HOLIDAY DONATION DRIVE - SUPPORT MSW - DO YOUR PART TO KEEP THIS GREAT FORUM GOING! (Only 72 donations so far out of 49,000 members - Can we at least get 100? C'mon guys!)

×

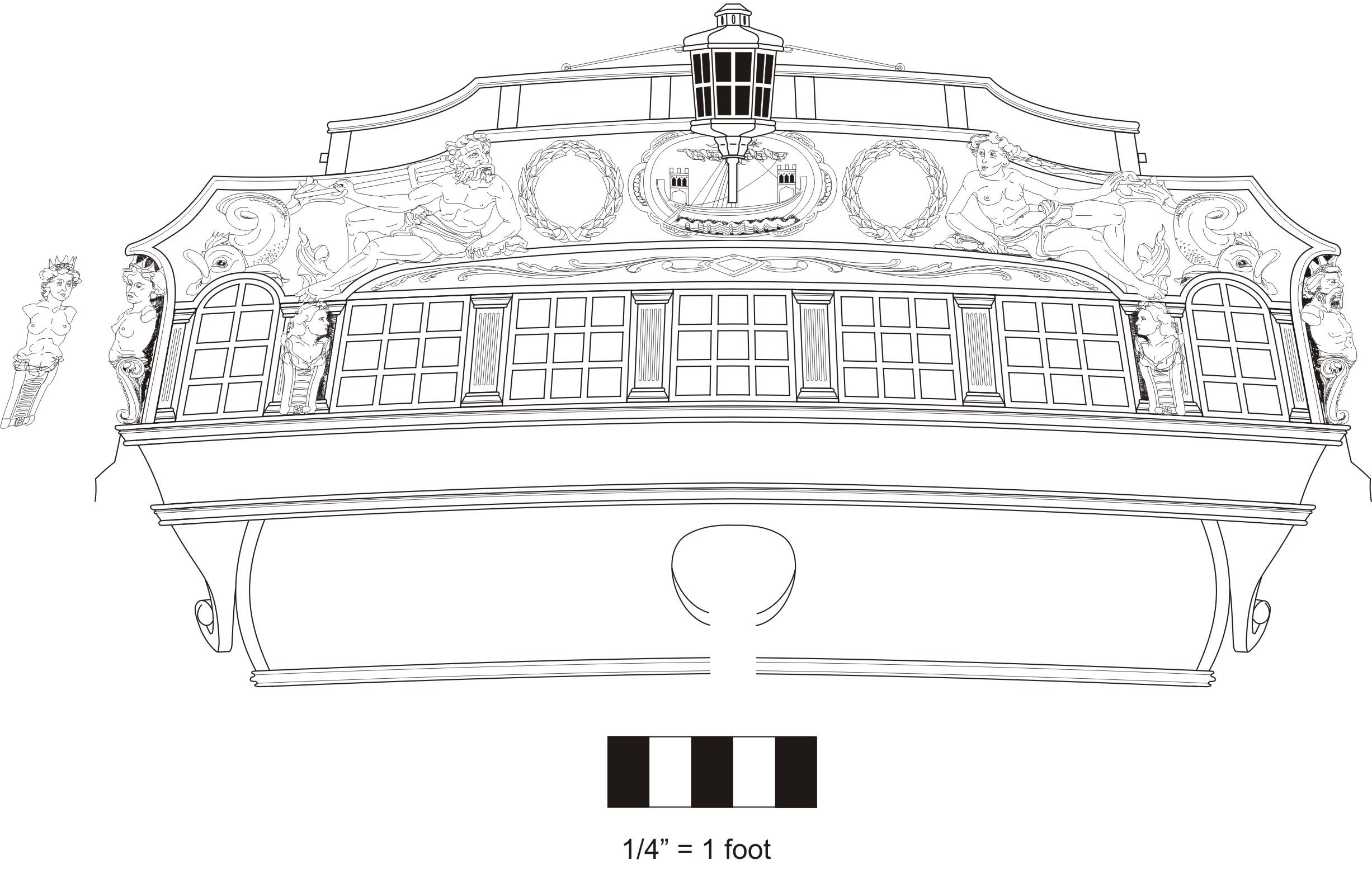

Group Prototype HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

Recently Browsing 0 members

- No registered users viewing this page.

Recommended Posts