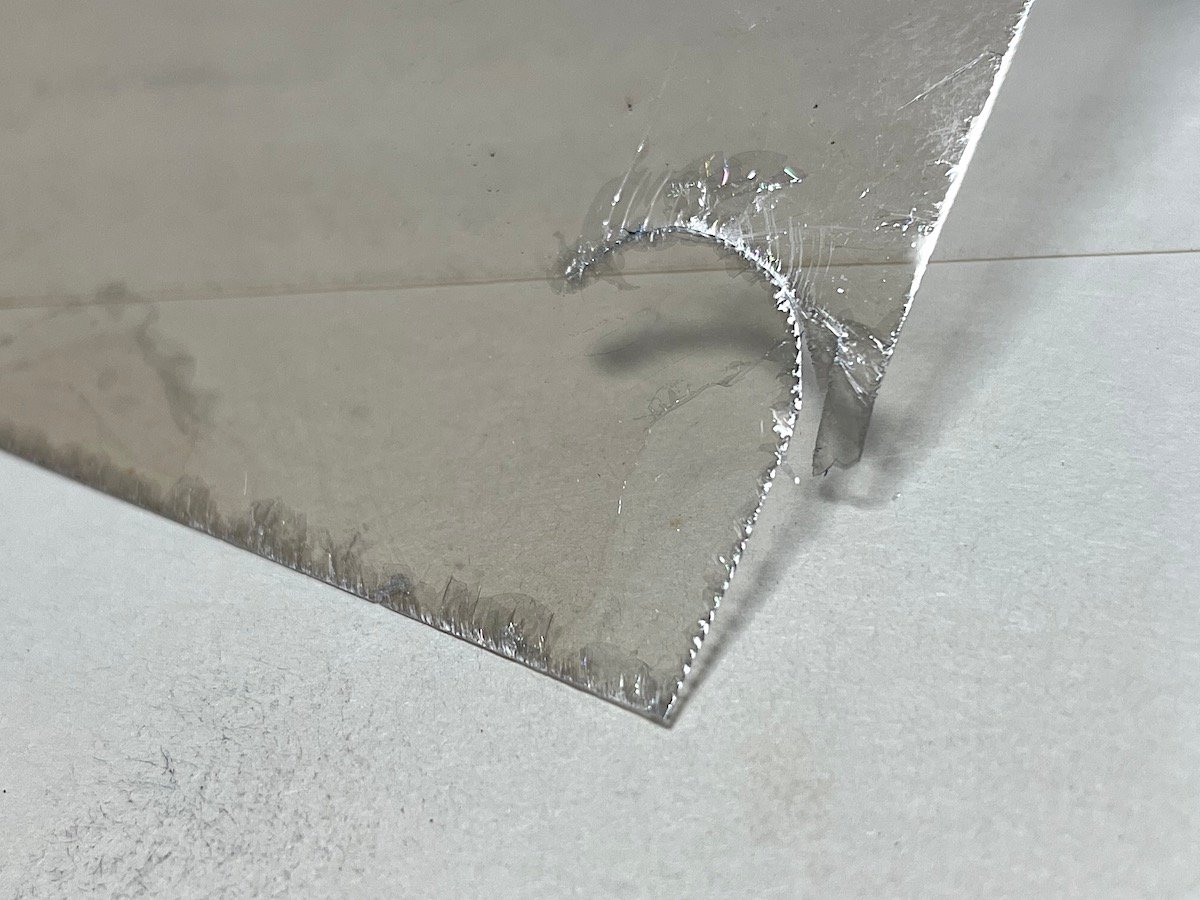

Frank, After our nice conversation - I got curious about your idea of using a Dremel wheel to smooth out the edges. - I used the wrong kind of scissors in the above image . Mica will cut nice and clean.

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

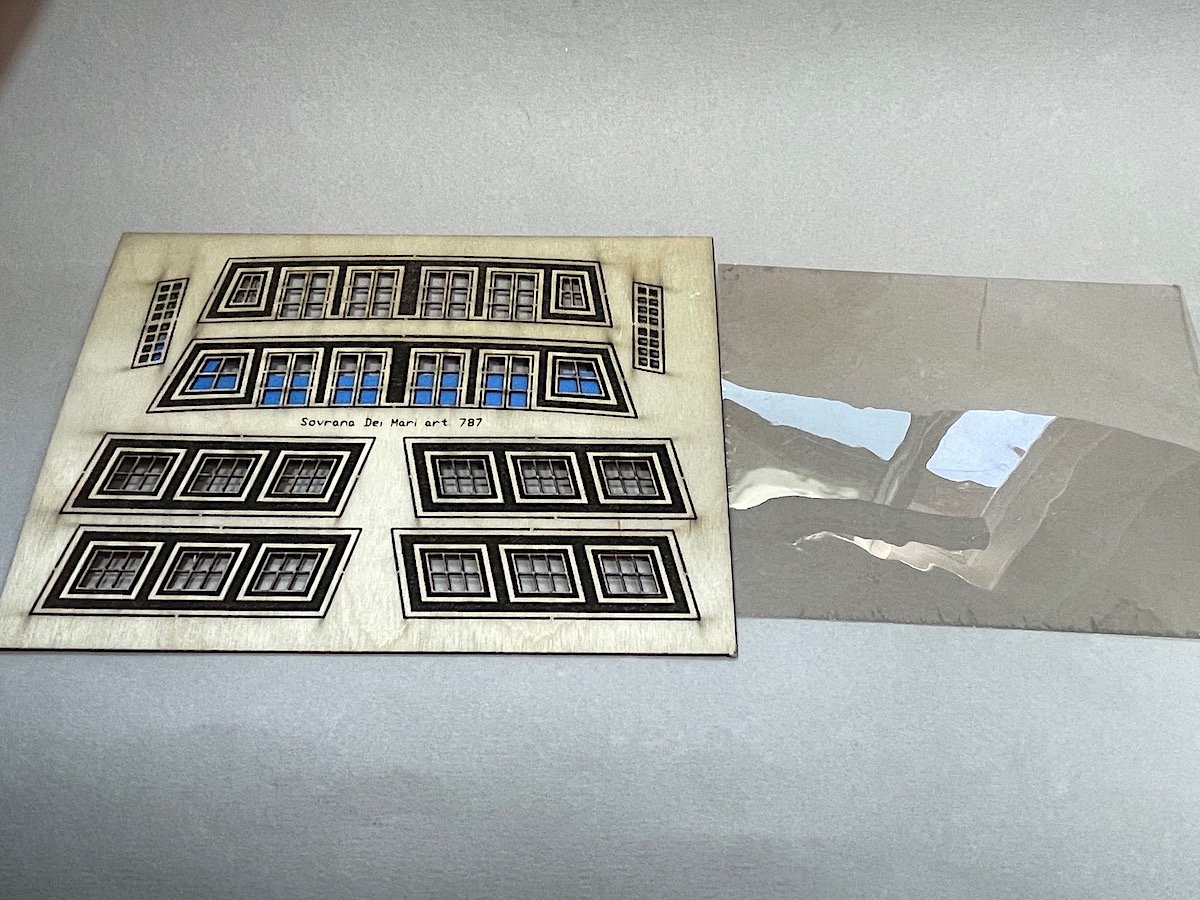

Frank, It is paper thin. But since it is a silicate mineral - cutting it leaves edge marks. I was intending to cut larger size sheets to place behind windows edge to edge, since in my case windows are only seen from the outside. Your project would make this difficult. But for other projects, great idea. As as far as glue - don't know will need to experiment

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

Frank, I have been thinking about your current log, and the window "issues" - this might be too late but I have discovered what should be a great alternative to clear plastic sheets. Mika - found on eBay - the great positive of these sheets is that they are slightly "wavy" looking and show up "defects" as glass would of the earlier centuries. I will use these sheets on my current project for the dozens of needed glass panes. Here are a few images FYI. Hard to capture the actual look of these, but this should give you an idea - does add a lot to realistic looking glass IMO. PS: very thin and easy to cut with scissor --- Love your log awesome build !! Regards my friend

- 510 replies

-

- reale de france

- corel

-

(and 1 more)

Tagged with:

-

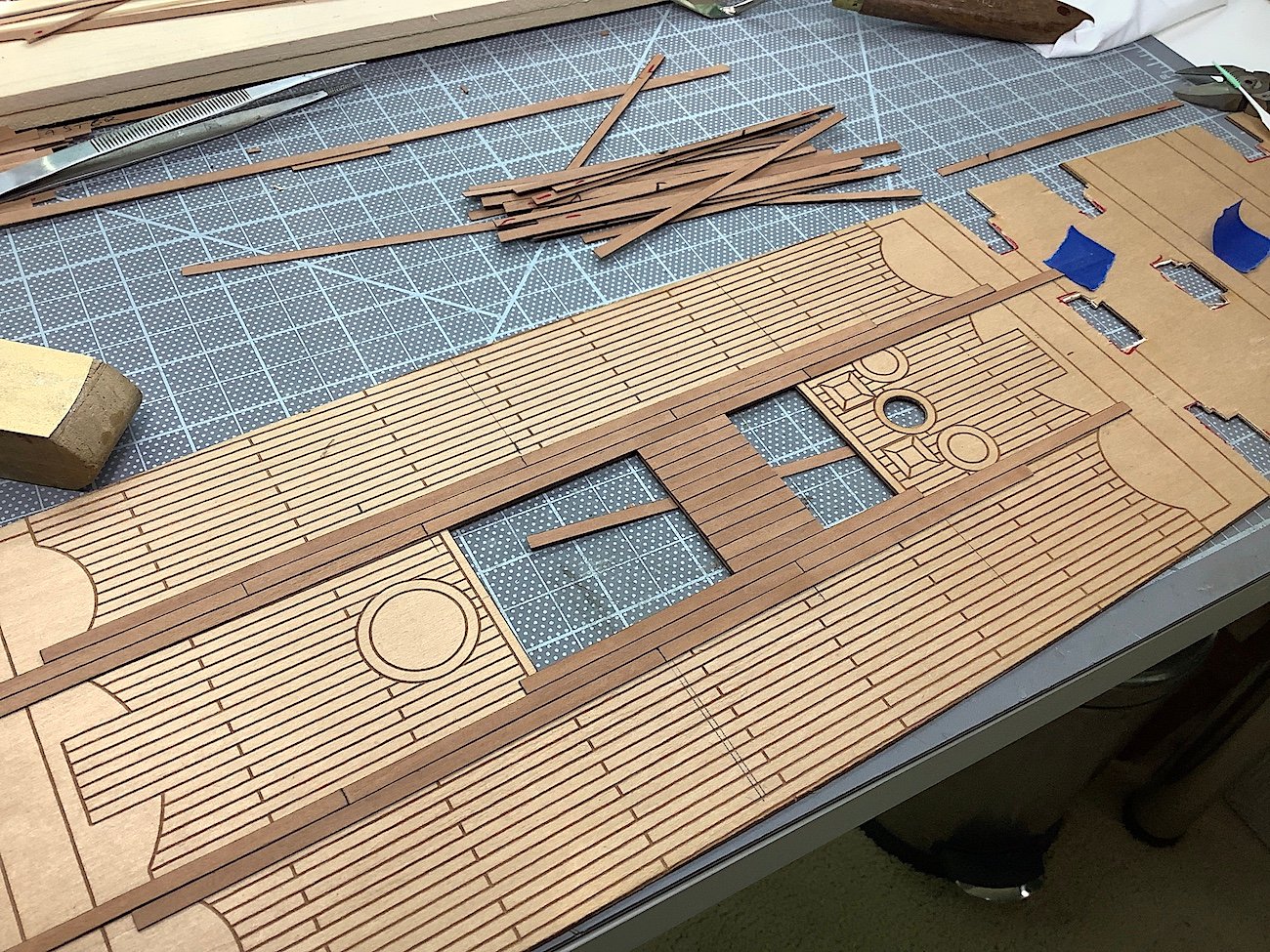

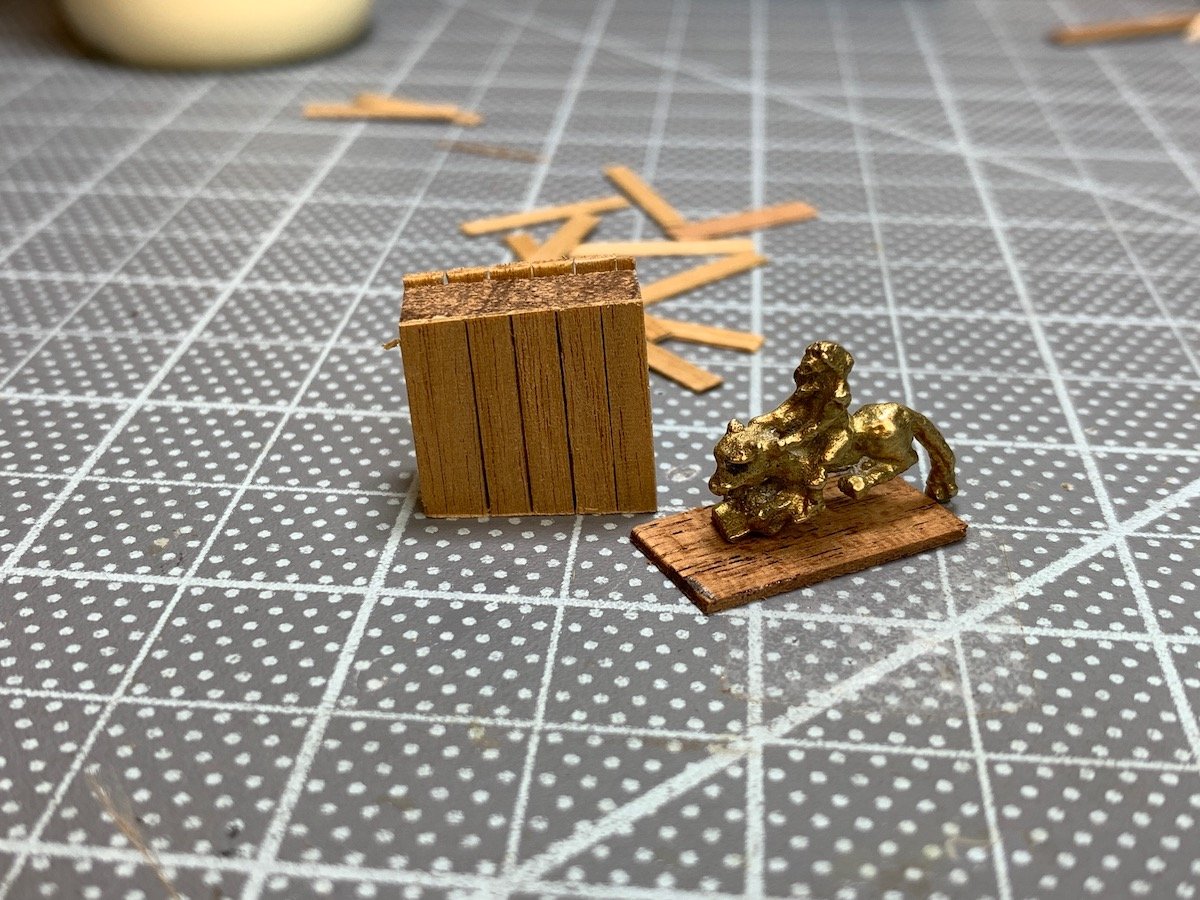

Patrick: thanks as always Frank: The current upgraded Sergal SoS includes all pre-scored decks which they consider to be "finished"planking; saving the builder time from having to plank the decks. So they don't include planking strips. The vintage kit supplied blank decks, but included some strips for planking. All well with us thanks for asking!! Cheers,

-

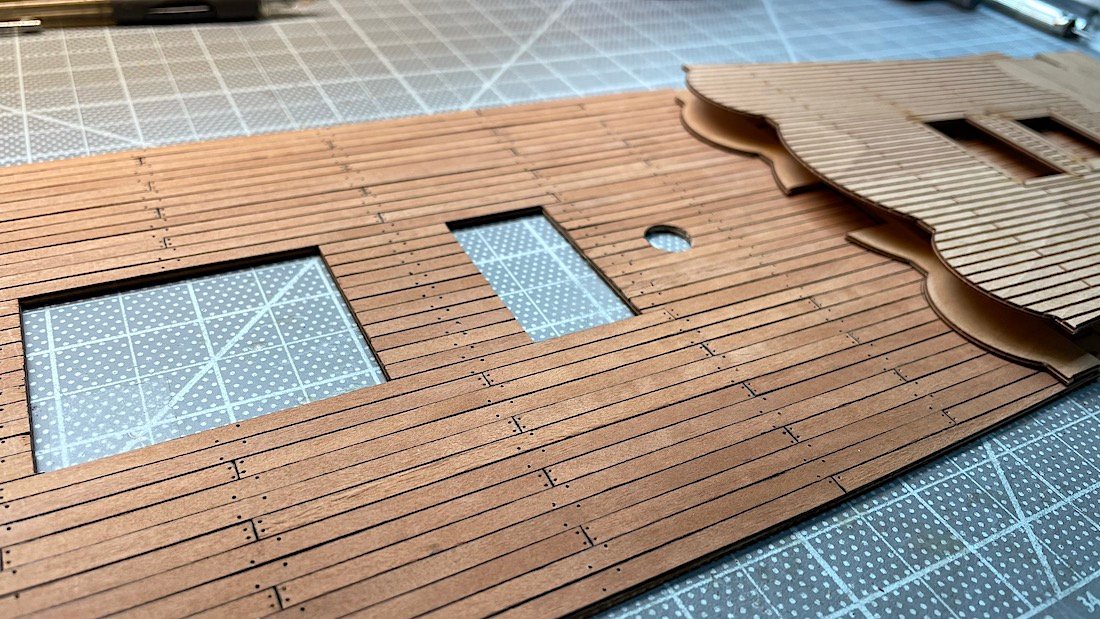

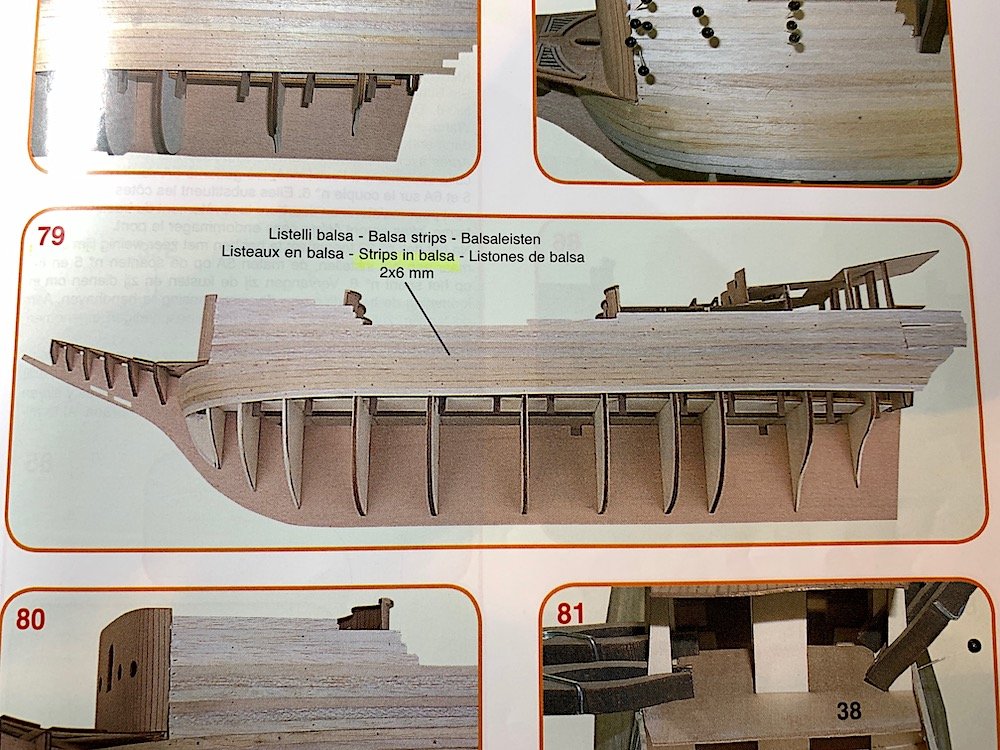

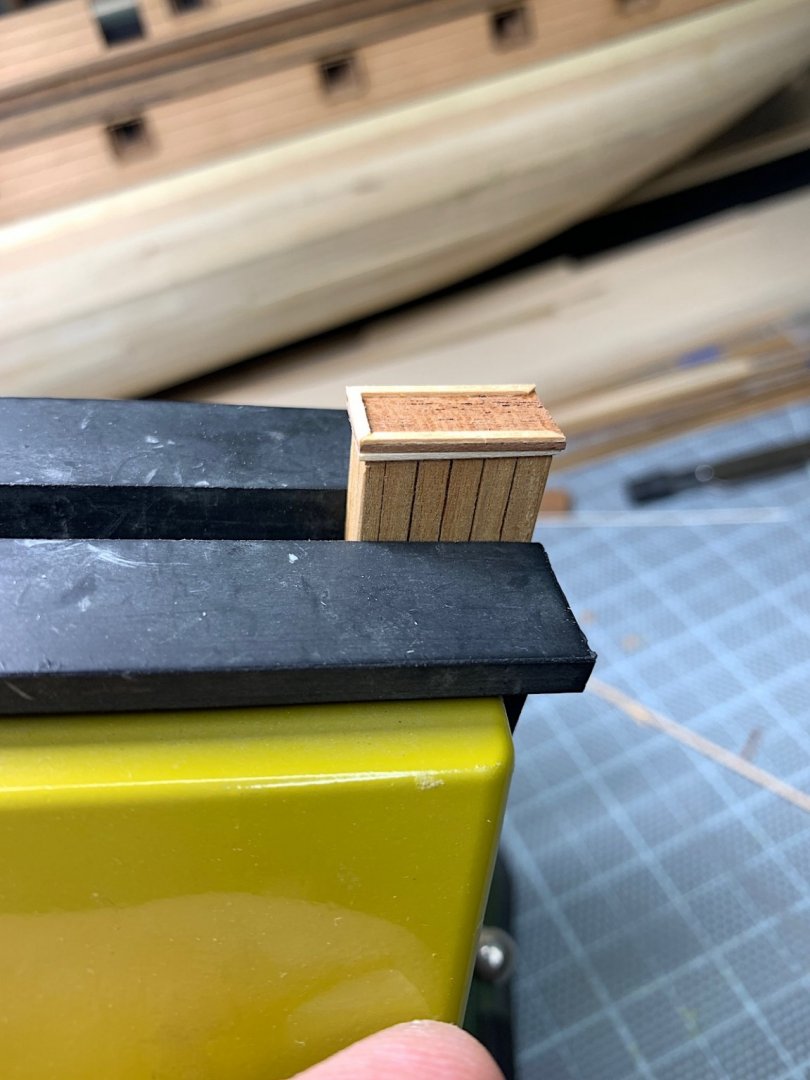

Hi All, Finishing up hull first planking and sanding. PS: I've been so impressed with other builders whose first planking will probably look better than my second hull planking 😁 I still need to use wood fillers - also hard to see if there are any slight indentations - second Pear Wood covering will hopefully all run nice and even 🙏 Will now start planking the main deck with Pear Wood using the current kit's template as a guide. This will be more fun haha. Got great planks from Cornwall in the UK. Regards,

-

Jim, Your cross section project is really "very very special" Cheers,

- 66 replies

-

Thanks, Finally your update -- now I can finally get a good night's rest PS: Nice planking !!

-

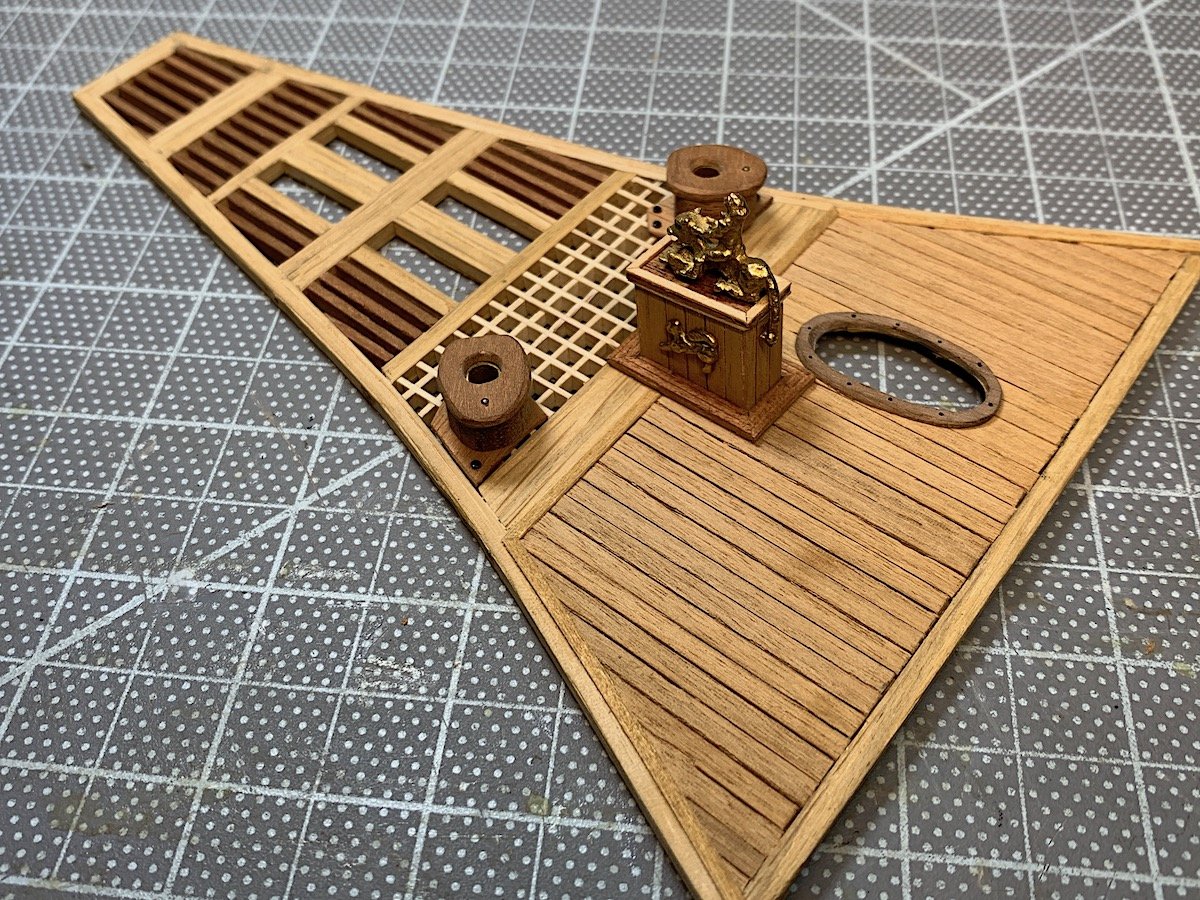

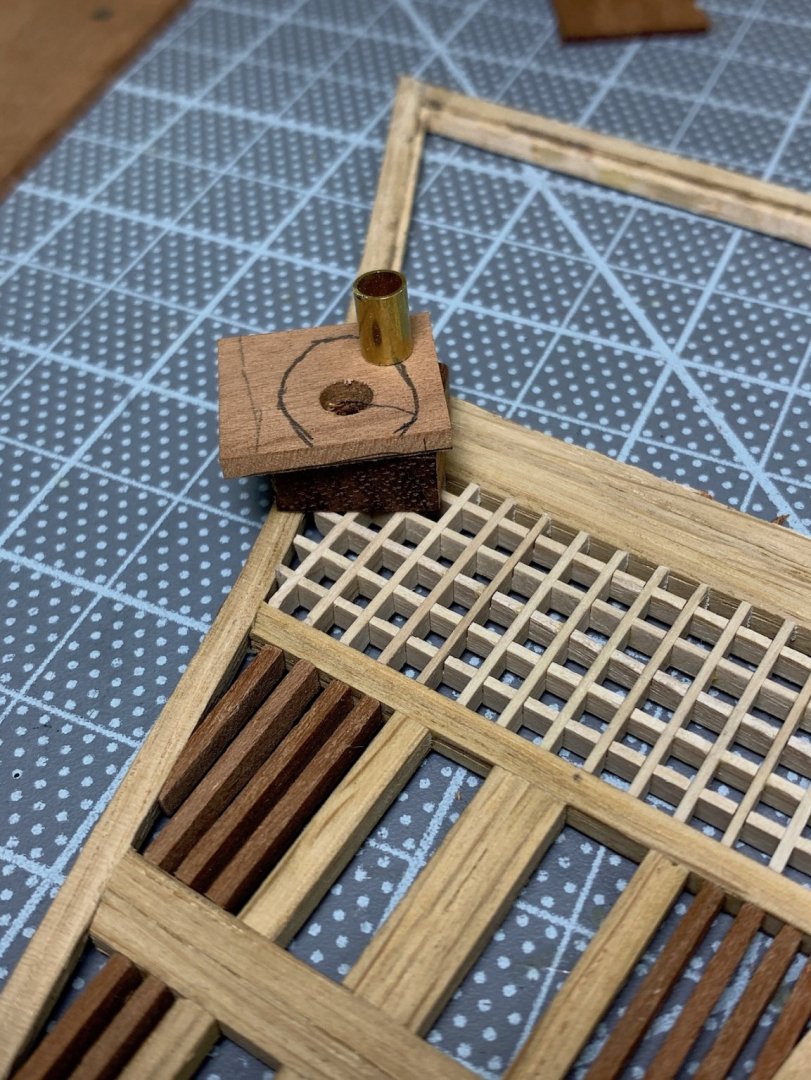

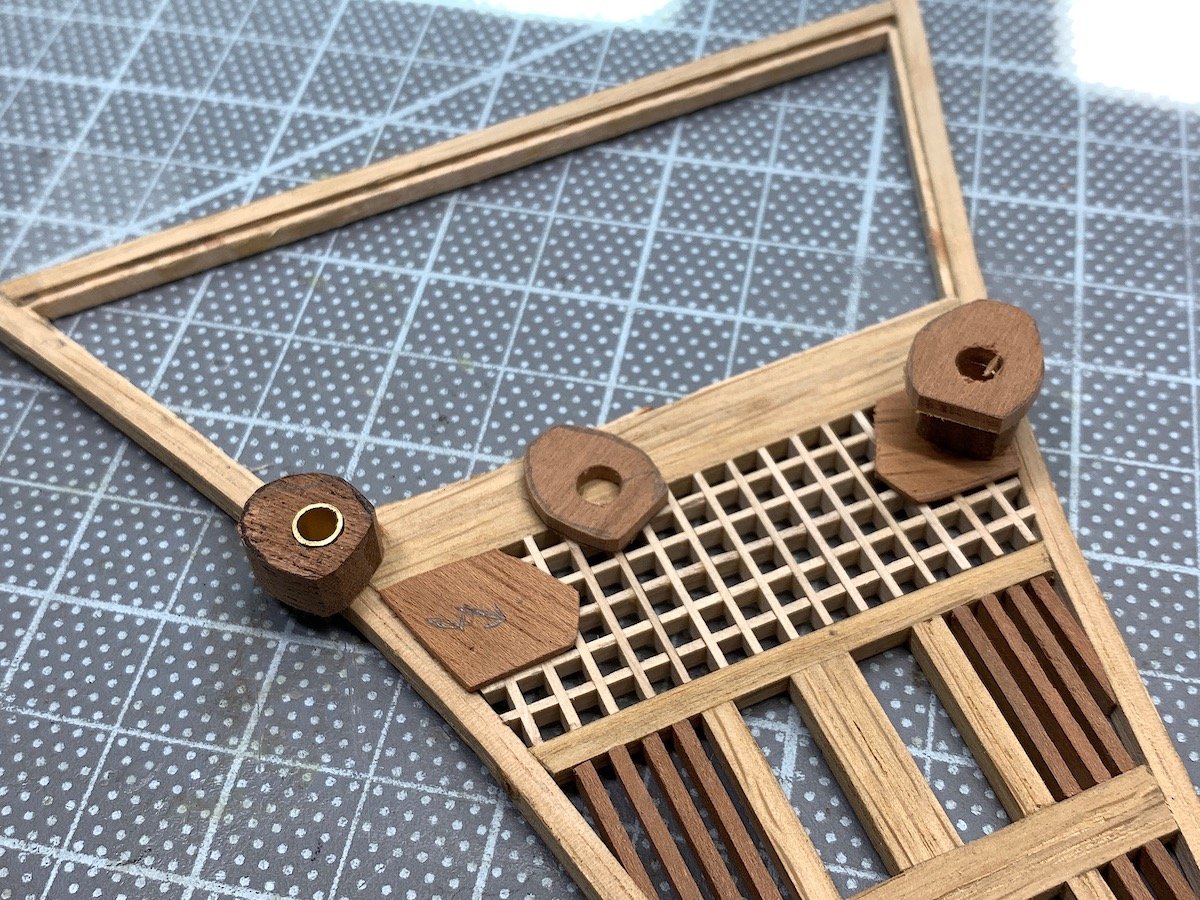

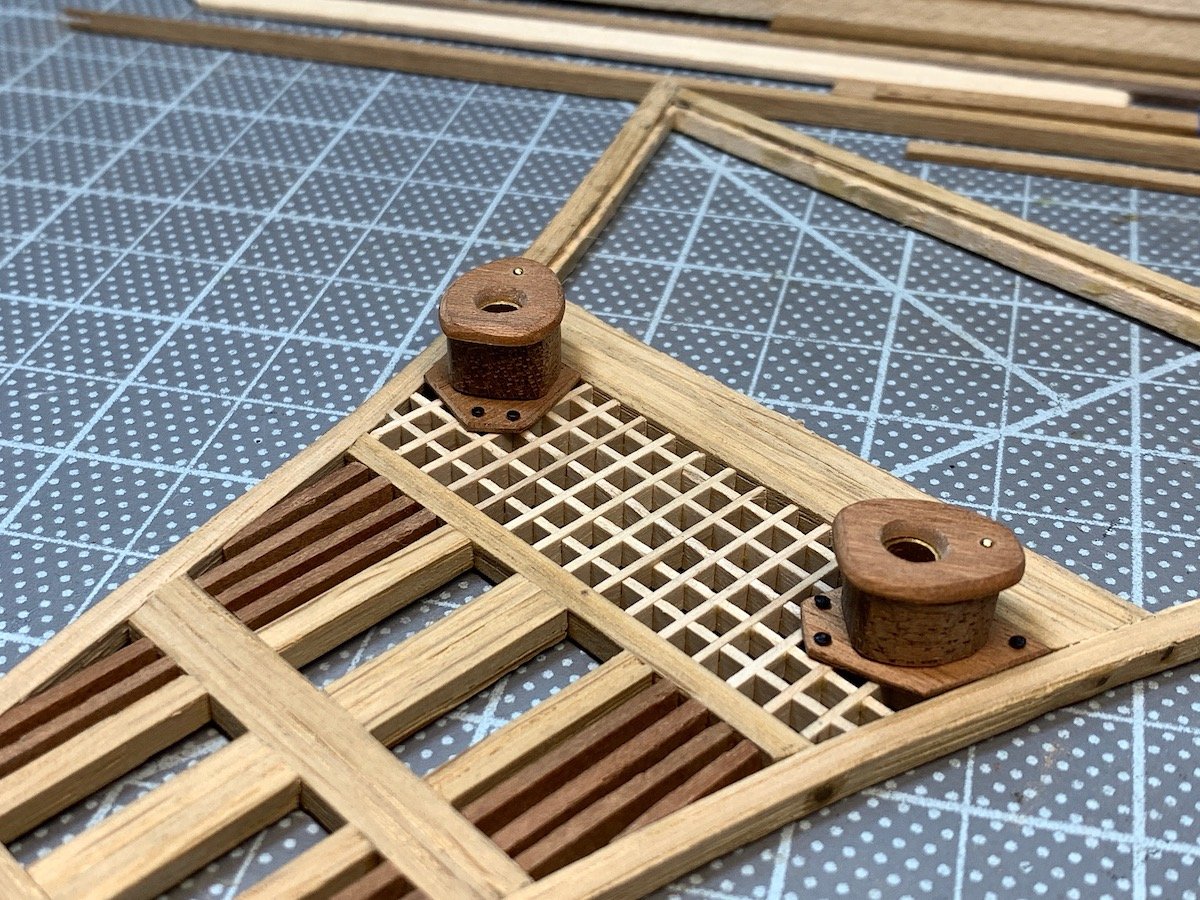

OC: Thanks appreciated --- Funny - actually after I add the side railings I will also add a small “hold onto handle” on each side of these first class (up front) loos, 😂 Small update; finished up the bowsprit beakhead deck as well as detailing the area where the mast comes up and through the planks. The last image is obviously the kit provided bit. Thanks for you visits sand kind words.

-

Robert, Very excellent work masts and caps

- 527 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

Patrick, comme toujours un très bon travail. !! Je ne sais pas si votre deuxième langue, après le néerlandais est le français - je suis né en France donc c'était ma première .... Je pratique juste haha - J'ai aussi vécu au Mexique quand j'étais adolescent, j'ai épousé un Brésilien donc juste par «chance» pas par intelligence, je peux parler quatre langue hmmmm Many Europeans speak three - two are very common indeed.

- 756 replies

-

- galleon

- golden hind

-

(and 2 more)

Tagged with:

-

Jim, Just catching up - as always with your log I need to refill my coffee and stay a while - brilliantly worked out details. Regards,

- 66 replies

-

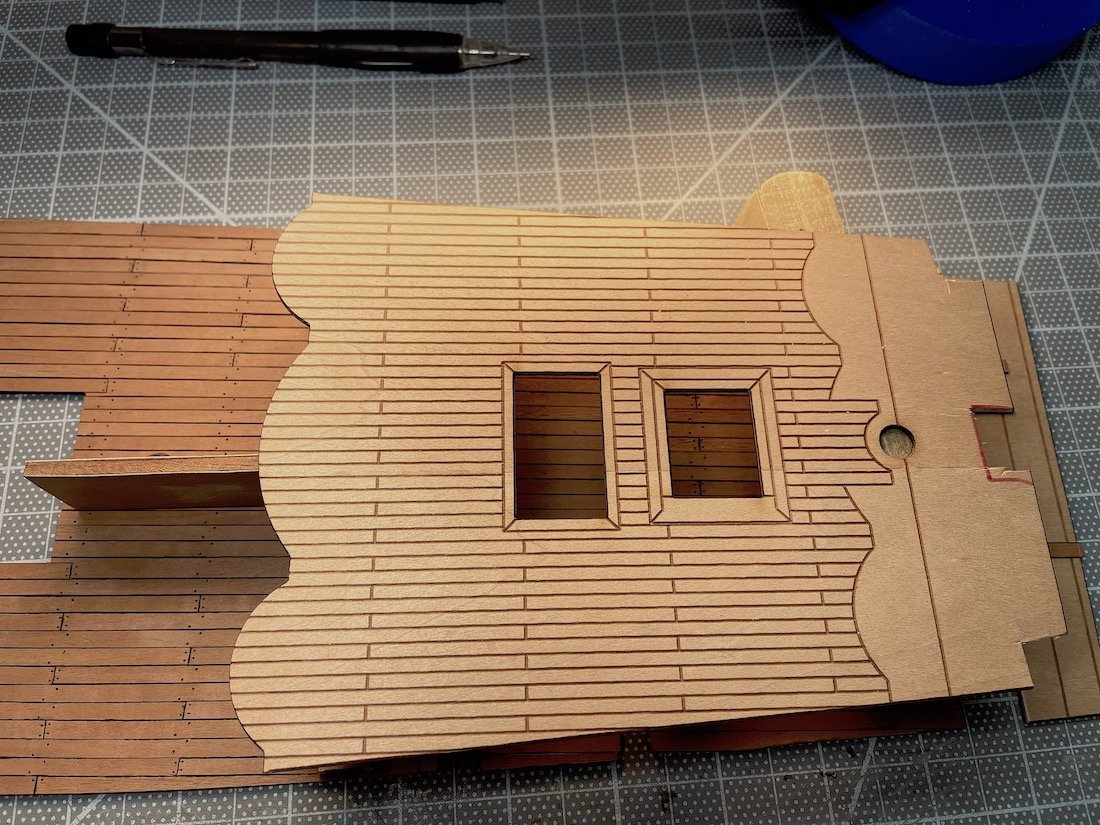

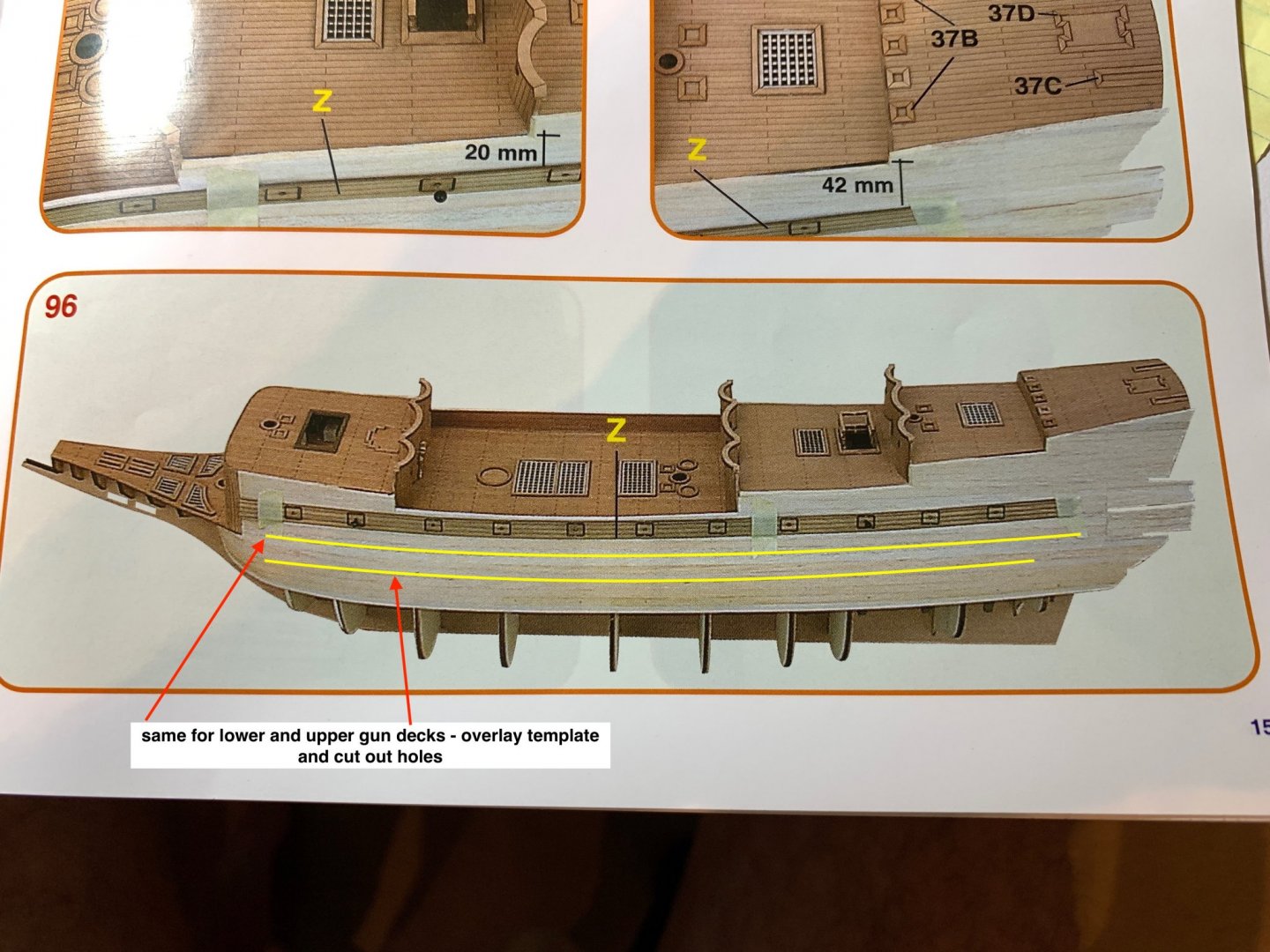

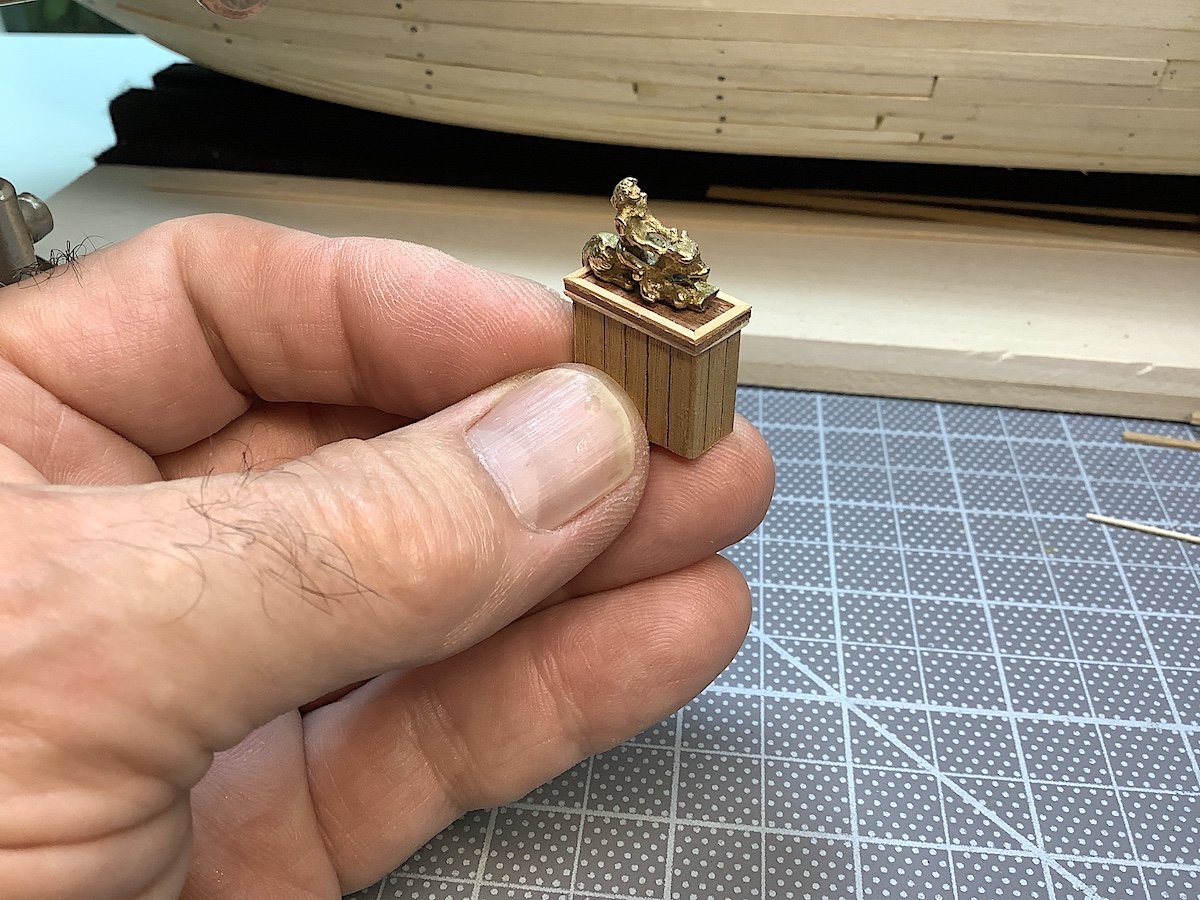

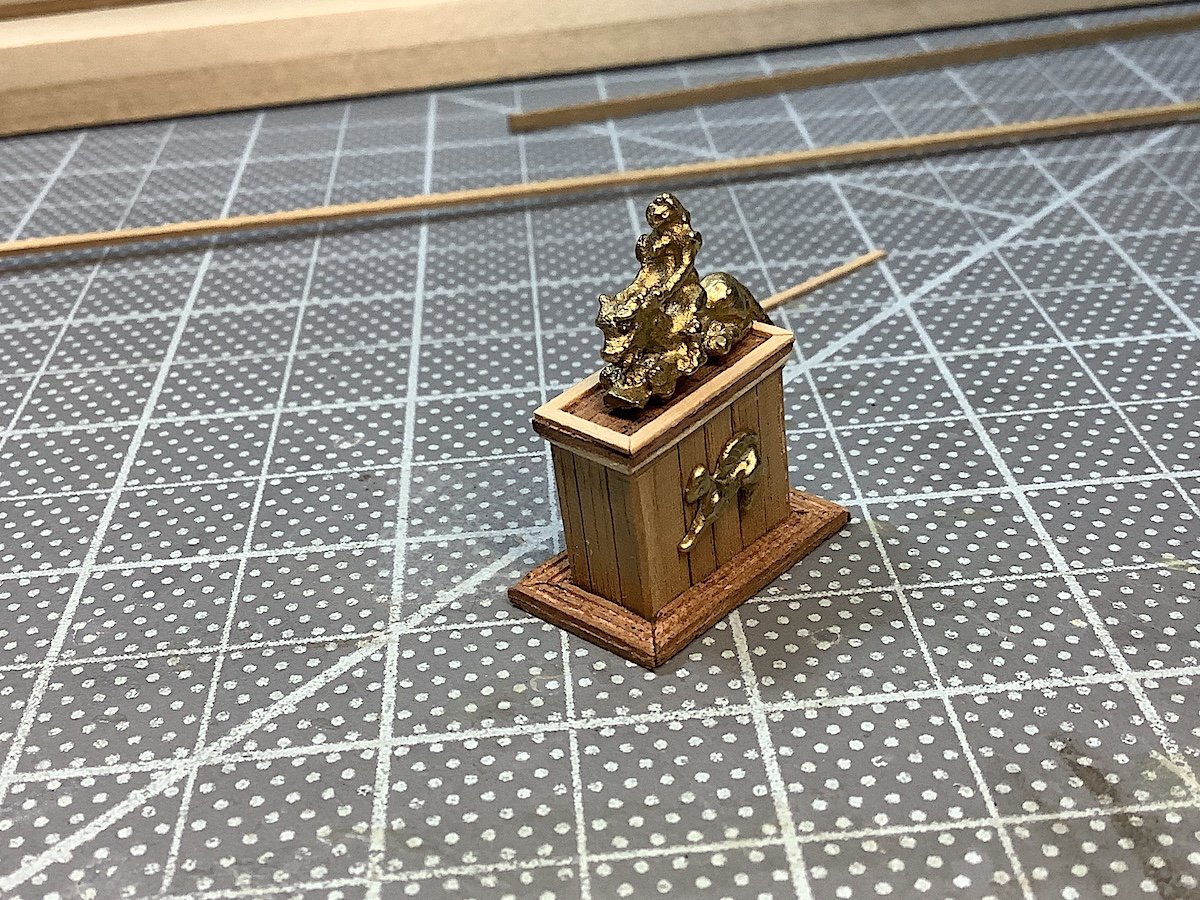

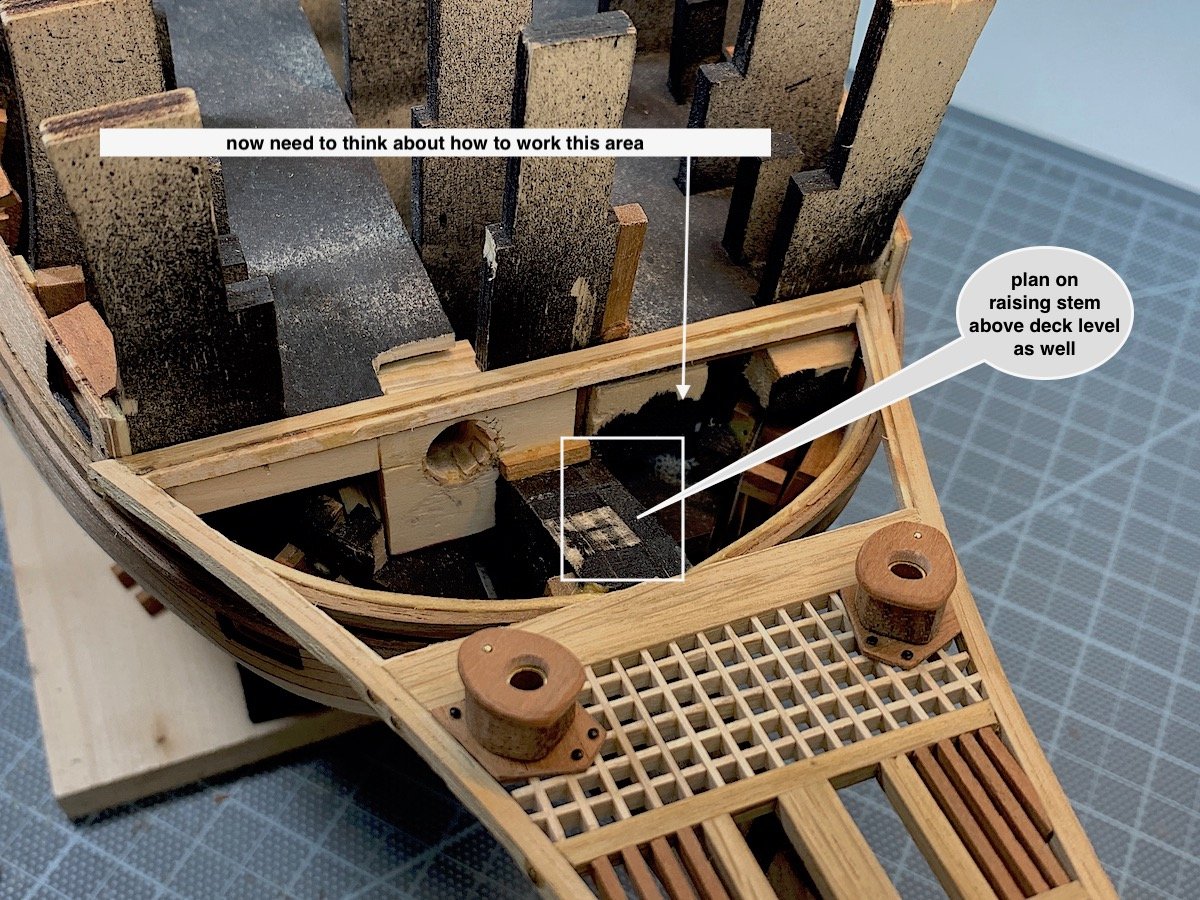

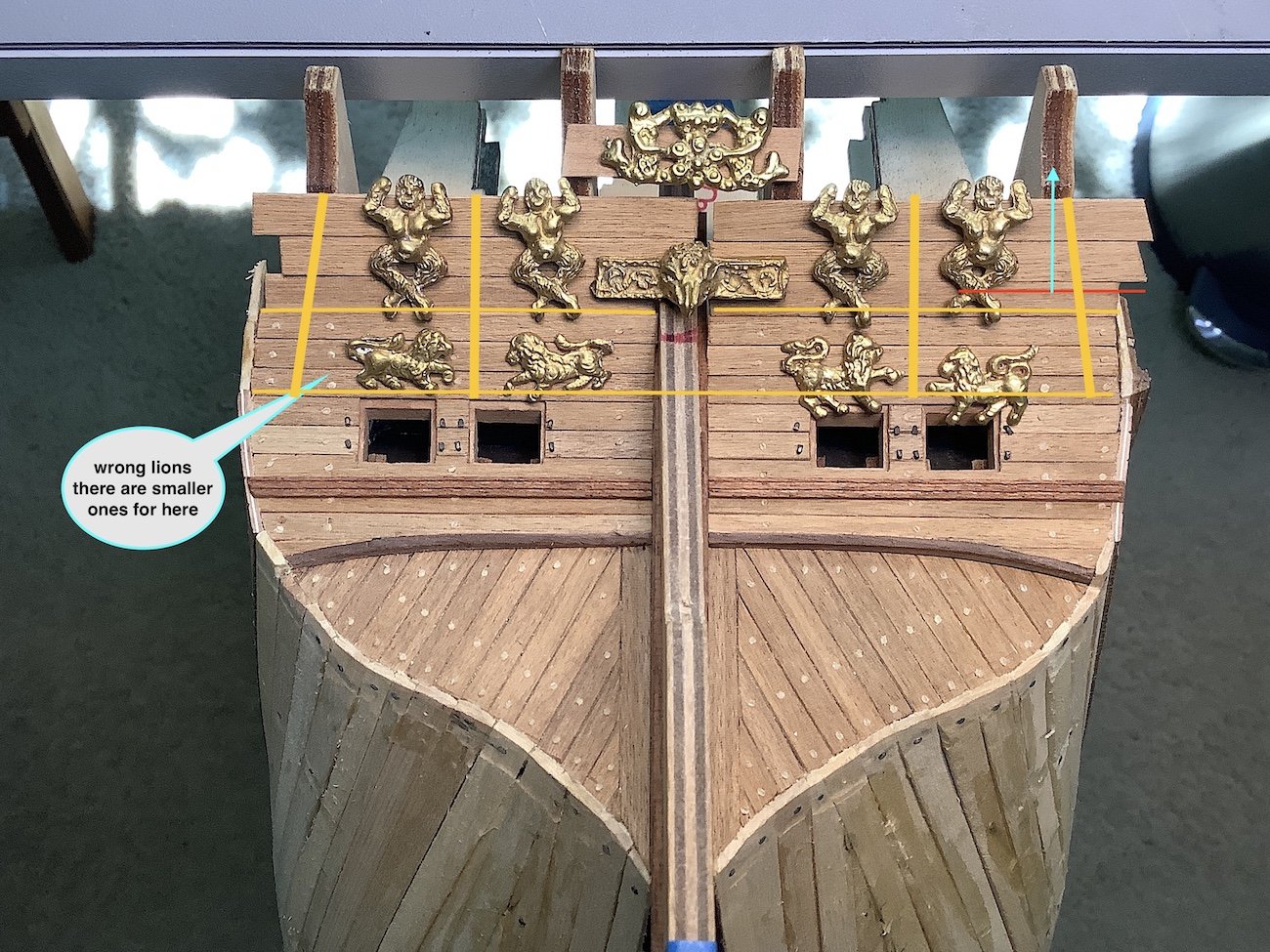

Hi, Richard: As always big thanks – glad that you like this log – your work is so over the top Boxbuilds: Thanks for your kind words. Regarding this Sovereign, as I had noted in my first post I did not intend to follow Sergal’s instructions for exactly the reason you state for your Soleil, along with other reasons as well. The template for cannon doors that Sergal included (for this kit) made this part of the build obviously much easier. I don’t know of a generic guide for locating the gun openings. For my previous Vasa, Corel intuitively added segmented grooves in their framings indicating location spaces for doors. That made it much easier indeed. My current Sergal SoS does not have these clever grooves. Hence I did not follow their instructions of covering the entire hull with basswood, then having to sorta blindly hunt for properly cutting holes for openings. ================ A build update I had intended to raise the stem above the bowsprit beakhead area – but having already done all the framing for the deck area, would again need to remove and re-do more pre done framing. As it is, given the offset mast re-work as well I thought against it -- instead --- went to plan B. I looked through some brilliant museum examples and decided to emulate their work by just framing a cover above and around my missing “stem” and just affix the needed cupid and lion on top visually it works as a good “go around” The Sergal kit does indicate for a frame to be constructed above the non-offset mast with the cupid/lion then affixed above. see last image. As is known, a mast offset was required, given how close the foremast is sunk through the forecastle. This came out pretty well. Now really need to get back to finishing and prepping first planking. Thanks for your kind posts as well as likes or just dropping by....

-

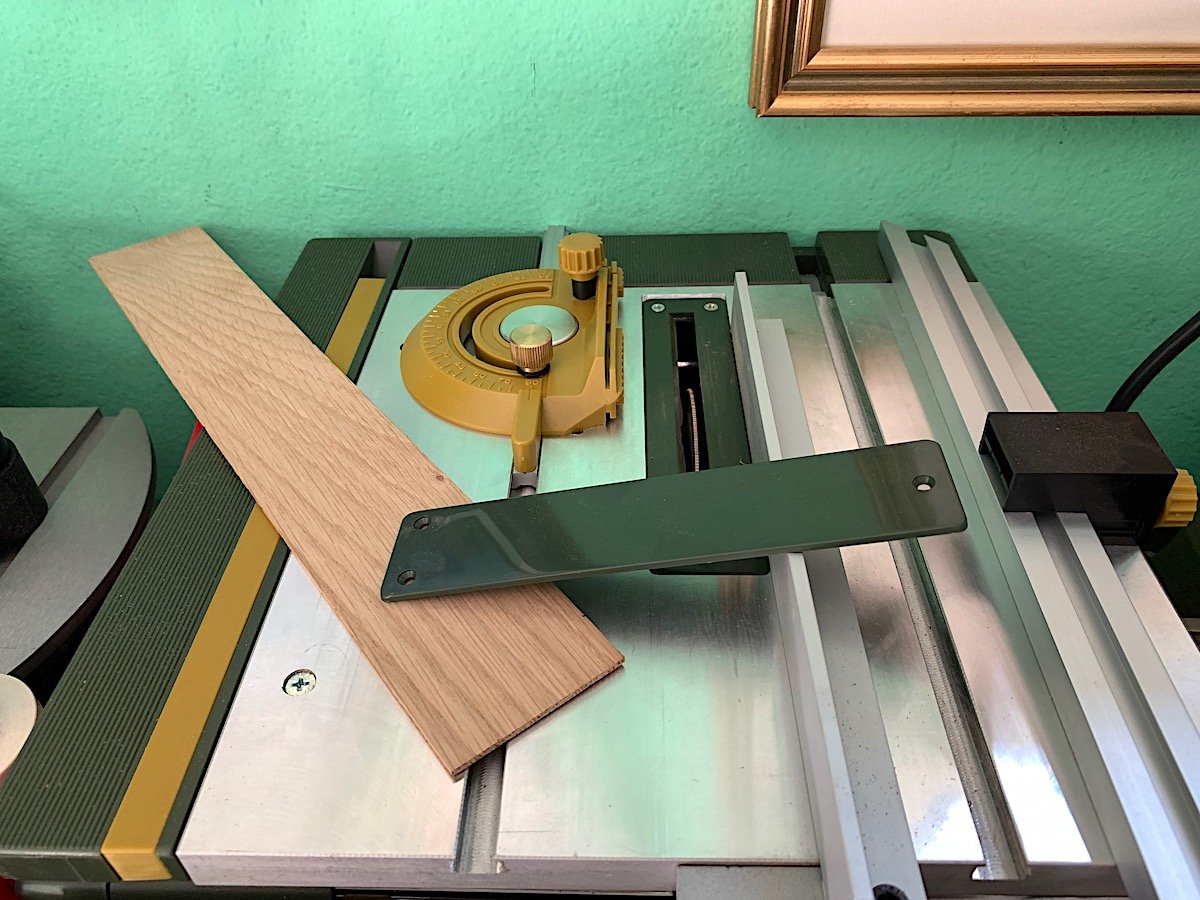

Frank, Yes – perfect idea indeed. When I looked at saw reviews on Youtube one of the reviewers indeed made just what you suggested. I later realized that Proxxon now encloses just what you suggested. I may make one out of thin oak planks that I can cut to size. Need to set that bit up – on my list – as soon as I need to cut very small planks – been using my very, small and old Proxxon KS-115 in the meantime Stuglo: funny – that would have indeed been a disaster back then – No actually it is supposed to be a “slider” pin – creative silliness on my part. That said back in those days is where the “he’s a sun of a gun”, came from: sailors (gunners) enjoying the working girls who would sometimes get them pregnant hence the phrase. Though some etymologists dispute this particular use of the phrase. The most plausible is this; there was an allowance for some women (spouses or working girls) to live on English Navel ships. Any child born on board who had uncertain paternity would be listed in the ship’s log as “son of a gun”.

-

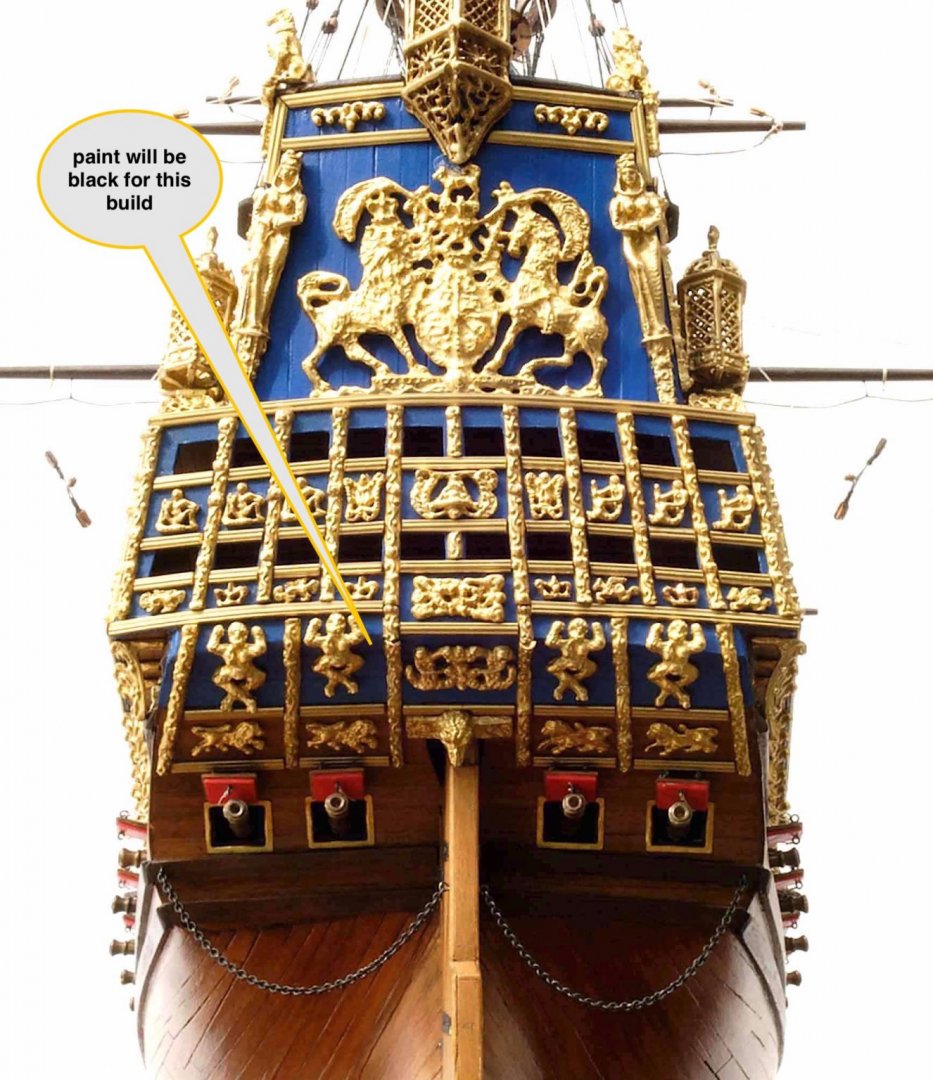

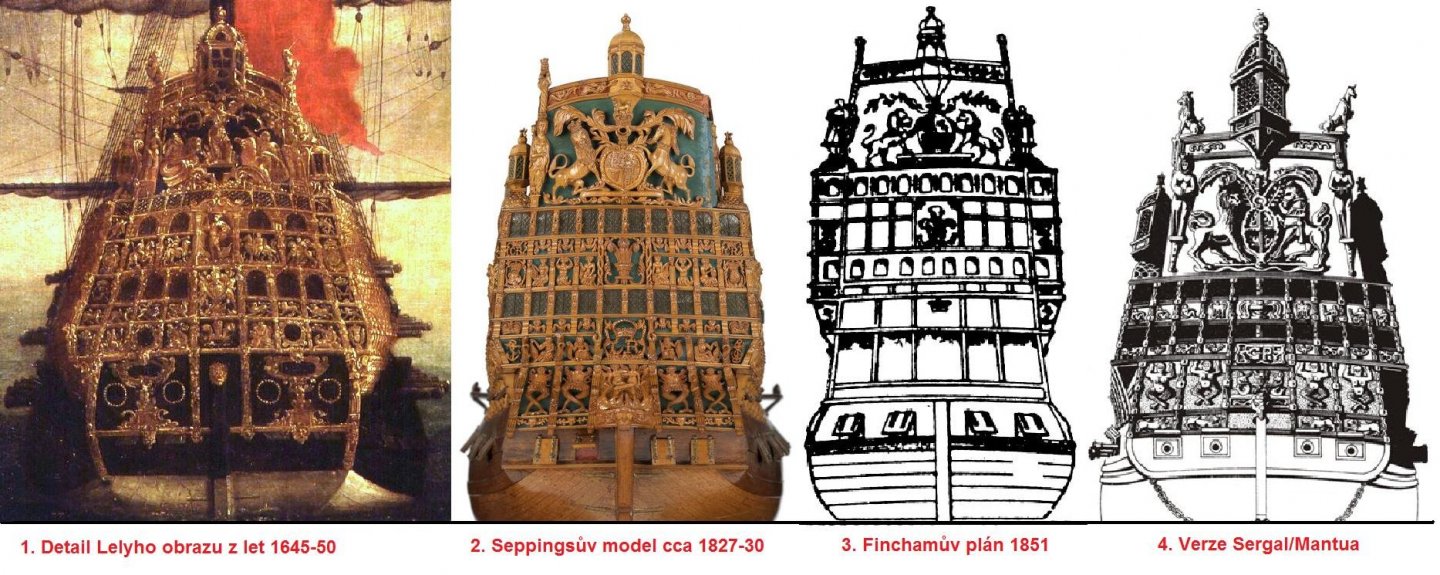

Thanks Frank, Though treenails, as we all know, should be two bits in tandem across planks. So not too satisfied with how this looks. That said when all of the ornamentation is added they won't look too out of scale (will re-think "how to" for sides of hull). Some builders use very thin brass wire resulting in perfect scaling. For the Vasa I drilled holes and used wood filler - came out very nicely. Many builders like this method. But for now at least I think that I got the stern cannon openings in just about the right places - the bronze pieces will locate as they should. Thanks for dropping by and your nice comment - Don't know whom to credit for that great SoS (below) that I have been using as a guide. Speaking of which, you have all been so nice not asking about the round tucked stern. Sergal's kit is certainly not representative of the 1637 Payne engravings and the Heck painting, and the Levy portrait is inconclusive. It could be that Sergal used a much later re-build of the SoS to emulate its stern, lanterns and galeries (though instructions do suggest a tucked stern). I do believe, however, that McKay does have the stern totally wrong (the book is an otherwise a brilliant study of this ship). His drawings would make the rudder totally useless - see image below - In that regard I have raised the stern waterline planks a bit more. Also there are no credible plans in existence - AND given my lack of confidence along with inconclusive historical data I have put this issue to sleep. Regards,

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.