-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Michael, Your clean build and attention to all the details makes this a masterpiece. I'm enjoying watching this log progress.

-

Matti, Some ships (mostly warships) were planked on the inside of the weather deck bulwarks. Some weren't. There's no hard and fast rule on this. The extra planking gave some protection to the deck crews from grapeshot, canister, and assorted small arms fire. The Berlin seems to be one that had the planking.

-

Golden Hind by Keith B - FINISHED

mtaylor replied to Keith B's topic in - Build logs for subjects built 1501 - 1750

Wonderful work, Keith. The loss of a camera with un-saved pics is hard to take. But, please continue to share your log. The Hind is a fascinating ship. -

Thanks for looking in and the support, everyone. When I saw this, I realised the fore and quarter decks will be the real canvas for the work. Christian, I had thought about it but then I recalled the Admiral's directive: completely planked, no "unfinished look".

-

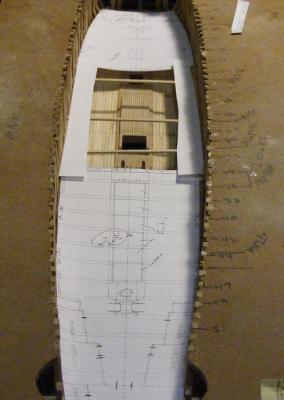

Played with a mockup of how much of the gundeck will really be seen. It was a real eye-opener to me. The first pic show both the foredeck and quarterdeck and walkways mocked up and on "beams" The second shows how much is actually visable. Based on this, there's not going to be a MkV deck, but I do want that whole deck smooth as a baby's backside. And all appropriate furniture in place. Back to sanding and sanding and sanding and.....

-

Popeye, She's looking grand with her finery hanging the breeze. I'm enjoying watching this build and the fun you're having with it.

- 377 replies

-

- america

- billing boats

-

(and 1 more)

Tagged with:

-

Royal William by derebek - 1/72

mtaylor replied to derebek's topic in - Build logs for subjects built 1501 - 1750

Nice work on the hull and lovely carving work. What kind of wood are you using for the carvings? -

Nice work, Andy. If nothing else, if you don't add the blocks, you (and the rest of us) will know they're not there. But presumably, we can keep this secret... or not. But no pressure, no guilt. The pics were worth the wait.

- 1,148 replies

-

It's great to see this coming back, Len.

- 122 replies

-

- bellerophon

- victory models

-

(and 1 more)

Tagged with:

-

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

-

Next kit suggestion???? moved by moderator

mtaylor replied to Rich_engr's topic in Wood ship model kits

Rich, You've set your scale, so in my opinion, build the one you want. Those are all good choices. Even the Conny's probably not out of your league. -

Rats... I went to all that trouble and I could have bought one??? Oh well.. it was good experience anyway.

-

Randy, See here: http://modelshipworld.com/index.php?/topic/341-micro-power-sanders/ I'm using the top one on the deck for finishing. Augie, Sorry for the oversight.

-

Jay, I almost bought one of those, but it's still way to big to get into hull. There's some serious tumblehome to deal with. Thanks for the comments everyone. I thought I'd add a bit more.... I'm using 220 grit with a very very light touch. Too much and I'll get swirl marks which I found out in testing on scrap. Too large a grit (100 or less) and it shreds and swirls the wood. For finishing, I'll be using my oscillating pencil sander with 320 paper. The scrapers are great but that deck area is in such a tight spot (between the raised center on oneside and under the tumblehome... well.. my fat fingers argue the point.

-

Christian, The gratings are on the center which is raised above the deck. When I sanded that, I used a pencil oscillating sanding with 240 grit paper followed by 320 grit. Michael, Admittedly, the planking was not as smooth as I'd have liked. The deck sander is being used with 220 grit to get it down level and smooth. I'll finish with my pencil osillating sander with 320 paper. I started with the scraper but everything is pretty tight in there due to the tumblehome. Popeye, No swirl marks that I can see, but see my response to Michael on how I'll finish. A very light touch is mandatory.

-

Dooohhh.. JP, you are so right. I pass by Lowe's on the way home from work.. they're two blocks from where I work. Those rubber feet people put on furniture might work better also.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.