-

Posts

3,624 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yvesvidal

-

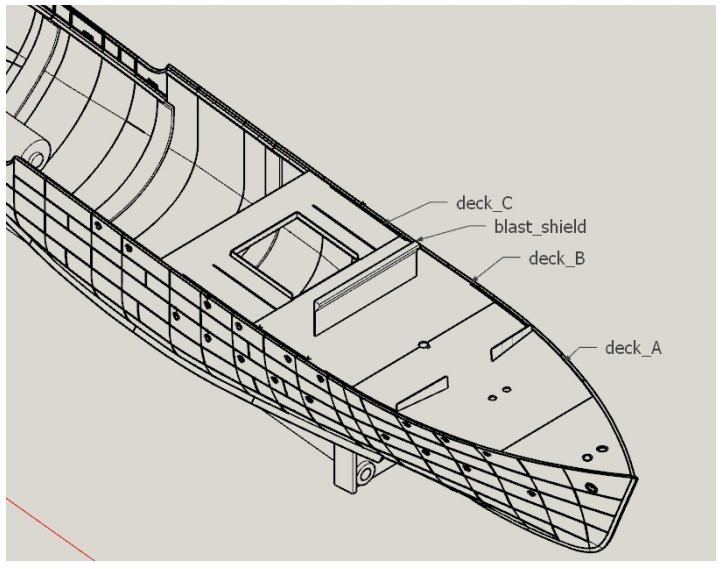

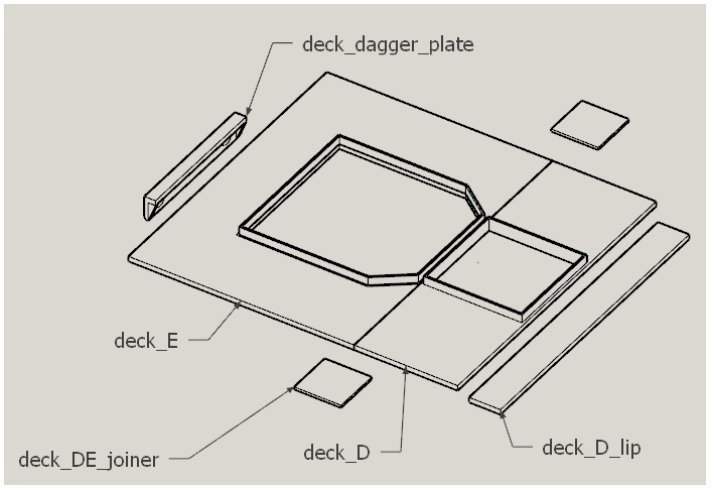

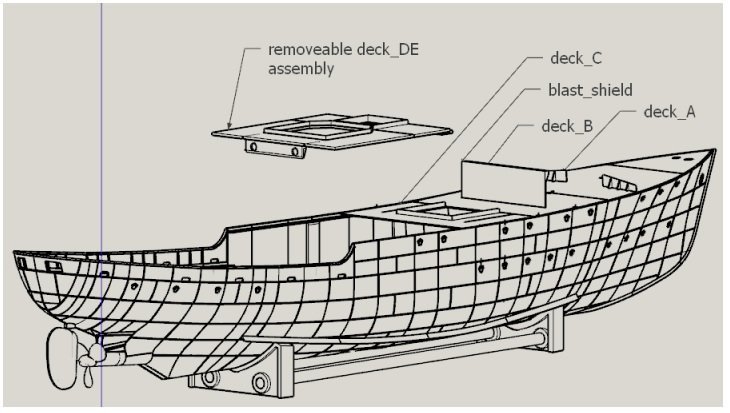

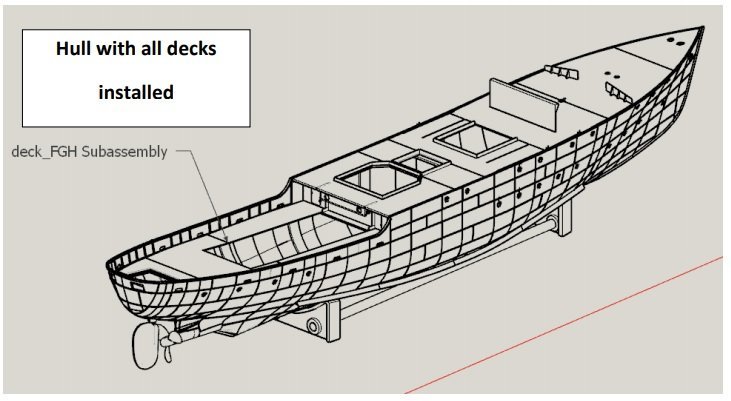

A quick update on the hull and decks: Hull has been puttied and primed. There will be more sanding, before the first coat of paint. Also working on the printing of the deck sections. Following are a few excerpts from the instructions manual: And the printed parts: Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Some good progress. I think I solved the deck issues, at least in the stern area. Hopefully, this method may help future builders of this virtual kit. The set of decks, out of the printer looks like this: The stern railing is glued to a frame that help connect the following deck, and holds the platform with the depth charges. These parts are glued with the MEK, resulting in an unbreakable and very solid part. That MEK is just perfect as it flows by capillarity between the parts and weld them. Do not forget to "cut the corners", as they will conflict with the hull stern. I am cutting the U shaped deck and using the two short legs with the side decks of the engine room. This is done to provide a base that will be planked with wood. The Matchbox/Revell models are only specifying a very short section of wood planking, but that does not make sense as we will see. The side deck and short piece are glued together and planking can start. Do not forget to leave un-planked, a small edge that will fit on the side of the engine room walls. To finalize the installation of the rear decks, you will need to assemble the four walls of the engine room: The engine room will be positioned into the hull and locked with two small pieces of styrene: It was necessary to shim the front wall of the engine room, to make the top of the planking, flush with the culpers. The front bulkhead rest on the white coupling part and on the shim. The side decks are now correctly positioned and fitting perfectly. We need to work on the stern decks. The stern decks (metallic) must be flush with the planking and will need to be raised a tad. Raising these decks, will make them a little bit too small in the width dimension. We correct all this, by gluing a 1.5 x 1.5 mm square styrene strip (raising) and a 1 x 3.2 mm strip to fill up on the side: At this point, the rear deck fits perfectly and no gaps are visible: Putting everything together, we now have a smooth transition between the decks and a perfect match with the culpers, to evacuate the water: The same recipe will be used on the bow and the rest of the decks. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Very nice model. I am looking forward to watching your base with water. If you ever get tired of 1/700, a similar model is available in 1/72nd. Ten times bigger: Yves

- 14 replies

-

- O-class destroyer

- Tamiya

-

(and 2 more)

Tagged with:

-

So, you are depicting the Snowberry towards the end of its life, all rusty and beaten up. Yves

-

I am now working (at least planning) on the decks. This is a delicate part of this kit for the reason that the model has been designed for Radio Control. The designer is suggesting caulking the deck to the hull, if a possible access to the inside of the hull was required, in the future. In most place the deck sits too low and we will need to come up with a solution. Let's look at the stern, for instance: You can clearly see that the deck level of the stern is not at the same level than the rest of the decks. In fact, the stern deck sits at the right height and everything else is way too low. One of the problems is that the deck pieces are not wide enough, if you raise them. Also, the scuppers must be flush with the deck, to fulfill their role. One solution would be to slightly increase the width of the deck (X-Axis) when slicing the model. An increase of 2% may do the trick but may also result in an opening for the engine room, which no longer fits. You still have to raise and support the decks, from underneath.... The other solution is to raise the hull side/support and to use a thin styrene strip to fill up the gaps. This is the solution I will be using. Another thing to take into account is the use of wood planking, while keeping a constant height for the deck. I will be presenting a solution in the coming days, that may work to my satisfaction. In the meantime, let's enjoy some pictures of the recently glued stern. And yes, the hull received a first coat of primer. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

This model is way beyond Museum Quality..... The pedestal itself, is a piece of art !!! Magnifique. Yves

-

Lancia Assunta by maurino

yvesvidal replied to maurino's topic in - Build logs for subjects built 1901 - Present Day

Beautiful colors on your sails. Yves -

From these: To this: It is literally amazing. The hull as you see it, has a total cost of $45 plus $3 for the pedestal. Once the license has been purchased ($50), you could print out as many hulls and parts as you want. A few more picture of this behemoth: This last picture gives you an idea of the size of this hull: Next, is the delicate application of acrylic putty and some sanding, before a first coat of primer. Originally, this kit is intended for navigation and Radio Control and as such the designer is suggesting to cut the inside frames to gain access to the RC equipment, batteries and motors. I am going to keep them all, as they will be perfect to support the decks and cabins. Hull is very stiff and would not require them, but they will make my life so much easier for what is to come. Yves Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Moving along and close to the hull completion. First working on the bow and front sections (1, 2 and 3): Last section (#4) glued: This is going to be a large hull, to say the least. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Craig, we are now using CURA 4.10. Update is free. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Congratulations Alan and welcome to the 3D printer club. I strongly suggest you watch and follow the Video from "Just Vlad" on the Ender 3 V2. That guy will lead you through the fine tuning of the machine and the various mistakes to avoid. Worth your 40 minutes of YouTube. Really !!! After following his recommendations, I had absolutely no problem printing. Levelling has to be done very carefully.... and then you never touch it again. Use a very think sheet of paper (I use the little flyer provided with the kit, in the plastic bag). Perfect adjustment. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Most of the parts are "part" of the virtual kit. Of course, you can always add more and turn it into a museum piece, with time and money. I am exploring the feasibility of such kits and not shooting for the stars. I intend to finish the hull, with a few decks and mingle some wood, in this jungle of PLA. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Superb rendition of a fjord and exquisite model. The water is very tempting but must be too cold for my taste. Yves

-

Sections 6 and 5 are now glued: Still using a dab of CA glue to immobilize the parts and then welding with the MEK. Seems to hold....so far. Having reached the middle of the boat, I am going to focus on the bow, from now on. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

I use Ultramaker CURA like most people for slicer program. Yes, everything can be adjusted and will go into your profile. But being a complete newbie, I am using the default values and sticking to what the Kit designer specified. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

I wanted to go back to the printing process and slicing of the hull parts. The nozzle of the printer is the standard 0.4 mm diameter. The filament is extruded at 200 Degrees Celsius from 1.75 mm diameter and kept under pressure in the extruder. The pressure will be quickly relieved when the nozzle has to move to a location where no filament is needed. Then pressure is applied back. I mentioned that the thickness of the hull is about 4 mm. In fact, the hull parts are made of a sandwich of two walls and some filling in between. All this is determined at the conception of the model and by setting the Slicer. I have watched the nozzle run its course and noticed that each wall is comprised of 3 runs. That gives us a total of 6 runs plus the filling in between. When the filament is placed on the hot glass surface and later on, on top of the part as it gets built, the 0.4 mm of the hot filament becomes 0.5 mm. This is called over-extrusion and is accounted for by the slicer program. The net result is that we have two walls totaling six times 0.5 mm in thickness plus a middle section of 20% filling and 80% empty. Again the filling is determined by the Slicer and set to 20%, to increase speed, reduce printing time and material (filament) consumption. Walls plus filling amounts to 3.0 mm plus 1 mm, giving approximately 4 mm thickness. Another interesting parameter is the printing height: it is typically half of the nozzle diameter, which is to say 0.2 mm. That is the increment in which the Z axis is building the part (vertically). For every 0.2 mm of material, we have six complete travelling of the nozzle (two walls), one Z shaped travelling (20% filling) and one additional travelling for details outside the hull, such as plates, rivets....etc. In summary, 8 complete sweeping of the part by the nozzle for every 0.2 mm on the vertical axis. For every millimeter, that translates to 40 passes.....Hull sections are 155 mm high....I will let you do the math...That is why some sections take 40 hours or more of non-stop printing. Yves

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.