-

Posts

5,613 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by James H

-

-

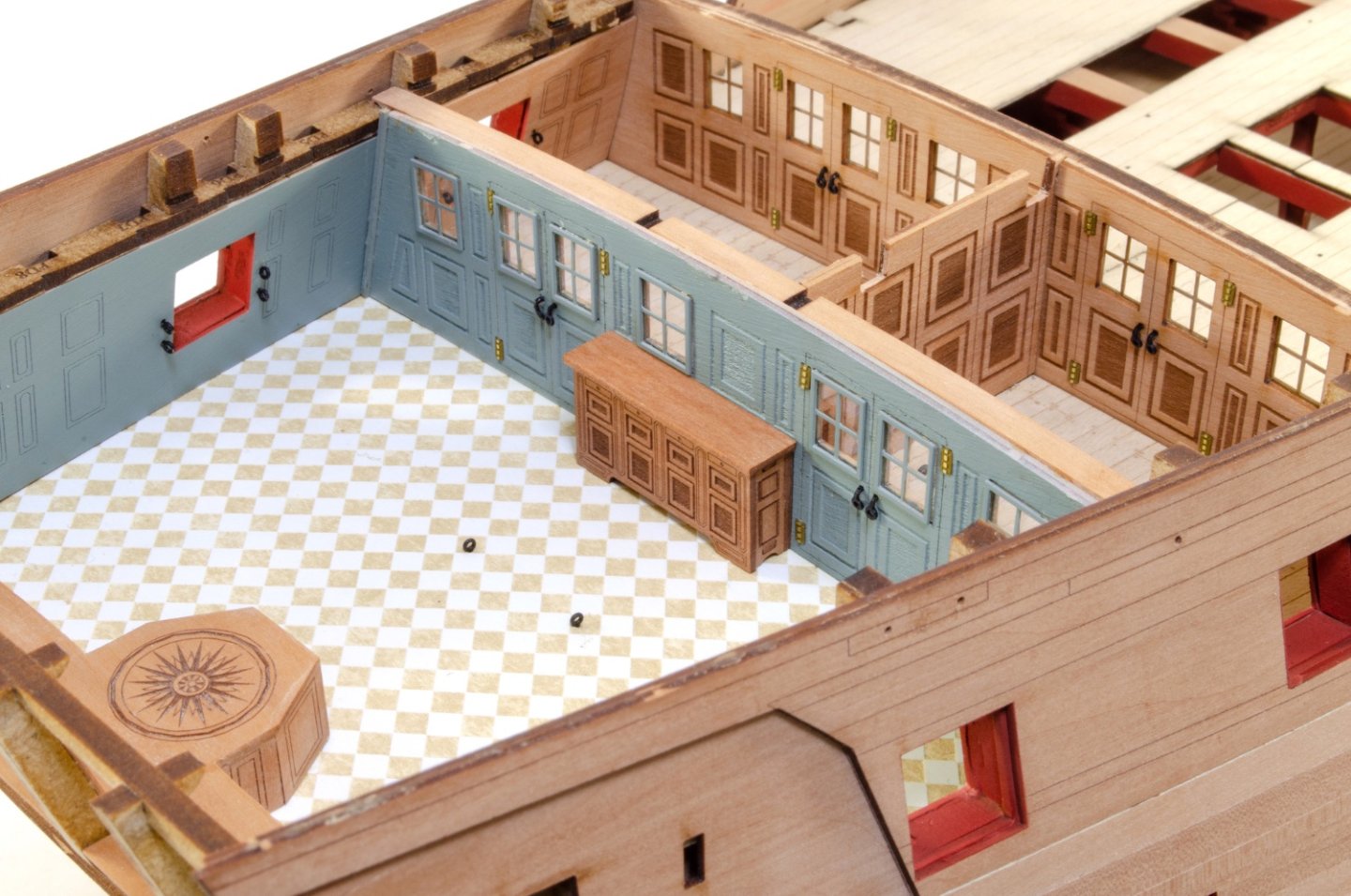

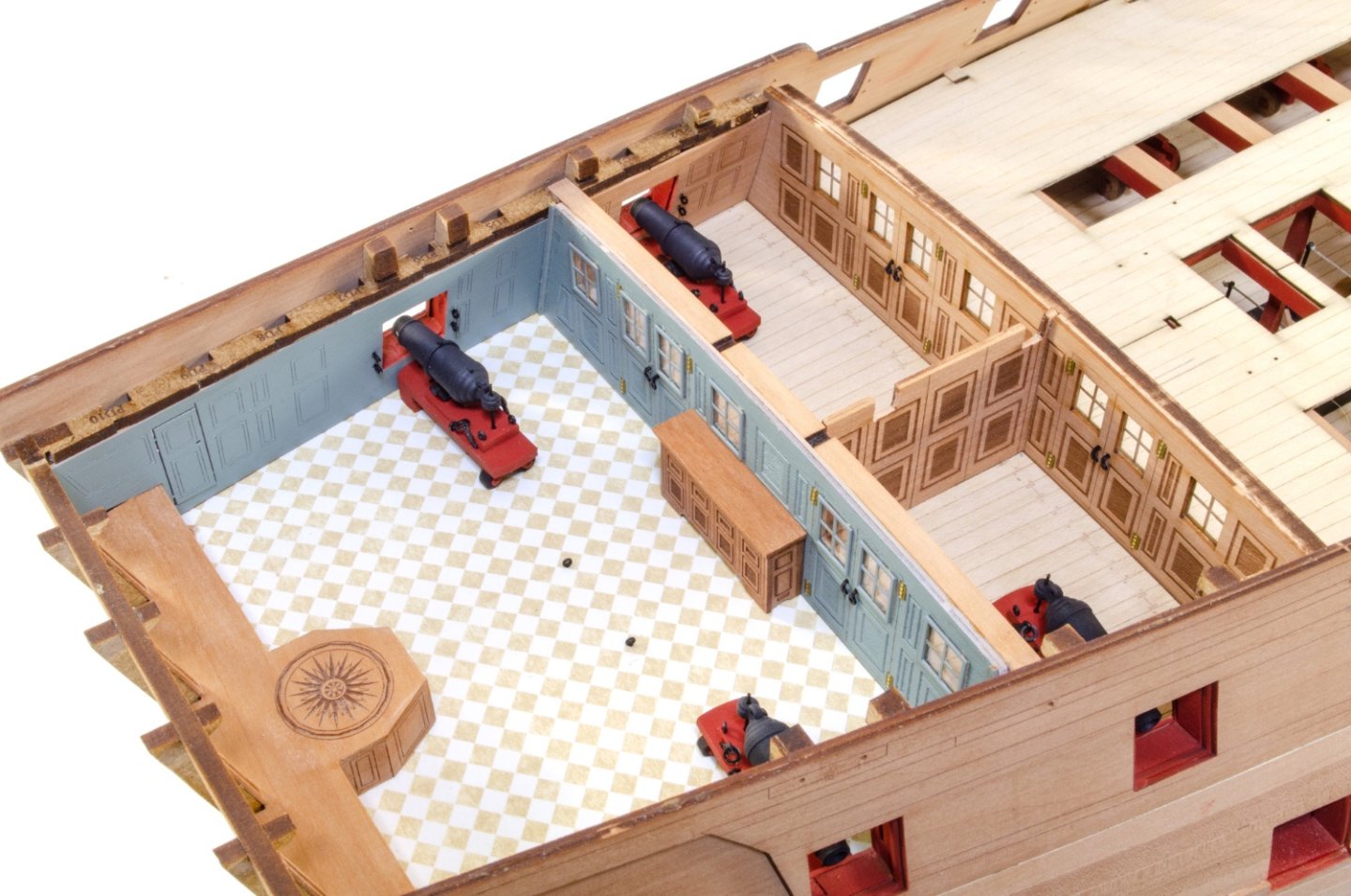

The cabin walls and internal cabin screen are now painted, and the screens fitted out.

I can finally glue into place the cabin walls, screens and partition. Note the eyelets are added to the ports and floor.

Did I say this came with a cabinet? No? Well, it does, and this is now fitted into place.

The carronades in this area differ from the others as they will retract into hull during the hull painting process. They can be rolled out into position when that job is complete. These are now fitted to the cabins area.

Time for some furniture and maps too.

Hope you like the work so far. Onwards!!

-

This is my weekend update time as I'll be working flat out from this stage to get the upper deck work done. Getting the cabin built and fitted out seemed like a good time to post.

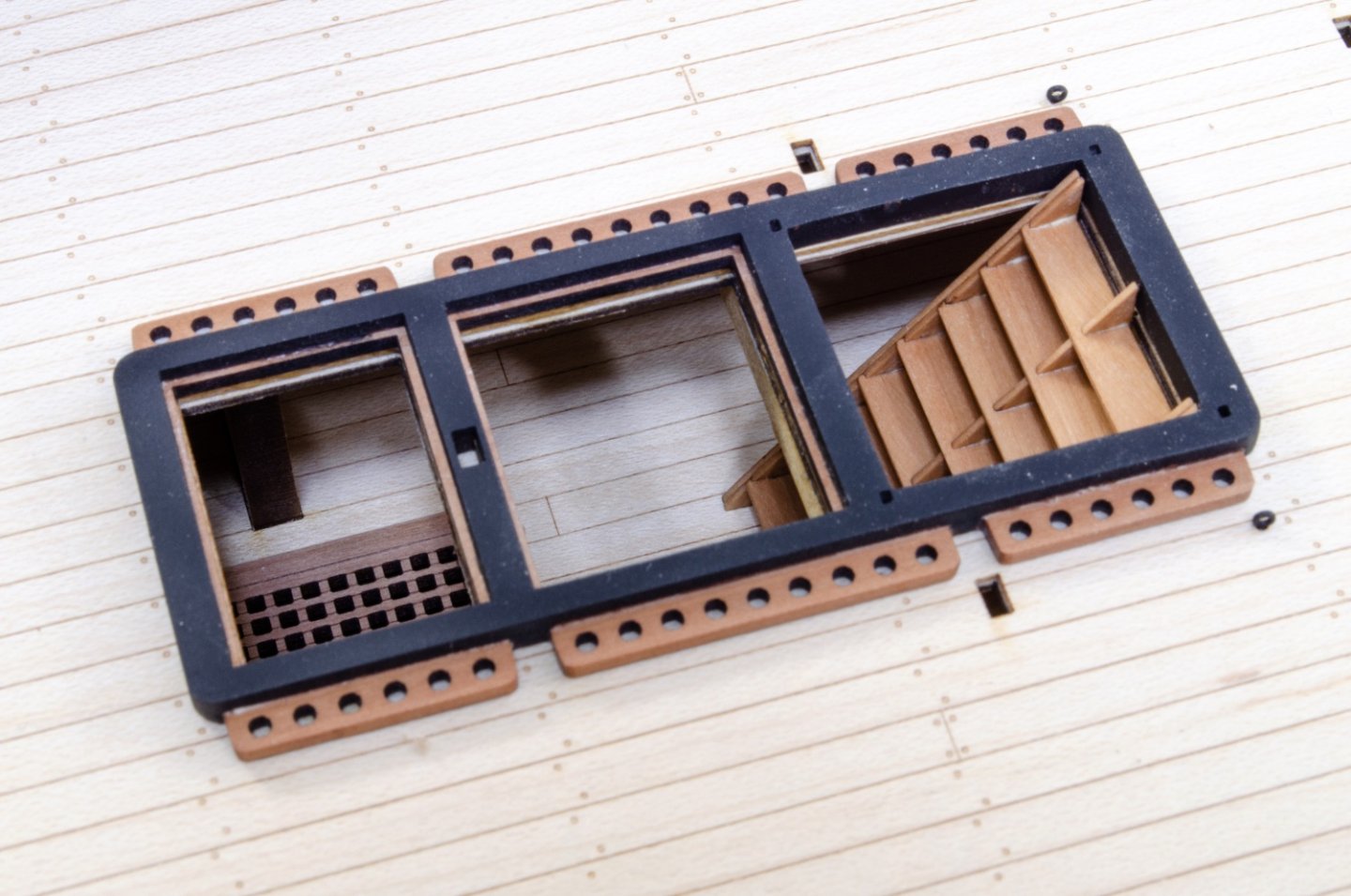

The first thing that's to be done is to fit the vertical face for the benching in rear of captain's office.

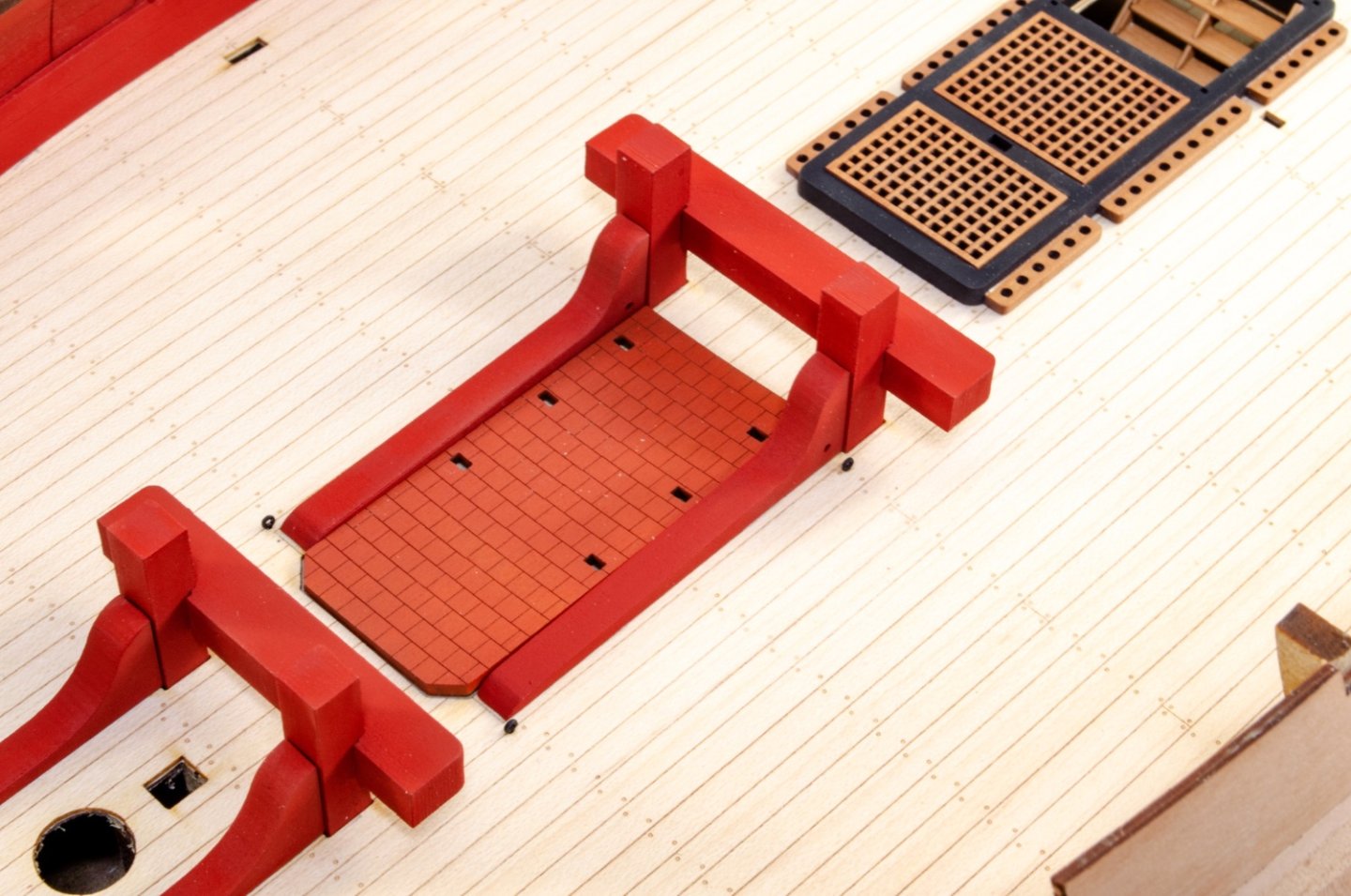

With that fitted, the parquet floor is added. This is supplied in card and it looks nicer than the maple version, and a cool contrast. Titebond is used to fit this. The remainder of the rudder housing boxing is then completed.

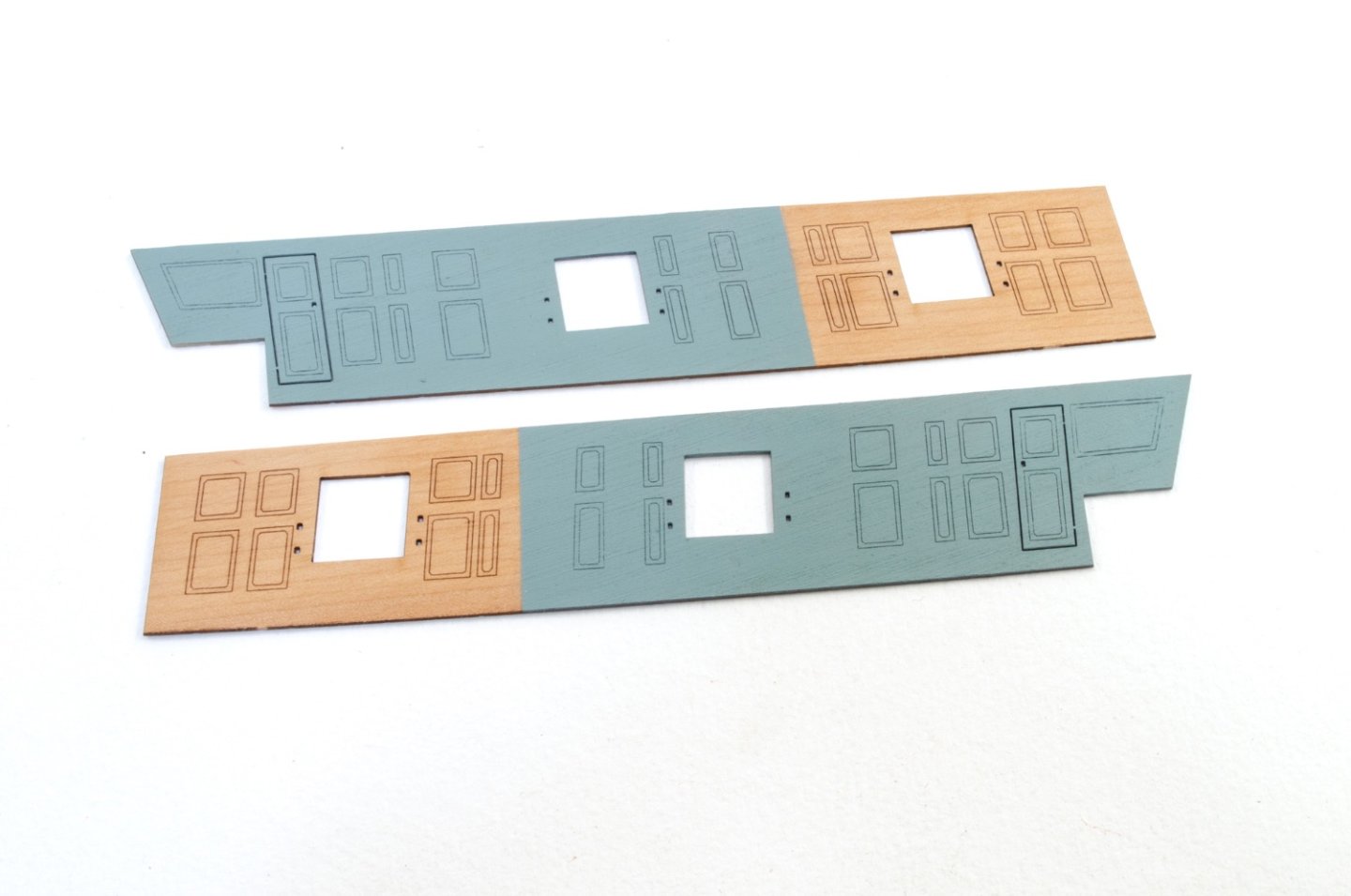

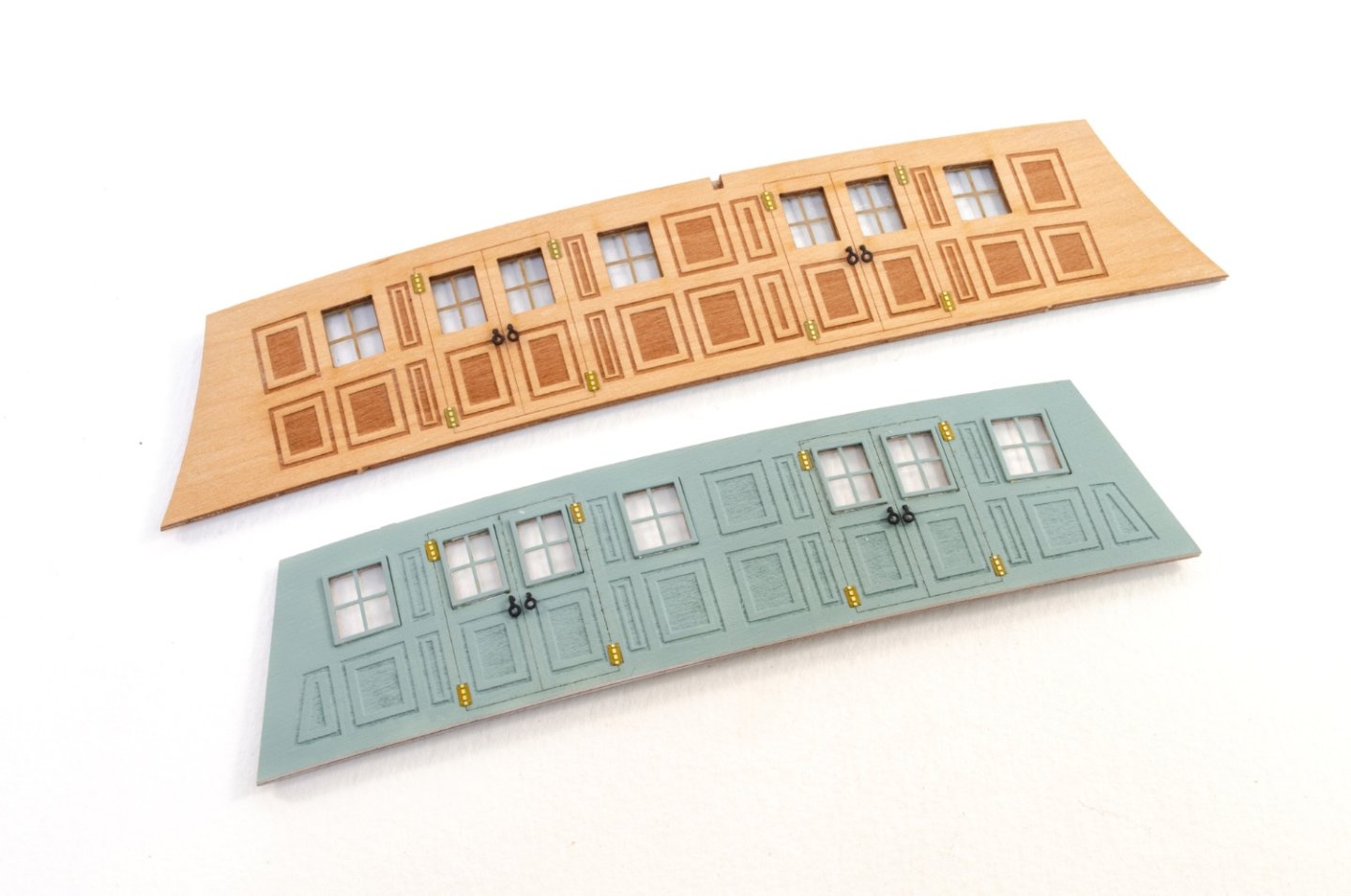

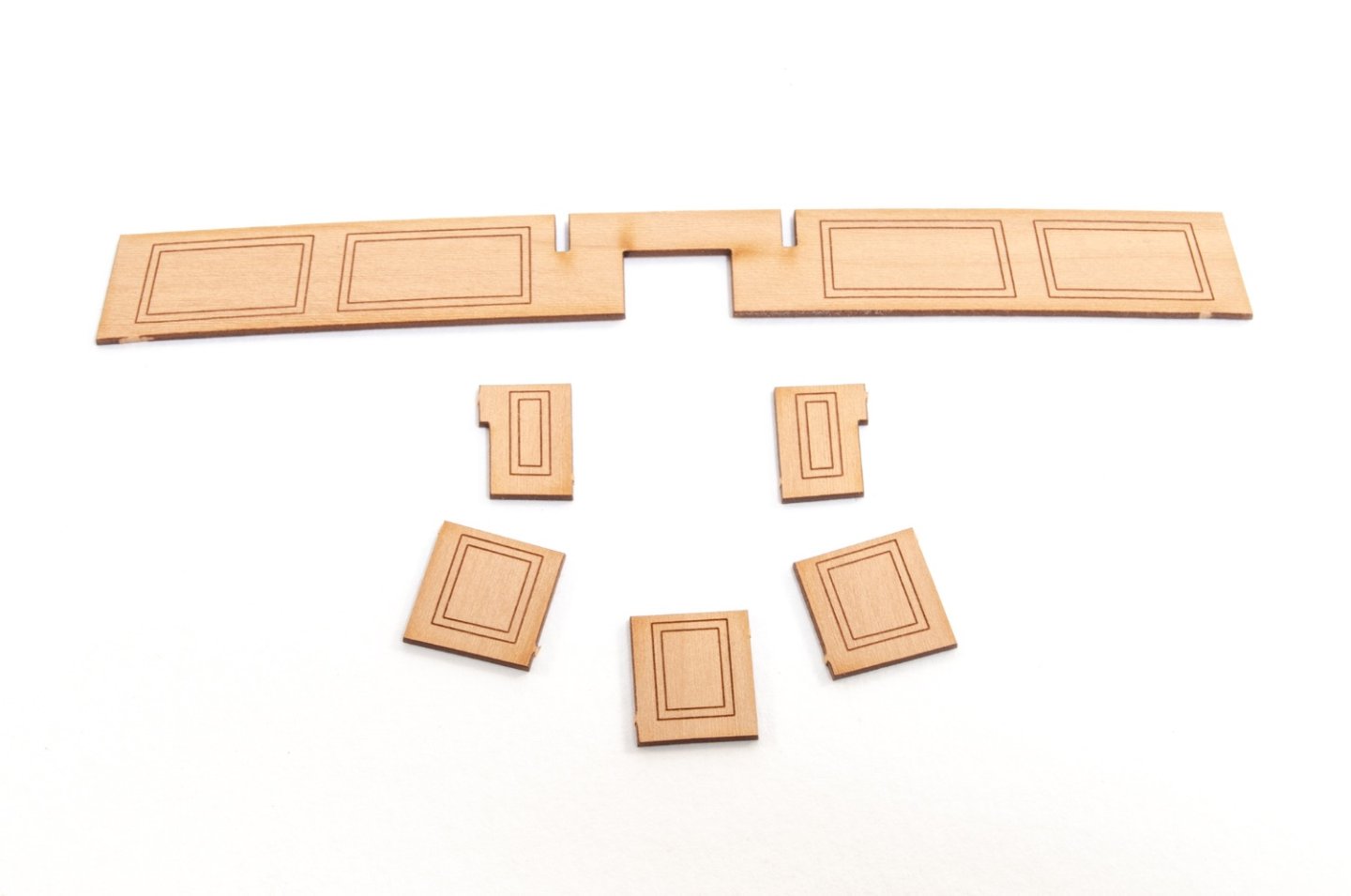

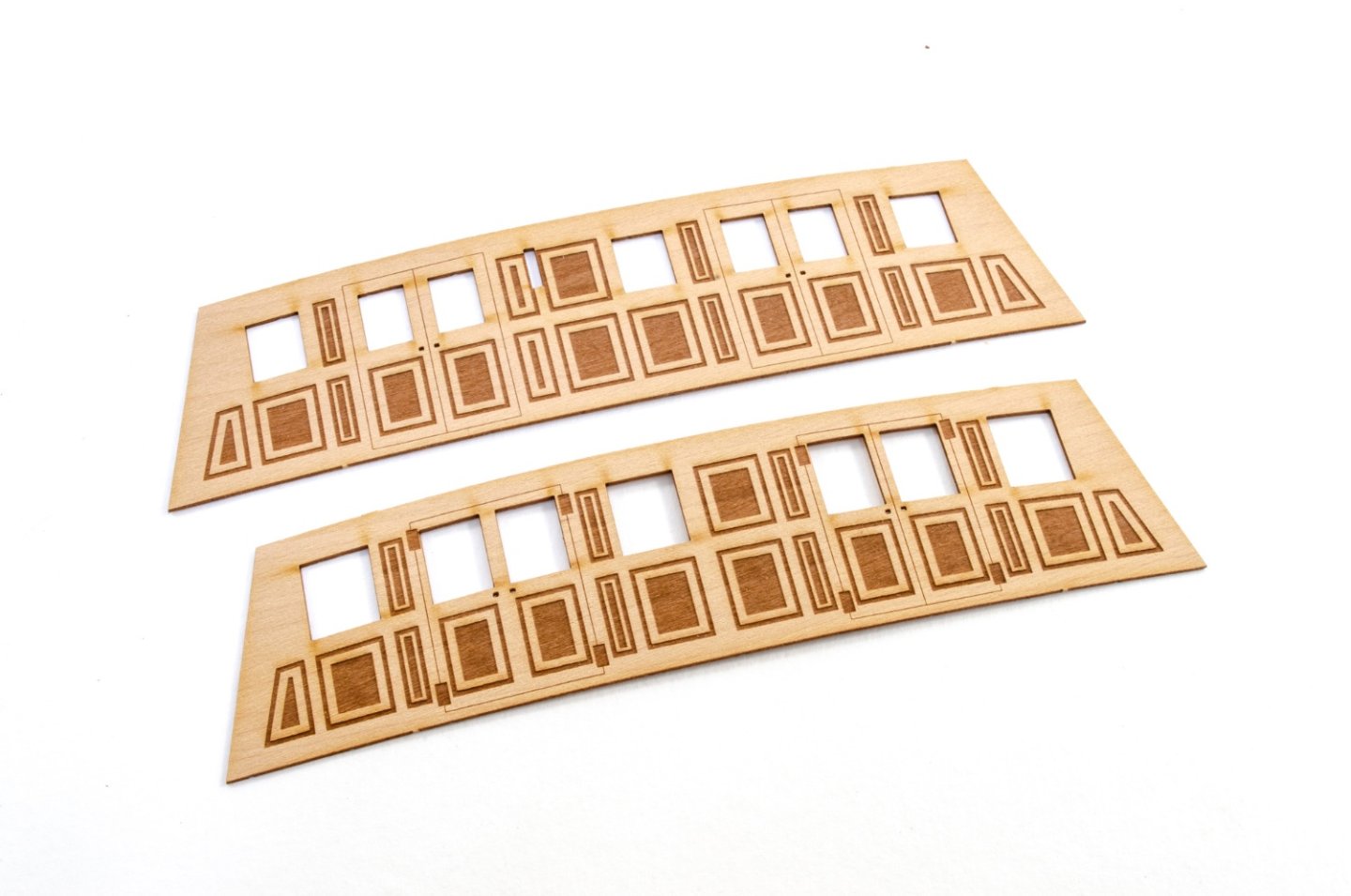

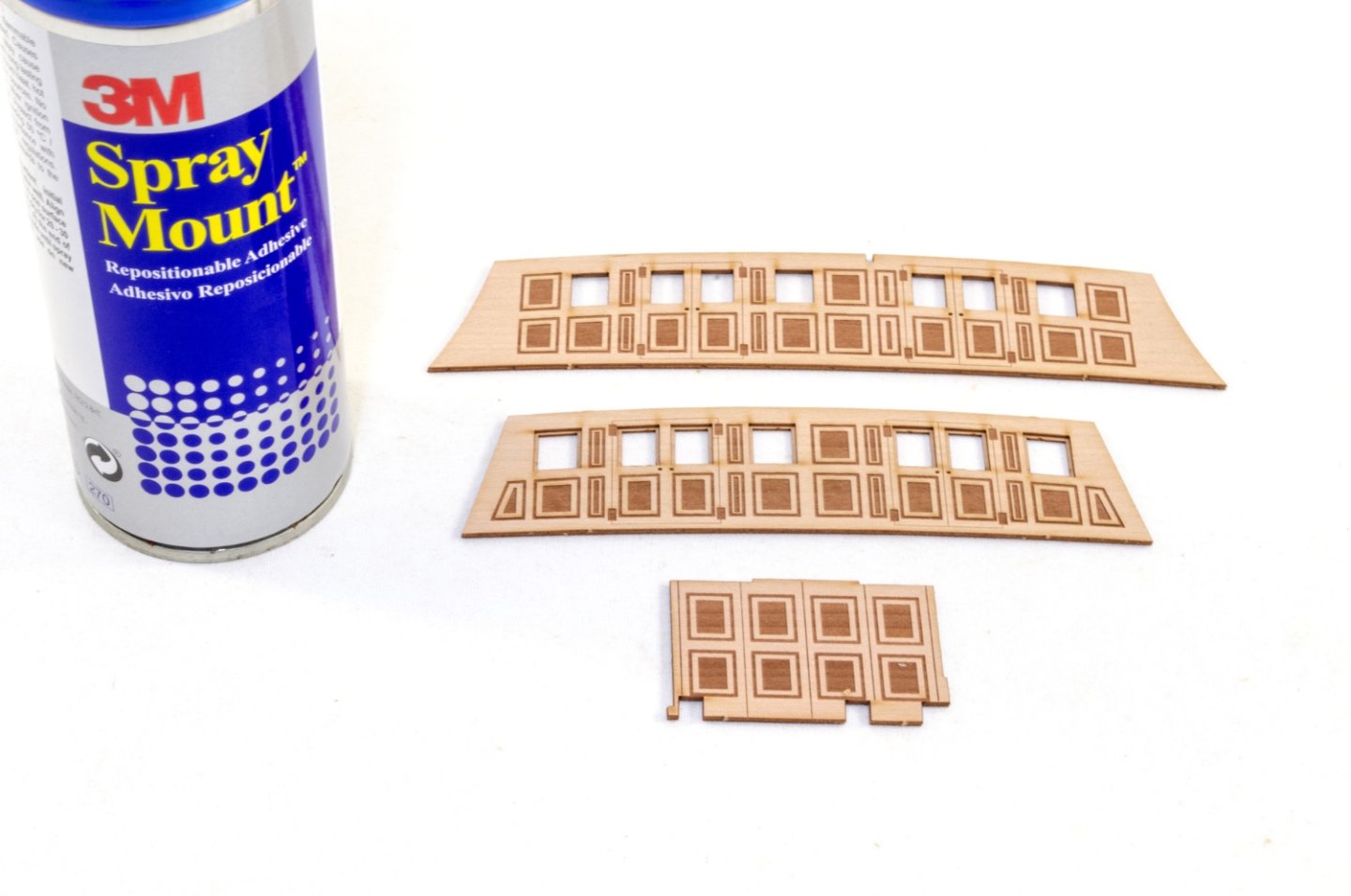

The bulkhead screens are supplied in two 0.6mm engraved laminates. Instead of using wood-curling white glue, 3M Spray Mount is used. The parts are lovely and glass flat.

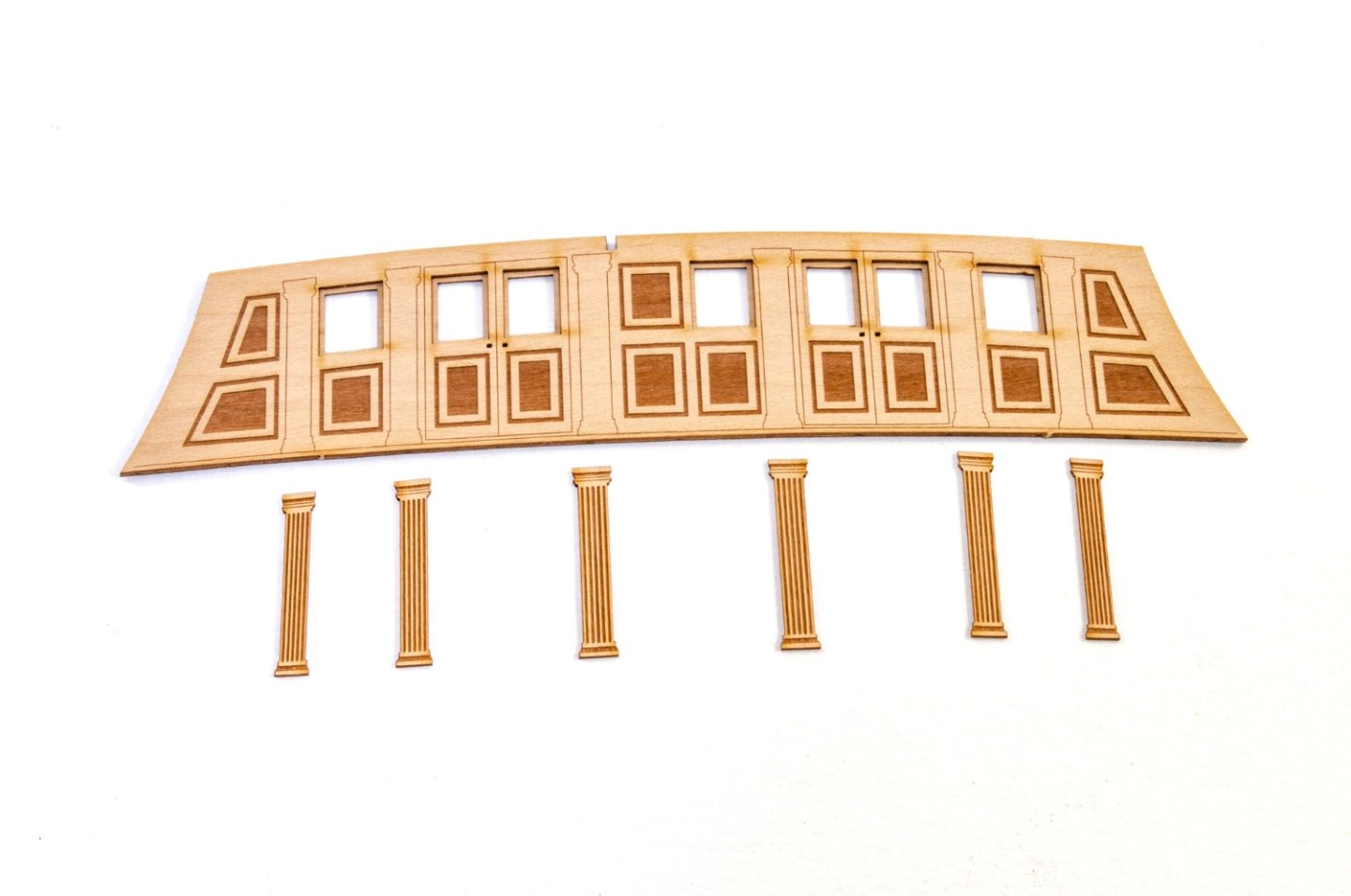

The outer bulkhead screen is fitted with laser-engraved columns.

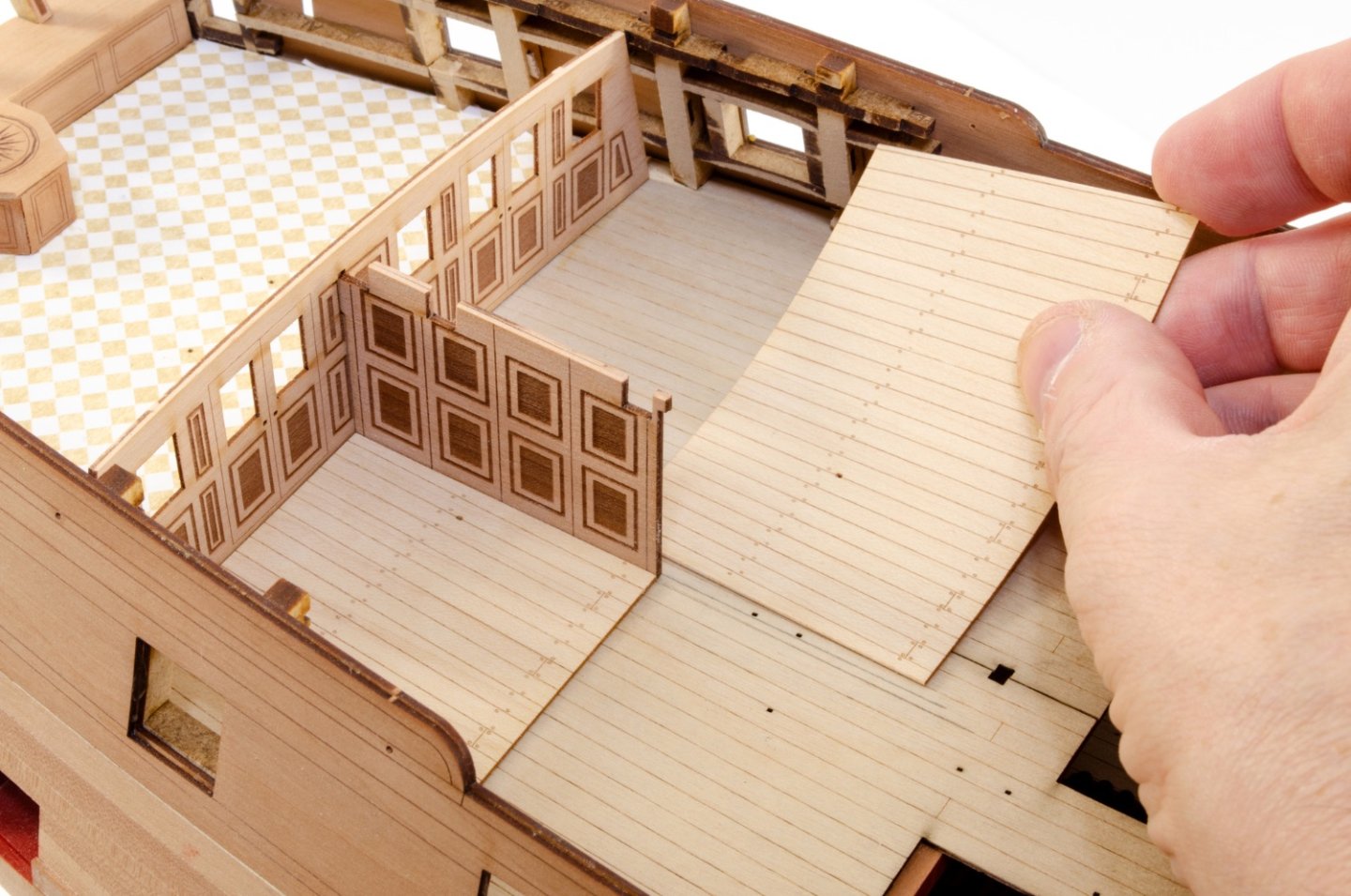

The inner bulkhead screen and the partition wall are temporarily fitted so that the engraved maple floor sections in that area can be trimmed to size. Once they are done, the floor sections are glued into place and the screen and partition removed until later.

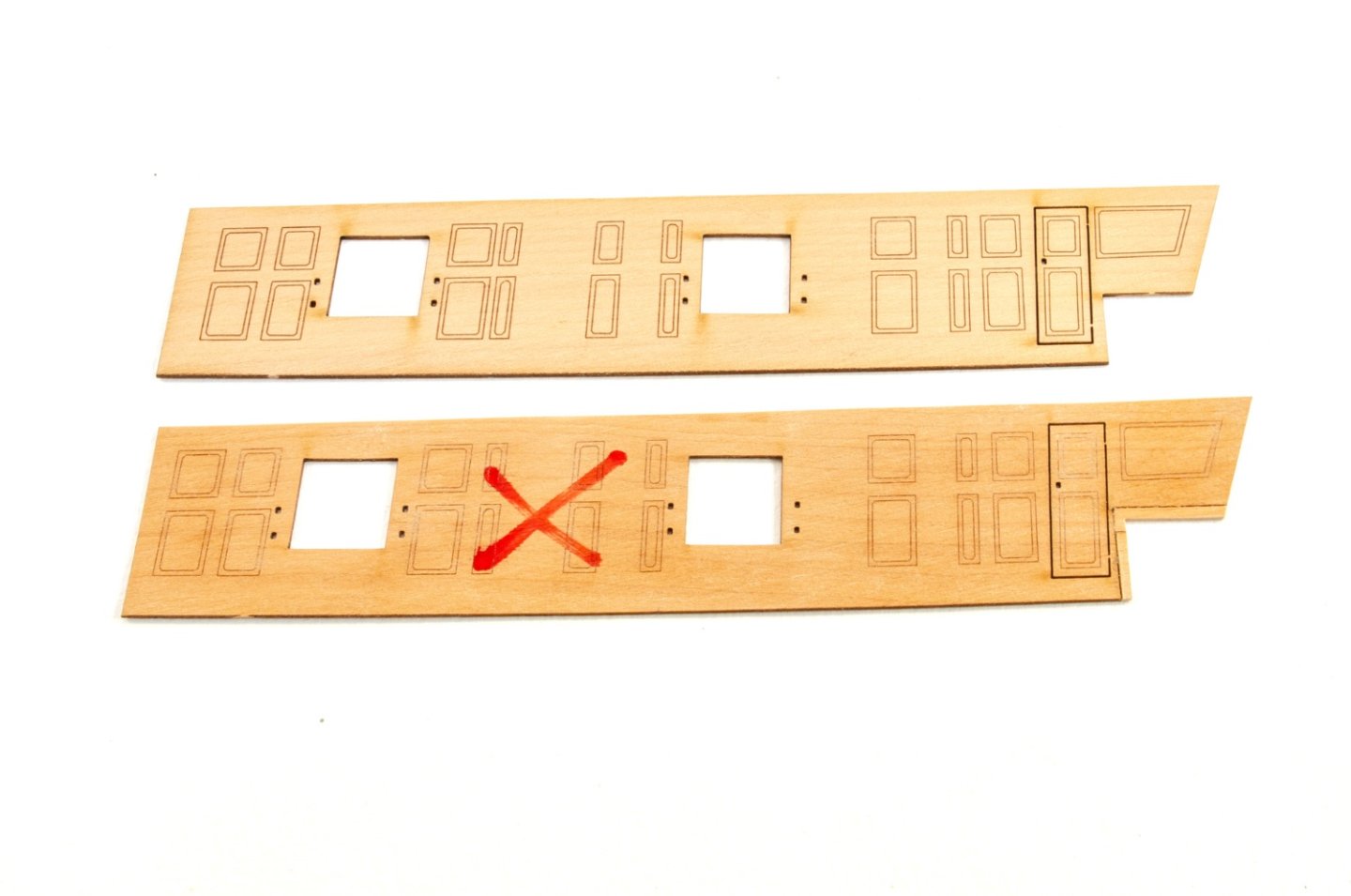

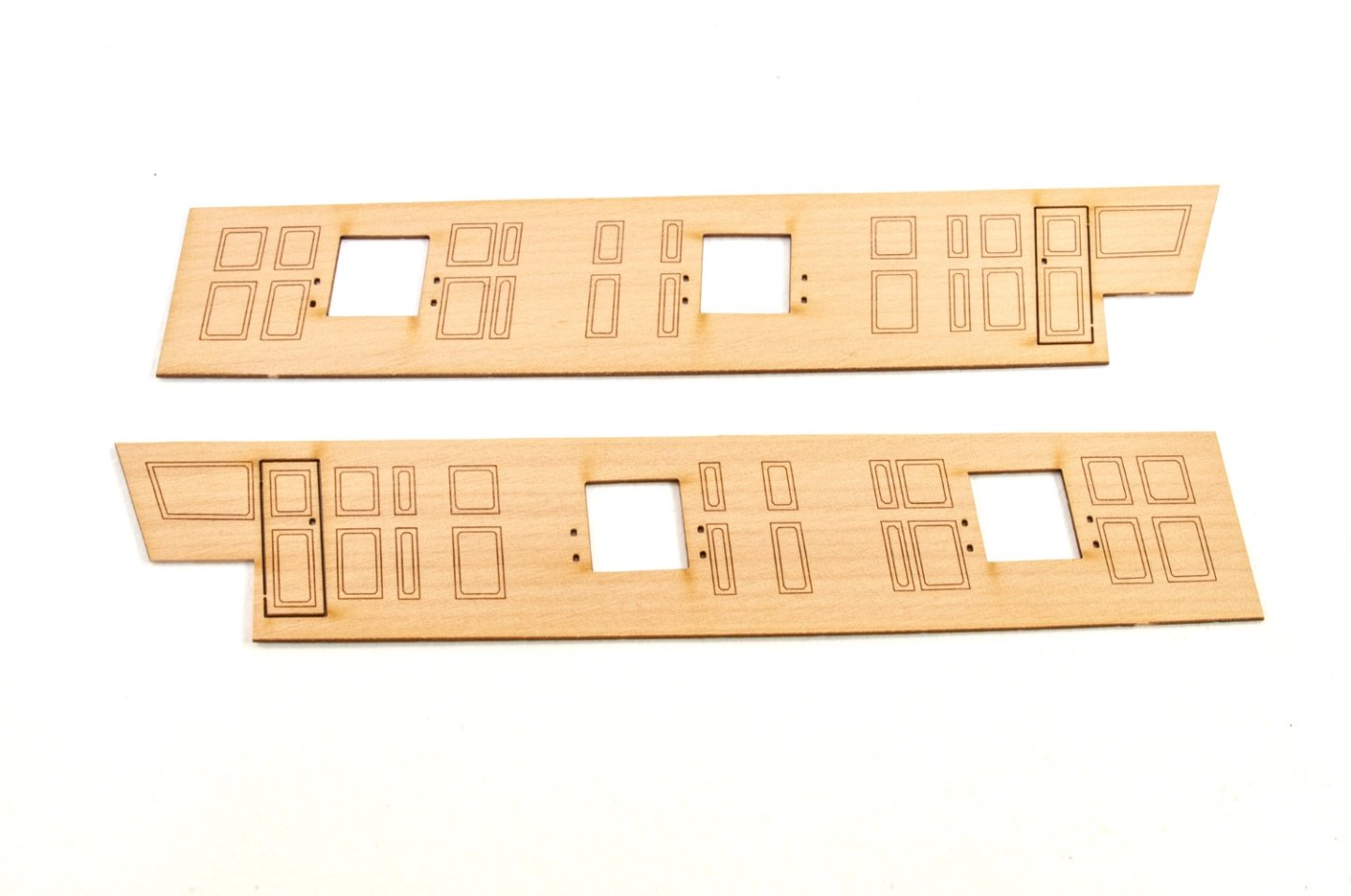

This picture will give a good idea about the post design process that I am engaged in when building the production prototype. I will invariably find a small number of things which needed amending. This is either because it was missed during the initial cut build, or because something in the design was changed and a small number of affected areas may have missed an update. Here you see the cabin side wall and the changes made from the initial part. That includes shifting details by 2mm to align gun ports and also packing out the rear to cater to the lowered cabin shelf. Hey, at least we can show you how we do this as a tag-team!

I temporarily fit the cabin walls and the screens so that I can draw a demarcation line to guide me for painting the cabin interior.

-

Posting in my capacity as part-time VM employee (😆), this is to let you all know that today is the last day of the VM Summer Sale, with 10% off all VM kits, except for Ranger, as that's a new release.

If you want a nice discount on a fisher, Duchess, Sphinx, Flirt or Speedy etc. NOW really is the time to pull the trigger!

- Kevin, jpalmer1970, thibaultron and 5 others

-

7

7

-

1

1

-

- BMT, mtaylor, Edwardkenway and 3 others

-

6

6

-

Ok, just an interim update.

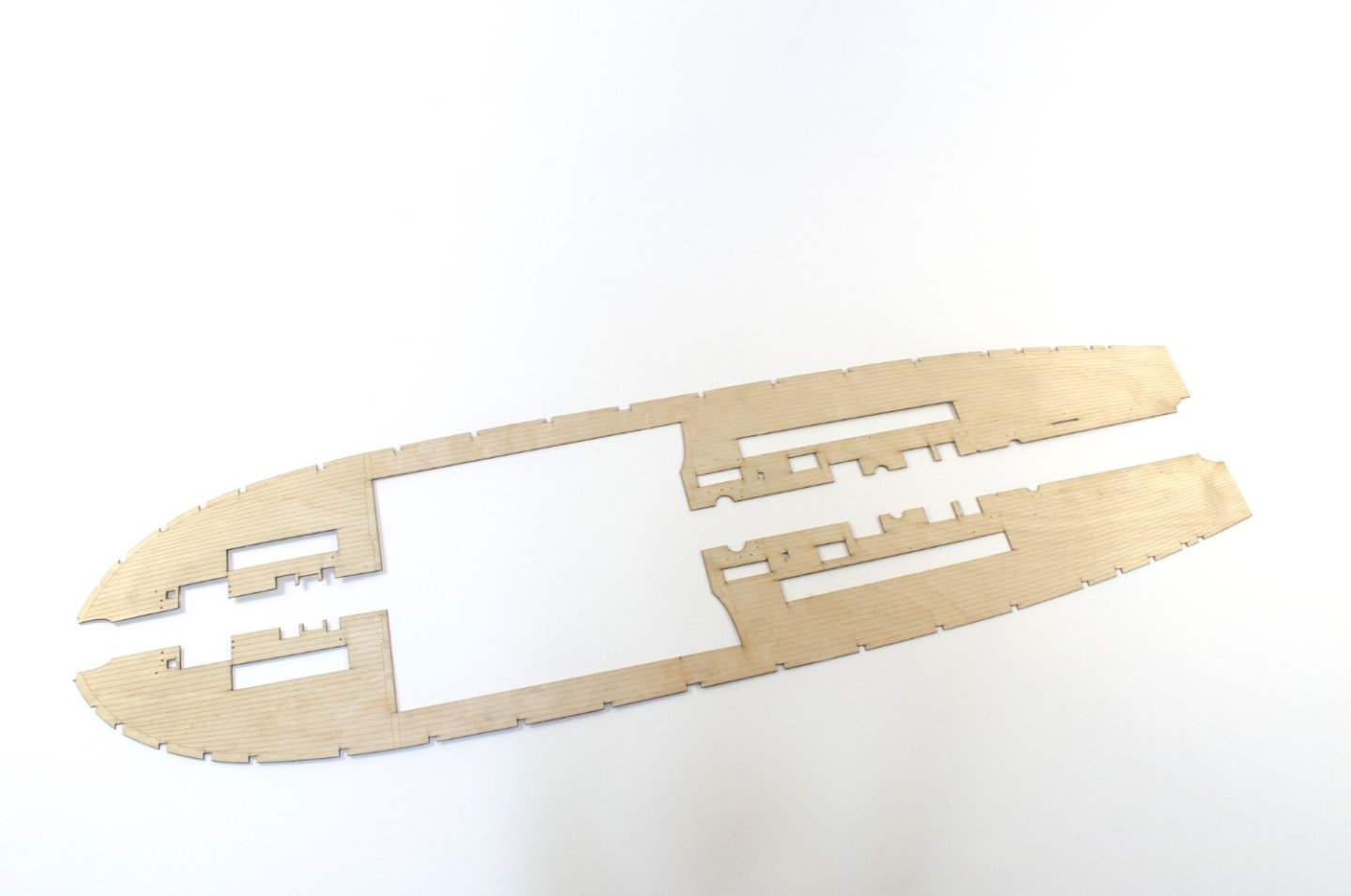

I was going to leave this until weekend when the office was installed, but I may as well show the upper deck being fitted and prepped for further work. Indy will be supplied with deck planking material as standard. At the moment, this looks like it will be red alder, which is gorgeous. I have some here that I'll do a couple of stages showing how to present it, assuming the modeller will have a good idea already. Indefatigable isn't marketed at modellers who are novices or intermediate. This is an 'Advanced' level kit in VM's new 5-point kit categorisation. More on that when it's released. What you see here are the standard ply sections which are laser-engraved so you have something as a planking guide.

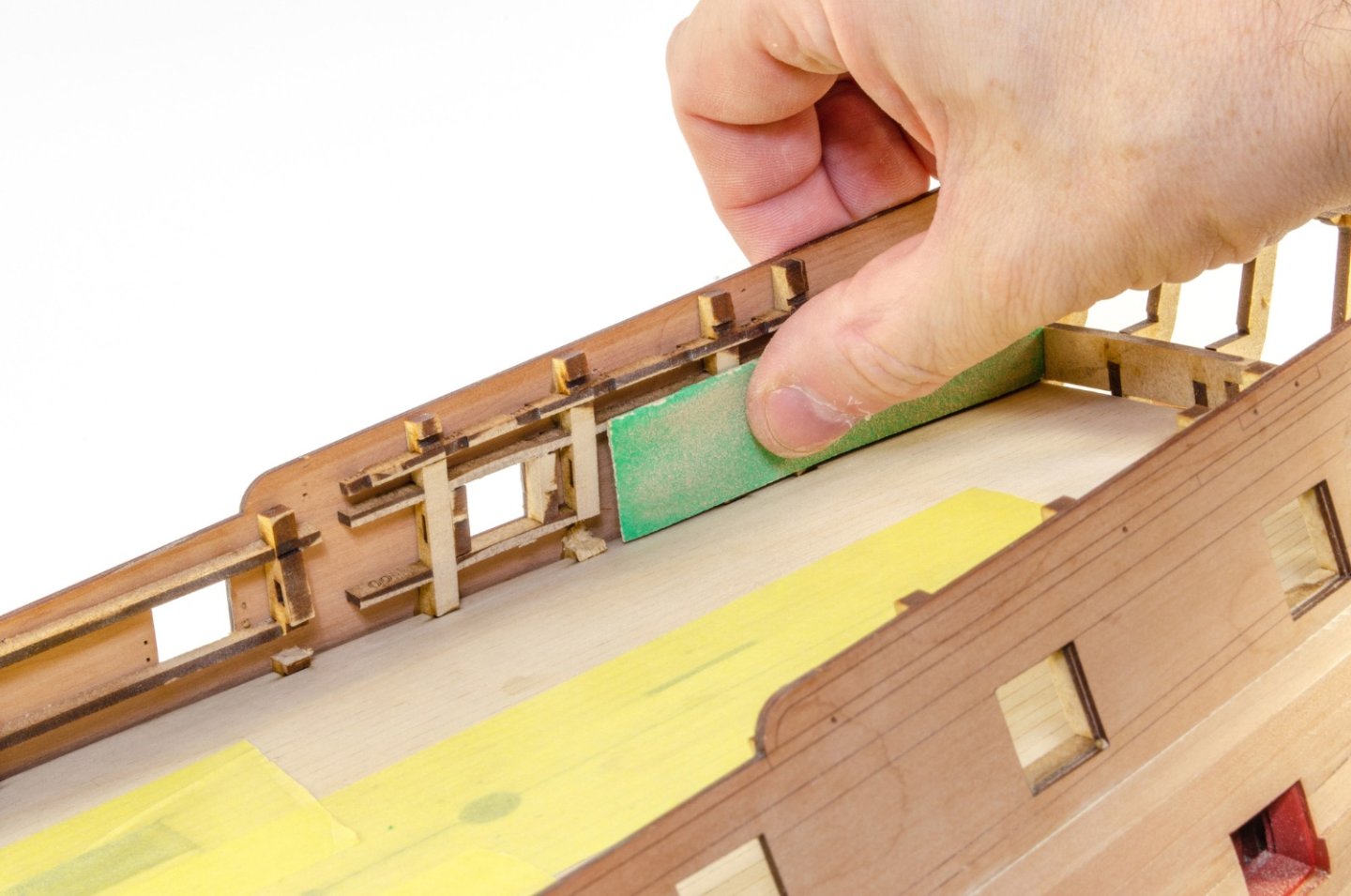

This is where checking the lay of the deck beams really does pay off. This deck is fitted in halves, unlike the main deck, simply as it's a more complex item. With everything test fitted and dry run several times, the deck beams have glue added to them and the deck is slotted into the outer bulkhead ears. Weights and clamps are then used to hold things down until dry. The 2 inch clamps are perfect for this, especially the cutouts where the front end clamps the joint and the clamp tail holds down the opposite side.

And then the other deck half is fitted in the same way.

There is a little more internal fairing to do, but this is easy enough. This is where the cabin walls will be installed and I need to make sure there's no bumps anywhere.

And while this seems drastic, these frames DO need to now be removed as the next build stages will incorporate engraved inner bulwarks which glue onto the the sides.

The forecastle bulkhead ears are now history too.

More at weekend when I have the painted furniture in hand.

-

1 minute ago, VTHokiEE said:

Those are truly amazing. Do you have any tutorials on how to even approach doing painting like that?

Nope! This is why I farm this stuff out as he knows what he's doing, plus I'm still busy with woodwork 😆

- Dave_E, chris watton, hollowneck and 3 others

-

6

6

-

-

-

A very brief update before the weekend one.

The office furniture has been painted by a friend of mine, and here it is. The round table will not be included with Indy, but the other table will, along with a couple of chairs. Here you can see a couple of incarnations of the furniture, 3D-printed and painted with oils. My friend also added the navigation charts for some extra effect!

These items, including the round table are available already though. https://vanguardmodels.co.uk/product/cabin-furniture/

-

Looking forward to seeing this.

Remember to check out the notes I added about the position of the lower stern counter. Check step 149 for info.

- hollowneck, Ryland Craze, Mr Whippy and 1 other

-

4

4

-

-

You're doing a nice job of your planking. Good to see her coming along so well.

- aydingocer and mtaylor

-

2

2

-

I left the hammock cranes off the model as they would've fouled the shrouds. That won't be a problem with your build.

- Blue Ensign, mtaylor, Mr Whippy and 1 other

-

4

4

-

2 minutes ago, Peregrinator said:

What a wonderful looking kit and a simply superb build so far. Congrats to both Chris and James.

This is the kind of build I dreamt of when I first bought my HMS Cruiser kit as a "learner build". Maybe one day I will feel up to attempting such a beauty. (Mind you I need to finish the Cruiser first!! lol)

While it's an advanced level kit, if you've got some building experience under your built and can think logically, this won't be beyond many people.

- mtaylor, Mr Whippy, DonSangria and 6 others

-

9

9

-

11 minutes ago, JerryTodd said:

Hornblower was a midshipman on Indefatigable. He wouldn't have that coat or epaulets, and midshipmen carried a dirk (about a foot long blade) as a badge of rank), or a ship's cutlass in combat, not a sword.

Hornblower isn't supplied with this kit. Just Pellew. It's up to the modeller if they want to include Hornblower and any uniform vagaries (bearing in mind most folk wouldn't know anyway...I certainly didn't).

-

17 minutes ago, Blue Ensign said:

Looking great James, would have loved those lodging knees for Sphinx, would have saved me a whole load of cutting out.

Ah well.

B.E.

Sounds like this will be perfect for you 😉😜

- Dave_E, Edwardkenway, mtaylor and 2 others

-

5

5

-

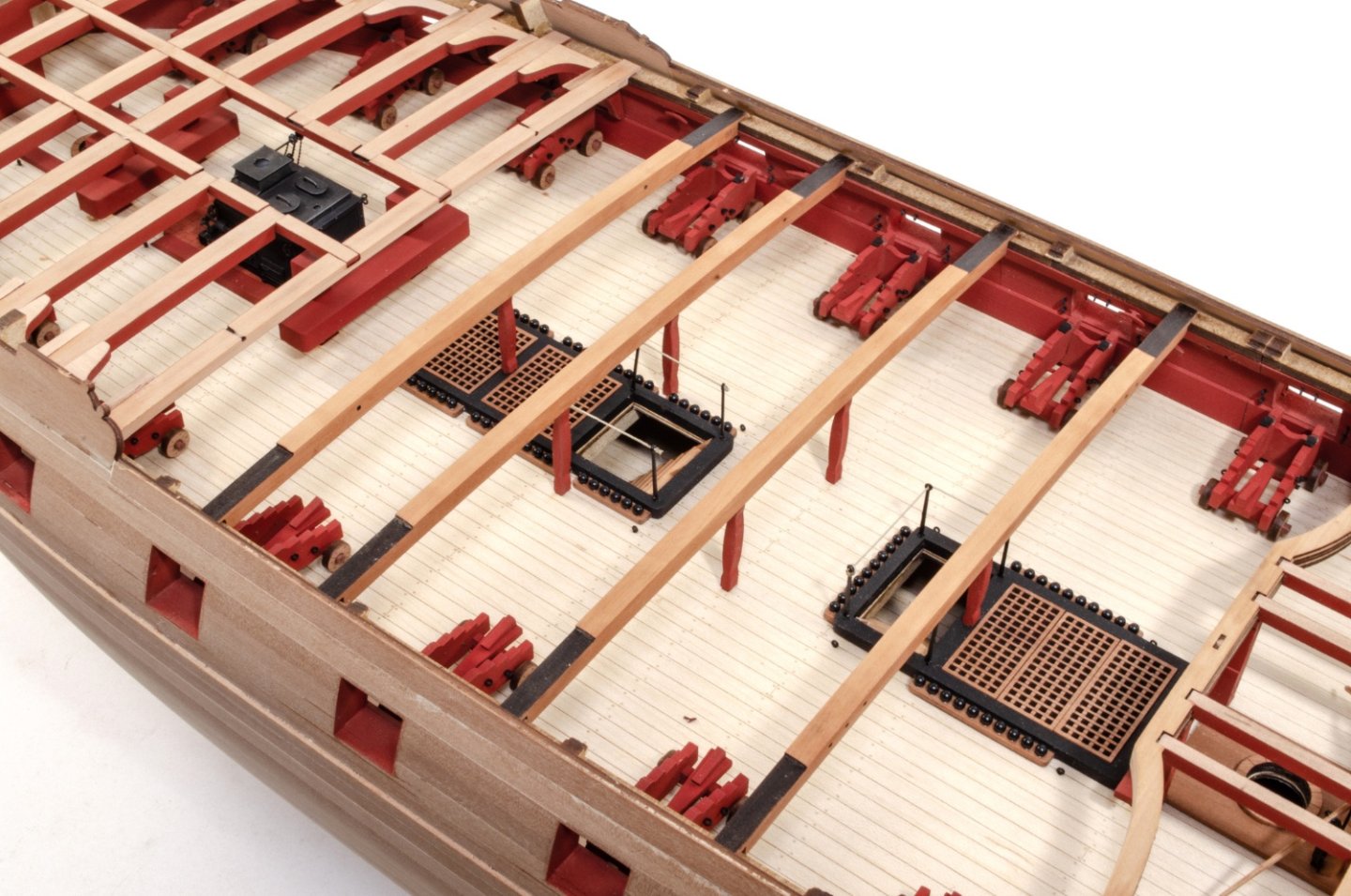

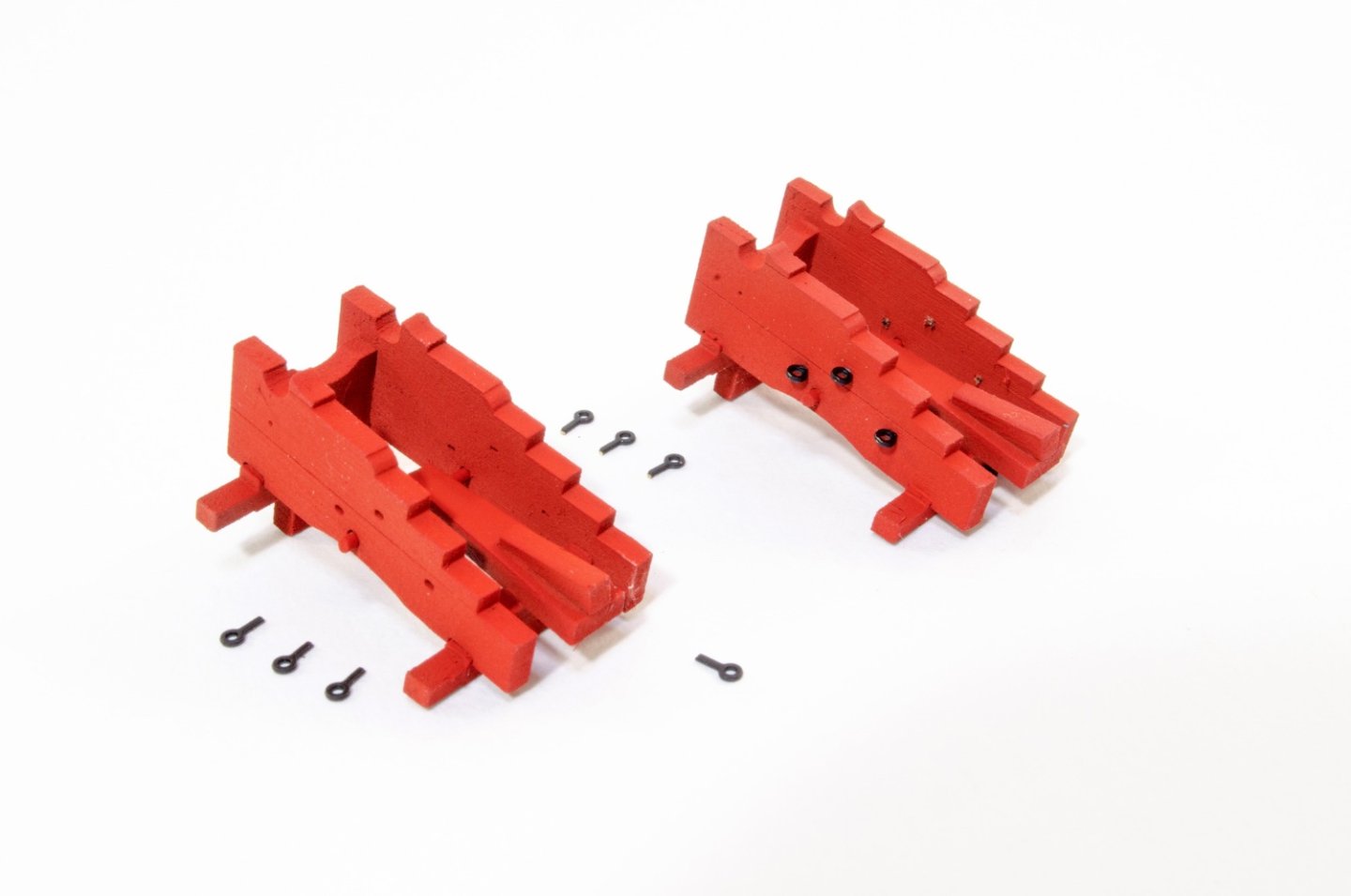

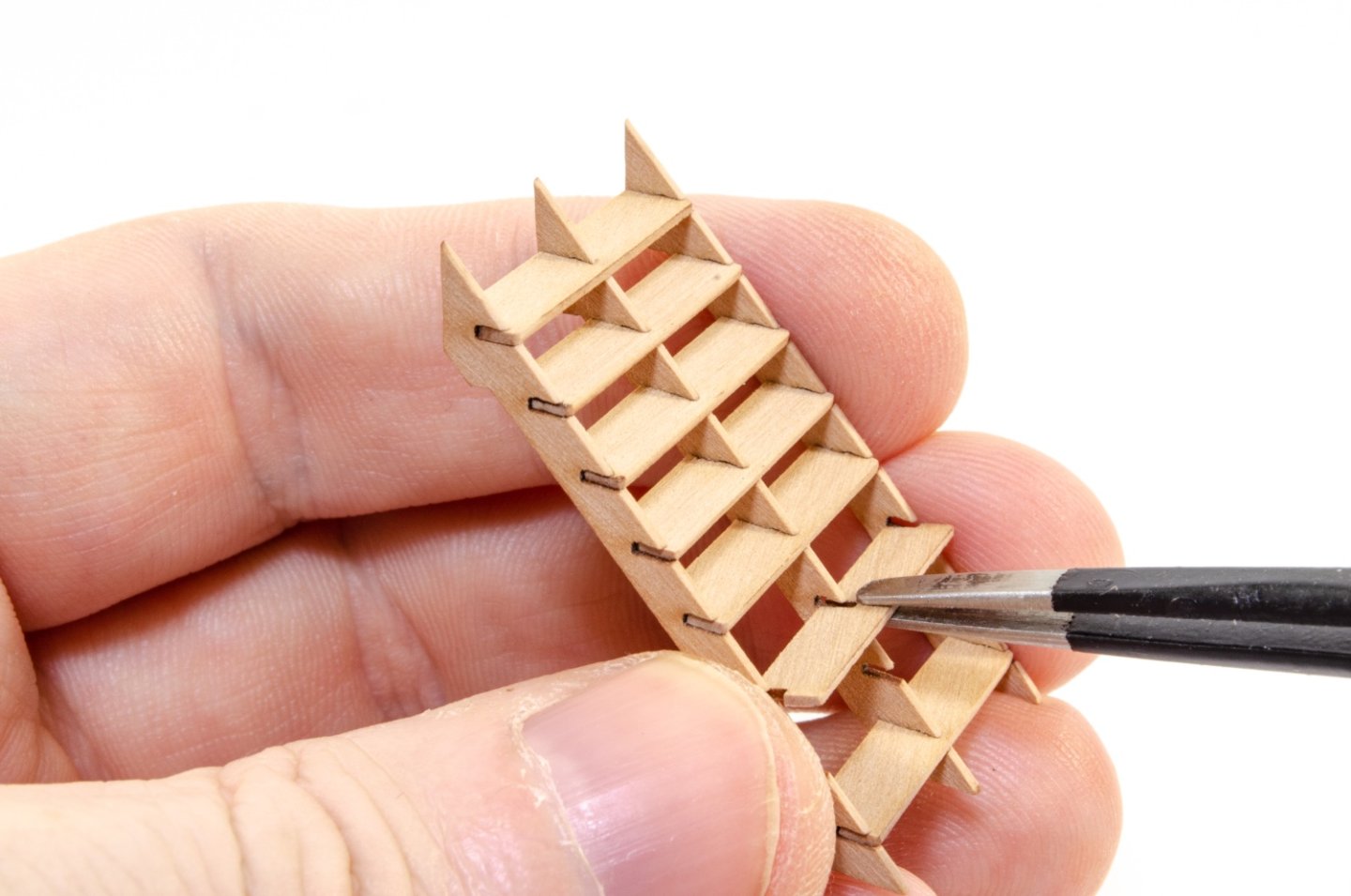

Included in the kit will be a set of optional lodging and hanging knees. It'll be up to you if you want the extra work, but for the manual, I have to take one for the team! These are the hanging knees. The truncated ones are the parts that will be fitted where the gun port would otherwise be obstructed by the longer part. Of course, each part also needs to be specifically shaped to its position. Plenty of spares are supplied.

Here they are fitted, along with the lodging knees.

And the fore deck beams are now added, with the optional knees also installed, followed by the boat beams. These also have optional knees.

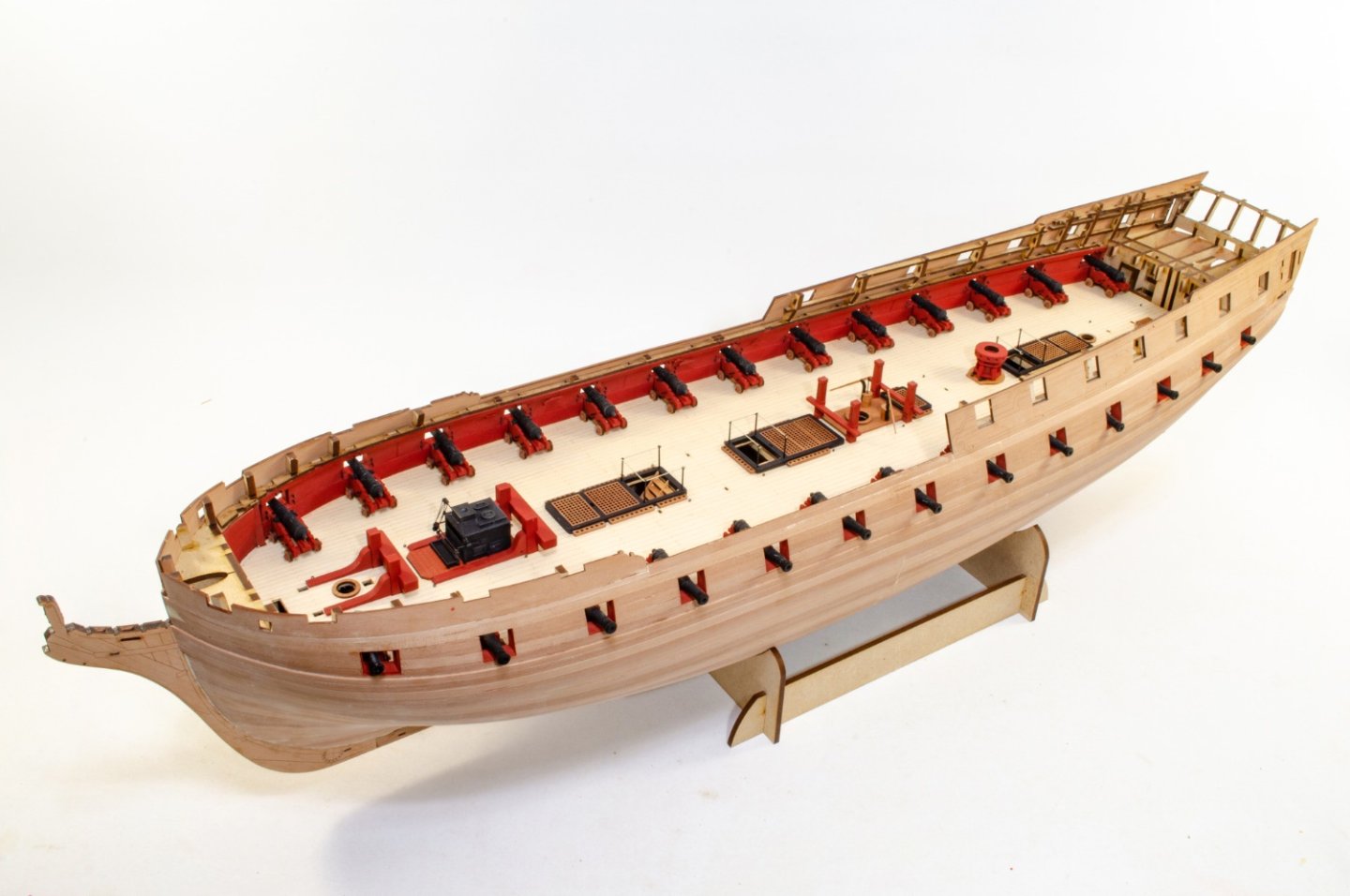

And here she is so far!!

-

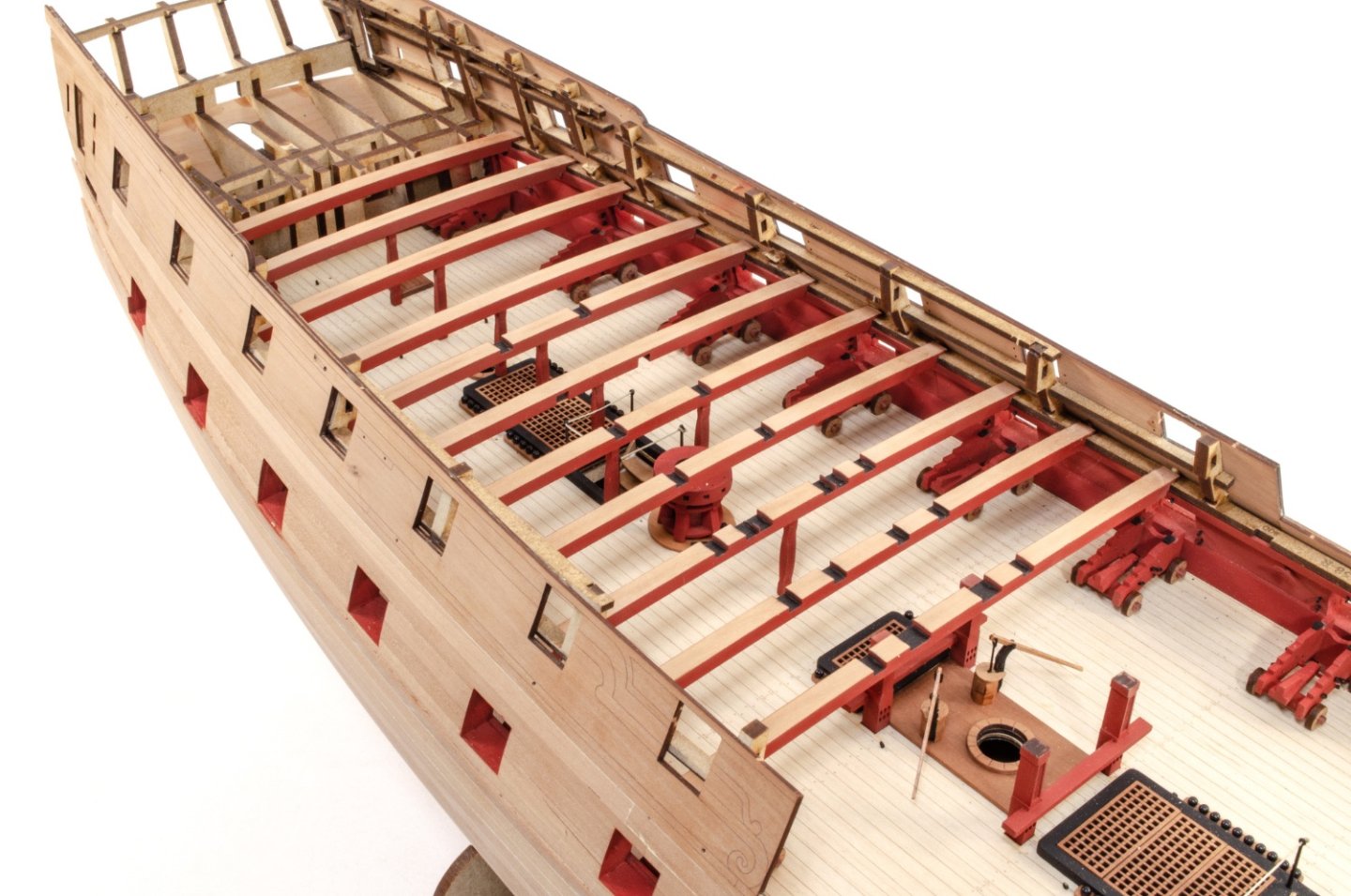

Time for another update.

This was something I was looking forward to doing. Not covering up all that work I'd just done, but to turn a corner and be able to do it all again for the next layer in the Indy cake.

Before I did that, I needed to add the scale-sized cannonballs to the shot garlands. These are done with liquid CA and some thin-ended paddle tweezers that won't knock the previous ball glued into place.

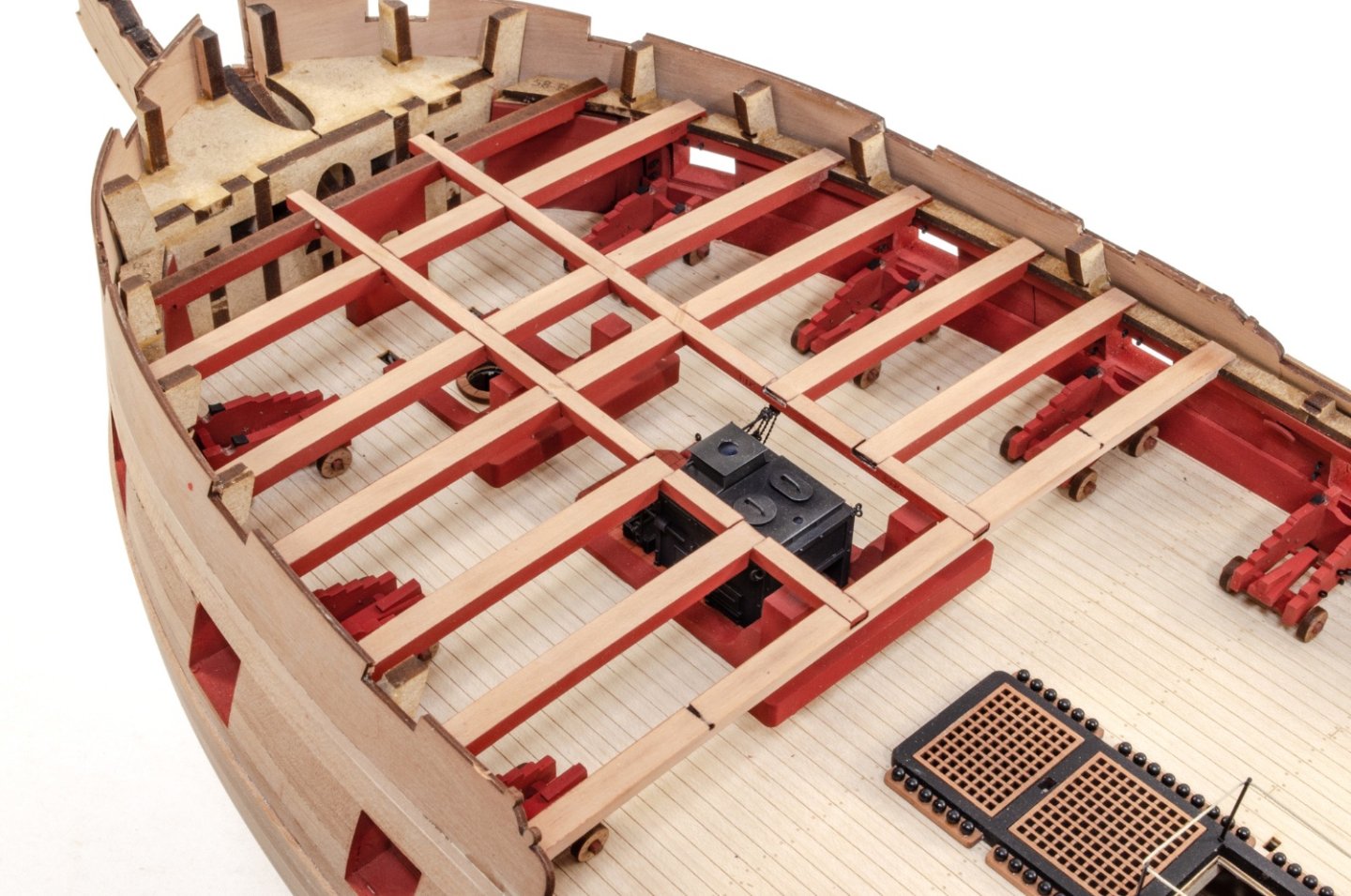

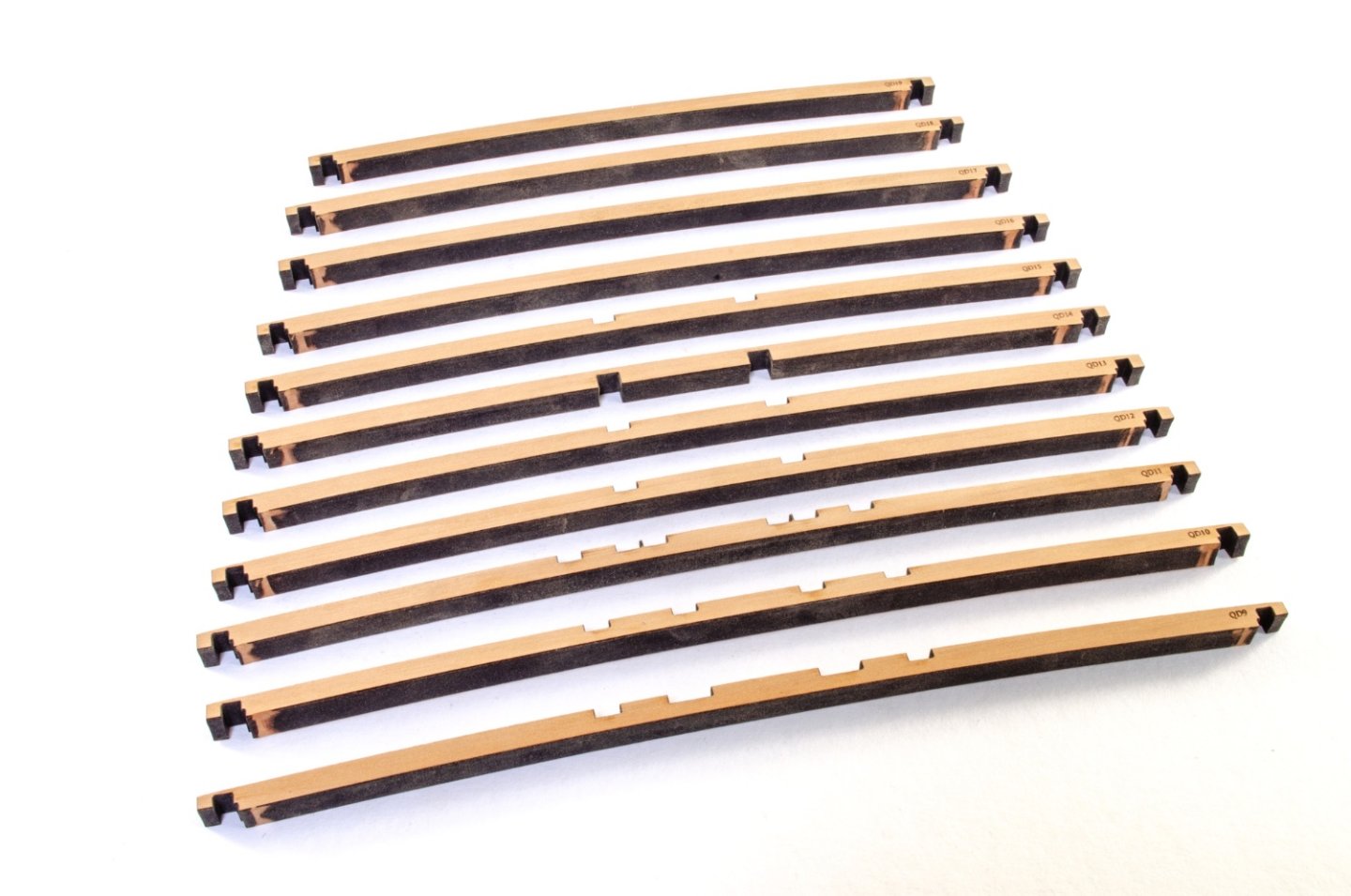

And with that, it's onto the beams. As the upper side will have some timber showing through the deck cutouts, these were totally cleaned of char. The whole upper face was cleaned also because they look much better for the instruction photos.

There are two lengths of pillar, depending on whether they sit on a deck or on a grate coaming.

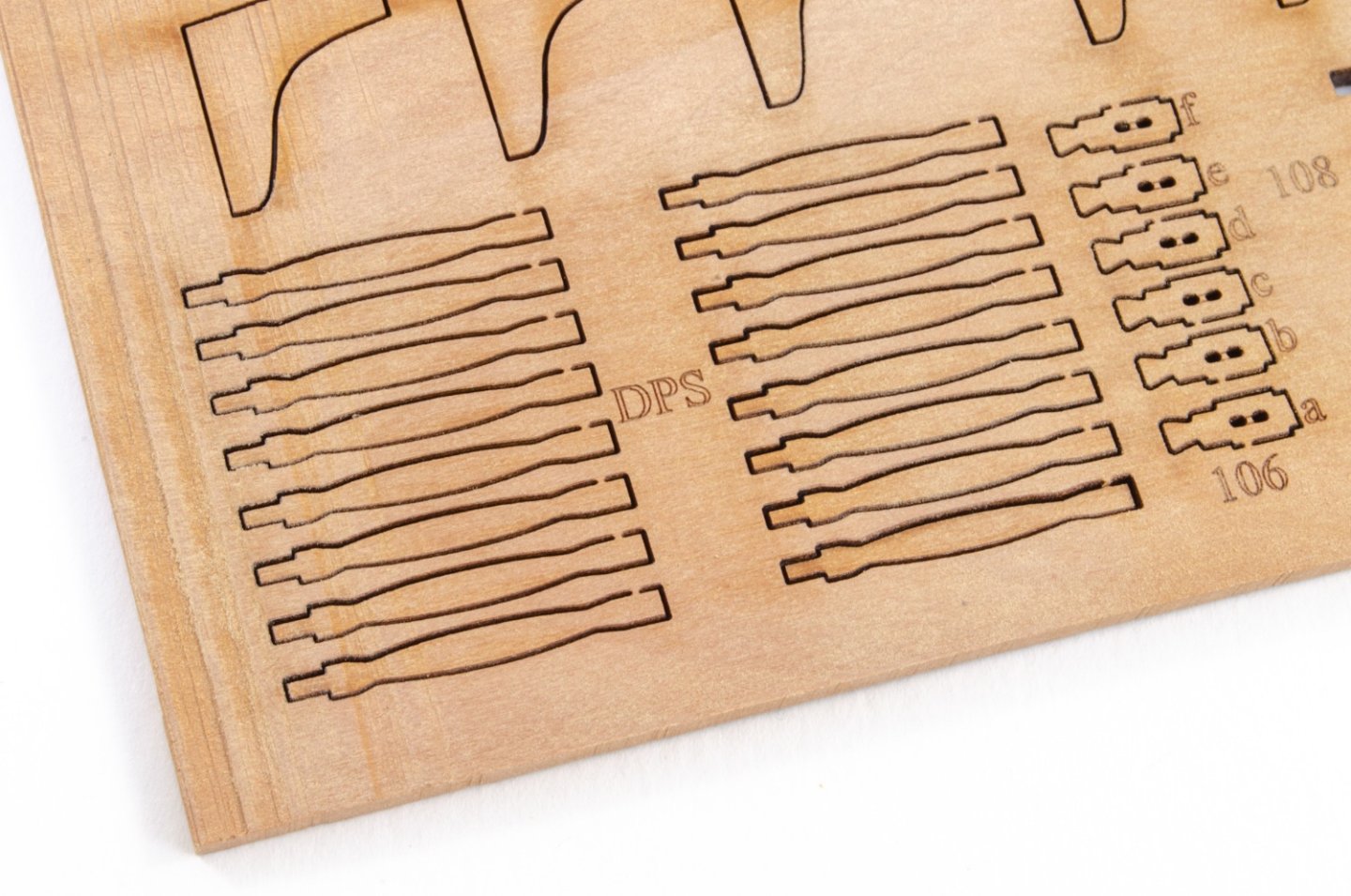

All deck beams were painted red, except for the upper side and all the slots. The beam ID is engraved on each beam and this ties in with the engraved number of the deck beam sill. The beams are now slotted and glued into position. Those beams that are supported are continually test fitted with a pillar before being finally glued. Also important to make sure the pillar doesn't push the beam higher than was intended. A steel rule checks this as I go.

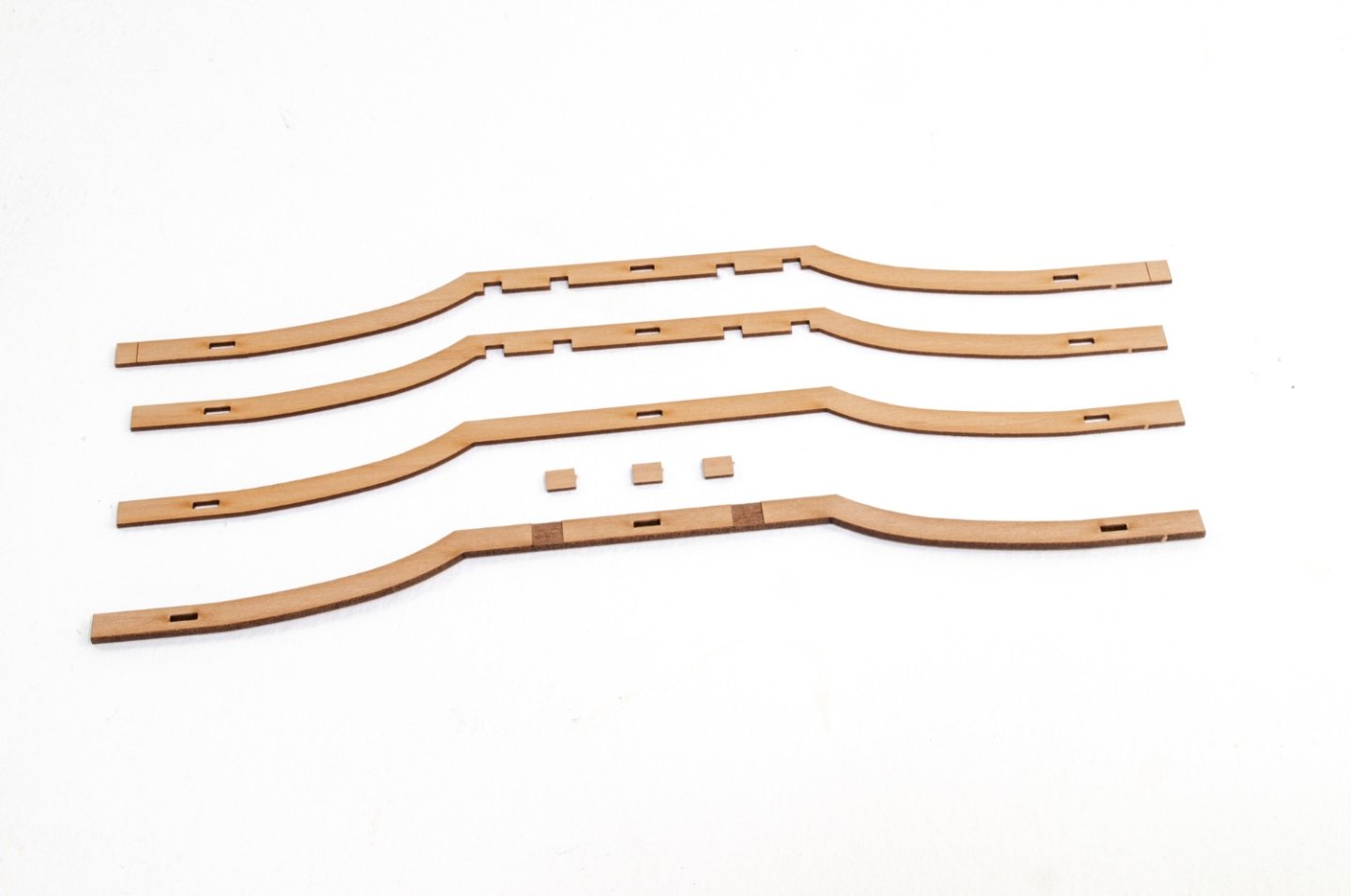

The forward beam for the quarterdeck is not only shaped in profile, but also curved across its length. To create this, the beam is made from laminated pear parts, glued together over a jig. When this is dry, the part is cleaned up and fitted into place, sitting atop two of the bitts.

-

I've always wanted a really long wait of tweezers with precision tip, and reverse grip too.

These would be for belaying, and I reckon about 8 inches long. I really do need to look for some.

- mtaylor, chris watton, Glenn-UK and 1 other

-

4

4

-

-

And more...

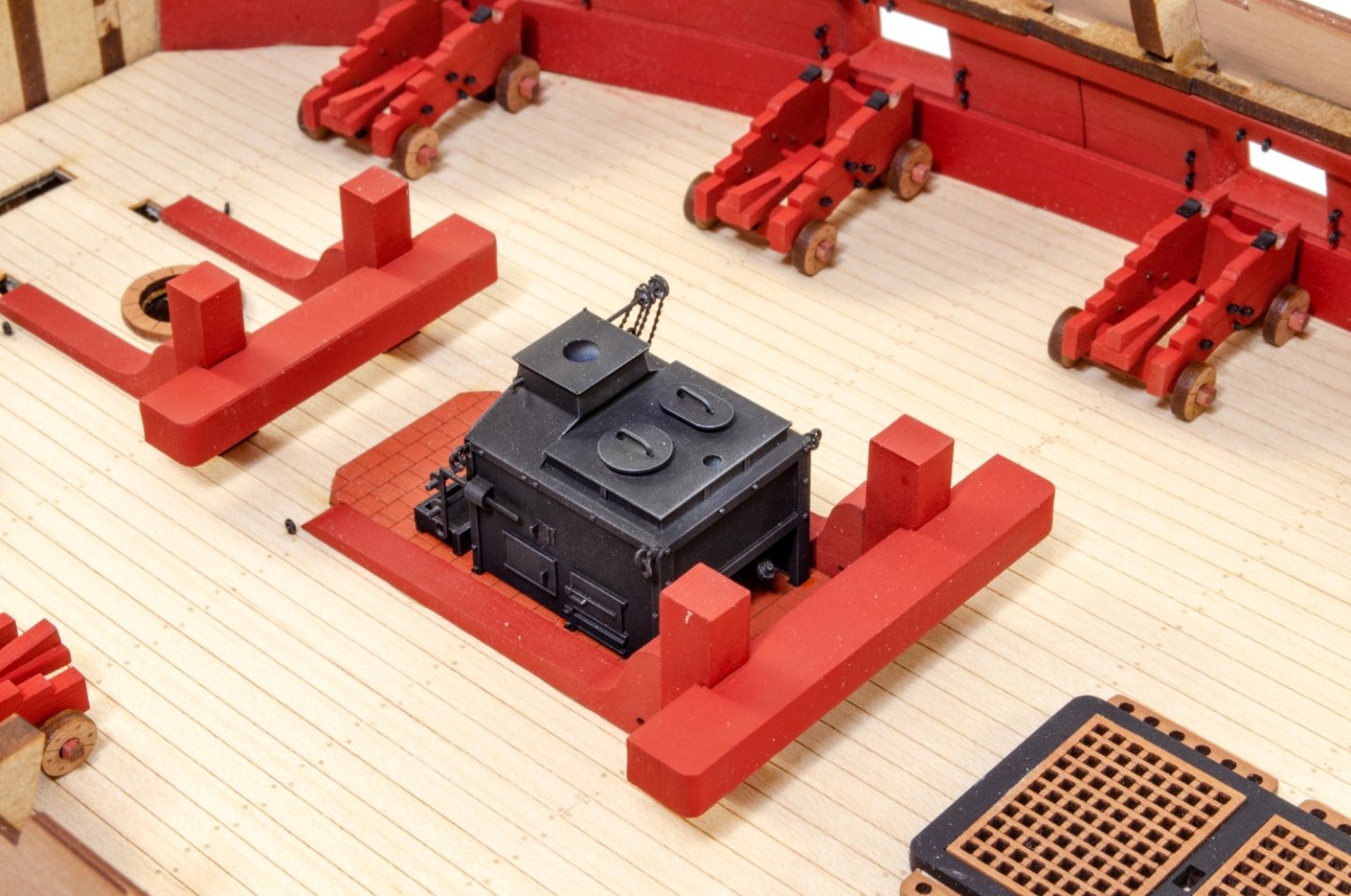

Knees(?) now added, as well as a painted brick floor for the stove.

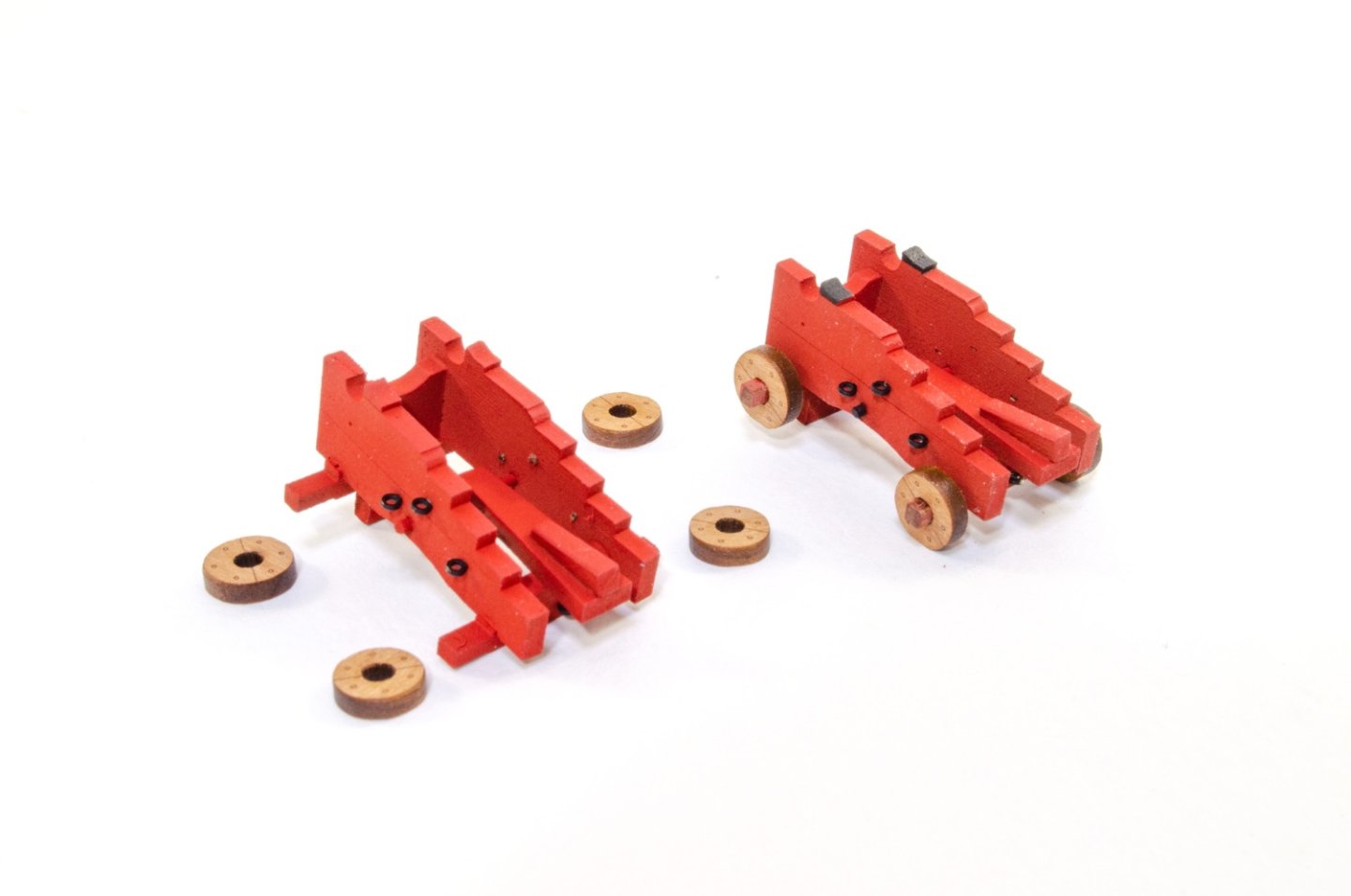

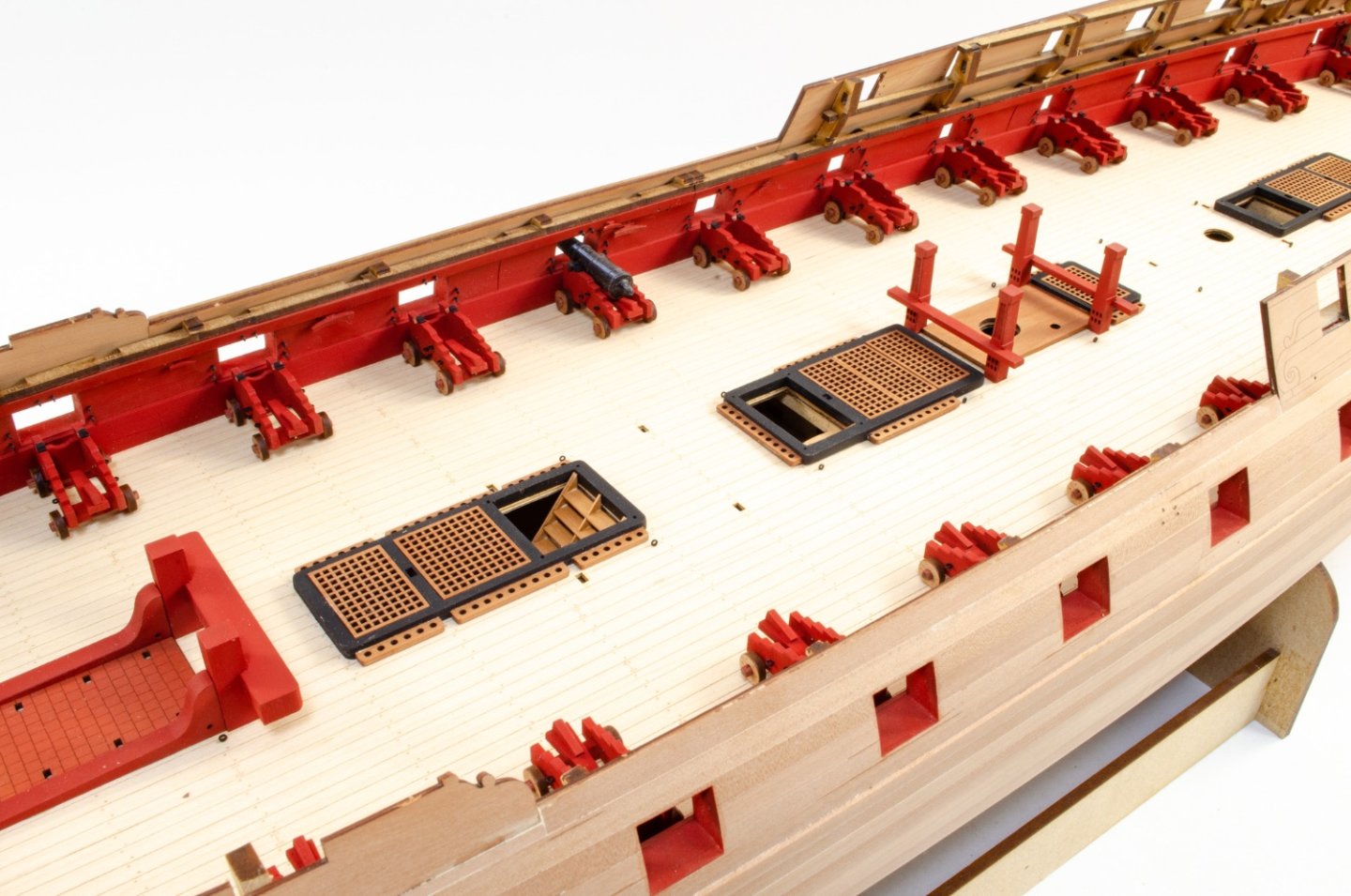

And the gun carts now have some colour applied to them, as well as ironwork and wheels. Remember, these won't be fitted with barrels until the model is more or less complete.

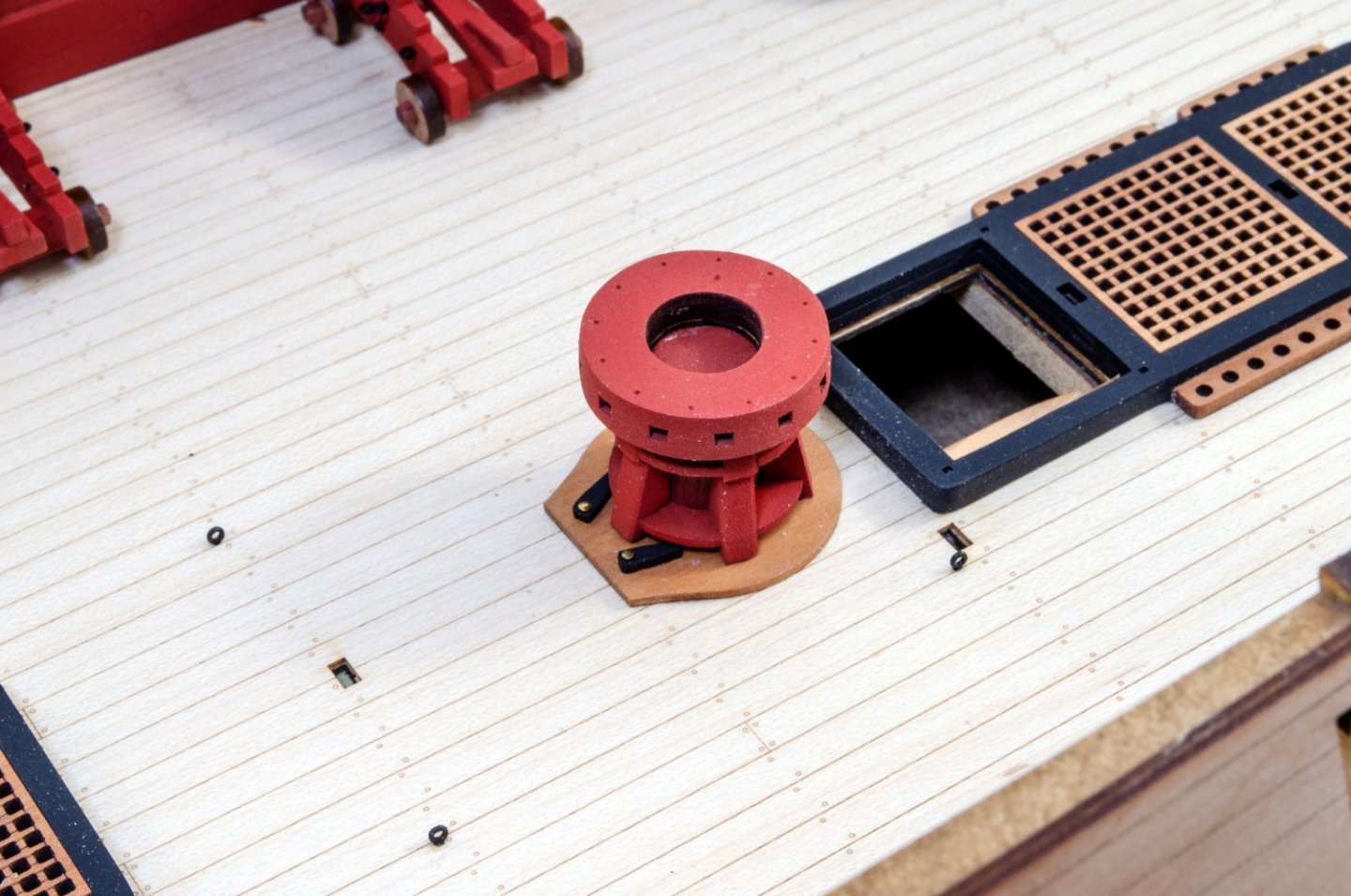

Capstan finally done.

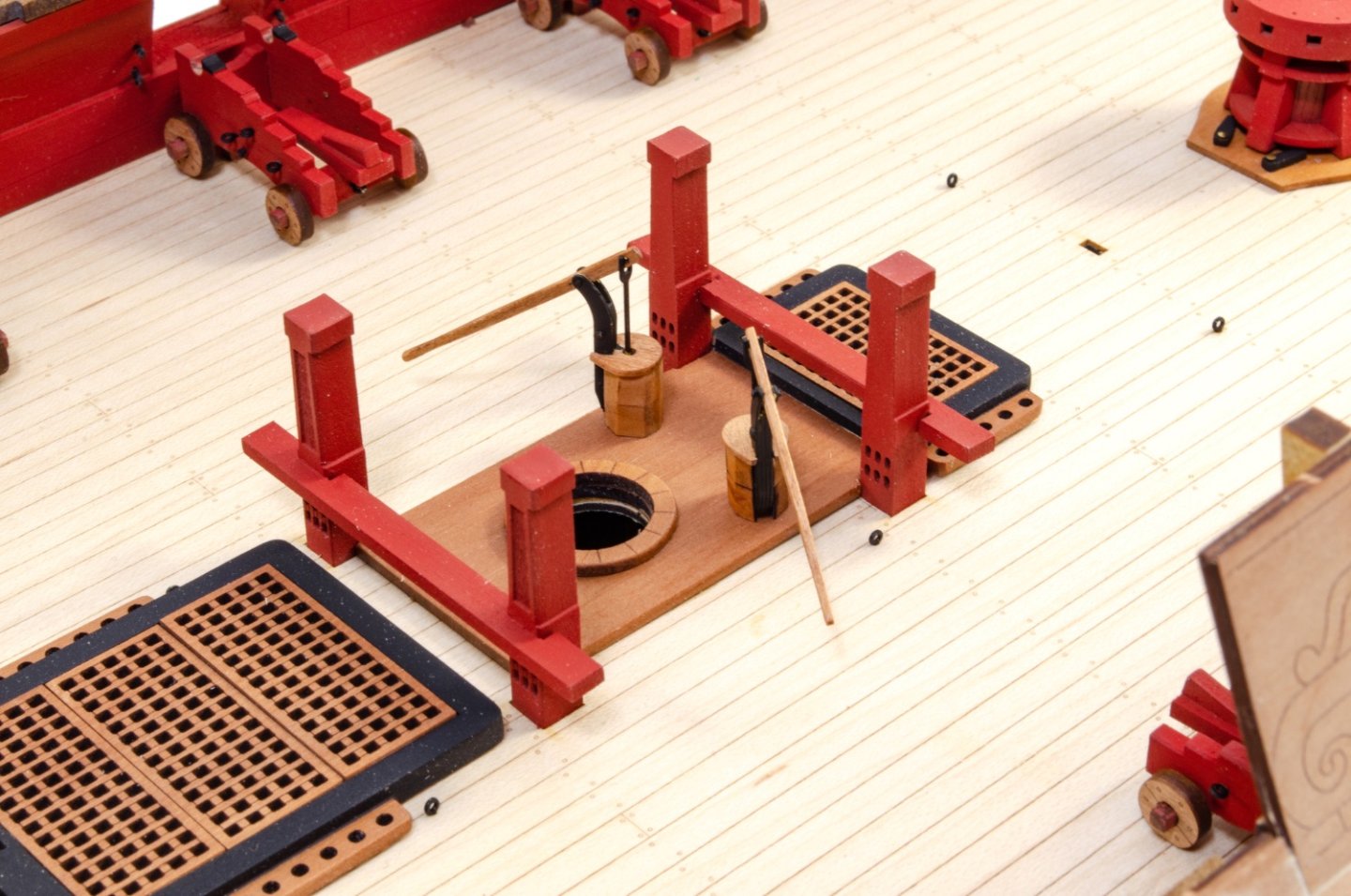

As are the hand pumps.

No one wants to walk down stairs without a safety rope around them!

And the stove makes an appearance.

And this is Indy up to date. Back in the shipyard tomorrow

-

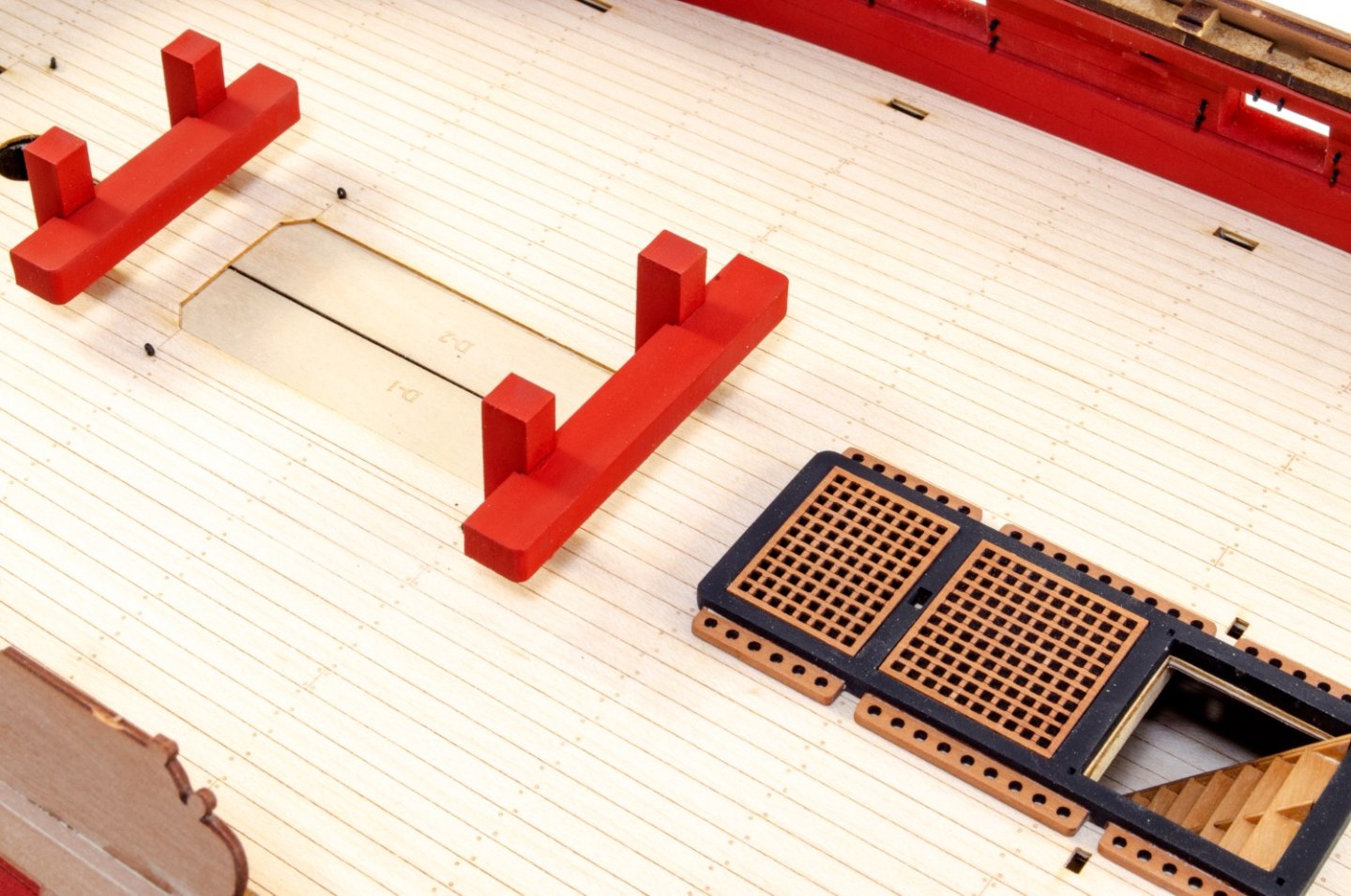

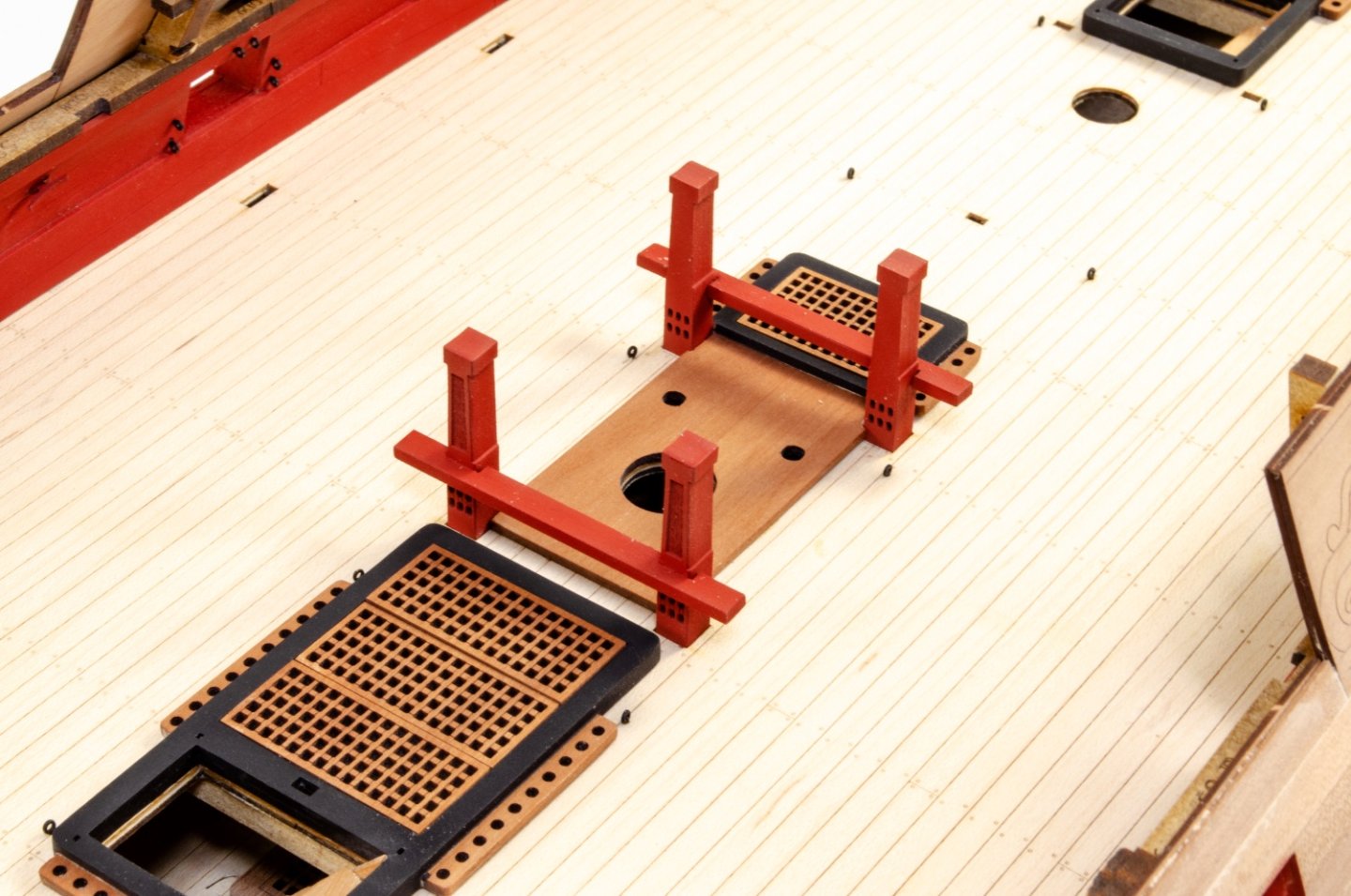

Ok, major update time!

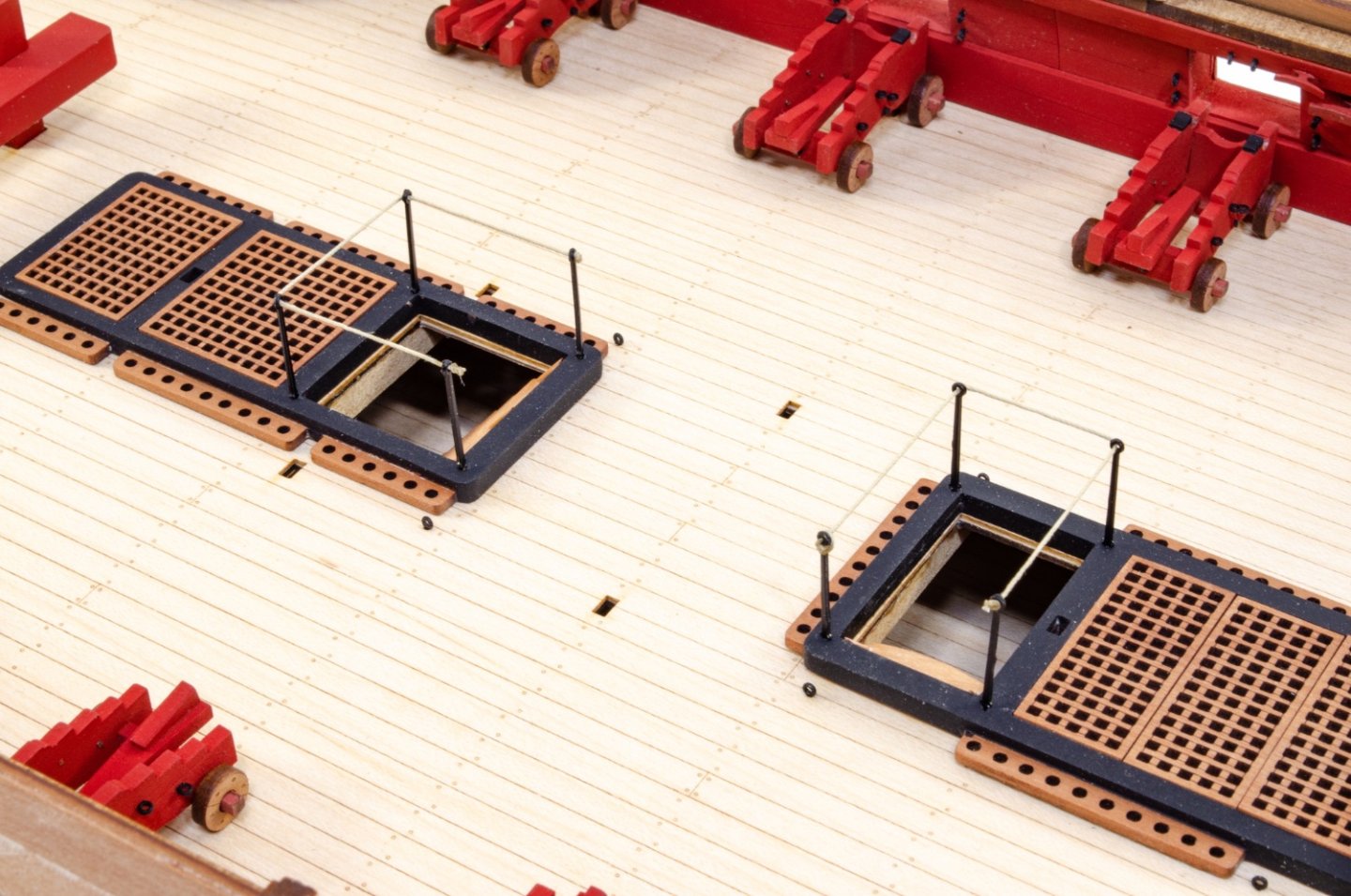

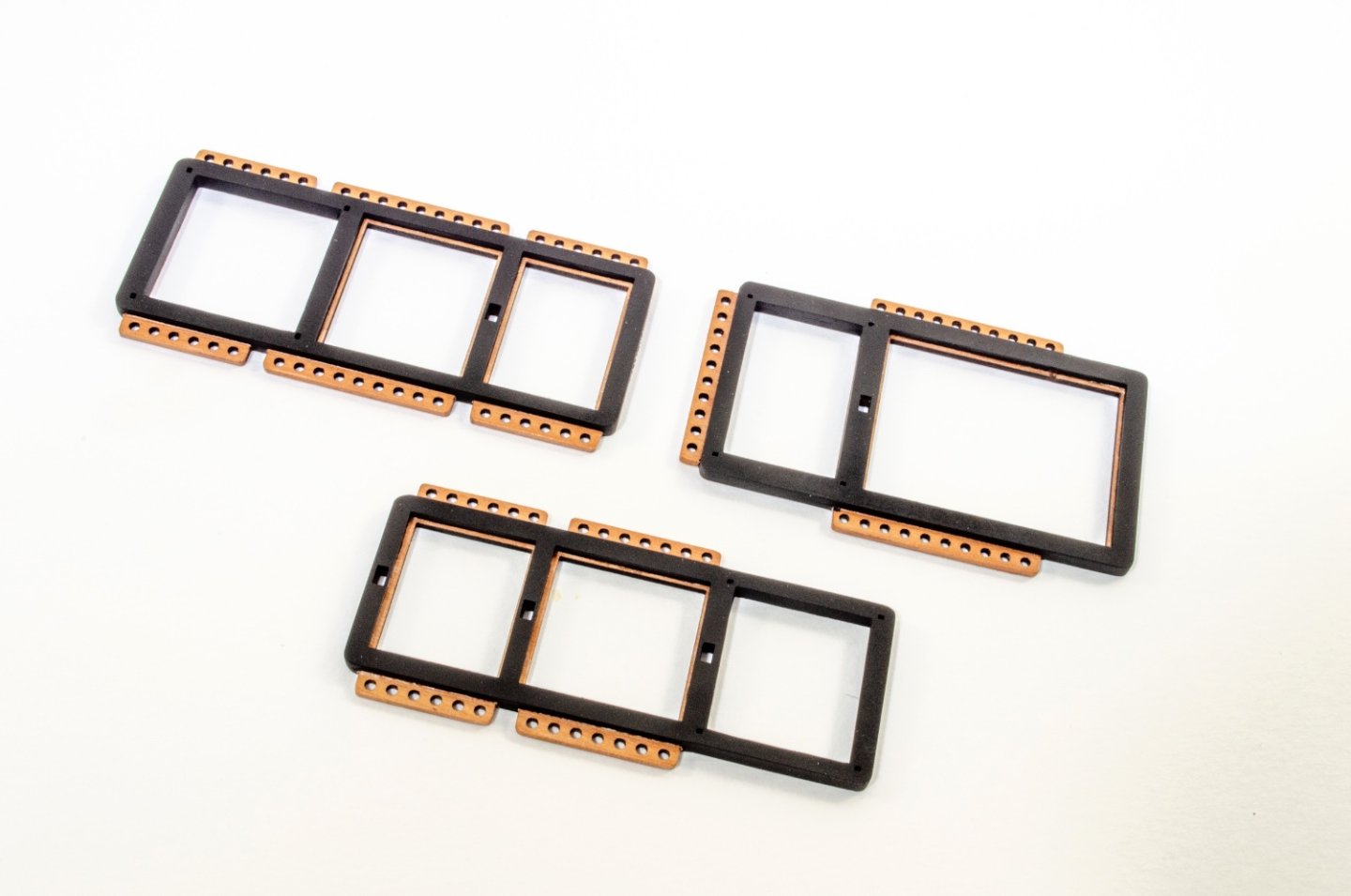

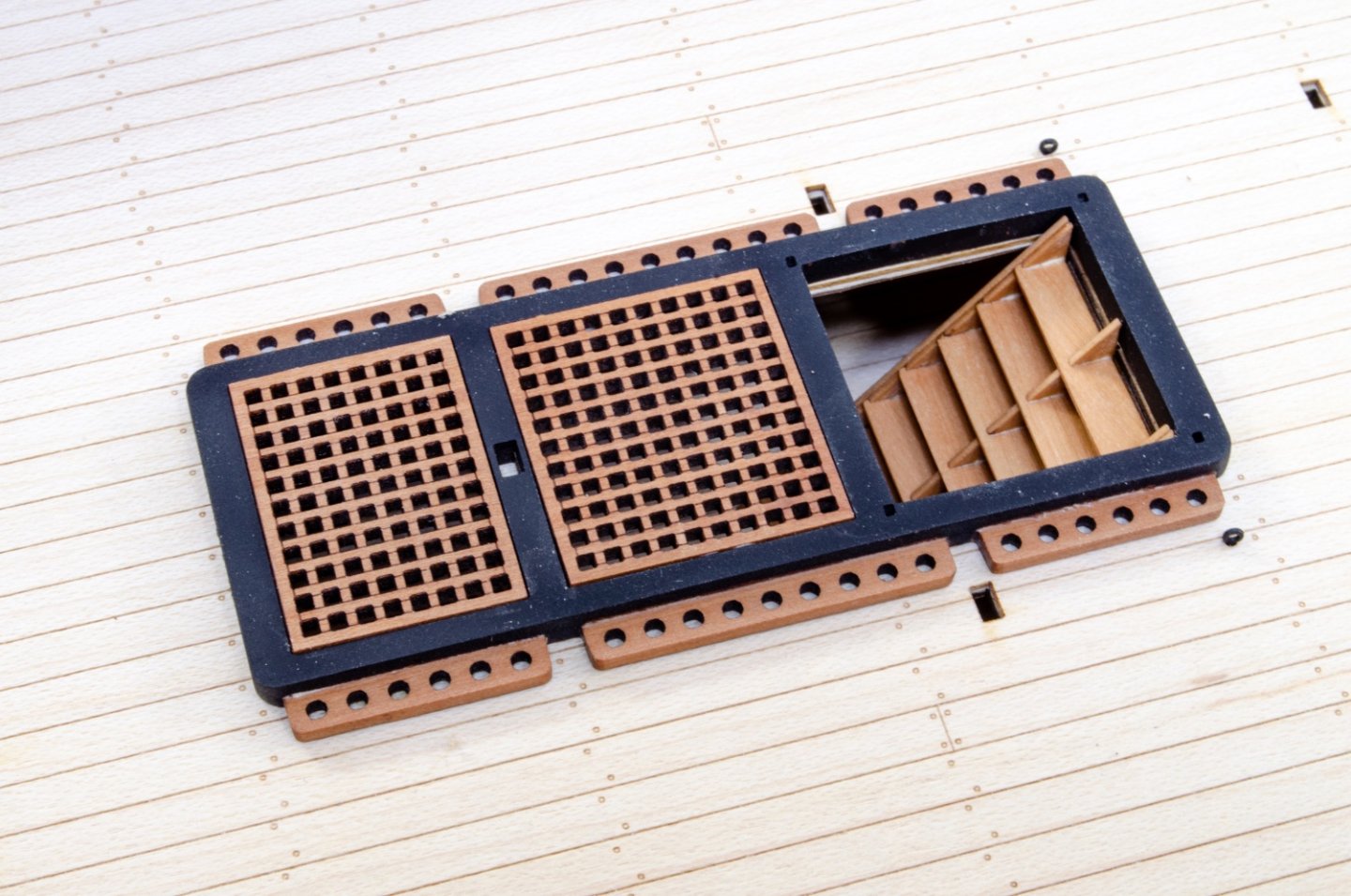

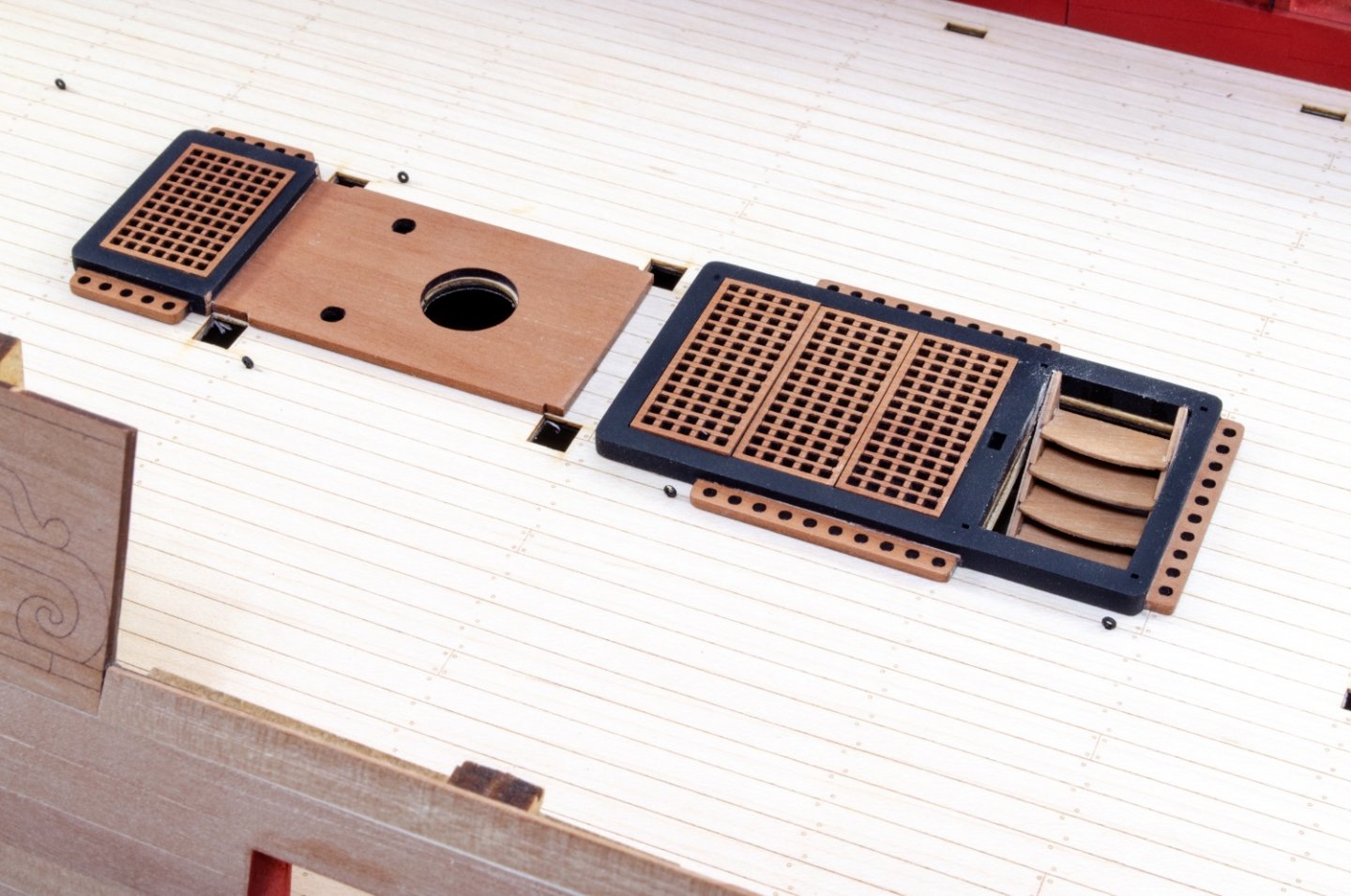

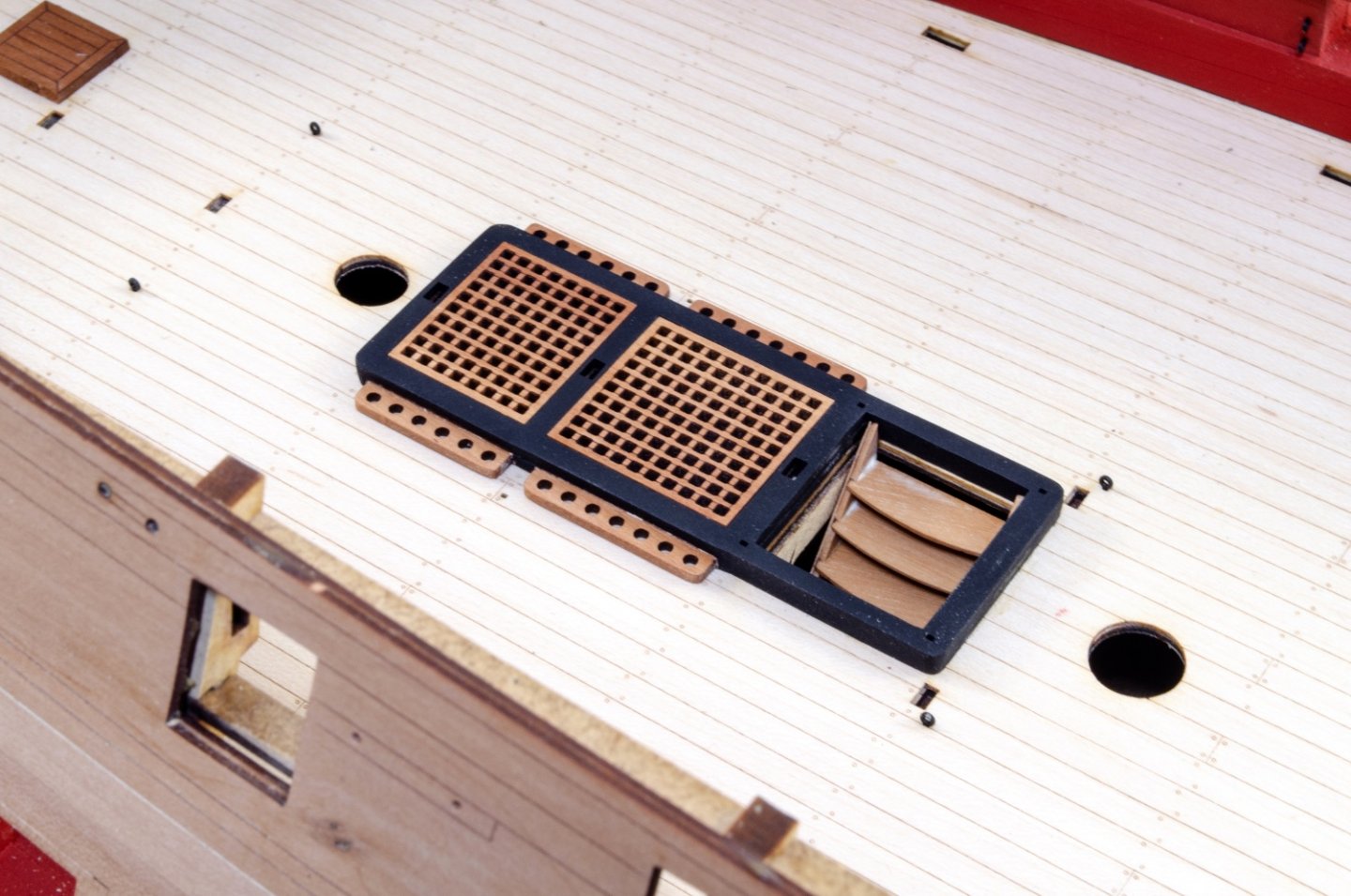

I've actually had a lot of subassemblies ready for a while, as this log shows, but now it's time for adding them in. What I haven't shown here is the spirketting that I added and fitting the eyelets to the inner bulwark gun positions. You'll have to wait until manual is finished for those! I've had to take about 100 photos these last days and sequence them, with the ones I took ages ago. Ok, first paint is for the coamings, after masking off the garlands and glue area for grates.

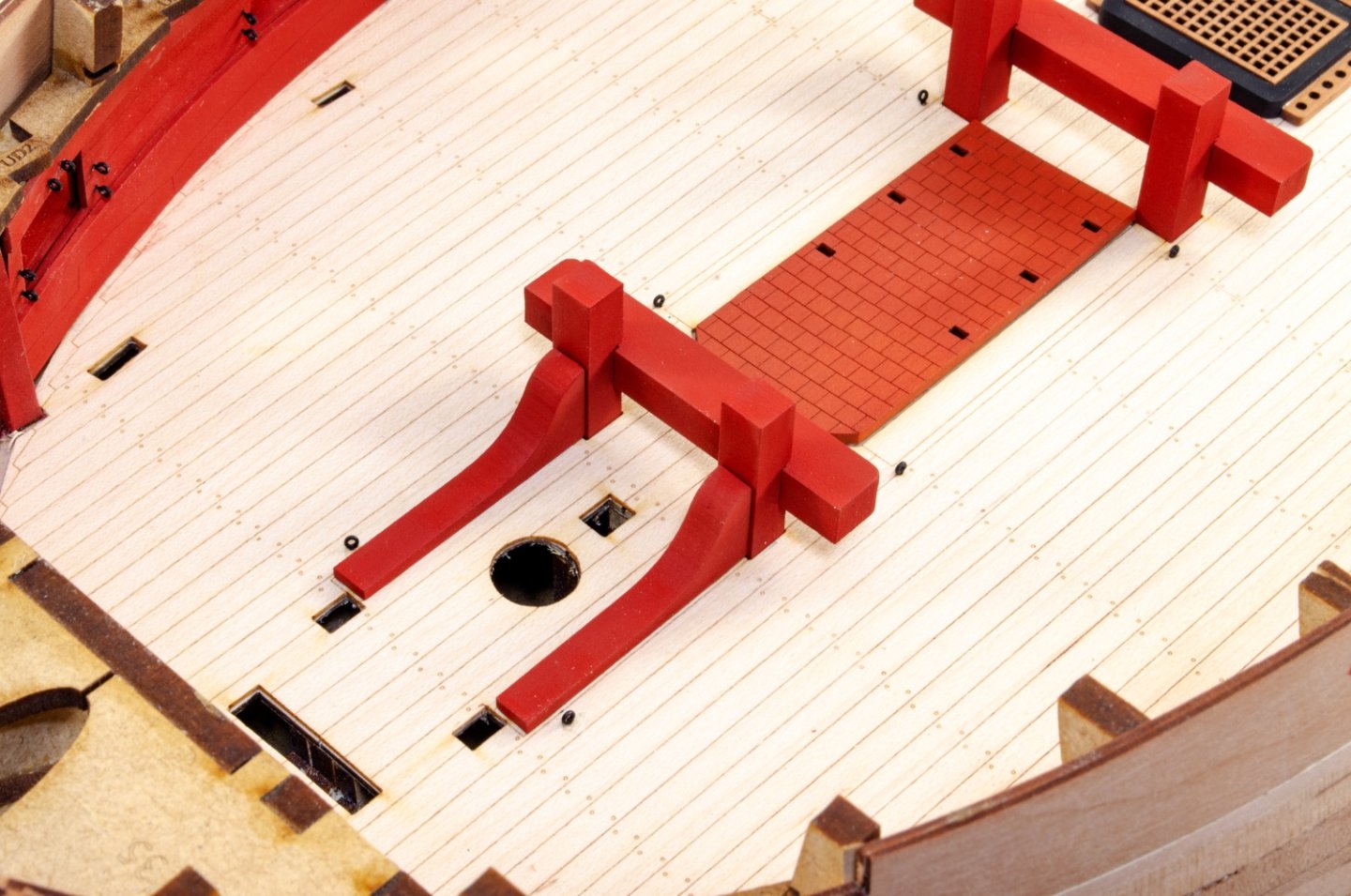

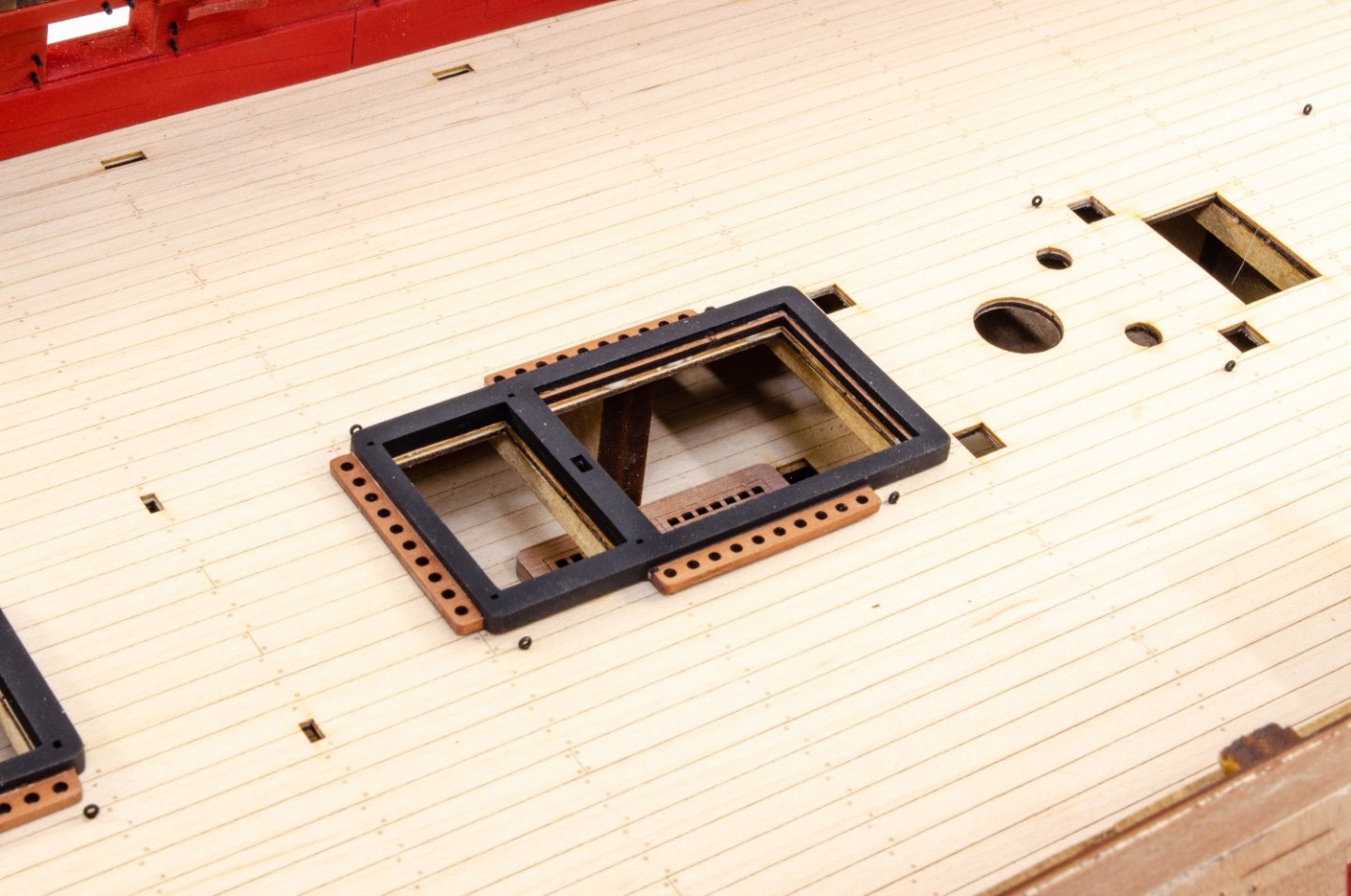

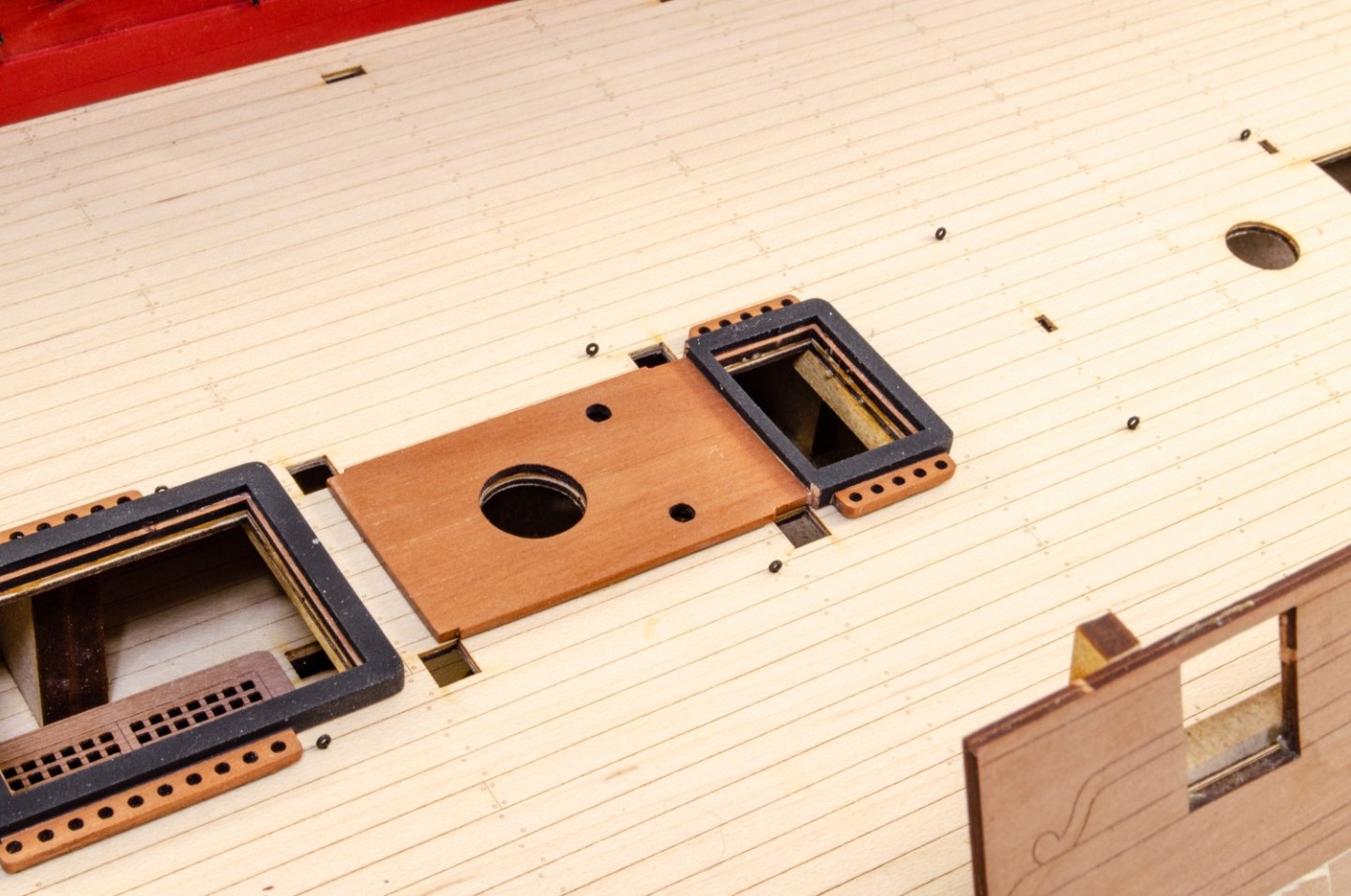

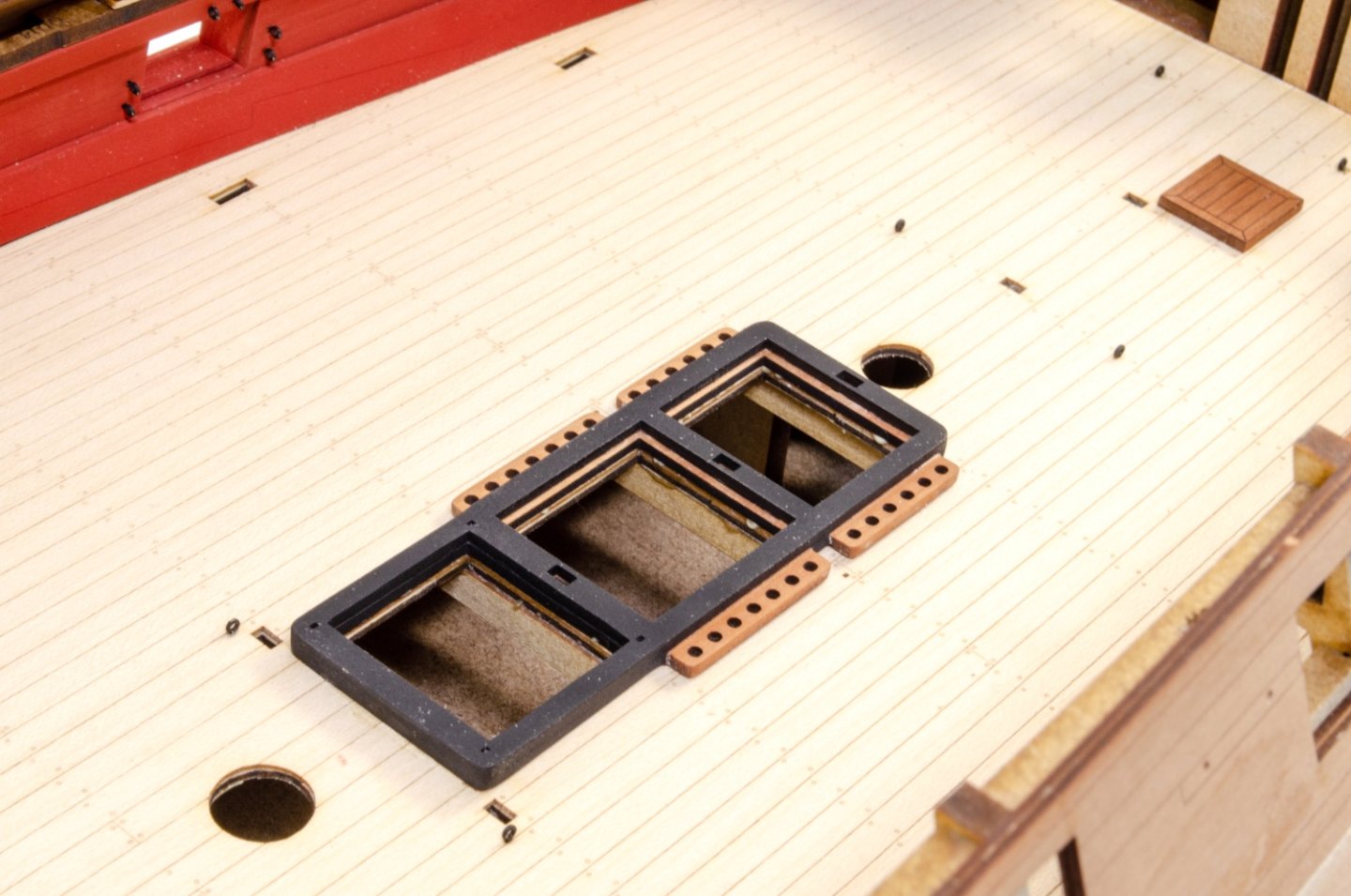

Coamings now fitted without grates as they are more flexible for deck curve.

I've probably posted this pic before, but this just shows that the ladders are now being fitted, along with the grates.

I pre-assembled the bitts etc in situ, then removed them when dry before painting. These are now added into place for the last time.

-

25 minutes ago, Vane said:

Seeing the sometimes intense discussion on things like this, I think some people overthink it. A kit is just a kit and you have to decide what quality and correctness you can put in it to get happy customers and also make profits. Woodenship are perfect for scratchbuidling and if you want to add or remove parts its quite simple to do that. As long as you are happy with your own build its noones business if you decide to paint it in pink.

Maybe apart from the 'pink' bit (😆), you are absolutely right. In fact, including the pink!

As long as the materials are there to build the model as intended, then any small extra effort is up to the modeller in how they depict a vessel.

- Canute, chris watton, Mr Whippy and 7 others

-

10

10

-

14 minutes ago, catopower said:

...but being located in Australia, they also have to deal with horribly high shipping costs from the manufacturers in Europe (mostly).

I can almost guarantee that's the reason, and no other.

Shipping prices for business are awful at the moment, and these folk need to recoup that.

HMS Indefatigable 1794 (prototype) by James H - Vanguard Models - 1:64 - FINISHED

in - Kit build logs for subjects built from 1751 - 1800

Posted

We look forward to your purchase 😘