-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Looks fantastic in the sun with her ports hanging down like that. Bravo on the milestone!!! I suppose you'll need to make a wheeled cart to move from here on out?

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

Ah... first one here so I can pick my seat... er... chair.

- 259 replies

-

- Gunboat

- Philadelphia

-

(and 1 more)

Tagged with:

-

I'm assuming that bloodshed was minimal and a great time was had??? So much talent in one place...

-

Sheesh.. that's incredible. As for not a "real ship n the bottle"... picky, picky, picky. Put a cork in it and you will have a shipbuilder in a bottle.

- 94 replies

-

Artesiana Latina HMS Victory 1:84 scale kit (REVIEW)

mtaylor replied to mtdoramike's topic in Wood ship model kits

Well...if you have a niche market... your price point is whatever the market will bear. Now I think your $1200 is list price so one would have to wait for a sale. It's still a shame that they've gone up so much. Even wood for scratch building is getting spendy. -

Beautiful work on her and the rework of the lanyards should make you very proud. That was a major undertaking.

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

Daniel, A stunning achievement. The water and sails give it a unique character. A pity one can't bottle a 1:64 size ship....

- 94 replies

-

HMS Druid by Krug - FINISHED - 1:48 - Hahn

mtaylor replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

Only 5 months? Crikey.. and a beautiful ship to boot. Hmm... I guess it'll take about an hour for the figurehead? Ok... seriously.. it's only wood. Make some sawdust, or in this case, carving dust. If it's not right.. do it again. We have confidence in you. -

Artesiana Latina HMS Victory 1:84 scale kit (REVIEW)

mtaylor replied to mtdoramike's topic in Wood ship model kits

Well... there's inflation, rising transportation costs and various "green" initiatives that have made wood more expensive. From where I sit, everything is more expensive. -

Thanks for the "likes" and comments. Sam, On Licorne, they are 1/2 the frame thickness. Other ships... not going to vouch for them. I have some other Hahn plans which when I dig them out of the dark recesses of my storage area, I'll check.

-

Pops, Been there, done that, have the pile of firewood. While you're waiting, give some thought to removing the thwarts and adjusting the risers. The biggest obstacle would be glue type. I hate to see you bagging this model as you've learned a lot on it and were doing a great job. Someone around here once said: "It's only wood... it can be fixed."

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Looks very good, David. Congratulations on a well-done build.

- 39 replies

-

- lehigh

- papercraft square

-

(and 3 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Sweet looking coppering, Nenad. You are flying along quite nicely on this part.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

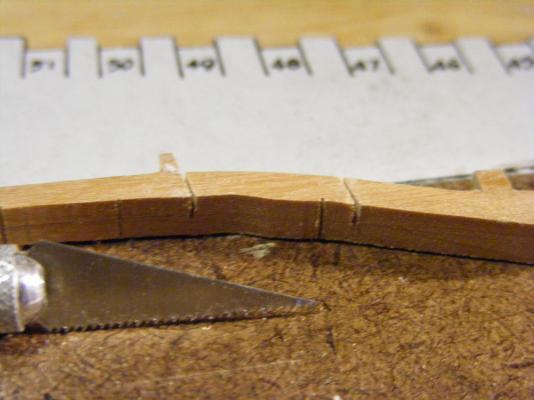

I mentioned above about how I cut gunports. So here's how I do it. I make no guarantees that it's the best way but it works for me. First up is a laminated frame blank (I'm using a half frame as the full frames are done). I then rubber cement the frame plan to it and carefully cut it out. I fit the frame into position and check all the reference points both against the plans and in situ using the EdT tool. After that, the reference points are etched using the scroll saw and the frame cuts are made with the saw pictured. I soak the joint in 91% isopropyl and wrap in a scarp of paper towel which is also soaked in the isopropyl. The joint is then wrapped in plastic wrap and secured at each end with clothes pins (pegs) so as not let the whole frame separate. After doing something else for about a half an hour, I grab the frame with pliers and piece to be removed with a pair of cutters. A slight pull and the piece comes out, usually cleanly. At this point, the frame is glued into place, space blocks added between the newly installed frame and the existing frame, everything clamped and the glue allowed to cure. After curing, I double check all reference points, just in case.... I hope this helps someone.

-

Mayflower by SawdustDave - Finished

mtaylor replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

Go for the bamboo, Dave. It looks great! You got me thinking about ripping up one my cutting boards, but the Admiral would be really irritated as the one in kitchen is a lot larger than one I have. -

Advice on disc sander

mtaylor replied to Don Quixote's topic in Modeling tools and Workshop Equipment

I simply put the plank in a vise (between two long piece of scrap wood) and sand using a very long sanding stick held at the proper angle. I'm afraid that with a power tool, I take too much off the plank. -

Sure you can... tell them you took a nap and the alarm didn't go off.

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Ulises, Frolich (The Art of Ship Modeling) saves the barrels until last so they don't get knocked about during rigging. As the French ships rig the breeching rope different, this works for him. I can see where it would work for you, just put epoxy on the trunnions and the area that sits on the quoin. But try to make it the final step (or nearly final) of the build. Yeah.. I'm doing a Frenchie but we'll see on when I do the guns.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.