-

Posts

25,785 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Thank you all for the comments and the likes. I'm on a "practice retirement" week this week (or vacation/holiday, as you will) and getting quite a bit done. Mostly though, what's getting done is work around the house. But that'll change. On the mask.. I do use it, even thought I hate it. I use it when cutting and sanding any wood, not just ebony. Ok... admission time.. except when I'm working outside. For now, I think I'm sticking with the ebony. I'm using up my stock of Madagascar and have ordered a "small" stash of gaboon from Woodworker's Source. Couldn't resist, they had a great price. Ferit, Thanks for the suggestions on woods. I've used the wood-database site a lot as well as certain suppliers sites. Blackwood is a tougher wood than ebony. I fiddled with a sample and found it eats saw blades like popcorn. Chris & Mike, Yeah.. laminating is an issue. I'm headed to Lowe's later this week. Might try some TiteBond as I've not located a local source for slow-cure epoxy. I have some Fieblings and some MinWax Ebony Stain, but I know from experience that I'm better off doing this stuff 'off-ship". Both look equally well, in my opinion. Back to the shipyard...

-

Thanks Hamilton and Janos. I tried staining. Problem is (see picture) that the main wales only stand proud of the hull planking at the top. The lower end is blended into the hull planking below them. There will be sanding involved and then, if needed, the stain would have to be re-applied as it doesn't go very deep into the wood. If the stood proud at the lower end, I wouldn't have a problem with re-applying the stain. I can get pretty good bend on a piece of 1/8" (3 mm) thick ebony by soaking, heat bending. Cool and allow to completely dry. More soaking, more heat bending. Keep repeating as needed. Even faster if I use 1/16" (1.5 mm) and laminate them together. The dust is an ongoing issue. I'm constantly vacuuming the stuff up and I do wear a mask, which I absolutely hate since it causes my glasses to fog.

-

Great looking scarf joint, Piet. Your framing is coming out very well.

- 102 replies

-

Dave, Well done. Can you add some instructions for the light at the other end? I think it would be great if you could put this in a format (PDF if you can, Word probably could be used but we'd have to convert it). and let me know. I'd like to get it added to the articles area as a reference topic.

- 48 replies

-

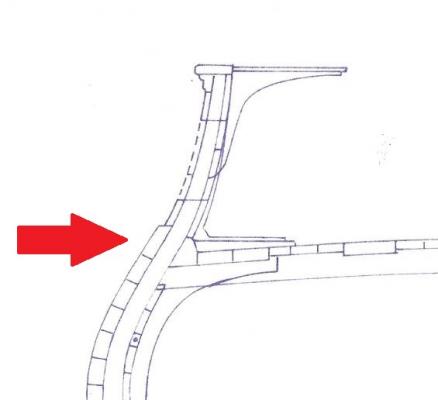

Looks like update time... The port side (or as it's called around the shipyard: The Wall Side, has it's first area planked.. namely the area between the main wales and the chain or sheer wale. Not sure what to call it really... since only the main mast channel sits on it. Planked, and then final shaped the gunports. A bit (for me) of weirdness as I was doing this and sent me scrambling back to the research department. Seems the gunports are NOT square. The sides are straight with respect to the frames but the sills follow the deck. So.. some look really "extreme" to my eye but they match the Hahn plans, the NMM plans, a couple of shots I received via PM of the original French plans from when the ship was first built in 1755. Footnote... I'm building her as she was in 1778 after a major rebuild/repair but not "as captured". I don't like the roundhouses on the poop/quarterdeck as Hahn built her. I've also started adding the wales. Notably the chain/sheer wale first. This took a bit of figuring out due to the nature of the mailns. I was going to use the walnut that came with the timbering set but didn't like the look against the swiss pear planking. I wanted the look of ebony for contrast. Tried staining the walnut and then sanding it.... which created a different set of issues since the wales are blended into the lower hull planking.. sanding killed the stain and after testing, I realized I couldn't restain without ruining any planking and the stem. So....back to the drawing board. Finally concluded... it has to be ebony. I've played with my homemade bender and think I can overcome the biggest problem and that's bending the stuff using the thickness of the wales I need. We'll see... I may be laminating. On the plus side, I've got enough ebony lying around to do this but not enough to finish the build (rails, trim, etc.) so I found a supplier who's shipping me some at a reasonable price. Anyway.. here's photos... still needs to be hit with the 600 grit and then finished but I'll hold on that for awhile. I know, I have talked people out of using ebony because it's just nasty stuff. I really am not fond of it. But if someone knows of a different solution (no paint--please) let me know.

-

Sweet looking deck, Adam. Carry on... BTW, Frank has a good idea about the dry wash and sanding, IMO. I think that would work.

- 97 replies

-

- Willie L Bennett

- SkipJack

-

(and 2 more)

Tagged with:

-

I wouldn't call it "wasted"... Learning never is. I'm waiting for what you realised... Photo-etch? Gnomes working with tiny pieces of wood? Magic munchkins dancing in the woods and casting spells? The suspense is terrible......

-

Matti, Looking super nice. As for "bending" those carvings.... be real careful. It doesn't take a whole lot of heat to turn them into blobs of plastic. Don't ask how I know... I did however, have two sets of fittings

-

Damn.. that's two, now. I hope both companies get their wishes and find owners who will uphold the "traditions" instead milking them for profits.

-

Jim, Nothing wrong with staining or painting them black. Yeah.. ebony is a pain to work with: brittle, sawdust is a fine black powder and likes to go everywhere. Oh... almost forgot... it's also an irritant to skin and lungs. Go with what you're comfortable with.

-

- 515 replies

-

- artesania latina

- whaleboat

-

(and 1 more)

Tagged with:

-

Jay, Are you sure about Bluejacket. ME recently posted to MSW (link: http://modelshipworld.com/index.php?/topic/2911-hobby-kit-manufacturing-company-looking-for-investors-or-a-buyer-500k-negotiable/) about this. Bluejacket is news to me also.

-

Not just fast, but very clean and precise. That netting proves that. Close eyes, put a cool damp cloth over them. The sit back with your favorite beverage. Works for me everytime.

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Nice ratlines... pity the rats don't know how to tie those since they're named after them.

-

Nice looking guns, Clare. One thought... if you're interested. Get some ScotchBrite pads (the green ones) in fine grit. You can then polish the brass on the lathe and get rid of any tooling marks. Funny thing about this hobby... we have to be masters at woodworking, metal work, machining, sail making, carving, and knot-tying. The real shipyards had different people doing all this work.

-

Holy Batstuff Batman!!! Beyond incredible.

- 241 replies

-

- royal caroline

- yacht

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.