-

Posts

4,891 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

Pffffffffffffffffff!!!!! .....oh, that was for Sjors....... Lovely work Augie. She's looking quite splendiferous! (translate that one Sjors )

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Simply wonderful details Remco. I do think though, that you should show the drawers of the wardrobe open, just to prove they do. Wait for it.........................................

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Nice to see an update Robbyn. I totally understand how life can get in the way sometimes. Looks like your new hull is taking shape nicely - well done. Be careful on that bike of yours - just had a phone call from an old friend this evening. He's in hospital after crashing his bike in the Snowy Mountains on the weekend. Not the way he'd planned to experience his first ever helicopter flight!

-

Nice work Toni. If you need more crew members, you could always sub-contract Doris!

- 1,449 replies

-

Congratulations on a truly fine model Len. Whether you subsequently come back and rig her or not, she remains a real beauty. What's next for you then?

- 122 replies

-

- bellerophon

- victory models

-

(and 1 more)

Tagged with:

-

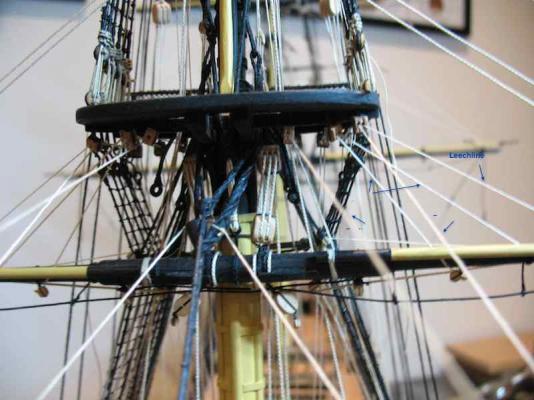

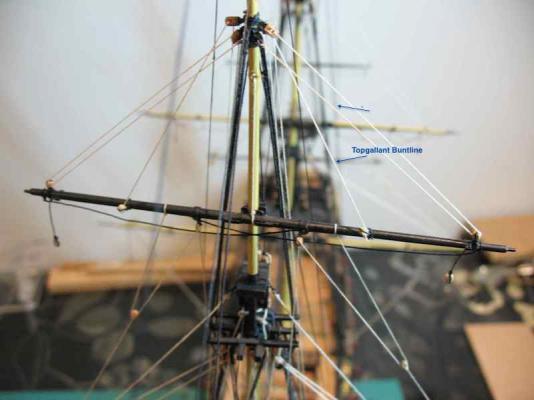

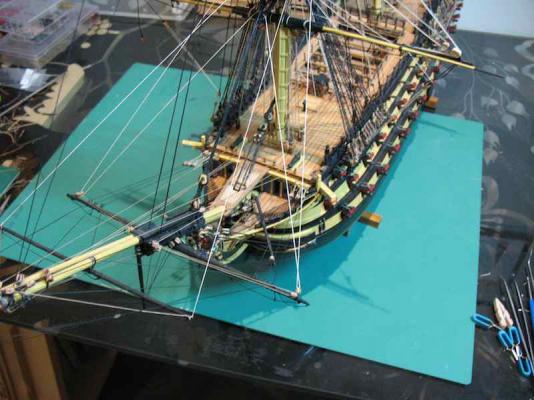

Thank you Patrick and Marc. I seem to have finally made a bit of progress attaching string this weekend! First up, here's the Mizzen Pinrail with lines attached. The mast cleats that I removed from here have been relocated to the Belfry, because reading ahead, I realised that I was going to need these and as usual the kit hadn't provided for them. This weekend I have managed to fit: Topsail Sheet and Clue Lines to both Fore and Main lower yards. Leech Lines and Bunt Lines (Fore Lower Yard) Spritsail Yard Brace Spritsail Topsail Yard Brace Topsail Yard Reef Tackle (Fore) Topsail Yard Buntlines (Fore) Topgallant Sheet and Clue Lines (Fore) Topgallant Bunt Lines (Fore) The kit plans aren't too bad, once you figure out which line you are looking at. The only real issue is the belaying points - because the kit omits both shroud and mast cleats, it takes a while to figure out where the lines really need to go. Longridge has been indispensable for this. I also have to acknowledge Gil Middleton's excellent log. On one occasion, he was able to save me when even Longridge let me down! Thanks Gil. Pics - starting with Topsail Sheets and Clue Lines Edit: I put a number of labels on these pics, but when I resized the pics, I lost most of the annotations. Topsail Buntlines: Topgallant Sheet and Clue Lines: Topgallant Buntlines: A close up showing the underside of the Fore Top - it's getting quite busy under there! And finally, a couple of overview shots:

-

Really, REALLLY, nice work there Bob! Your pictures show just how cramped it would be working around that stove.

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Sweet! Glad to hearing you're warming up over there, just as were starting to cool down over here.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thank you all for the kind words and also the "likes". It's not so much the faces, Bindy, as the language - enough to make a true sailor blush!

-

Just be extra careful not to bump or snag those masts or you'll end up as I did (twice) with a break right across that drilled hole! Such events are fixable though

- 525 replies

-

- cutty sark

- mantua

-

(and 2 more)

Tagged with:

-

Those stern bends sure look tricky Sjors. Looks like you've got it covered though. Progressing nicely.

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Beautifully done Timmo. She is looking superb.

- 366 replies

-

- granado

- caldercraft

-

(and 1 more)

Tagged with:

-

ancre LE BONHOMME RICHARD by Jeronimo - FINISHED

gjdale replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

I'm with Wacko too - just speechless!- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

That's a mighty fine looking rear end there Augie!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.