-

Posts

4,894 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

ancre LE BONHOMME RICHARD by Jeronimo - FINISHED

gjdale replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

That's very, VERY, clever Karl! Thanks for sharing.- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

HMS Sussex by mij - Scale 1:48

gjdale replied to mij's topic in - Build logs for subjects built 1501 - 1750

Can you tell us the model number of the one on the right in the photo please? I can't seem to spot it on the Proxxon site. Looks cool though! -

Hi Eric, Welcome to the MSW forum from Down Under! Sorry to hear of your troubled start but I'm sure it will get rectified soon. I think you have chosen probably the best Victory kit currently on the market and I wish you well with it. While there are a number of CC Victory builds here, and even more from other manufacturers, I do recommend that you have a look through Gil Middleton's build log. I think his is a great guide for any Victory builder, with lots of tips and tricks to guide your way. I look forward to following your progress.

-

I think that will be a good choice Clare. A nice contrast to draw the eye to a feature of the build.

-

Sam, I think the closest to describing how to pronounce Sjors, would be "See Yours", which of course explains why he is always asking for pictures of other people's builds!!! :P By the way, nice work on the mast SeeYours!

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Looking good Augie, but I can't understand the delays either!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Masterful as always Ed, and a joy to watch this emerge.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

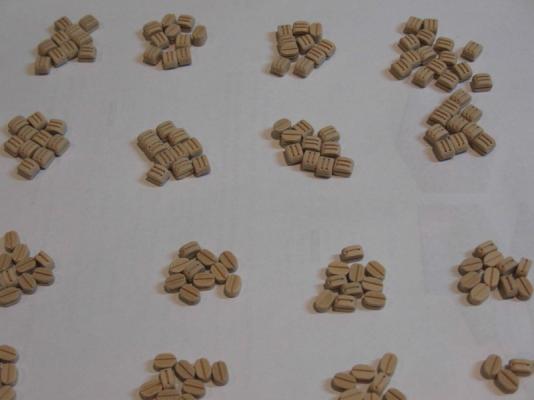

Okay - I lied! Here's a couple of pics of this weekend's limited production run. These are all 9/32" (7mm) blocks, single and double. These are the largest I've made to date. I think I've got the sheave holes pretty much in the right place now. And a couple of close ups. Some final finishing around the holes is all that's required to use these. Hopefully more production next weekend - I'm getting into the groove now (pun intended).

-

Thanks everyone, I'm pretty comfortable with the production method now. Mark - it's only the two larger sizes that I'm thinking of scrapping as these were early production runs that don't have the sheave holes placed quite right. I'll see how they rig up first - it may be that the error isn't noticeable. It's no big deal to re- make those few - the larger sizes are relatively easy to work with! Chuck - I don't know how on earth you managed to make them at 1.5mm - the 2mm were almost too much for me! Not much time in the shipyard this weekend, but have managed to make a few more. No pictures today as it's just more of the same.

-

Bismarck by NBP - 1:100

gjdale replied to NBP's topic in - Build logs for subjects built 1901 - Present Day

Fantastic work Norberto! I'll follow along wih great interest. -

ancre LE BONHOMME RICHARD by Jeronimo - FINISHED

gjdale replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Nice work on the tops Sjors. A pleasant change from rigging for you.

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

Hi Rusty, I'm no expert, but the larger ones look "right" to me.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Rusty, Not sure if I've understood your question correctly, but your maths is correct. That is, if your "real life" tree nail is 1 1/2", then at your chosen scale of 1:24, this would be 1/16". As to whether 1 1/2" tree nails are correct in the first place, I've no idea!

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Welcome home Rusty - looking forward to your next update.

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

Thanks John, I was wondering what the collective pronoun for blocks might be. Perhaps a "murder" of blocks would be appropriate!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.